Professional Documents

Culture Documents

FURNITURE AND CABINET MAKING Session Guide

Uploaded by

Ryan Purisima0 ratings0% found this document useful (0 votes)

5 views3 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views3 pagesFURNITURE AND CABINET MAKING Session Guide

Uploaded by

Ryan PurisimaCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

FURNITURE AND CABINET MAKING (FCM)

Cabinets and Built-Ins

Drawers, Doors, and Shelves

Internal Architecture

Bases, Backs, and Tops

Hardware and Fasteners

Part One TOOLS AND MATERIALS

Sec. 1 Shop Necessities

Sec. 2 Woodworking Machines and Tools

Sec. 3 Working Wood

Sec. 4 Designing Furniture

Part Two BOX AND CASE CONSTRUCTION

Sec. 5 Basic Case

Sec. 6 Shelves

Sec. 7 Nails, Screws, and Other Fasteners

Sec. 8 Assembling Cases

Sec. 9 Cutting and Attaching Mouldings

Sec. 10 Drawers

Sec. 11 Drawer Hardware

Part Three DOORS

Sec. 12 Building Doors

Sec. 13 Fitting and Hinging Doors

Sec. 14 Door Pulls and Hardware

Part Four Bases, Feet, and Stands

Sec. 15 Bases

Sec. 16 Feet

Sec. 17 Stands

Part Five Frame Construction

Sec. 18 Legs and Aprons

Sec. 19 Chairs and Stools

Sec. 20 Face Frames

Sec. 21 Frame and Panel

Part Six Tabletops and Work Surfaces

Sec. 22 Making Tops

Sec. 23 Attaching Tops

Introduction

*Unlike most other crafts, furniture making and cabinet

making demand vast knowledge – and attentiveness.

*With it countless pieces and parts, cabinet making

involves a high level of organization, and organizing your

work and your shop space are part and parcel of the

craft.

*In a very real sense, woodworking is a personal journey.

That’s because there is no right or wrong way of making

furniture. What counts is what works.

*Can be a good exercise.

JIGS

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Cert Membership BilliardDocument1 pageCert Membership BilliardRyan PurisimaNo ratings yet

- Pepito OmnibusDocument1 pagePepito OmnibusRyan PurisimaNo ratings yet

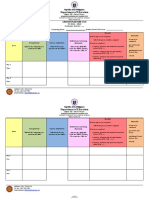

- Toledo National Vocational School Lesson PlanDocument4 pagesToledo National Vocational School Lesson PlanRyan PurisimaNo ratings yet

- Pepito OmnibusDocument1 pagePepito OmnibusRyan PurisimaNo ratings yet

- DepEd Toledo Vocational School OBE Committee RevisionDocument5 pagesDepEd Toledo Vocational School OBE Committee RevisionRyan PurisimaNo ratings yet

- Commitment Chaperones v2023Document1 pageCommitment Chaperones v2023Ryan PurisimaNo ratings yet

- 2023 Photo Gallery Athletics Secondary GirlsDocument12 pages2023 Photo Gallery Athletics Secondary GirlsRyan PurisimaNo ratings yet

- Division Meet Cover For Athletes Credentials 1 2Document1 pageDivision Meet Cover For Athletes Credentials 1 2Ryan PurisimaNo ratings yet

- FreewritingDocument3 pagesFreewritingRyan PurisimaNo ratings yet

- The Secrets of Succress and HappynessDocument23 pagesThe Secrets of Succress and HappynessMaizy DollNo ratings yet

- Online Education-The Future?Document2 pagesOnline Education-The Future?Ryan PurisimaNo ratings yet

- ENTREPRENEURSHIP PowerpointDocument5 pagesENTREPRENEURSHIP PowerpointRyan PurisimaNo ratings yet

- 501 Writing PromptsDocument181 pages501 Writing Promptspapersue99% (266)

- Money and Youth - 2018-ENDocument228 pagesMoney and Youth - 2018-ENAnthony PhelpsNo ratings yet

- List of Tools and Equipment AvailableDocument1 pageList of Tools and Equipment AvailableRyan PurisimaNo ratings yet

- Short Welcome SpeechDocument1 pageShort Welcome SpeechRyan PurisimaNo ratings yet

- Department of Education: Republic of The PhilippinesDocument8 pagesDepartment of Education: Republic of The PhilippinesRyan PurisimaNo ratings yet

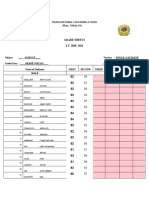

- Toledo National Vocational School Grade Sheets for Science ClassDocument3 pagesToledo National Vocational School Grade Sheets for Science ClassRyan PurisimaNo ratings yet

- Detailed Lesson Plan: Learning ObjectivesDocument1 pageDetailed Lesson Plan: Learning ObjectivesRyan PurisimaNo ratings yet

- Causes of War ExplainedDocument25 pagesCauses of War ExplainedMuzafar Shah Mosam ShahNo ratings yet

- 2022 Jet Programme Application Form Chart SheetDocument3 pages2022 Jet Programme Application Form Chart SheetHoney Mae OritaNo ratings yet

- English Language Education in Japan, Indonesia and The Philippines: A Survey of Trends, Issues and ChallengesDocument11 pagesEnglish Language Education in Japan, Indonesia and The Philippines: A Survey of Trends, Issues and ChallengesRyan PurisimaNo ratings yet

- ENTREPRENEURSHIP PowerpointDocument5 pagesENTREPRENEURSHIP PowerpointRyan PurisimaNo ratings yet

- Business Plan oDocument2 pagesBusiness Plan oRyan PurisimaNo ratings yet

- Beginners ManualDocument58 pagesBeginners ManualPrasaf100% (2)

- Aice Icecream Daily Sales ActivityDocument2 pagesAice Icecream Daily Sales ActivityRyan PurisimaNo ratings yet

- Carpentry LASDocument18 pagesCarpentry LASRyan PurisimaNo ratings yet

- Cash Flow Management 17-08-04Document19 pagesCash Flow Management 17-08-04SilasNo ratings yet

- BFARDocument1 pageBFARRyan PurisimaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)