Professional Documents

Culture Documents

5 - TIL 2157 (Vent Port Orientation of Solenoid Operated Pneumatic Valves)

Uploaded by

Baran ShafqatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 - TIL 2157 (Vent Port Orientation of Solenoid Operated Pneumatic Valves)

Uploaded by

Baran ShafqatCopyright:

Available Formats

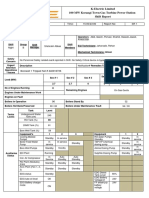

TECHNICAL BULLETIN

TIL 2157: Vent Port Orientation of Solenoid Operated

Pneumatic Valves

Abstract

This Technical Bulletin is to inform Customers of the applicability of TIL 2157 to units serviced by BH.

BH would like to highlight that the codes mentioned inside the TIL 2157 are only for example and that the

elbow fitting should be selected on the base of the existing configuration at site applying the

recommendation as best practices to help prevent sluggish operation of solenoid operated pneumatic

valves.

Serviceable Units

All units serviced by BH using solenoid operated pneumatic valves with vent port upwards.

Compliance Category

M - Maintenance Identifies maintenance guidelines or best practices for reliable equipment operation.

C - Compliance Required Identifies the need for action to correct a condition that, if left uncorrected, may result in reduced equipment

reliability or efficiency. Compliance may be required within a specific operating time.

A - Alert Failure to comply with the Technical Bulletin could result in equipment or facility damage. Compliance is

mandatory within a specific operating time.

S – Safety Failure to comply with this Technical Bulletin could result in personal injury. Compliance is mandated within a

specific operating time.

Timing Code

1 Prior to Unit Startup / Prior to Continued Operation

2 At First Opportunity / Next Shutdown

3 Prior to Operation of Affected System

4 At First Exposure of Component

5 At Scheduled Component Part Repair or Replacement

6 Next Scheduled Outage

Nuovo Pignone Tecnologie S.r.l. con socio unico (Registro Imprese di Firenze, Codice Fiscale 06593380485 e Partita IVA di Gruppo 06872660482)

Capitale Sociale € 100.000.000,00 i.v. - Società soggetta a direzione e coordinamento di Baker Huges Company

Nuovo Pignone Tecnologie S.r.l. Proprietary Information

The information published in this Technical Bulletin is offered to you by BH in consideration of its ongoing sales and service relationship with your organization. However, since

the operation of your plant involves factors not within our knowledge, and since operation of the plant is within your control and responsibility for its continuing successful

operation rests with you, BH disclaims responsibility or liability for damage of any type, including but not limited to direct, consequential or special damages that may be

alleged to have occurred as a result of applying this information, regardless of whether it is claimed that BH is strictly liable, in breach of contract, in breach of warranty,

negligent, or is in any other respect responsible for any alleged injury or damage sustained by your organization as a result of applying this information. The information

contained in this Technical Bulletin is confidential and proprietary. This Bulletin and the information contained in it are protected by copyright and/or other intellectual property

rights. This Bulletin and information are provided for authorized use only, and may not be used by or disclosed to others without the prior express written consent of Nuovo

Pignone Tecnologie S.r.l.

GE Power

POWER SERVICES ENGINEERING TIL 2157

PRODUCT SERVICE Publish Date: 23 SEPTEMBER 2019

Compliance Category - M

Timing Code - 6

TECHNICAL INFORMATION LETTER

VENT PORT ORIENTATION OF SOLENOID OPERATED PNEUMATIC VALVES

APPLICATION

All gas turbines using solenoid operated pneumatic valves with vent port upwards.

PURPOSE

To inform users of best practices to help prevent sluggish operation of solenoid operated pneumatic valves.

COMPLIANCE CATEGORY

M - Maintenance Identifies maintenance guidelines or best practices for reliable equipment operation.

C - Compliance RequiredIdentifies the need for action to correct a condition that, if left uncorrected, may result in reduced

equipment reliability or efficiency. Compliance may be required within a specific operating time.

A - Alert Failure to comply with the TIL could result in equipment damage or facility damage. Compliance

is mandated within a specific operating time.

S - Safety Failure to comply with this TIL could result in personal injury. Compliance is mandated within a

specific operating time.

TIMING CODE

1 Prior to Unit Startup / Prior to Continued Operation (forced outage condition)

2 At First Opportunity (next shutdown)

3 Prior to Operation of Affected System

4 At First Exposure of Component

5 At Scheduled Component Part Repair or Replacement.

6 Next Scheduled Outage

© 2019 General Electric Company

The proprietary information published in this Technical Information Letter is offered to you by GE in consideration of its ongoing sales and service relationship

with your organization. However, since the operation of your plant involves many factors not within our knowledge, and since operation of the plant is in your

control and ultimate responsibility for its continuing successful operation rests with you, GE specifically disclaims any responsibility for liability based on

claims for damage of any type, i.e. direct, consequential or special that may be alleged to have been incurred as result of applying this information regardless

of whether it is claimed that GE is strictly liable, in breach of contract, in breach of warranty, negligent, or is in other respects responsible for any alleged injury

or damage sustained by your organization as a result of applying this information. This Technical Information Letter contains proprietary information of

General Electric Company and is furnished to its customer solely to assist that customer in the installation, testing, operation and/or maintenance of the

equipment described. This document shall not be reproduced or distributed in whole or in part nor shall its contents be disclosed to any third party without the

written approval of GE Power Services Engineering. All rights reserved.

Date Printed: 23 SEPTEMBER 2019

BACKGROUND DISCUSSION

Solenoid operated pneumatic valves are used in critical gas turbine auxiliary systems like fuel systems, cooling and

sealing air systems, etc. Pneumatic valves are engineered to operate within the slew times specified to meet

functional and safety requirements of the system. One of the reasons that valves may not be able to open/close

within the specified slew time can be due to debris accumulation and blocking of solenoid valve vent ports.

A 7F unit recently reported slow closing of the safety shut off valve (SSOV) installed in their gas fuel system, resulting

in continuous gas venting to atmosphere through the vent line located in downstream piping. Further investigation

revealed that the vent port of the solenoid was pointing upwards and was blocked with ice build-up during cold

ambient temperatures. Solenoid vent screens or bug screens, if pointed upwards, might experience debris/ice

buildup which may cause vent restrictions or allow water ingress resulting in corrosion inside the valve and affect

slew times.

Figure 1: Solenoid vent port in the vertical direction (viewing from top)

RECOMMENDATIONS

To reduce the risk of debris/ice buildup at the vent screen or water ingress inside the valve, it’s recommended for

sites with solenoids installed with vent ports pointing upwards to install an elbow fitting on the vent port and have a

bug screen at the other end of the elbow.

Elbow fittings should be ordered based on the size of the solenoid vent port. For example, an elbow fitting for a

Maxseal solenoid valve with a ¼”or ½” vent port is 156A1086P005 or 156A1086P013, respectively. An equivalent

elbow fitting should be used depending on the size of the vent port.

Note: This TIL can be considered complete when the affected solenoids are installed with an elbow fitting onto the

vent port.

PLANNING INFORMATION

Compliance

• Compliance Category: M

• Timing Code: 6

© 2019 General Electric Company

The proprietary information published in this Technical Information Letter is offered to you by GE in consideration of its ongoing sales and service relationship

with your organization. However, since the operation of your plant involves many factors not within our knowledge, and since operation of the plant is in your

control and ultimate responsibility for its continuing successful operation rests with you, GE specifically disclaims any responsibility for liability based on

claims for damage of any type, i.e. direct, consequential or special that may be alleged to have been incurred as result of applying this information regardless

of whether it is claimed that GE is strictly liable, in breach of contract, in breach of warranty, negligent, or is in other respects responsible for any alleged injury

or damage sustained by your organization as a result of applying this information. This Technical Information Letter contains proprietary information of

General Electric Company and is furnished to its customer solely to assist that customer in the installation, testing, operation and/or maintenance of the

equipment described. This document shall not be reproduced or distributed in whole or in part nor shall its contents be disclosed to any third party without the

written approval of GE Power Services Engineering. All rights reserved.

Date Printed: 23 SEPTEMBER 2019

Parts

156A1086P005, or equivalent - ¼” elbow fitting

156A1086P013, or equivalent - ½” elbow fitting

TIL DISPOSITION

Disposition of TILs should be entered in local records and also in GE Power ServiceNow. Follow the below instructions for

entering the disposition record;

• Log into the Power ServiceNow at https://gepowerpac.service-now.com/til_new/ using your GE SSO number and

password.

• Select "TIL Disposition".

• Click on the TIL for the serial number you want to update.

• Choose the most appropriate "Disposition Status" and enter "Disposition Notes".

• Click "Save".

Contact your local GE Services representative for assistance or for additional information

© 2019 General Electric Company

The proprietary information published in this Technical Information Letter is offered to you by GE in consideration of its ongoing sales and service relationship

with your organization. However, since the operation of your plant involves many factors not within our knowledge, and since operation of the plant is in your

control and ultimate responsibility for its continuing successful operation rests with you, GE specifically disclaims any responsibility for liability based on

claims for damage of any type, i.e. direct, consequential or special that may be alleged to have been incurred as result of applying this information regardless

of whether it is claimed that GE is strictly liable, in breach of contract, in breach of warranty, negligent, or is in other respects responsible for any alleged injury

or damage sustained by your organization as a result of applying this information. This Technical Information Letter contains proprietary information of

General Electric Company and is furnished to its customer solely to assist that customer in the installation, testing, operation and/or maintenance of the

equipment described. This document shall not be reproduced or distributed in whole or in part nor shall its contents be disclosed to any third party without the

written approval of GE Power Services Engineering. All rights reserved.

Date Printed: 23 SEPTEMBER 2019

TECHNICAL BULLETIN

Contacts

For units under warranty or covered under a Contractual Service Agreement (CSA) please refer to your BH

Project Manager.

For technical questions or application and commercial requests please contact:

Baker Hughes Company

Customer Service Center

Via Felice Matteucci, 2

50127 Florence, Italy

e-Mail: customer.service.center@bhge.com

Web: https://www.bhge.com/upstream/production-optimization/turbomachinery/rotating-equipment-services

Phone: +39 055 427 2500

Fax: +39 055 423 2800

Please specify the Unit Serial Number and Technical Bulletin associated with the request and whether the

request is technical or commercial.

To directly access and download BH Technical Bulletins published for your fleet or to subscribe to Technical

Bulletin e-mail notification service, please visit the Technical Enhancements & Notifications Platform:

https://www.bhge.com/portals/services-portals

This online tool is available only to registered BH Customers.

In addition, Customers can update the implementation status of Technical Bulletins applicable to their

fleet directly for one or multiple serial numbers.

To update the implementation status of Technical Bulletins:

• Log in to the TEN platform – https://www.bhge.com/portals/services-portals

• Go to the “My implementation status” page

• Search by document code or by unit serial number.

• Flag the record(s) to be updated

• Click on “Update Status”.

Expense Policy

The recommendations contained in this Technical Bulletin are for information only. Unless otherwise

indicated in a Contractual Service Agreement (CSA) in force between the parties, a specific Purchase

Order must be in place and all costs associated with the implementation of the recommendations shall

be paid by the Customer.

2/2

Nuovo Pignone Tecnologie S.r.l. Proprietary Information

The information contained in this Technical Bulletin is confidential and proprietary. This Bulletin and the information contained in it are protected by copyright and/or other

intellectual property rights. This Bulletin and information are provided for authorized use only, and may not be used by or disclosed to others without the prior express written

consent of Nuovo Pignone Tecnologie S.r.l.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 1 - NIC 20.07 (Microsoft ® Product End of Support Notice - Operating System)Document4 pages1 - NIC 20.07 (Microsoft ® Product End of Support Notice - Operating System)Baran ShafqatNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Simple Pressure Safety Valve Calibration ProcedureDocument5 pagesA Simple Pressure Safety Valve Calibration ProcedureBaran Shafqat0% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Mech Seal Setting LengthDocument2 pagesMech Seal Setting LengthrajibsinghaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Trouble Shooting&SolutionsDocument21 pagesTrouble Shooting&SolutionsBaran ShafqatNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Presentation Title: Your Company InformationDocument3 pagesPresentation Title: Your Company InformationBaran ShafqatNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Understanding SMAW and GMAW electrode symbolsDocument4 pagesUnderstanding SMAW and GMAW electrode symbolsBaran ShafqatNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 10 - PSSB 20190708.A (Safe Operation of Valves During Bench Testing)Document4 pages10 - PSSB 20190708.A (Safe Operation of Valves During Bench Testing)Baran ShafqatNo ratings yet

- NORSOK Standard Jacket PipesDocument28 pagesNORSOK Standard Jacket PipesvuongNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Question ResponsesDocument1 pageQuestion ResponsesBaran ShafqatNo ratings yet

- Presentation On Dollars TemplateDocument5 pagesPresentation On Dollars TemplateBaran ShafqatNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- SWGVRFGDocument1 pageSWGVRFGBaran ShafqatNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- CV Resume Format 1Document1 pageCV Resume Format 1Zaib RehmanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Turbine Overspeed Systems and Required Response TimesDocument12 pagesTurbine Overspeed Systems and Required Response Timesramnadh803181No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Books For MLA-1Document1 pageBooks For MLA-1Baran ShafqatNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Analytical ReasoningDocument6 pagesAnalytical ReasoningHaseebPirachaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- DMPLBG PDFDocument108 pagesDMPLBG PDFThiha MinNo ratings yet

- CaseStudy OBSDocument10 pagesCaseStudy OBSBaran ShafqatNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Case Study Pakistan Foods and Beverage CDocument1 pageCase Study Pakistan Foods and Beverage CRehan AnsariNo ratings yet

- 452260802Document152 pages452260802Baran ShafqatNo ratings yet

- CV Resume Format 1Document1 pageCV Resume Format 1Zaib RehmanNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Profile To VisitDocument3 pagesProfile To VisitBaran ShafqatNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CV Resume Format 1Document1 pageCV Resume Format 1Zaib RehmanNo ratings yet

- Profile To VisitDocument3 pagesProfile To VisitBaran ShafqatNo ratings yet

- Trainee LearnDocument13 pagesTrainee LearnBaran ShafqatNo ratings yet

- Training Ver7.1 Calculate Flange - General Example - PDFDocument13 pagesTraining Ver7.1 Calculate Flange - General Example - PDFDHANANJAY SURESHNo ratings yet

- Training PLanDocument8 pagesTraining PLanBaran ShafqatNo ratings yet

- LeisureDocument5 pagesLeisurejamal009No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Emailing PPSC Nts FPSC Data For All TestsDocument146 pagesEmailing PPSC Nts FPSC Data For All TestsANas AliNo ratings yet

- Evening Shift Report 31-08-2019Document4 pagesEvening Shift Report 31-08-2019Baran ShafqatNo ratings yet

- F FS1 Activity 3 EditedDocument15 pagesF FS1 Activity 3 EditedRayshane Estrada100% (1)

- COR2-03 Admist The Mists and Coldest Frost PDFDocument16 pagesCOR2-03 Admist The Mists and Coldest Frost PDFLouis BachNo ratings yet

- TM T70 BrochureDocument2 pagesTM T70 BrochureNikhil GuptaNo ratings yet

- LTG 04 DD Unit 4 WorksheetsDocument2 pagesLTG 04 DD Unit 4 WorksheetsNguyễn Kim Ngọc Lớp 4DNo ratings yet

- Bai Tap Bo TroDocument6 pagesBai Tap Bo TroKhiết TrangNo ratings yet

- The Completely Randomized Design (CRD)Document16 pagesThe Completely Randomized Design (CRD)Rahul TripathiNo ratings yet

- FacebookH Cking 1 3 (SFILEDocument10 pagesFacebookH Cking 1 3 (SFILEFitra AkbarNo ratings yet

- Training Report On Machine LearningDocument27 pagesTraining Report On Machine LearningBhavesh yadavNo ratings yet

- Idler Sprockets: Poly Chain GT and Powergrip GTDocument2 pagesIdler Sprockets: Poly Chain GT and Powergrip GTVolodymуr VorobetsNo ratings yet

- Inventario de Autoestima de Coopersmith PDFDocument10 pagesInventario de Autoestima de Coopersmith PDFNancy BerduzcoNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Mysteries of Plato: Lunar NotebookDocument2 pagesThe Mysteries of Plato: Lunar NotebookDavor BatesNo ratings yet

- Nettoplcsim S7online Documentation en v0.9.1Document5 pagesNettoplcsim S7online Documentation en v0.9.1SyariefNo ratings yet

- Reporte Corporativo de Louis Dreyfus Company (LDC)Document21 pagesReporte Corporativo de Louis Dreyfus Company (LDC)OjoPúblico Periodismo de InvestigaciónNo ratings yet

- Orion C.M. HVAC Case Study-07.25.23Document25 pagesOrion C.M. HVAC Case Study-07.25.23ledmabaya23No ratings yet

- Summarised Maths Notes (Neilab Osman)Document37 pagesSummarised Maths Notes (Neilab Osman)dubravko_akmacicNo ratings yet

- Theory and Practice of Crown and Bridge Prosthodontics 4nbsped CompressDocument1,076 pagesTheory and Practice of Crown and Bridge Prosthodontics 4nbsped CompressYuganya SriNo ratings yet

- Spare Parts List: WarningDocument5 pagesSpare Parts List: WarningÃbdøū Èqúípmeńť MédîcàlNo ratings yet

- Su1 Assessment U01Document14 pagesSu1 Assessment U01Cristian Seas ArceNo ratings yet

- What Is Robotic Process Automation?: ERP SystemDocument5 pagesWhat Is Robotic Process Automation?: ERP SystemAna BoboceaNo ratings yet

- Satisfaction ExtraDocument2 pagesSatisfaction ExtraFazir AzlanNo ratings yet

- Finding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Document39 pagesFinding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Jernel Raymundo80% (5)

- 01 The-Mckinsey-Edge-Hattori-En-26154Document5 pages01 The-Mckinsey-Edge-Hattori-En-26154Waqar AhmedNo ratings yet

- Health Fitness Guide UK 2018 MayDocument100 pagesHealth Fitness Guide UK 2018 MayMitch Yeoh100% (2)

- 2 Integrated MarketingDocument13 pages2 Integrated MarketingPaula Marin CrespoNo ratings yet

- Format of Synopsis - Project - 1Document5 pagesFormat of Synopsis - Project - 1euforia hubNo ratings yet

- School of Education, Arts and Sciences General Education Area 1 SEMESTER S.Y 2021-2022Document4 pagesSchool of Education, Arts and Sciences General Education Area 1 SEMESTER S.Y 2021-2022JaylordPalattaoNo ratings yet

- ECE SAR OldDocument168 pagesECE SAR OldNagaraja RaoNo ratings yet

- FIL M 216 2nd Yer Panitikan NG PilipinasDocument10 pagesFIL M 216 2nd Yer Panitikan NG PilipinasJunas LopezNo ratings yet

- Management Theory and Practice: Methods of Performance AppraisalDocument3 pagesManagement Theory and Practice: Methods of Performance AppraisalRadha maiNo ratings yet

- JMPRTraininga I5545e PDFDocument500 pagesJMPRTraininga I5545e PDFmvptoxNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)