Professional Documents

Culture Documents

Worktip36 Sprayed Seals Prespraying

Uploaded by

La FoliakCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Worktip36 Sprayed Seals Prespraying

Uploaded by

La FoliakCopyright:

Available Formats

Sprayed seals – pre-spraying

to correct surface texture

work tips pavement work tips — no. 36

INTRODUCTION Binder application

January 2003

rates

Key Summary

Pre-spraying is a technique developed for:

• Resealing of roads where different binder The rate of

This issue of

application rates are required to compensate application of pre- 'pavement work tips'

for variations in texture in different areas of sprayed binder will provides a guide to

the existing surface. It is particularly used depend on differences pre-spraying of road

where there is a significant difference in texture in surface texture surfaces to

between wheel-paths and areas outside the allowances, traffic compensate for

wheel-paths. volume, pavement variations in surface

crossfall and alignment. texture and binder

• Sealing or resealing with geotextile fabrics

It is generally the application rates

where additional binder is required on outer

difference between the

edges or along centrelines and between wheel-

lower rate of

paths.

application designed for the low texture condition

• Pre-spraying of shoulders to enable the (usually the wheel-paths) and that required for the

pavement

shoulder and adjoining traffic lane to be coarse textured areas (outside the wheel-paths).

sprayed without a longitudinal join in the Rates of application are typically in the range of

finished surface. 0.3 to 0.5 L/m2.

Pre-spraying is done without cover aggregate Spraying of rates less than 0.3 L/m2 is generally

and is usually applied immediately ahead of the neither necessary nor practicable.

second binder application.

Pre-spraying of rates greater than 0.5 L/m2 in

traffic lanes is generally undesirable, as excess

SURFACE CORRECTION PRIOR TO binder may migrate into critical areas. Where the

RESEALING required rate exceeds 0.5 L/m2, consideration

General should be given to an alternative treatment.

Binder application rates for reseals are usually Alternative treatments include use of a smaller

designed for the wheel-path condition and can aggregate as a short-term corrective treatment,

generally tolerate a variation in surface texture treatment of excess binder in wheel-paths, or

allowances of up to about 0.2 L/m2. some other surfacing type such as slurry surfacing

Greater variation requires consideration of or hot mix asphalt (See also Work Tip No 7 –

alternative treatments or the use of variable Treatment of bleeding or flushed surfaces).

application rates. Some sprayers enable variable

application rates to be sprayed using complex Binder type

twin-bar systems. Pre-spraying should be done with the same

The pre-spraying technique can be readily binder type as that intended for the reseal.

applied using conventional equipment. continued on reverse

AUSTROADS

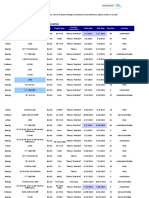

Figure 1. Variable pavement texture prior to treatment

pavement work tips is produced by AUSTROADS in conjunction with AAPA

Sprayed seals – pre-spraying to correct surface For more

information on any

texture – page 2 of the construction

practices discussed

Procedure procedures and may differ by a greater amount in "pavement work

than that applicable to surface correction within tips", please contact

Wheel-path areas must be carefully noted, either your local

particularly on winding alignments where traffic traffic lanes.

AUSTROADS

may wander across the pavement. It is important The difference between the two rates becomes Pavement Reference

to keep pre-spraying clear of actual wheel-path the pre-spray rate. For example: Group

areas to reduce risk of subsequent bleeding. This Shoulder design binder application rate = 2.2 L/m2 representative or

risk increases at higher traffic volumes and Traffic lane design binder application rate = 1.5 L/m2

AAPA —

increased numbers of heavy vehicles. tel (03) 9853 3595;

Difference in design rates = 2.2 – 1.5 = 0.7 L/m2 fax (03) 9853 3484;

The width and limits of areas to be pre-sprayed e-mail:

should be clearly marked for guidance of sprayer Procedure info@aapa.asn.au

driver and operator, allowing a suitable margin 1. Spray the shoulder only at a rate of application A complete list of

for small variations in sprayer alignment. equal to the difference in design rates (0.7 L/ "pavement work

Pre-spraying may not be practicable near m2 in above example). tips" issues is

intersections and turning lanes, and alternative 2. Spray the shoulder and traffic lane in a single available on AAPA's

treatments may need to be considered. web site:

width at the lower application rate (1.5 L/m2

www.aapa.asn.au

Where light rates of application are involved, in above example).

Issues may be

smaller spraying nozzles, e.g. AN 9, will reduce 3. Spread and roll aggregate as normal. downloaded using

the need for high sprayer forward speeds and assist Adobe Acrobat

in uniformity of application. Pre- spraying of shoulder on previous day Reader. Copies may

Two sprayers are generally required to enable Depending on job size, traffic volume, weather also be obtained

pre-spraying immediately ahead of main spray and site conditions, it may be feasible to undertake from AAPA.

application and avoid any risks involved in traffic pre-spraying of shoulders on the preceding Material may be

driving on pre-sprayed areas. afternoon. freely reproduced

To compensate for additional binder cooling, providing the source

is acknowledged.

PRE-SPRAYING OF SHOULDERS the pre-spray binder should be cut back with 2

parts (or 2%) more cutter oil than that otherwise This edition was

General prepared by

required. The total amount will depend upon

Pre-spraying of shoulders in conjunction with by John Rebbechi

aggregate type and condition and the prevailing

sealing of the adjoining traffic lane may be used and Walter Holtrop

traffic and weather conditions and should be not in consultation with

where the aggregates are of the same size and

less than 4 parts (4%). members of the

type and it is desired to reduce the number of

longitudinal joins and improve efficiency of The second application rate should be cut back National

as normal. The heat of the binder in the second Bituminous

spraying and spreading operations. Surfacings Research

application is generally adequate to combine with

Binder Application Rates Group.

the pre-sprayed binder for effective embedment

In this case the design binder application rates of aggregate provided that the binder is cut back

for the shoulder and the traffic lane are as recommended above and the pre-sprayed

determined separately using standard design binder has not been damaged by traffic.

Figure 2 Applying pre-spray Figure 3 Applying final spray

Austroads and AAPA believe this publication to be correct at the time of printing and do not accept responsibility for any consequences arising from the use of the information

herein. Readers should rely on their own skill and judgement to apply information to particular issues.

You might also like

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- WorkTip 11 Bituminous Surfacing CharacteristicsDocument3 pagesWorkTip 11 Bituminous Surfacing CharacteristicsLa FoliakNo ratings yet

- Fundamentals of Building Components and Systems: For Community Association ManagersFrom EverandFundamentals of Building Components and Systems: For Community Association ManagersNo ratings yet

- Chippings For Surface Dressings Note03Document2 pagesChippings For Surface Dressings Note03CarolNo ratings yet

- Introduction to Superpave Mix DesignDocument12 pagesIntroduction to Superpave Mix DesignAjay JainNo ratings yet

- Irc.82 2015Document2 pagesIrc.82 2015K&J Projects Pvt. Ltd. Pvt. Ltd.No ratings yet

- OTM Book 11 - Materials Section 3.3 - Pavement Hazard and Delineation Markings - Mar 2000Document9 pagesOTM Book 11 - Materials Section 3.3 - Pavement Hazard and Delineation Markings - Mar 2000Kristin CarrereNo ratings yet

- 1507 002 PDFDocument10 pages1507 002 PDFVictor ThobiasNo ratings yet

- Surface Dressing . UneditedDocument2 pagesSurface Dressing . UneditedRonnie AyesigwaNo ratings yet

- Types of Surface Dressing Note03 PDFDocument3 pagesTypes of Surface Dressing Note03 PDFVictorNo ratings yet

- Asphalt Mix Design-Marshall Method: Rajib Chattaraj Astt. Chief Engineer, NH, PW (R) DDocument42 pagesAsphalt Mix Design-Marshall Method: Rajib Chattaraj Astt. Chief Engineer, NH, PW (R) DPriyadarshini Saha Chowdhury100% (1)

- Standard Practice For ASTM 5360Document3 pagesStandard Practice For ASTM 5360Sushil RajakNo ratings yet

- Asphalt tack coating guideDocument2 pagesAsphalt tack coating guideDilhara WickramaarachchiNo ratings yet

- Superpave Future HMA PavementsDocument4 pagesSuperpave Future HMA PavementsAlvin RamirezNo ratings yet

- Technical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksDocument3 pagesTechnical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksSpiros LicoudisNo ratings yet

- 139157-882132 Smt2p2lentztonyDocument8 pages139157-882132 Smt2p2lentztonybhf_86No ratings yet

- Design of Surface Dressing PDFDocument11 pagesDesign of Surface Dressing PDFChristian Nicolaus100% (1)

- Lec - 8 Mix Design Applications PDFDocument68 pagesLec - 8 Mix Design Applications PDFAZIMERAWNo ratings yet

- Granular Pavements With Thick Asphalt SurfacingDocument4 pagesGranular Pavements With Thick Asphalt SurfacingIlham FeryantoNo ratings yet

- Rotor Selection Guide: For Reclamation and StabilizationDocument12 pagesRotor Selection Guide: For Reclamation and StabilizationOhana IngaNo ratings yet

- 1 Vegetated Swale Technical GuidanceDocument4 pages1 Vegetated Swale Technical GuidanceAnkit KodinariyaNo ratings yet

- Tech Spec 2 ConstructionDocument8 pagesTech Spec 2 ConstructionHuascar Medrano LazarteNo ratings yet

- Automated Asphalt Paving Controls Improve Shape and Ride QualityDocument2 pagesAutomated Asphalt Paving Controls Improve Shape and Ride QualityVany LunaNo ratings yet

- Selection and Use of Emulsified Asphalts: Standard Practice ForDocument4 pagesSelection and Use of Emulsified Asphalts: Standard Practice ForLuis LunaNo ratings yet

- Primer SN enDocument4 pagesPrimer SN enNishant VasuNo ratings yet

- Low Volume RoadDocument6 pagesLow Volume RoadNoel ElivertNo ratings yet

- Technical Note TN 048 Differences Between Conventional HSS SAM and SAMI TreatmentsDocument2 pagesTechnical Note TN 048 Differences Between Conventional HSS SAM and SAMI TreatmentsKarina Benavides BurgosNo ratings yet

- Attachment #03Document1 pageAttachment #03Mohab AzizNo ratings yet

- Worktips 04 Asphalt JointsDocument2 pagesWorktips 04 Asphalt Jointssyed sardar hussain shahNo ratings yet

- Ground Improvement Oct2014 PDFDocument24 pagesGround Improvement Oct2014 PDFPatrick AscañoNo ratings yet

- Geotextile Handling Storage InstallationDocument4 pagesGeotextile Handling Storage InstallationMamat XNo ratings yet

- IS 16393 Geotextile Used in Subsurface Drainage Application - SpecificationDocument16 pagesIS 16393 Geotextile Used in Subsurface Drainage Application - SpecificationVinay TripathiNo ratings yet

- DN-PAV-03074 (HD 300) TII Surface Dressing Design Method: Brian MulryDocument38 pagesDN-PAV-03074 (HD 300) TII Surface Dressing Design Method: Brian Mulrysonam phunthsoNo ratings yet

- Sr. Main Theme/Focus Method Major Findings AuthorsDocument12 pagesSr. Main Theme/Focus Method Major Findings Authorssalman khattakNo ratings yet

- Manual For The Application of Cold Milling Machines: Edition: January 2004Document164 pagesManual For The Application of Cold Milling Machines: Edition: January 2004nenad100% (1)

- Surface Texture Measurement On Local Roads TRL PPR148Document89 pagesSurface Texture Measurement On Local Roads TRL PPR148luchassNo ratings yet

- ACPA PROJETOS - Design of Concrete Pavement For StreetsDocument16 pagesACPA PROJETOS - Design of Concrete Pavement For StreetsTamara Aparecida de PaulaNo ratings yet

- Selection of Cutback Asphalts: Standard Practice ForDocument3 pagesSelection of Cutback Asphalts: Standard Practice ForD IZomer Oyola-GuzmánNo ratings yet

- FLU GSN 2021R1 EN WS06 Duct VanesDocument48 pagesFLU GSN 2021R1 EN WS06 Duct Vanes2nnnfhx4kqNo ratings yet

- Caminos PaviDocument19 pagesCaminos PaviCarlosPNo ratings yet

- 7-Elemen Lain Dalam Rekabentuk JalanDocument83 pages7-Elemen Lain Dalam Rekabentuk JalanAnonymous pQhG5e2No ratings yet

- Chapter 8 Surface DressingDocument53 pagesChapter 8 Surface DressingPronab Kumar Das100% (1)

- April 2013 1366124011 113f4 50 CRMBDocument2 pagesApril 2013 1366124011 113f4 50 CRMBramudu oneNo ratings yet

- Design and Construction of Bituminous Surface Treatments: Standard Practice ForDocument3 pagesDesign and Construction of Bituminous Surface Treatments: Standard Practice ForAhmedNo ratings yet

- Worktips16 Reinstatement PDFDocument2 pagesWorktips16 Reinstatement PDFjoebriffaNo ratings yet

- Astm E1703 2000Document2 pagesAstm E1703 2000Nick AndroulakisNo ratings yet

- Hein PDFDocument20 pagesHein PDFMEGHA ANKALKOTINo ratings yet

- Seamleass Fluids Programs - CementingDocument15 pagesSeamleass Fluids Programs - CementingCláudio VirgílioNo ratings yet

- Grasscrete: Cast Insitu Paving System Design and Specification GuideDocument23 pagesGrasscrete: Cast Insitu Paving System Design and Specification Guidemssrao1977No ratings yet

- 05 - Infrastructure - Design - FootpathsDocument5 pages05 - Infrastructure - Design - FootpathsScooby DooNo ratings yet

- Gradation of AggregatesDocument3 pagesGradation of AggregatesVictoriaNo ratings yet

- Strengthening Methods For Subsoil Under Existing Railway LinesDocument11 pagesStrengthening Methods For Subsoil Under Existing Railway LinesValerioNo ratings yet

- pg4 - Intro ESC Measures PDFDocument1 pagepg4 - Intro ESC Measures PDFArchipelago Travel ToursNo ratings yet

- Dense-graded and permeable aggregate basesDocument18 pagesDense-graded and permeable aggregate basesSoran SaadNo ratings yet

- Method Statement Patch WorkDocument9 pagesMethod Statement Patch Worknoko100% (1)

- Ferfa Guide To Flowable Polymer Screeds As Underlayments For Resin Floor FinishesDocument7 pagesFerfa Guide To Flowable Polymer Screeds As Underlayments For Resin Floor FinishesAndrew KasanaNo ratings yet

- MAPbrief7 2Document4 pagesMAPbrief7 2JOSEPH KIWANGONo ratings yet

- Subgrade: Subgrade Preparation For New PavementsDocument5 pagesSubgrade: Subgrade Preparation For New PavementsmuhanadNo ratings yet

- Chip Seals Process Design OverviewDocument3 pagesChip Seals Process Design OverviewAriel VargasNo ratings yet

- ASI Rhinophalt Technical and SafteyDocument2 pagesASI Rhinophalt Technical and SafteyIndrajeet UpadhyayNo ratings yet

- AP-R648-21 Use of Road-Grade Recycled Plastics For Sustainable Asphalt PavementsDocument48 pagesAP-R648-21 Use of Road-Grade Recycled Plastics For Sustainable Asphalt PavementsLa FoliakNo ratings yet

- AP-R658-21 Investigation of Pavement Assessment Methodologies For Performance Based Standards AccessDocument77 pagesAP-R658-21 Investigation of Pavement Assessment Methodologies For Performance Based Standards AccessLa FoliakNo ratings yet

- AP-T359-21 National Specification For Crumb Rubber Binders in Asphalt and SealsDocument177 pagesAP-T359-21 National Specification For Crumb Rubber Binders in Asphalt and SealsLa FoliakNo ratings yet

- AP-R648-21 Use of Road-Grade Recycled Plastics For Sustainable Asphalt PavementsDocument48 pagesAP-R648-21 Use of Road-Grade Recycled Plastics For Sustainable Asphalt PavementsLa FoliakNo ratings yet

- AP-T343-19 Deformation Performance of Foamed Bitumen Stabilised PavementsDocument121 pagesAP-T343-19 Deformation Performance of Foamed Bitumen Stabilised PavementsLa FoliakNo ratings yet

- AP-R648-21 Use of Road-Grade Recycled Plastics For Sustainable Asphalt PavementsDocument48 pagesAP-R648-21 Use of Road-Grade Recycled Plastics For Sustainable Asphalt PavementsLa FoliakNo ratings yet

- AP-R648-21 Use of Road-Grade Recycled Plastics For Sustainable Asphalt PavementsDocument48 pagesAP-R648-21 Use of Road-Grade Recycled Plastics For Sustainable Asphalt PavementsLa FoliakNo ratings yet

- AP-T343-19 Deformation Performance of Foamed Bitumen Stabilised PavementsDocument121 pagesAP-T343-19 Deformation Performance of Foamed Bitumen Stabilised PavementsLa FoliakNo ratings yet

- Worktip42 Nuclear Density Testing PDFDocument2 pagesWorktip42 Nuclear Density Testing PDFLa FoliakNo ratings yet

- AP-T308-16 Review Specifications Performance Tests For BitumenDocument58 pagesAP-T308-16 Review Specifications Performance Tests For BitumenLa FoliakNo ratings yet

- AP-T359-21 National Specification For Crumb Rubber Binders in Asphalt and SealsDocument177 pagesAP-T359-21 National Specification For Crumb Rubber Binders in Asphalt and SealsLa FoliakNo ratings yet

- AP-R658-21 Investigation of Pavement Assessment Methodologies For Performance Based Standards AccessDocument77 pagesAP-R658-21 Investigation of Pavement Assessment Methodologies For Performance Based Standards AccessLa FoliakNo ratings yet

- AP-R655-21 Inclusion of Recent Road Safety Research in GRDDocument91 pagesAP-R655-21 Inclusion of Recent Road Safety Research in GRDLa FoliakNo ratings yet

- Worktip53 Joints Geotextile Reinforced SealsDocument2 pagesWorktip53 Joints Geotextile Reinforced SealsLa FoliakNo ratings yet

- TB 107Document3 pagesTB 107La FoliakNo ratings yet

- Work Tips 41Document2 pagesWork Tips 41Timothy MalinziNo ratings yet

- Worktip46 Asphalt Cooling Rates PDFDocument2 pagesWorktip46 Asphalt Cooling Rates PDFLa FoliakNo ratings yet

- Worktip46 Asphalt Cooling Rates PDFDocument2 pagesWorktip46 Asphalt Cooling Rates PDFLa FoliakNo ratings yet

- Worktip36 Sprayed Seals PresprayingDocument2 pagesWorktip36 Sprayed Seals PresprayingLa FoliakNo ratings yet

- Worktip53 Joints Geotextile Reinforced SealsDocument2 pagesWorktip53 Joints Geotextile Reinforced SealsLa FoliakNo ratings yet

- Worktip42 Nuclear Density Testing PDFDocument2 pagesWorktip42 Nuclear Density Testing PDFLa FoliakNo ratings yet

- Technical Bulletin: 800 Roosevelt Road, Building C-312, Glen Ellyn, IL 60137Document3 pagesTechnical Bulletin: 800 Roosevelt Road, Building C-312, Glen Ellyn, IL 60137La FoliakNo ratings yet

- Work Tips 41Document2 pagesWork Tips 41Timothy MalinziNo ratings yet

- Technical Bulletin: 800 Roosevelt Road, Building C-312, Glen Ellyn, IL 60137Document4 pagesTechnical Bulletin: 800 Roosevelt Road, Building C-312, Glen Ellyn, IL 60137La FoliakNo ratings yet

- TB 113 MixTime 13april2017 SDocument2 pagesTB 113 MixTime 13april2017 SLa FoliakNo ratings yet

- TB 112Document2 pagesTB 112La FoliakNo ratings yet

- General Aruba General (See Plan) : Opening/Closing HatchesDocument6 pagesGeneral Aruba General (See Plan) : Opening/Closing Hatcheswaleed yehiaNo ratings yet

- Piling & Concrete Rate AnlysisDocument79 pagesPiling & Concrete Rate AnlysisfinesomalinNo ratings yet

- Rpub AipDocument8 pagesRpub AipL LNo ratings yet

- CT - 1700-26 - EN - Truck-Mounted Concrete Pumps PDFDocument17 pagesCT - 1700-26 - EN - Truck-Mounted Concrete Pumps PDFEslamAldenAbdoNo ratings yet

- Prisma-Daps Brochure EN PDFDocument8 pagesPrisma-Daps Brochure EN PDFHasan GhanoumNo ratings yet

- E-Ticket ReservationDocument1 pageE-Ticket ReservationGuru RajaNo ratings yet

- Literature Review On Traffic Congestion in IndiaDocument5 pagesLiterature Review On Traffic Congestion in Indiac5hzgcdj100% (1)

- Next Gen Everest 2024 Specification ENDocument3 pagesNext Gen Everest 2024 Specification ENwasifsaeedNo ratings yet

- Taguig City - Penalties & Violations: Code Type of Offence/Violation PenaltiesDocument3 pagesTaguig City - Penalties & Violations: Code Type of Offence/Violation PenaltiesZoe SanchezNo ratings yet

- 2 StructuralDocument19 pages2 Structurallayaljamal2No ratings yet

- KTM Duke 250 Abs 2017 GST 0Document1 pageKTM Duke 250 Abs 2017 GST 0zaim nur hakimNo ratings yet

- Rogue Trader Ship Hulls GuideDocument2 pagesRogue Trader Ship Hulls Guidetopherfuzz100% (3)

- This Picturesque Line Was Closed in 1961 and The Viaduct Which Spanned This Valley Has Been RemovedDocument4 pagesThis Picturesque Line Was Closed in 1961 and The Viaduct Which Spanned This Valley Has Been RemovedhellomontevideoNo ratings yet

- Research on Flat Slab, Ribbed Slab and Lift Slab Construction MethodsDocument17 pagesResearch on Flat Slab, Ribbed Slab and Lift Slab Construction MethodsArgelita Alpuerto UnlayaoNo ratings yet

- Inspection criteria for discard of deck fittingsDocument4 pagesInspection criteria for discard of deck fittingsStylianos100% (1)

- Arif Corporation SDN BHDDocument2 pagesArif Corporation SDN BHDMOHD NAIM MOKSIN HUSSINNo ratings yet

- January2016page1to36 Layout 1Document36 pagesJanuary2016page1to36 Layout 1c737No ratings yet

- Live Load DispersionDocument36 pagesLive Load Dispersionneeta rautelaNo ratings yet

- ASM Masters Solved Past Question Papers Solved Numericals From Sept16 Till Nov21Document302 pagesASM Masters Solved Past Question Papers Solved Numericals From Sept16 Till Nov21arivarasanNo ratings yet

- AFIKLMEM Schedule Technical Training 2023 v15NOV22Document4 pagesAFIKLMEM Schedule Technical Training 2023 v15NOV22Dylan GalpeNo ratings yet

- Holcim Vehicle OptimisationDocument7 pagesHolcim Vehicle OptimisationLen XinNo ratings yet

- SM - BOBCAT S130 SKID STEER LOADER Service Repair Manual (SN 529211001 & Above SN-abcDocument3 pagesSM - BOBCAT S130 SKID STEER LOADER Service Repair Manual (SN 529211001 & Above SN-abcAly Abdelhamed0% (2)

- Activity 2.1 - Superlatives and ComparativesDocument2 pagesActivity 2.1 - Superlatives and ComparativesRuby MoonNo ratings yet

- Basic Facts About ImoDocument11 pagesBasic Facts About ImoTambe Chalomine AgborNo ratings yet

- CTI Technical Paper TP10-19Document28 pagesCTI Technical Paper TP10-19Mehul BansalNo ratings yet

- 01AeroModeller January 1958Document60 pages01AeroModeller January 1958Juan TrampaNo ratings yet

- Heli Ops FrontierDocument114 pagesHeli Ops Frontierarticnorth141No ratings yet

- BAIL 16008 Catalogue Update DE5 PROOF Issuu v2Document38 pagesBAIL 16008 Catalogue Update DE5 PROOF Issuu v2Chris LuiNo ratings yet

- General Suitability Survey Template (Report)Document23 pagesGeneral Suitability Survey Template (Report)evrim korıNo ratings yet

- Karakteristik Perjalanan Dan Ketersediaan AngkutanDocument9 pagesKarakteristik Perjalanan Dan Ketersediaan AngkutanSentania AtariNo ratings yet

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (542)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowFrom EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowNo ratings yet

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- Digital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsFrom EverandDigital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsRating: 5 out of 5 stars5/5 (3)

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- The Graphene Revolution: The Weird Science of the Ultra-thinFrom EverandThe Graphene Revolution: The Weird Science of the Ultra-thinRating: 4.5 out of 5 stars4.5/5 (4)

- Electrical Principles and Technology for EngineeringFrom EverandElectrical Principles and Technology for EngineeringRating: 4 out of 5 stars4/5 (4)