Professional Documents

Culture Documents

Hardox 450: General Product Description

Uploaded by

Jaime PérezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hardox 450: General Product Description

Uploaded by

Jaime PérezCopyright:

Available Formats

Data sheet 168uk Hardox® 450 2021-04-16

Hardox® 450

General Product Description

The most popular abrasion-resistant steel with excellent structural properties.

Hardox® 450 is an abrasion-resistant steel with a nominal hardness of 450 HBW. Hardox® 450 combines good bendability and weldability. The products can

be used in many different components and structures that are subject to wear. Hardox® 450, with an extra 50 Brinell hardness over our 400 grade, provides

better dent and abrasion resistance as well as longer wear life, so you can achieve even greater savings.

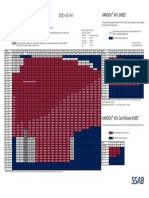

Dimension Range

Hardox® 450 is available as plate in thicknesses of 3.2 - 130.0 mm, as sheet in thicknesses 2.0 - 8.0 mm and as cold rolled sheet in thicknesses 0.8 - 2.1 mm.

For thicknesses over 80 mm the preferred width is 1650 mm. More detailed information on dimensions is provided in the dimension program.

Mechanical Properties

Grade Thickness Hardness1) Tensile strength Rm Typical yield strength

(mm) (HBW) (MPa), guaranteed (MPa), not guaranteed

Hardox® 450 CR sheet 0.8 - 2.10 425 - 4752) 1370 - 1600 1250

Hardox® 450 sheet 2.0 - 8.0 425 - 475 - 1250

Hardox® 450 plate 3.2 - 80.0 425 - 475 - 1250

Hardox® 450 plate 80.1 - 103.0 410 - 475 - 1250

Hardox® 450 plate 103.1 - 130.0 390 - 475 - 1250

1) Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.5 – 3 mm below surface. At least one test specimen per heat and 40 tons.

2) Hardness test is not performed or guaranteed for Hardox 450 cold rolled material. The hardness interval is a conversion from the tensile strength.

The nominal thickness of supplied plates will not deviate more than +/- 15 mm from the thickness of the test specimen used for hardness testing.

Hardox® wear plate is through-hardened. Minimum core hardness is 90 % of the guaranteed minimum surface hardness.

Impact Properties

Grade Longitudinal test, typical impact energy, Transverse test, guaranteed impact energy,

Charpy V 10x10 mm test specimen. Charpy V 10x10 mm test specimen.

Hardox® 450 sheet & plate 50 J/ -40 oC -

Hardox® 450 Tuf 1) - Min. 27 J/ -20 oC 2)

1) Impact testing is performed on thicknesses ≥ 6 mm for plate and ≥ 3 mm for sheet. For thicknesses between 3 and 11.9 mm, sub-size Charpy V-specimens are used. The specified minimum value

is proportional to the cross-sectional area of the test specimen, compared to a full-size specimen (10 x 10 mm). Impact testing according to ISO EN 148 per heat and thickness group. Average of

three tests.

2) Single value minimum 70% of specified average.

Chemical Composition (heat analysis)

Grade C*) Si*) Mn*) P S Cr*) Ni*) Mo*) B*)

(max %) (max %) (max %) (max %) (max %) (max %) (max %) (max %) (max %)

CR sheet 0.19 0.30 1.50 0.020 0.005 0.10 0.10 0.05 0.004

Sheet & plate 0.26 0.70 1.60 0.025 0.010 1.40 1.50 0.60 0.005

The steel is grain refined. * ) Intentional alloying elements.

Carbon Equivalent CET(CEV)

Thickness CR sheet sheet plate plate plate plate plate plate

0.8 - 2.10 2.0 - 8.0 3.2 - 4.9 5.0 - 9.9 10.0 - 19.9 20.0 - 39.9 40.0 - 80.0 80.1 - 130.0

Max CET(CEV) 0.36 (0.49) 0.35 (0.48) 0.37 (0.48) 0.38 (0.49) 0.39 (0.52) 0.41 (0.60) 0.43 (0.74) 0.41 (0.67)

Typ CET(CEV) 0.32 (0.41) 0.26 (0.39) 0.29 (0.39) 0.33 (0.45) 0.36 (0.48) 0.38 (0.56) 0.38 (0.61) 0.39 (0.64)

Data sheet 168uk Hardox® 450 2021-04-16

Tolerances

More details are given in SSAB’s brochure Hardox® Guarantees or at www.ssab.com.

Thickness

Tolerances according to Hardox® Thickness Guarantees. Hardox® Guarantees meet the requirements of EN 10 029 Class A for plate. For sheet, the

guarantees meet the requirements of 1/2 EN 10 051 and EN 10 131 for cold rolled sheet products.

Length and Width

According to SSAB’s dimension program. For plate, the tolerances are according to SSAB´s mill edge standard or tolerances that conform to EN 10 029 and

EN 10 131 for cold rolled sheet. Tolerances conform to EN 10 051 for sheet, tighter tolerances available on request.

Shape

Tolerances according to EN 10 029 for plate, EN 10 051 for sheet and EN 10 131 for cold rolled sheet.

Flatness

Tolerances are according to Hardox® Flatness Guarantees Class D for plate, which are more restrictive than EN 10 029. For sheet, the tolerances are

according to Hardox® Flatness Guarantees Class A, that offer narrower tolerances compared to EN 10 051. Cold rolled sheet tolerances are according to

Hardox® Flatness Guarantees Class B.

Surface Properties

According to EN 10 163-2, Class A Subclass 1.

Bending

Bendability for plate is according to Hardox® Bending Guarantees Class F. For sheet, the bendability is according to Hardox® Bending Guarantees Class C for

cold rolled sheet and Class B for sheet.

Delivery Conditions

The delivery condition is Q or QT (Quenched or Quenched and Tempered). Hardox® 450 plates are delivered with sheared or thermally cut edges, and

thicknesses over 80 mm are delivered with mill edge as standard. Hardox® 450 sheets are delivered with an as-rolled surface and mill edge as standard.

Hardox® 450 cold rolled sheets (0.80 - 2.10 mm (0.031 - 0.083")) are supplied as cold rolled surface.

Delivery requirements can be found in SSAB’s brochure Hardox® Guarantees or at www.ssab.com.

Fabrication and Other Recommendations

Welding, bending and machining.

Recommendations can be found in SSAB’s brochures at www.hardox.com or consult Tech Support, techsupport@ssab.com.

Hardox® 450 and Hardox® 450 Tuf are not intended for further heat treatment. Mechanical properties are achieved by quenching and when necessary, by

means of subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 250 oC (482 oF).

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer

coated plates, may produce dust with a high particle concentration.

Contact Information

www.ssab.com/contact

The English version of this document shall prevail in case of discrepancy. Minor changes and updates to the document may occur, please download

the latest version of this document at www.ssab.com

SSAB, Strenx, Hardox, Docol, GreenCoat, Toolox, Armox, Ramor, SSAB Domex, SSAB Laser, Raex, Duroxite are trademarks owned by the SSAB group

of companies.

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Hardox 450Document2 pagesHardox 450Brandon Vicuña GalánNo ratings yet

- Hardox® 450: General Product DescriptionDocument2 pagesHardox® 450: General Product DescriptionAmal RajNo ratings yet

- Hardox® 400: General Product DescriptionDocument2 pagesHardox® 400: General Product Descriptionmini p shendeNo ratings yet

- Hardox 450 Plate: General Product DescriptionDocument2 pagesHardox 450 Plate: General Product Descriptiongorane11No ratings yet

- Hardox 500 DatasheetDocument2 pagesHardox 500 DatasheetPetrus Slamet Putra WijayaNo ratings yet

- Data Sheet 151uk Hardox 400 Plate 2017-04-19 313 371857150 en PDFDocument2 pagesData Sheet 151uk Hardox 400 Plate 2017-04-19 313 371857150 en PDFLuis GuevaraNo ratings yet

- Hardox 450 PDFDocument2 pagesHardox 450 PDFAriel Toño Vaquera ZeballosNo ratings yet

- 1 500tufDocument2 pages1 500tufNguyên NguyễnNo ratings yet

- Hardox 400 PlateDocument3 pagesHardox 400 PlateAli TalebiNo ratings yet

- 500 TuffDocument2 pages500 TuffSubodh ShindeNo ratings yet

- Data Sheet 159us Hardox® 600 2021-02-22Document2 pagesData Sheet 159us Hardox® 600 2021-02-22Kevin GuoNo ratings yet

- Hardox 600: General Product DescriptionDocument2 pagesHardox 600: General Product DescriptionNguyên NguyễnNo ratings yet

- Hardox 550: General Product DescriptionDocument2 pagesHardox 550: General Product DescriptionNguyên NguyễnNo ratings yet

- 151 Hardox 400 Uk Data-SheetDocument2 pages151 Hardox 400 Uk Data-Sheetanon_94641581No ratings yet

- Hardox® 600: General Product DescriptionDocument2 pagesHardox® 600: General Product DescriptionTimur SonkayaNo ratings yet

- Hardox 500 Sheet: General Product DescriptionDocument2 pagesHardox 500 Sheet: General Product DescriptionDylkanWingsNo ratings yet

- Hardox 400 UkDocument2 pagesHardox 400 Uksingaravelan narayanasamyNo ratings yet

- Abrasion Plate Data SheetDocument2 pagesAbrasion Plate Data SheetMario MereniNo ratings yet

- Hardox 450: General Product DescriptionDocument2 pagesHardox 450: General Product DescriptionTeodor EzaruNo ratings yet

- Hardox 450 Uk Data SheetDocument2 pagesHardox 450 Uk Data SheetNenad BozicNo ratings yet

- Data Sheet 2067uk Hardox 500 Sheet 2016-03-02 50 371857150 enDocument3 pagesData Sheet 2067uk Hardox 500 Sheet 2016-03-02 50 371857150 enPtbbi TubanNo ratings yet

- Data Sheet 159 Hardox 600Document3 pagesData Sheet 159 Hardox 600Ehab Attia SelimNo ratings yet

- Hardox HiTuf 2016-01-14 264 371857150 enDocument3 pagesHardox HiTuf 2016-01-14 264 371857150 enRodrigoNo ratings yet

- Hardox 500 PlateDocument3 pagesHardox 500 PlateYousab CreatorNo ratings yet

- Hardox Techsupport 55webDocument4 pagesHardox Techsupport 55webCristian Mena HidalgoNo ratings yet

- Hardox Hiace: General Product DescriptionDocument2 pagesHardox Hiace: General Product DescriptionFilipe CordeiroNo ratings yet

- Hardox 450 Abrasion Resistant Steel Data SheetDocument2 pagesHardox 450 Abrasion Resistant Steel Data SheetpedroNo ratings yet

- 168 Hardox 450 Uk Data SheetDocument2 pages168 Hardox 450 Uk Data SheetBambang WibisonoNo ratings yet

- 932 Entechsupport 65 V22022Document4 pages932 Entechsupport 65 V22022VALNo ratings yet

- Tata Steel - AR400 & 450Document2 pagesTata Steel - AR400 & 450Gabriel CamargoNo ratings yet

- Data Sheet 173 Armox 440T 2016-04-22 34 371857150 enDocument3 pagesData Sheet 173 Armox 440T 2016-04-22 34 371857150 enJose ManuelNo ratings yet

- 152 - HARDOX - 500 - UK - Data Sheet PDFDocument2 pages152 - HARDOX - 500 - UK - Data Sheet PDFneto-portoNo ratings yet

- 5 - Hituf - Thick Structural WearDocument2 pages5 - Hituf - Thick Structural WearNguyên NguyễnNo ratings yet

- Data Sheet Raex 450Document3 pagesData Sheet Raex 450Amit GauravNo ratings yet

- Hardox 450 Data SheetDocument2 pagesHardox 450 Data SheetmatthewpincottNo ratings yet

- Raex 400: General Product DescriptionDocument2 pagesRaex 400: General Product DescriptionFilipe CordeiroNo ratings yet

- 6 - HiAce - Acidic WearDocument2 pages6 - HiAce - Acidic WearNguyên NguyễnNo ratings yet

- 107 - WELDOX - 700 - UK - Data Sheet PDFDocument2 pages107 - WELDOX - 700 - UK - Data Sheet PDFDaniel CringusNo ratings yet

- 055 TS Hardox Upgrading From Hardox 400 To Hardox 450 UKDocument4 pages055 TS Hardox Upgrading From Hardox 400 To Hardox 450 UKNguyen Duc DungNo ratings yet

- Tehnical Sheets For HardoxxDocument2 pagesTehnical Sheets For HardoxxZeu AressNo ratings yet

- Strenx 700: General Product DescriptionDocument2 pagesStrenx 700: General Product DescriptionpeterNo ratings yet

- Datasheet Strenx 700E - en - 2016Document3 pagesDatasheet Strenx 700E - en - 2016peterNo ratings yet

- 151 Hardox 400 Uk Data SheetDocument2 pages151 Hardox 400 Uk Data SheetArief TirtanaNo ratings yet

- Data Sheet 2006 Strenx 700 20170420 121 371857150 enDocument2 pagesData Sheet 2006 Strenx 700 20170420 121 371857150 enRodrigoNo ratings yet

- Akasdfksbkv KJHNFDocument16 pagesAkasdfksbkv KJHNFCats SafeNo ratings yet

- 168 - HARDOX - 450 - UK - Data Sheet PDFDocument2 pages168 - HARDOX - 450 - UK - Data Sheet PDFemad sabriNo ratings yet

- Wear Resistant Steel Sheet Material DataDocument6 pagesWear Resistant Steel Sheet Material DataJuan LeonNo ratings yet

- AAC LeichtBric 2020Document10 pagesAAC LeichtBric 2020Jared Josef GomezNo ratings yet

- Armox 370T Class 1: General Product DescriptionDocument2 pagesArmox 370T Class 1: General Product DescriptionSuneelNo ratings yet

- Cold Rolled CoilDocument23 pagesCold Rolled Coilmametcool100% (1)

- 008 Alloy Tool SteelDocument66 pages008 Alloy Tool SteelAbdelfattah MoheyeldinNo ratings yet

- Wear Resistant Steel: Product DescriptionDocument6 pagesWear Resistant Steel: Product DescriptionoomoomNo ratings yet

- 170 Hardox Hituf Uk Data SheetDocument2 pages170 Hardox Hituf Uk Data SheetTimNo ratings yet

- 107 Weldox 700 Uk Data SheetDocument2 pages107 Weldox 700 Uk Data SheetAnurag JainNo ratings yet

- Technical Data Sheet For The HPS 1 Impact Anchor Technical Information ASSET DOC 2331152Document4 pagesTechnical Data Sheet For The HPS 1 Impact Anchor Technical Information ASSET DOC 2331152counter1835No ratings yet

- Catalogo de Ejes CromsteelDocument20 pagesCatalogo de Ejes CromsteelJhonFerneyBohorquezSaldarriagaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Data Sheet 2062uk Hardox 450 Sheet 2016-03-02 85 371857150 enDocument3 pagesData Sheet 2062uk Hardox 450 Sheet 2016-03-02 85 371857150 enJaime PérezNo ratings yet

- Hardox 450 PLATE 2021-03-04 Hardox 450 SHEET: Maximum Length 16 000 MMDocument1 pageHardox 450 PLATE 2021-03-04 Hardox 450 SHEET: Maximum Length 16 000 MMJaime PérezNo ratings yet

- HardoxDocument22 pagesHardoxtruca_trucaNo ratings yet

- Hardox On SiteroadbuildingDocument2 pagesHardox On SiteroadbuildingBalajiKothandanNo ratings yet

- Hardox 450 Data SheetDocument2 pagesHardox 450 Data SheetmatthewpincottNo ratings yet

- How To Plot MATLAB Graph With Colors, Markers and Line Specification?Document8 pagesHow To Plot MATLAB Graph With Colors, Markers and Line Specification?Jaime PérezNo ratings yet

- MATLAB Plotting GuideDocument21 pagesMATLAB Plotting GuideJaime PérezNo ratings yet

- Dipslab Com Matlab 2d Plot ExamplesDocument12 pagesDipslab Com Matlab 2d Plot ExamplesJaime PérezNo ratings yet

- Dipslab - Com - Matlab-3d-Plot-Examples - Fbclid IwAR0AhZgq6NBfC6gJ4K8pkdDspRIK3ZXZN2gfX5vMEEwLIovWefi8cVNGg2EDocument28 pagesDipslab - Com - Matlab-3d-Plot-Examples - Fbclid IwAR0AhZgq6NBfC6gJ4K8pkdDspRIK3ZXZN2gfX5vMEEwLIovWefi8cVNGg2EJaime PérezNo ratings yet

- Advances in Engineering Desing and SimulationDocument348 pagesAdvances in Engineering Desing and SimulationJaime PérezNo ratings yet

- Beautylish The Ordinary Treatment Guide 1 - PDFDocument2 pagesBeautylish The Ordinary Treatment Guide 1 - PDFarinilhaque25% (4)

- Methacrylic Acid - MSDSDocument10 pagesMethacrylic Acid - MSDSMohamed HalemNo ratings yet

- Aluminum Manufacturing ReportDocument30 pagesAluminum Manufacturing ReportmalynNo ratings yet

- 1 s2.0 S014181302201563X MainDocument7 pages1 s2.0 S014181302201563X Mainjulio cesar gurreonero fernandezNo ratings yet

- Saikat Sil Tech Tex Assignment 3 (Final)Document7 pagesSaikat Sil Tech Tex Assignment 3 (Final)Saikat SilNo ratings yet

- A866Document4 pagesA866Deepak JNo ratings yet

- Faber Castell Polychromos - 2018 - Colour Chart - ShinebrightdesignDocument4 pagesFaber Castell Polychromos - 2018 - Colour Chart - ShinebrightdesignMagrizNo ratings yet

- Aalco Metals LTD - Stainless Steel 14003 3CR12 Sheet and Plate - 96Document3 pagesAalco Metals LTD - Stainless Steel 14003 3CR12 Sheet and Plate - 96Rourkela Fabrications Pvt. Ltd.No ratings yet

- Cdiars3 Module Act. DinangwatanDocument2 pagesCdiars3 Module Act. DinangwatanEngland Israel SevidalNo ratings yet

- Edible Flowers A New Source of MineralsDocument19 pagesEdible Flowers A New Source of MineralsIJRASETPublicationsNo ratings yet

- Extrinsic Semiconductor: An Extrinsic Semiconductor Can Be Further Classified IntoDocument2 pagesExtrinsic Semiconductor: An Extrinsic Semiconductor Can Be Further Classified IntoRitvik ChaturvediNo ratings yet

- 2024 Assignment 1Document3 pages2024 Assignment 1Simphiwe MokoriNo ratings yet

- Questions For Polar Bear CartoonDocument3 pagesQuestions For Polar Bear CartoonMaggie McGregorNo ratings yet

- Anti-spatter liquid prevents weld spatterDocument2 pagesAnti-spatter liquid prevents weld spatterTamal SenguptaNo ratings yet

- Hair-Save Unhairing Methods in Leather ProcessingDocument37 pagesHair-Save Unhairing Methods in Leather ProcessingdavidberarNo ratings yet

- Silicone Sealants: High Performance SealantDocument4 pagesSilicone Sealants: High Performance SealantParamdeep SinghNo ratings yet

- M Rev PPT Huber Catalytic Processes For The Production of Fuels and Chemicals From Lignocellulosic BiomassbDocument26 pagesM Rev PPT Huber Catalytic Processes For The Production of Fuels and Chemicals From Lignocellulosic BiomassbFemita RodríguezNo ratings yet

- Hormones, ClassificationDocument10 pagesHormones, ClassificationMenoNo ratings yet

- Our Lady of Fatima University Urinalysis Midterm ExamDocument7 pagesOur Lady of Fatima University Urinalysis Midterm ExamALEXANDRA MAE MAIPIDNo ratings yet

- Water Coagulation and Flocculation 1663749610Document53 pagesWater Coagulation and Flocculation 1663749610salehNo ratings yet

- Cera Corroguard EpDocument2 pagesCera Corroguard EpSure Tech TrivandrumNo ratings yet

- Product DataDocument2 pagesProduct DataBNo ratings yet

- Experiment 9: Reactions of Alcohols Aim: This Experiment Is Conducted To Observe The Reactions of Alcohols With Sodium and TheirDocument5 pagesExperiment 9: Reactions of Alcohols Aim: This Experiment Is Conducted To Observe The Reactions of Alcohols With Sodium and Theirqienqien0% (1)

- 1 SS400 Material Properties - Beyond-Steel & MetalDocument1 page1 SS400 Material Properties - Beyond-Steel & MetalmarselNo ratings yet

- DAMILOLA ADEOYE SOP FOR University of AlabamaDocument4 pagesDAMILOLA ADEOYE SOP FOR University of AlabamaIndra SaputraNo ratings yet

- Inorganic Chemistry: Duward Shriver and Peter AtkinsDocument65 pagesInorganic Chemistry: Duward Shriver and Peter AtkinsMilano TorresNo ratings yet

- Chemoselective Reductions With Sodium BorohydrideDocument6 pagesChemoselective Reductions With Sodium BorohydrideVassili RevelasNo ratings yet

- EDU 514 Science Exec Preview 7 Digital 2020Document66 pagesEDU 514 Science Exec Preview 7 Digital 2020Seema Chaturvedi60% (15)

- Finecoat TVA 1410Document2 pagesFinecoat TVA 1410Karishma Prabhu100% (3)

- Controlled Release Pregabalin NanoparticlesDocument7 pagesControlled Release Pregabalin NanoparticlesRobbyAlivianNo ratings yet