Professional Documents

Culture Documents

Ptj-Wps-Sum-Tk-01-2017 Rev-0 Welding Procedure Specification For Tank (Smaw)

Ptj-Wps-Sum-Tk-01-2017 Rev-0 Welding Procedure Specification For Tank (Smaw)

Uploaded by

Kareem Abdelaziz100%(1)100% found this document useful (1 vote)

26 views27 pagesWPS

Original Title

PTJ-WPS-SUM-TK-01-2017 REV-0 WELDING PROCEDURE SPECIFICATION FOR TANK (SMAW)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWPS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

26 views27 pagesPtj-Wps-Sum-Tk-01-2017 Rev-0 Welding Procedure Specification For Tank (Smaw)

Ptj-Wps-Sum-Tk-01-2017 Rev-0 Welding Procedure Specification For Tank (Smaw)

Uploaded by

Kareem AbdelazizWPS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 27

&...

Project : ASPH- LOT II TANK FARM & i

TOPSIDE FACILITIES (PROJECT No. | Zapp! GED

3656/200)

<7 occ Tae roo [Pana

PIES SUMED TR \WFLDING PROCEDURE SPECICATION = a

WELDING PROCEDURE SPECIFICATION

SUMED TK 01/2017

Project ASPH LOT TANK FARM & TOPSIDE FACILITIES

Employer ‘ARAB PETROLEUM PIPE LINE Co, @UMED)

Contacior ‘CONSORTIOM (ENPPI/PETROIET)

Prost No. 36567300

Document No PIE-WPS SUMED TK 01/2017 & POR KIOW2AI007

Document revision Sas 00

Pies

| ser | menor < OAe Tepe

eae ascerrw ‘oxsoertomrsenery | suwen/mn

|

rato

‘TOPSIDE FACILITIES (PROJECT No. F2=app! zal

. Project © ASPH - LOT II TANK FARM &

fp... 3656/200)

Cer er Docent Ti raat

PORES SIRE TE ‘WELDING PROCEDURE srHCIieATION =

Revised WPS

Brief description

“Approval issue

‘AWS Class for filler metal E7018 is replaced by E7018-1 as they are the same in F

No. & A No, and no changes in essential variables.

Paget or

WELDING PROCEDURE SPECIFICATION

coves)

ACCORDING 10

APL 650 & ASME IX 2015,

appt GB

INT: ARAB PE ROLFUM PIPELINE Co. SUMED)

WPS NO: TTEWPS SUMED TRGIU1Y Res 09

PORTING POR: KJO 0282107 [Pa 34

WELDING FROCESS(ES):_SMAW (MANUAL) [IMPACT REQUIREMENTS: NO

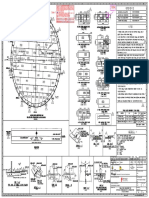

JOINTS (QW-402)

BASE METALS (QW-403)

FILLER METALS (QW-40)

POSITION (QW-405)

‘GAS (QW-408)

ELECTRICAL CHARACTERISTICS (QW-409)

Paget

:

@...

WELDING PROCEDURE SPECIFICATION

coves)

‘ORDING TO.

&S

SME 1X 2015

appt

‘CLIENT: ARAB PETROLEUM PFS UNE Co SOMEDY

[WPS NO-_PTI-WPS SUMED TR DIOTT Rex 00

SUPPORTING POR: KIO 104207 [ Pgs tort

WELDING PROCESS(ES) SMIAW (MANUAL

IMPACT REQUIREMENTS: NO

WHLDSEOUENCESOF PASSES ryan

TECHNK

QUE (QW-410)

NESTE ELEGHROOE ZEN) ma

HEAT (W- 406)

POST WELD HEAT TREATMENT (QW-407)

Dession CONSORTIUM (PTIENPPD SUMED Rep.

ww eat ate

simmax FET

age ot

HELIO

arr

Binpph

REF PieTAIESS SDE ACCEPTED

JORO DELA TORRE -WELDING SPECIALIST | 31UL-2012,

saya 2002 ‘ “TRANSMITTAL,

L MATHKAR STATE TRON; WAELLOTFY MOSTAFA

"ANY REPIESENTATIVE SPL Projet Menger

ICO OVERSEAS COMPANY BX ENeris sit

Jon: 3}s1a00, YANBU EXPORT REVINERY PROJECT TANK FARM (St)

JATACHED ARE As Described Bulow _ PRINTS OFFACIT WE RELEASE THEM FOR

Avenoyp. pence consreuction

eomaers xenon nibieniewration

jAwORIATION CO mew OD o

DESCRIPHION

Welding Procedure Specification (WPS)

= SAME (ASTIMANSSPALAS.1-Clossfetion

17018 (7 O20 PICEA

Dock HSA-YBRP-3353.300-0002 en

= SAME ASTMAWSISFAMAS 1-Clasfetion

7D (1 GR2 10 PIGR) 0°

Babee ram ossione ino ¥S° SP

16-7202

SANIW (ASTUZAWSSPA/AS.1-Clicaton

ars) A

Dock KSA-rsKP-8383-300.00029 Rew KS"

SAMI (ASTIOAMSSEAIS 5 Clsfeation

cause)

Dock KSA-YBRP-1335300-0028 Revd

SAW SAW (ASTALANSIEUAS.| 83.17

(Cusfaton 7018/ Frag BMI

Doc# RSA-YRRP-3335300-00027 Revd

SUA SAW CASTANTSSPAIS 4323 A

Gtectin OTB GFRAGENTENI? yporel2™

Dock AR TER 59 300-0906 Red

2662012

= cre Gs Welding (2019)

‘ASTMANSSEAAS 26 Clanton (007271)

Dock KSA-vene-3332 3000025 Rend Ty. \

reeom

Pil

TR MOOT

AK

YAGRER PUT RCESS SSR FACETED

HELIODORO DE LA TORRE -WELDING SPECIALIST 25 JUL-2012

PiPiNiG FABRICATION PROCEDURE ~~~ a

SA.YERP.3355.908-00031

Ravan 00 | Sue FA

Document typo wes [Sytem subaytn: WA | Gespine MEG | Rev baw BE esicaars

‘Goniretr document number: KSAYERP-3385-00-00001 Page tot

YANBU EXPORT REFINERY PROJECT

‘TANK FARM PACKAGE (SP-1)

q MECHANICAL WORK

Enpp: =e

"Barthes pete nes errr tn ae euaton oe

+ chant ‘yasRer

+ Contact Ewer

+ Sibeontactor : PETROVET

“yt Contacto, = YOS-YERP-6800004874 (0)

+ WPS.No. 0-van007

+ PAR Ne oon2007

‘SMAI (ASTIUAWS'SEA 5.1 Csieaton £7018)

0 [A [aeanezoi2 | leaed Foran | Omowata Ze chy

Date Reison memo Tesuedby | Chesed by | Abproved by

‘Bladen emery o CMP ture td ets whl tan eon mth compe

Frooties

semome | MegpIezaocenins seeciricaniON

of “vag ACCORDING TO 4SMH 1 Abt aotene

fev.»

YASREFPuTICESS cove 1

HELIODORO DE LA TORRE - WELDING SPECIALIST

“pete Maal supped

PANSION OH ROT CRUDE OW SHORE PRODUCTION PACH.

ROGERTED

25siuL-2012

ing PQR_ 24/2007

&

LINE

jotrosmm wep METAL sacHNassiuNES -UPFaCI mm

ome

CFERIAL SPECIFICATION wa in

vio ae a

frames quam Sm

™

ai ca

sro ie im

[Ses ernie inn oe

inte | ae

[ected Nense wa

[avec Ba

Irs wei

aE

lon

&

f YASREE PAT ICESS OBE TACEEPED

HELIODORO DE LATORRE WELDING SPECIAUST. 254 JL 2012

fives + xackagon

ramon | WELDING PRocEDURE-sencurrcartoN [es —+ HSE 207

i Acconpive 70 asi mx,aPtisaarieao [EY

‘aereenoerr ASAESIONT least + says

ion seraye 30

Walbing rere: ae NA

tlt “Au i

Wouve With

oF Gas Cw Ste aya

nit aneterpen Cnsngerste Creag) a, Cre

sted mene Gousig Geog eater wea gre

lovee A

[cose ae 19 Work Distance WA

sitio singe ass (pre) Malle

hme vowesaneo She ae per enact ese dt

site nr Sod Tpe an

ise ora etc tor CUA A

1), Petros Wireweed Speed ange NA,

1 Ta wicker Taist aa

LP MAE | ome Se Tame Rape] ame] Yok | St get

vo sr | rote

| Vitec Tae —[_ ates [cass [bem [ico [eas [aia | ation

{Pisses [asa “sone ase [eer [abi [ane [vase | data

| ferme] ow f pT i

fe ae ot

‘ ce a

“name |" 5. c

«Pa eu

Dae Wace

.

ad ©

PETROJE

Cover Sheet

nitor ‘ing She

# e,

é Monitoring Sheet

a TA

PETROJET [ses

ptesne ions netonnince [PORN RS RT Dae

Piet: Espusiu of Howt Qe Onto Pronton Eales. Witting rove

‘WPSNO.:10

hint: ALK Feit Opontions

Appline Cole! ASME IE APT 6S, P1620 Aranes Spas SABS-W-O27

loin: Double Vee

> MATERIAL

aE

TERT.

TYPE Pte 4537 Cas T

TICES a

CERTBICATEND: 37

Postion: 56

Progression ap

> pQuPMeNT

uN

| Chavo anrane

THERMO COUPLE

THICRNESS ETERE

| measuemic tar

[series Ow

> CONSUMABLES

[erasmcarTON | DE

Eu Bas

Era

> Method Of Gouging: — Grinding

% Prebeasng Temps 10°C

HEATTREATMENT? WA,

WEA [caiman [vow

____Youser MonaMaD ma E :

5G

Safer

— ®@ Monitoring Sheet

PETROJET 2 PM aga

ON (EN a

jet Bposan of ont Ce Ons Pron Fes. WaingPnce SHAW

(et abst oat Options ‘WEENG:1)O- cor

(Bpletleoe AE APT, APLC Arc Spa SAES- WA?

¥

3}3]|=)3)3|2] 3]

ple |el ayaa

TT QNDeAs

fy

aL RNG?

aE

‘Welding Proces(es) —-

Code =ASMEIX &SAES-WO7

‘Formats (oweanzy

OSTWELD HEAT TREATMENT (CW

senpentee ——NA-————}

ser nett

Wald ne Ayes No —t—

See Oiler Met —2256 sam

Wald abl Tha ——3 a

‘Wald ?rgasan (pow) UPB

Oke ata Dass

Sasa

eco

‘is

Wa Wa

By NA

pe Orne Poe er io) MULTE

PREINEAT (QW-409)

Prehet Tenperasus———10°-—

Interpess Tempers

Ofer

90

:

Feta] et —— = =

aa, “0 [= a= | a

Resa | ava —| ao] Poa

CaF | aa “aa | Taves [ans | a

‘rca emai Capa ‘ahaa add et yhaaigg,

PETROET, pe Chua ji

siathie

RECORDIPORY

oRnter- 24207 ‘ur 2047

egal Tost (OW.

srmmne | | Mart [ity | cg [tenes [rife

c : y

Gadel Bea Tn (QW)

RATT T ra

Sie RT ep =

Sted net ret

Heb ips co

Tonghows Fe (OW)

tei [ettein | Ome | alee |e

Tilet- Weld ests (W280)

Otter Teste

ype OF Tst-— Rr Sac Bape) — —_—_—_——_|—_|

‘Depo Arp

Wilder ioe YOUSEF MOHAMED Samp Nan

“Ten Cont Dy: Cato Ue

ect esma R AC ac a

|

? Ig @) WELD DESCRIPTION

‘Git Name” A-ha Jot Operon WHSNor

Projet Name: Expansion of Hot Cride Onhore Podton Faia

Weld ienicnon.

Shell Lessin (“J ShelltoRoot —()——PipetoFting

Sha Gia) owls Atsebment( Pipe toPipe

Stelle Baton ( AsmularPite () Otter Describe)

‘te dtatnnt Dead

SELF NO iA Detail Lats: 9

MSR: ssl 290... Tas: SiransGRen

ASMEIASTM: GSH Cb>| P-NO. nfo Tekese Finan geen

(onrastor Wali Proce tion

WES NO i50.~-e0/tuof REV. Dit nd g/t.

Wald Type

Walled Fom Both Sider (7 ) Files ¢

Cont No: QS}

Welded om: One Side (" ) Owety (

‘Wit Bucking oO)

Withom Backing = ()

Joint Sketch

(Show bevel anges, Land, as, Sequene, nt beekng)

Root__ ee ee ee

Em ii

Bl2 oe ee

et ei

Some Oey OE

ee ey

Be aalle w OR Cr

PrebetTempennse: 0 C Cin Se A

y |

10s

Cover Sheet

aes & pase o

Pave, 1ap-aniy_[ WENO RIOR

oj: Lao fo

Gen: Aku Jose 0

s

"Tensile

"Bend

“Hardness

cnanical Test Rep,

Heche! Testing Lbortory

Mealurgia Egieering

iro Universiy = Feely of Engen

Asal bist Jane

hal a

Arig ais ata fate

aa

Dats: 23402007

(Contractor: PETROSE Eastern Branch

Clint: AF Kati Joint operation

Projet name: Expansion of Hout Crude on Shoe Production Factities

Applsble Code: ASME IX &SAES-W-17 |

Material 837 CL |

Thickness: 30mm POR: 02472007 |

All Speximens Seat By PETROJET, |

‘Tensile Test Results |

‘Specimen | Wath | Toidss | Ava | Uhiorevant [OMPRECUE [pe

ode | tam | tom) | om) | ond hon ves

ae | Bs [ese |S sm co

man0o res [99 [sssi5 | 00 Ea 5

Guided Bend Test

Spaciaar | Specimen ee | Type Bed Comma

Na

i Se a

2 ‘Sie Accept

s caan007 ie eon

“ Se ect

rests |

En, Ane eyed |

Reviewed By Swpervised By |

Dis M. Raat oussy

“eb S67RSit-IOBGOTORS Fox 778606 Nall -nle2E rch

acral Testing Lbertary Asta obtusd!

Matalin! Enleening| Sl ans

iva Uiversiy Feely of Engcrig Aung als- 604

Date: 35/2007

Contractors: PETROMET=

Client: AI Khafi Joint operation

Project name: Expansion of Hout Crue on Shore Production Faiies

“Appliesble Code: SAES-W-17 SASTM 192 &AB-4S6386 Rev. (1)

‘Material: A587 CLA

Thickness: 30mm QR: 024/2007

All Specimens Sent By PETROJET.

sn Branch

Hardness Test Results

‘The Results ate acceptable.

‘Tested By

ug, Ahmed esayed

Reviewed By

sx ae

ee

‘Tel: 567851 - O105607023-Fax 7746026 een

De,

7

ea

coo

wor

“RT

“Visual

Ht

EXPANSION OF HOUT CRUDE ON SHDRE.

— PRODUCTION FACILITY

Visual Testing Report

eles Bay Tom Open Teer oe TY

[Cont No: HQS06PCOS Date Hh

[Drawing Ske No:..p@e..o8A/Ben2 %Exumeastion 047:

Arpt cote sein

Seno. weno. | Meller | Srataion Remass |

ot |eadfon T

rs ewoe

inspection Da:

L_

_—

UXPANSION OF HOUT CRUDE ON SHORE

PRODUCTION FACILITY

jraphic Testing Report

em ay iain 3

em ics Te afb

Drawing SeN0:. RA. -andfeone

arti cD, —_—_ Minden ft

aa BRAT [paste aso [AN aT

ar SW i z

isch pea =

folie ened Soy: ae

com ey Dove 0 temas 0 at

wed | Wel | om 7 a

oe ee

eadbert |- Be 7 Ae | Pe

: t

ame

oe Meat sec

a ai

ie en

ese stam A foe

Cover Sheet

a. [RRO a aT_| WENO OT

elder Certificay

TENT ISN TT

Dare tinue

woo

Sap Re

ROBE ELD. aD

Wye

arerial Certific, :

g

Cover Sheet

Pao, a0 aa _| WIBNOT ROW AT

ctrode Certif;,

oY tq

EQUAL : FOX EVs

CHEMICAL ANALYSIS OF DEPOSIT

‘The above mentioned wold meteral is cureily approved by the folowing: GLU. At

Q.C. DEPT,

‘Samir Hashim

so,

C

5 Co.Easieri Branch”

PRODUCED BY KADESIA ENG. IND-EO

BOHLER TECHNOLOGY MEETING THE SAME QUALITY OF BOHLES PRODUL

i

°T UNDER LICENSE IN ASGORDAI

(ALL WELD METAL-TYPICAL

veld | Tonsil,

{| stengtn | strength

imma | winma

Fer BOM

edd Ori

ee ERS.

io]

Wealting Postionss [~~

ce wit

ET ANO

he

it

jpact

nth

pute ||

arse |

ui uggtnommonr

[CERTIFICATE |

‘INO : 45612008 ~ Date : 26/2003,

ris ety tha the king materiel hee under

\PMATERIAUBOMLER KAD "EVSiI E01o"

$f quaaenrey” 1500, S128: 4.97380 nm

BATCH NO: 26108

CLIENT: HETROMEE CO, « xstern bach *

Co NOand pais eferier: 12262009 9 23a

FROPUCED BY KADESIA ING. IND. EGYPT UNDER LICENCE IN ACCORDANC Wt

¢, BOBLER TECHNOLOGY MEETING TH SAME QUALITY OF BOILER PRODUCT)

tu STuQUAL Pox EVs0 :

“THE CHENECAL ANALYSIS OF pErbstr yaLt, WRLD

Sie Mi

Ata.

-

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Asme Viii - Div.1 (2019) - Quality Control SystemDocument3 pagesAsme Viii - Div.1 (2019) - Quality Control SystemKareem AbdelazizNo ratings yet

- Presentation in Maintence of Heat ExchangersDocument16 pagesPresentation in Maintence of Heat ExchangersKareem AbdelazizNo ratings yet

- F (11-16) Requst For Renewal - Qualify WeldersDocument2 pagesF (11-16) Requst For Renewal - Qualify WeldersKareem AbdelazizNo ratings yet

- WPS P 011Document3 pagesWPS P 011Kareem AbdelazizNo ratings yet

- Kareem Ebraheem Abdelaziz: Welding QC EngineerDocument2 pagesKareem Ebraheem Abdelaziz: Welding QC EngineerKareem AbdelazizNo ratings yet

- Sumed - TK 01-2017 Rev 0Document4 pagesSumed - TK 01-2017 Rev 0Kareem AbdelazizNo ratings yet

- 28046E01Document72 pages28046E01Kareem AbdelazizNo ratings yet

- Company Specification: Piping and Piping Components of Line For Plants Assembling and Inspection of PipingDocument17 pagesCompany Specification: Piping and Piping Components of Line For Plants Assembling and Inspection of PipingKareem AbdelazizNo ratings yet

- Ayman Ayman Ayman Ayman Mohamed Mohamed Mohamed MohamedDocument4 pagesAyman Ayman Ayman Ayman Mohamed Mohamed Mohamed MohamedKareem AbdelazizNo ratings yet

- Piping Classes: Company SpecificationDocument8 pagesPiping Classes: Company SpecificationKareem AbdelazizNo ratings yet

- 193201DVDAS5873 EXDE01 01 Bottom Plate Development For Off Spec Condensate Storage TankDocument1 page193201DVDAS5873 EXDE01 01 Bottom Plate Development For Off Spec Condensate Storage TankKareem AbdelazizNo ratings yet

- 199597Document12 pages199597Kareem AbdelazizNo ratings yet

- Radiographic Examination ReportDocument1 pageRadiographic Examination ReportKareem AbdelazizNo ratings yet

- Catalog Soldamatic - SEABERYDocument11 pagesCatalog Soldamatic - SEABERYKareem AbdelazizNo ratings yet

- 06 VD Mee-Welding of Super Duplex Stainless SteelsDocument12 pages06 VD Mee-Welding of Super Duplex Stainless SteelsKareem AbdelazizNo ratings yet

- 1) Intro To MinitabDocument29 pages1) Intro To MinitabKareem AbdelazizNo ratings yet