Professional Documents

Culture Documents

Telemecanique Xsav11801 Datasheet

Uploaded by

Renato Antonio Zenteno TapiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Telemecanique Xsav11801 Datasheet

Uploaded by

Renato Antonio Zenteno TapiaCopyright:

Available Formats

Functions, Inductive proximity sensors 0

operating principle, Application Osiprox®

Sensors for rotation monitoring, slip detection, shaft overload

setting-up detection

Cylindrical type

Functions

Example : These self-contained rotation speed monitoring sensors have the special feature of incorporating, in the same case,

Coupling breakage monitoring the pulse sensing and processing electronics as well as the output switching amplifier that are required to make up an

integrated rotation monitoring device.

The unit provides an economical solution to the problems of detecting slip, belt breakage, drive shaft shear and

overloading, etc., in the following applications : conveyor belts, bucket elevators, Archimedian screws, grinders,

crushers, pumps, centrifugal driers, mixers, etc.

Operating principle

The output signal of this type of proximity sensor is processed by an impulse comparator, incorporated in the sensor.

The impulse frequency Fc generated by the moving part to be monitored is compared to the frequency Fr preset on the

sensor. The proximity sensors output switching circuit is in the closed state for Fc > Fr and open state for Fc < Fr.

XSA-V proximity sensors are particularly suitable for the detection of underspeed, i.e. when the speed of the moving

part Fc falls below a preset threshold Fr. This causes the sensors output circuit to switch off.

Note : The normal operation of the sensor is automatically subjected to a delay of 9 seconds from energisation. This is

to allow for the run-up period of the machine or installation being monitored.

- +

(1) Adjustment of the frequency threshold

(2)

p Adjustment of sensors frequency threshold : using potentiometer, 15 turns approximately.

p Increasing the sensors frequency threshold : turn the adjustment screw clockwise (+).

p Decreasing the sensors frequency threshold : turn the adjustment screw anti-clockwise (–).

b

a

(1) Potentiometer Diameter

(2) LED of sensor a b c

(3) c

(3) Metal target M30 x 1.5 4...6 30 60

b

Potentiometer adjustment curves (for XSA V1p801, 2-wire a or c sensors)

Low speed version (6…150 impulses/minute) High speed version (120…3000 impulses/minute)

Non metallic material

15 15

Number of turns

Number of turns

12 12

9 9

6 6

3 3

0 0

0,1 1 2,5 Hertz 2 10 50 Hertz

6 60 150 Imp/mn 120 600 3000 Imp/mn

10 1 0,4 Revs/s 0,5 0,1 0,02 Revs/s

Setting frequency Fr Setting frequency Fr

Setting-up

Minimum mounting distances (mm)

Side by side Face to face Facing a metal object Mounted in a metal support

d

e e

h

e ³ 20 e ³ 120 e ³ 30 d ³ 30, h ³ 0

Fixing nut tightening torque : < 50 N.m

31142-EN_Ver7.2.fm/2 Schneider Electric

References, Inductive proximity sensors 0

characteristics, Application Osiprox®

Sensors for rotation monitoring, slip detection, shaft overload

dimensions, detection

Cylindrical type

schemes

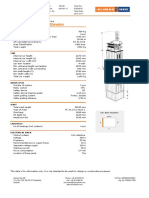

Flush mountable in metal

b

a

Lengths (mm) :

a = Overall a = 81

b = Threaded section b = 57

Ø = M30

DC DC AC/DC AC/DC

Nominal sensing distance (Sn) 10 mm 10 mm 10 mm 10 mm

Adjustable frequency range 6...150 impulses/min. 120…3000 impulses/min. 6...150 impulses/min. 120…3000 impulses/min.

References

3-wire c PNP XSA V11373 XSA V12373 – –

2-wire a or c – – XSA V11801 XSA V12801

Weight (kg) 0.300 0.300 0.300 0.300

Characteristics

Connection Pre-cabled, 3 x 0.34 mm2, 2 m length Pre-cabled, 2 x 0.5 mm 2, 2 m length

Degree of protection conforming to IP 67

IEC 60529

Operating zone 0…8 mm

Repeat accuracy 3 % of Sr

Hysteresis related to frequency 3…15 % of Fr

Operating temperature - 25…+ 70 °C

Output state indication LED

Rated supply voltage c 12…48 V with protection against reverse polarity a 24…240 V, 50/60 Hz or c 24…210 V

Voltage limits (including ripple on d.c.) c 10…58 V a or c 20…264 V, 50/60 Hz

Switching capacity £ 200 mA with overload and short-circuit protection a 5…350 mA or c 5...200 mA (1)

Voltage drop, closed state £ 1.8 V £ 5.7 V

Residual current, open state – £ 1.5 mA

Current consumption, no-load £ 15 mA –

Maximum switching frequency 6000 impulses/minute for XSA V11ppp, 48,000 impulses/minute for XSA V12ppp

Power on “run-up” delay 9 seconds ± 20 % + 1/Fr

Wiring schemes

3-wire c 2-wire a or c

XSA V1p373 XSA V1p801

+

BN

BN

PNP BK

BU BU

–

(1) These sensors do not incorporate overload or short-circuit protection and therefore, it is essential that a “quick-blow” fuse of 0.4 A be connected in series

with the load. See page 37317/2.

Other versions Sensors without initial “run-up” delay, or with reduced “run-up” delay on energisation of 3 seconds.

Sensors pre-cabled with other cable lengths.

SX2 DV units for monitoring overspeed or underspeed conditions, in the range 0 to 6000 impulses/min.

Please consult your Regional Sales Office.

Schneider Electric 31142-EN_Ver7.2.fm/3

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- D S L R-IntroductionDocument27 pagesD S L R-IntroductionInduchoodan RajendranNo ratings yet

- Telemecanique Xsav11801 DatasheetDocument2 pagesTelemecanique Xsav11801 DatasheetRenato Antonio Zenteno TapiaNo ratings yet

- (Ebook - PDF - Engineering) Allen Bradley Fundamentals of SensingDocument175 pages(Ebook - PDF - Engineering) Allen Bradley Fundamentals of Sensingrobertocadena100% (4)

- PLL 1397 PDFDocument63 pagesPLL 1397 PDFpamururamuNo ratings yet

- Cable Tray ManualDocument59 pagesCable Tray Manualamer_arauf100% (5)

- 13 Question PDFDocument57 pages13 Question PDFdnes9999No ratings yet

- AppGameKit Studio User Guide PDFDocument88 pagesAppGameKit Studio User Guide PDFkarthikeyan mariammalNo ratings yet

- Volvo Way To Electrification Tech Talk PDFDocument65 pagesVolvo Way To Electrification Tech Talk PDFcarbasemy100% (6)

- XS630B1MBL2 inductive sensor product data sheetDocument2 pagesXS630B1MBL2 inductive sensor product data sheetRenato Antonio Zenteno TapiaNo ratings yet

- XS630B1MBL2 inductive sensor product data sheetDocument2 pagesXS630B1MBL2 inductive sensor product data sheetRenato Antonio Zenteno TapiaNo ratings yet

- PLC RELAY TITLEDocument6 pagesPLC RELAY TITLERenato Antonio Zenteno TapiaNo ratings yet

- Data Sheet-Rele Bornera PLC-RSC-120UC21Document6 pagesData Sheet-Rele Bornera PLC-RSC-120UC21Renato Antonio Zenteno TapiaNo ratings yet

- Workshop Com Control StationDocument39 pagesWorkshop Com Control StationIsrael MoraisNo ratings yet

- CH 5 POnly ControlDocument9 pagesCH 5 POnly ControlRenato Antonio Zenteno TapiaNo ratings yet

- Workshop Com Control StationDocument39 pagesWorkshop Com Control StationIsrael MoraisNo ratings yet

- Manual-Modicon M340Document57 pagesManual-Modicon M340Renato Antonio Zenteno TapiaNo ratings yet

- FUNCIONALDocument120 pagesFUNCIONALRenato Antonio Zenteno TapiaNo ratings yet

- Norma-Iso 8601 Standard Date and Time AnotationDocument8 pagesNorma-Iso 8601 Standard Date and Time AnotationRenato Antonio Zenteno TapiaNo ratings yet

- Use Vanishing Point To Edit Images in PerspectiveDocument3 pagesUse Vanishing Point To Edit Images in PerspectiveHeavenlyPlanetEarthNo ratings yet

- The Fourier Transform ExplainedDocument35 pagesThe Fourier Transform ExplainedThanatkrit KaewtemNo ratings yet

- Ch. 8 - Substation Equipment, Location, and GorundingDocument20 pagesCh. 8 - Substation Equipment, Location, and GorundingMuhammad RiovanzaNo ratings yet

- AUSGRIDDocument33 pagesAUSGRIDNaramuk Ak UhtumiramNo ratings yet

- Prince Shri Venkateshwara Padmavathy Engineering College, Ponmar, Chennai-127 Assignment-5Document7 pagesPrince Shri Venkateshwara Padmavathy Engineering College, Ponmar, Chennai-127 Assignment-5HimajaNo ratings yet

- Xie Chang BLDC InfinionDocument18 pagesXie Chang BLDC InfinionFloeru SchrottNo ratings yet

- Introduction To Microprocessor-Based ControlDocument42 pagesIntroduction To Microprocessor-Based ControlAhdan FawwazNo ratings yet

- Bsim3v3 3.3 Manual PDFDocument200 pagesBsim3v3 3.3 Manual PDFfabbNo ratings yet

- Ece Eee f311 Tut 5 Sept 10-16 2019Document8 pagesEce Eee f311 Tut 5 Sept 10-16 2019ShreyanshJainNo ratings yet

- Microsense II - 5810: Non-Contact Capacitance Gauging Module For High Dynamic ApplicationsDocument2 pagesMicrosense II - 5810: Non-Contact Capacitance Gauging Module For High Dynamic ApplicationsasimNo ratings yet

- Theory of Operations AIRMAR PDFDocument24 pagesTheory of Operations AIRMAR PDFMiguel PerezNo ratings yet

- Digital India PresentationDocument20 pagesDigital India PresentationAreebaKhalidNo ratings yet

- 12a Timing OptimizationDocument29 pages12a Timing OptimizationSeshareddy KatamNo ratings yet

- Honeywell-Sensing-Kgz10 Series Oxygen SensorsDocument4 pagesHoneywell-Sensing-Kgz10 Series Oxygen SensorstpchoNo ratings yet

- Atomic Structure & The Periodic Table 1 QP PDFDocument8 pagesAtomic Structure & The Periodic Table 1 QP PDFVKNo ratings yet

- Wide Bandwidth Single J-Fet Operational Amplifiers: LF155-LF255-LF355 LF156-LF256-LF356 LF157-LF257-LF357Document14 pagesWide Bandwidth Single J-Fet Operational Amplifiers: LF155-LF255-LF355 LF156-LF256-LF356 LF157-LF257-LF357Yacine BàssotiNo ratings yet

- DSCW 5Document51 pagesDSCW 5shshsjNo ratings yet

- Rts5766dl Datasheet Adata v0.4Document29 pagesRts5766dl Datasheet Adata v0.4呂正典No ratings yet

- Rru 8872Document22 pagesRru 8872Rahul Sharma100% (1)

- Datasheet CT 4MDocument2 pagesDatasheet CT 4MYessa FitraNo ratings yet

- Optically coupled bilateral switch non-zero crossing triac datasheetDocument3 pagesOptically coupled bilateral switch non-zero crossing triac datasheetElectronicos CaldasNo ratings yet

- Vodafone's sales and distribution model interviewDocument29 pagesVodafone's sales and distribution model interviewHemanth KumarNo ratings yet

- Techn Data Sheet Port ElevatorDocument1 pageTechn Data Sheet Port ElevatorFikret DavudovNo ratings yet

- What Is MetastabilityDocument5 pagesWhat Is Metastabilityaarthi100No ratings yet

- APACHE REDIS Training: Trainer:David JosephDocument3 pagesAPACHE REDIS Training: Trainer:David JosephDavid JosephNo ratings yet