Professional Documents

Culture Documents

Experimental Investigation of Frictional Pressure Losses in Coiled Tubing

Uploaded by

Mariel BazanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental Investigation of Frictional Pressure Losses in Coiled Tubing

Uploaded by

Mariel BazanCopyright:

Available Formats

Experimental Investigation of Frictional

Pressure Losses in Coiled Tubing

Idir Azouz, SPE, S.N. Shah, SPE, and P.S. Vinod, SPE, U. of Oklahoma, and D.L. Lord, SPE,

Halliburton Energy Services

Summary understood, information on the corresponding flow of non-New-

liz This paper presents an experimental investigation of tubular fric- tonian fluids is rather scarce. Among the very few reported studies

tional pressure loss in coiled tubing (CT) and straight sections of on this subject, those of Mashelkar and Devarajan7–9 are worth

seamed and seamless tubing. Fluids investigated include water, mentioning. They conducted extensive experimental and theoret-

linear guar gum and hydroxypropyl guar (HPG), and borate- ical studies of laminar flow of non-Newtonian, viscous, and vis-

crosslinked guar gum and HPG, under conditions typically encoun- coelastic fluids and turbulent flow of non-Newtonian, viscoinelastic

tered in many CT field applications. The equipment used includes fluids through coiled tubes. However, the proposed empirical

a system of one 1000-ft and two 2000-ft CT reels that can be friction-factor correlations for turbulent flow of non-Newtonian

arranged to provide total CT lengths of 1,000, 2,000, 3,000, 4,000, fluids have a very limited range of engineering applicability. Conse-

and 5,000 ft. The system also includes straight sections of seamed quently, more exhaustive work needs to be perfomed in this area.

and seamless tubing with the same nominal diameter (11⁄2 in.) and The objective of current experimental investigation is to con-

wall thickness (0.156 in.) as that of the CT. The investigation tribute to a better understanding of turbulent flow in CT by

focuses mainly on the effects of CT curvature, tubing seam, fluid extending the studies performed by past researchers to non-New-

pH, and shear history on frictional pressure loss. Results obtained tonian, viscoelastic fluids, and by introducing another complexity

with water indicate that curvature, as well as the seam inside the CT, to the flow geometry, namely the CT seam. The study focuses

significantly affect the frictional pressure losses. Results obtained with mainly on fluids that are typically encountered in hydraulic

various polymer solutions and gels, however, suggest that tubing fracturing, including water and linear and borate-crosslinked

curvature has a more significant effect on the frictional pressure losses guar gum and HPG.

than the tubing seam. Moreover, it is observed that, for borate-

crosslinked HPG, the pressure gradient is dependent on both the fluid

pH and the length of CT across which it is measured. However, for Experimental Equipment and Procedure

borate-crosslinked guar gum, the pressure gradient is a function Fig. 1 shows a schematic of the layout of the experimental equip-

of pH and is not very sensitive to the length of tubing along ment used to investigate tubular frictional losses. The equipment

which it is measured. consists of a system of a 1,000-ft and two 2,000-ft CT reels that can

be arranged to provide lengths of 1,000, 2,000, 3,000, 4,000, and

Introduction 5,000 ft of CT. Furthermore, the CT reels can be bypassed if

desired. In this way, the test fluid can be sheared for various lengths

CT is used in many engineering applications, including heating and

of time, at the desired nominal shear rate. The nominal shear rate

refrigeration processes, bioengineering, and as chemical reactors.

in the CT is 1,400 sec21 at 60 gal/min. The residence time at this

More recently, CT has gained increased importance because of its

shear rate is approximately 1 minute per 1,000 ft of CT. The system

numerous potential applications in the petroleum industry.1 The

also includes straight sections of seamed and seamless tubing (Fig.

majority of these applications involve the flow of a fluid, and

2) with the same nominal diameter (11⁄2 in.) as that of the CT. The

require accurate assessment of frictional pressure losses in the

inside diameter of the seamless tubing and the hydraulic diameter

tubing. Accordingly, the flow through CT has been under extensive

of the seamed tubing were determined (from volumetric measure-

investigation, most of which is aimed at explaining its complex nature.

Flow through CT is uniquely different from that in a straight pipe ments) to be approximately 1.1817 and 1.1752 in., respectively. omar

because of the secondary flow pattern induced by the imbalance During any test, only one section is used, which is located down-

stream of the CT reels. The use of the straight sections allows the

between the forces acting in the radial direction of the pipe coil.

study of the effect of the seam on frictional pressure loss, whereas

This secondary flow pattern is composed of counterrotating vor-

CT was used for both shear preconditioning and the study of the

tices, commonly called Dean vortices, that cause an increase in

effect of pipe curvature on frictional pressure.

frictional pressure loss. Early studies of the flow through CT

Fluids investigated include water, linear guar gum and HPG, and

include that of White,2 who investigated the influence of curvature

borate-crosslinked guar gum and HPG, under conditions typically

upon the flow resistance of water for Reynolds numbers up to

encountered in stimulation operations. The degree of crosslinking

9,000. He made the important observation that the flow can be

is dependent on the pH of the fluids. The crosslinked fluids were

maintained laminar for a much higher Reynolds number than is

evaluated at pH values of 9, 10, and 11, which are typical values

possible in straight pipes. This claim was later verified by Taylor3

used in stimulation treatments. A 12% equivalent solution of boric

in his experimental investigation of the turbulent flow of water in

acid was used as crosslinking agent. The test fluids cover a wide

curved pipes. Ito,4 on the other hand, proposed empirical friction-

range of fluid-rheology types and exhibit strong drag-reducing char-

factor formulas derived from his experimental study of turbulent

acteristics. The linear polymer solutions and gels exhibit non-Newto-

flow of Newtonian fluids in curved pipes. Other studies dealing

nian behavior of the power-law type. The crosslinked structure of the

with Newtonian fluids flowing in CT include the experimental

crosslinked fluids gives viscoelastic characteristics to the fluid. These

investigation conducted by Sreenivasan and Strykowski5 on stabi-

fluids have a gel structure and are best approximated by the yield

lization effects in coiled-pipe flow, and that of Webster and Hum-

power-law model. However, in the range of shear rates considered,

phrey,6 who performed an experimental investigation of flow

they exhibit power-law-type behavior. The n and K values are obtained

instability in a helical coil.

from measurements performed with a Fann model 35 rheometer.

Although the flow of Newtonian fluids in curved pipes has been

The linear polymer solutions are prepared in batches of 100 bbl.

the subject of numerous technical publications and seems to be well

The fluid is pumped at the desired flow rate using a triplex pump.

A centrifugal pump, positioned downstream of the fluid-storage

Copyright 1998 Society of Petroleum Engineers

tank, is used to prime the triplex pump. During tests with

Original SPE manuscript received for review 11 September 1996. Revised manu- crosslinked fluids, the crosslinker is added through the eye of the

script received 10 July 1997. Paper peer approved 18 December 1997. Paper (SPE

37328) first presented at the 1996 SPE Eastern Regional Meeting held in Columbus, centrifugal pump to achieve optimum mixing. Crosslinker is added

Ohio, 23–25 October. at a rate that varies with the tubing flow rate in such a way that

SPE Production & Facilities, May 1998 91

Fig. 1—Layout of the experimental equipment.

Fig. 2—Flow geometries considered.

concentrations of 0.05 and 0.15 wt% are obtained for the guar gum

and HPG polymer gels, respectively. At 60 gal/min the crosslinker

addition rate is 398 mL/min and 1,192 mL/min for guar and HPG Fig. 3—Friction factor for water flowing in straight sections of

solutions, respectively. Crosslinker is added using two syringe seamed and seamless tubing.

pumps in tandem.

Results and Discussion Reynolds number (as much as 9% for the highest Reynolds-number

Figs. 3 through 15 summarize results of the experimental inves- value considered). Second, the seamed tubing yields results that are

tigation graphically. Data obtained with water are discussed first, very close to the smooth-pipe results, which would seem to suggest

followed by those obtained for the stimulation fluids. that it does not have any roughness. Although this may or may not

be the case, its lower friction factor, compared to that of the

seamless tubing, is more likely the result of the presence of the

Water. Friction factor vs. Reynolds number data are presented in seam. Indeed, instead of acting as an added roughness, the seam

Fig. 3 for the straight sections of seamed and seamless tubing, for alters the turbulence spectrum by damping the high-turbulence

a range of Reynolds number varying from 1.3 3 105 to 3.2 3 105 frequencies and, thus, causing a decrease in the turbulent frictional

(turbulent flow). Computed smooth-pipe results based on the fol- pressure drop. The seam and the roughness have opposing effects

lowing Prandtl’s equation are also plotted for comparison on the friction factor. This, in turn, suggests that some roughness

1 must be present in the seamed tubing used in this study. Otherwise,

5 2 log~NRe Î f ! 2 0.8. . . . . . . . . . . . . . . . . . . . . . . . . . (1) the friction-factor values would be lower than those of a smooth

Îf pipe. The experimental results suggest that the friction factor for the

Notice that the seamless tubing exhibits friction-factor values that seamed tubing is related to that of the seamless tubing by an

are higher than those for the smooth pipe, which is an indication that expression of the form

some roughness is present in the seamless tubing. This is not very fseamed 5 1.667 ~N20.049

Re ! fseamless. . . . . . . . . . . . . . . . . . . . . . . (2)

surprising. Alternatively, the results shown for the seamed tubing

are rather interesting. Indeed, two features are noteworthy. First, the Fig. 4 illustrates the effect of CT curvature on frictional pressure

friction factor for the seamed tubing is lower than that for the loss, which shows results obtained with water in CT and water in

seamless tubing, with the difference increasing with increasing a straight section of seamed tubing, for the same range of Reynolds

92 SPE Production & Facilities, May 1998

Fig. 7—Friction factor for linear 40 lbm HPG/1,000 gal solution.

Fig. 4 —Friction factor for water flowing in CT and in a straight

section of seamed tubing.

Fig. 5—Rheogram for determination of power-law parameters Fig. 8 —Pressure drop in seamed and seamless tubing for bo-

for linear 40-lbm HPG/1,000 gal and linear 35-lbm guar/1,000 gal rate-crosslinked 35-lbm guar/1,000 gal gel, at pH 5 9,

solutions. Q 5 60 gal/min.

Fig. 6 —Friction factor for linear 35-lbm guar/1,000 gal solution.

Fig. 9 —Pressure drop in seamed and seamless tubing for bo-

rate-crosslinked 35-lbm guar/1,000 gal gel, at pH 5 10,

Q 5 60 gal/min.

number as before. The results indicate that curvature of the CT has

a significant effect on frictional pressure loss. Results for CT are

much higher than for seamed tubing. The relative increase in the

friction factor, because of curvature, increases with increasing Linear 35-lbm Guar Gum/1,000 gal Polymer Solution. Results

Reynolds number, from 31 to 44%. Relationships between fric- obtained for a linear 35-lbm guar/1,000 gal polymer solution

tional pressure losses in CT and straight-pipe sections were derived (n 5 0.53, K 5 0.0112 lbf-secn/ft2, see rheogram in Fig. 5) are

and are of the form presented graphically in Fig. 6, for a range of Reynolds numbers

from 2.0 3 103 to 3.36 3 104. Laminar and smooth-pipe flow

nassi fCT 5 0.6~N0.068

Re ! fseamed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (3) results are also plotted for comparison. It can be observed that the

friction-factor values obtained for the polymer solution are much

and fCT 5 1.017~N0.019

Re ! fseamless. . . . . . . . . . . . . . . . . . . . . . . . (4) lower than those obtained with water. In the range of Reynolds

number considered, drag reduction varying from 29 to 78% is

Results obtained for the 1,000- and 2,000-ft CT, as shown in Fig. obtained with the polymer solution. As expected, curvature of the

4, suggests that the number of turns on the reel has no effect on the CT has a significant effect on frictional pressure loss. Indeed, it can

frictional pressure loss. However, the reader should be cautioned be observed that the friction-factor values determined for the CT are

that the reel diameters for the 1,000- and the 2,000-ft CT’s are not higher than those obtained for the straight sections. Interestingly,

significantly different, resulting in approximately the same value unlike for water, tubing seam does not seem to have any effect on

for the Dean number, ND (see Nomenclature). the friction factor. Because, as stated earlier, the seam tends to

SPE Production & Facilities, May 1998 93

Fig. 10 —Pressure drop in seamed and seamless tubing for bo- Fig. 13—Pressure drop in seamed and seamless tubing for borate-

rate-crosslinked 35-lbm guar/1,000 gal gel, at pH 5 11, crosslinked 35-lbm HPG/1,000 gal gel, at pH 5 10, Q 5 60 gal/min.

Q 5 60 gal/min.

Fig. 14 —Pressure drop in seamed and seamless tubing for borate-

crosslinked 35-lbm HPG/1,000 gal gel, at pH 5 11, Q 5 60 gal/min.

Fig. 11—Pressure drop in CT for borate-crosslinked 35-lbm

guar/1,000 gal gel.

Fig. 15—Pressure drop in CT for borate-crosslinked 35-lbm

Fig. 12—Pressure drop in seamed and seamless tubing for HPG/1,000 gal gel.

borate-crosslinked 35-lbm HPG/1,000 gal gel, at pH 5 9,

Q 5 60 gal/min.

Again, the same observations made earlier for linear guar, regarding

suppress the high-turbulence frequencies, the results suggest that, the effects of the tubing seam and the curvature of the CT, can also

for the drag-reducing fluid under investigation, the turbulence be made for linear HPG. It is noteworthy that results obtained for

spectrum is composed mainly of low-turbulence frequencies, on linear HPG indicate that it has better drag-reducing capabilities than

which the tubing seam has no effect. Examination of the experi- linear guar. However, this could be because of the higher concen-

mental data suggests that CT friction factor is related to straight- tration of HPG (40 lbm/1,000 gal) as compared to the previous case

pipe friction factor by the following relationship: involving guar. Again, as for the case of linear guar, the following

equation relating CT friction factor to that in straight pipe was

fCT 5 0.747~NRe

0.015

G

! fSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (5) derived based on the experimental results:

fCT 5 0.596~NRe

0.135

G

! fSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (6)

Linear 40-lbm HPG/1,000 gal Polymer Solution. Fig. 7 sum-

marizes the results obtained for a linear 40-lbm HPG/1,000 gal It must be emphasized that the effect of coil (reel) diameter is not

polymer solution (n 5 0.42, K 5 0.034 lbf-secn/ft2, see rheogram in taken into account. In principle, the correlations should be ex-

Fig. 5) for several flow rates in the range of 40 to 100 gal/min, pressed in terms of the Dean number instead of the Reynolds number.

corresponding to Reynolds numbers from 2.16 3 103 to 1.5 3 104. Unfortunately, only one reel diameter was available during the course

94 SPE Production & Facilities, May 1998

of this investigation. These correlations are unique to the specific fluid the term shear history is adequate because all of the the fluid

system under investigation and should be used with caution. particles in the straight section have been subjected to the same

In the case of crosslinked fluids, no equation was derived. This shear history, it is not so in the case of the fluid flowing in the CT.

is because the straight sections and the CT have different lengths. In this case, fluid particles in the exit region of the CT have

Consequently, it is impossible to distinguish between the effects of undergone much longer shear histories than those located in the

curvature and those associated with shear history. This shortcom- entrance region. This is because CT sections are much longer than

ing, as well as that discussed earlier in connection with the Dean the straight sections. However, the trends of the pressure drop vs.

number, will be corrected in the future and findings will be shear history observed earlier in the case of the straight sections can

reported soon. still be noticed (although barely) in the pressure drop vs. coiled-

tubing length across which the pressure is measured. For instance,

Borate-Crosslinked 35-lbm Guar Gum/1,000 gal Polymer Gel. the minimum pressure drop corresponds to that measured across

Figs. 8 through 10 show pressure-drop results obtained for borate- 3,000 ft of CT, for pH 5 10 and pH 5 11.

crosslinked 35-lbm guar/1,000 gal polymer gel from measurements

performed on straight-seamed and seamless-tubing sections. The

figures illustrate the effects of pH, shear history, and the presence

of a seam. Several features are noteworthy. It can be observed that Borate-Crosslinked 35-lbm HPG/1,000 gal Polymer Gel. Figs.

the effect of shear history is strongly dependent on the fluid pH. For 12 through 15 show pressure-drop results obtained for borate-

pH 5 9, the pressure drop decreases continuously with increasing crosslinked 35 lbm HPG/1,000 gal polymer gels. Unlike for borate-

shear history, as expected. On the other hand, for pH 5 10 and crosslinked guar, Figs. 12 through 14 show that for borate-

pH 5 11, the frictional-pressure drop first decreases to a minimum crosslinked HPG, the pressure drop in the straight-tubing sections

value, corresponding to a shear history of 1 minute, then starts is a decreasing function of shear history for all pH values consid-

increasing with increasing shear history. This intriguing behavior ered. This suggests that for all the shear histories considered, the

can be explained to some extent in terms of the different mecha- rate at which the crosslinked bonds are destroyed by shearing is

nisms that are present as the fluid flows in the tubing, namely, higher than the rate at which new bonds are formed or broken bonds

breaking of the crosslink bonds because of shearing, formation of are healed. Again, this results in the viscosity of the fluid and, thus,

new bonds, and rehealing of some of the broken bonds with time. the pressure drop, being a decreasing function of shear history.

The pressure-drop behavior of the fluid depends on the effect of Interestingly, as for borate-crosslinked guar, the tubing seam seems

each of these mechanisms on the continual decrease in pressure loss to decrease the pressure drop for pH 5 9 and no shear history.

with increased shear history can be hypothesized to be the result of Fig. 15 shows pressure-drop results measured in CT of various

crosslink bonds being destroyed more rapidly than they can reheal. lengths. Unlike for borate-crosslinked guar, the dependence of the

This results in a decrease in the viscosity of the fluid and, thus, in pressure gradient on the length of CT across which it is measured

geraldine the pressure drop. This same behavior is observed for pH 5 10 and is strikingly strong. The pressure gradient first decreases sharply as

pH 5 11 for shear histories less than or equal to 1 minute. However, the length across which it is measured is increased and then seems

for longer shear histories, the combined rate of formation of new to approach a limiting asymptote. However, this could be a local

crosslinked bonds and the rehealing of some of the bonds broken minimum in the curve of pressure drop vs. CT length. Observations

by shearing becomes higher than the rate at which the crosslinked made earlier for borate-crosslinked guar certainly tend to support

bonds are destroyed by shearing. This results in the presence of a this claim.

local minimum in the viscosity vs. shear-history curve and, thus, in

Frictional pressure-loss results obtained with borate-crosslinked

the pressure-drop vs. shear-history curve. Interestingly, the effect

35-lbm guar/1,000 gal and 35-lbm HPG/1,000 gal gels at 60

of the seam on the pressure drop is significant only for pH 5 9 and

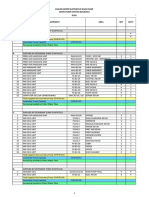

short shear histories. Although this may suggest that the seam may gal/min are compared in Table 1 for 1,000- and 3,000-ft lengths of

have some effect on the structure of the crosslinked bonds network, CT. Several observations can be made. First, HPG pressure losses

further investigation is required to qualify as well as quantify are significantly higher than those for guar at all pH values and for

this effect. all CT lengths, with the largest difference occuring at pH 5 10 for

Fig. 11 illustrates graphically the effect of pH and CT length on the 1,000-ft CT and pH 5 11 for the 3,000-ft CT. Second, the

the pressure drop measured in CT of various lengths. As expected, difference in pressure drop is lower for 3,000 ft of CT as compared

crosslinking increases the pressure gradient. Moreover, increasing with 1,000 ft of CT. This is because of the longer shearing time to

the pH results in lower values for the pressure gradient. The most which the fluids are subjected when flowing in the 3,000-ft CT.

striking feature in this figure is the insignificant dependence of the This shearing tends to destroy the crosslink network that is respon-

pressure gradient on the length of CT across which the pressure is sible for the higher frictional pressure losses of crosslinked fluids

measured. At first, this may seem inconsistent with the earlier claim compared to linear fluids. Consequently, it is expected that within

regarding the effect of shear history on the pressure drop in the limit of maximum shearing time, the difference between the

straight-tubing sections. However, although for this case, the use of frictional pressure losses of the two fluids will be minimum.

TABLE 1—COMPARISON OF FRICTIONAL PRESSURE LOSSES OF

BORATE-CROSSLINKED GUAR AND HPG

Pressure Drop

(psi/1,000 ft)

CT Length Borate-Crosslinked Borate-Crosslinked Difference

(ft) pH 35-lbm Guar/1,000 gal 35-lbm HPG/1,000 gal (%)

1,000 9 626 1,668 166

10 484 2,206 356

11 453 1,861 311

3,000 9 623 1,113 79

10 475 1,407 196

11 439 1,403 220

SPE Production & Facilities, May 1998 95

Conclusions 7. Mashelkar, R.A. and Devarajan, G.V.: “Secondary Flows of Non-

1. For water, the tubing seam decreases the frictional pressure Newtonian Fluids: Part I—Laminar Boundary Layer Flow of a Gen-

loss whereas CT curvature increases the frictional pressure drop, eralized Non-Newtonian Fluid in a Coiled Tube,” Trans., Inst. Chemical

with magnitude of the effect of curvature being much greater than Engineers (1976) 54, No. 2, 100.

that of the seam. 8. Mashelkar, R.A. and Devarajan, G.V.: “Secondary Flows of Non-

2. While the tubing seam does not seem to have any effect on Newtonian Fluids: Part II—Frictional Losses in Laminar Flow of Purely

frictional pressure loss for the linear solutions, the curvature of the Viscous and Viscoelastic Fluids Through Coiled Tubes,” Trans., Inst.

CT strongly affects the pressure drop. Chemical Engineers (1976) 54, No. 2, 108.

3. For borate-crosslinked HPG the pressure gradient is a strong 9. Mashelkar, R.A. and Devarajan, G.V.: “Secondary Flows of Non-

function of pH and CT length across which this gradient is measured. Newtonian Fluids: Part III—Turbulent Flow of ViscoInelastic Fluids in

4. For borate-crosslinked guar the pressure gradient is pH-de- Coiled Tubes,” Trans., Inst. Chemical Engineers (1977) 55, No. 1, 29.

pendent and is not affected in any significant manner by the length

of the CT across which it is measured. SI Metric Conversion Factors

5. For borate-crosslinked guar and HPG, the pressure-drop be- cp 3 1.0* E203 5 Pa z s

havior is a function of pH and shear history. ft 3 3.048* E201 5 m

ft2 3 9.290 304* E202 5 m2

Nomenclature ft3 3 2.831 685 E202 5 m3

d 5 pipe diameter, in. gal/min 3 6.309 020 E202 5 m3/s

D 5 diameter of curvature, in. in. 3 2.54* E100 5 cm

f 5 Fanning friction factor, 2tw/rv2 lbm/ft3 3 1.601 846 E101 5 kg/m3

fseamed 5 friction factor for seamed tubing lbf-secn/ft2 3 4.788 026 E101 5 Pa z sn

fseamless 5 friction factor for seamless tubing psi 3 6.894 757 E103 5 Pa

K 5 fluid consistency index, lbf-secn/ft2 *Conversion factor is exact. SPEPF

L 5 length of tubing, ft

n 5 flow behavior index

ND 5 Dean number 5 NReG=(d/D) Idir Azouz is an assistant professor of engineering at Southern

NRe 5 Reynolds number, rvd/m Utah U. in Cedar City, Utah, U.S.A. His areas of interest include

NReG 5 generalized Reynolds number, rv22ndn/K8n21 modeling of turbulent flows and drag-reducing fluids. Previ-

q 5 volumetric flow rate, gal/min ously, he worked as a mechanical engineer and research

engineer in his home country of Algeria, and as a postdoctoral

v 5 average fluid velocity, ft/sec

fellow at the Fracturing Fluid Characterization Facility at the U.

Dp 5 pressure drop in tubing, psi of Oklahoma. He holds a BS degree in petroleum engineering

m 5 fluid viscosity, cp and an MS and a PhD degree in mechanical engineering, all

r 5 fluid density, lbm/ft3 from the U. of Tulsa, Oklahoma. Subhash N. Shah is a Stephen-

tw 5 wall shear stress, dDp/4L, psi son Chair Professor and the Director of the Fracturing Fluid

Characterization Facility in the School of Petroleum and Geo-

Subscripts logical Engineering at the U. of Oklahoma (OU) in Norman,

CT 5 CT Oklahoma, U.S.A. before joining OU in March 1994, he worked

for 17 years with Halliburton Energy Services, and 11⁄2 years with

SP 5 straight pipe

Allied Corp. His research focuses on developing new methods

to characterize and understand the behavior of fluids under

Acknowledgements reservoir conditions, and other related issues in well stimulation

The authors wish to thank the Gas Research Inst. (Contract No. and completion. He holds a BS degree from the U. of Baroda,

5091–211-2114), the U.S. Dept. of Energy (Contract No. De- India, and an MS degree and a PhD degree from the U. of New

FC21–92 MC29077), the U. of Oklahoma, and Halliburton Energy Mexico, all in chemical engineering. He has been a member of

the Editorial Review Committee since 1984. P.S. Vinod is a

Services for their joint sponsorship of this work and for their development engineer at the Dowell R&D facility in Houston,

permission to prepare and present this paper. Many other people where he works in the area of fluid-loss control. He holds a BS

from the technical staff of the Fracturing Fluid Characterization degree in chemical engineering from the U. of Calicut, India,

Facility and Halliburton Energy Services have also contributed to and a PhD degree in chemical engineering from Rice U. in

the completion of this work. We thank them all. Houston. David L. Lord is a principal engineer in Production

Enhancement Products and Process at Halliburton Energy Ser-

References vices’ Technology Center, Duncan, Oklahoma, U.S.A. His re-

search efforts have concentrated on the properties of hydrau-

1. Sas-Jaworsky, A.: “CT, Operations and Services,” World Oil’s CT lic fracturing fluids, and he has authored numerous papers and

Handbook, M.E. Teed (ed.), Series Parts 4 and 5, Gulf Publishing Co., patents on the subject. He holds a BS degree in chemical

Houston (1993). engineering and an MS degree in petroleum engineering, both

2. White, C.M.: “Streamline Flow Through Curved Pipes,” Proc., Royal from the U. of Oklahoma. He was a 1982– 83 member of the

Soc. (London), Series A, (1929) 123, 645. Editorial Review Committee.

3. Taylor, G.I.: “The Criterion for Turbulence in Curved Pipes,” Proc.

Royal Soc. (London), Series A, (1929) 124, 243–249.

4. Ito, H.: “Friction Factors for Turbulent Flow in Curved Pipes,” J. of

Basic Engineering, Trans., ASME (1959) 81, 123.

5. Sreenivasan, K.R. and Strykowski, P.J.: “Stabilization Effects in Flow

Through Helically Coiled Pipes,” Experiments in Fluids (1983) 1,

No. 1, 31.

6. Webster, D.R. and Humphrey, J.A.C.: “Experimental Observations of

Flow Instability in a Helical Coil,” Trans., ASME (September 1993)

115, 436. Azouz Shah Vinod Lord

96 SPE Production & Facilities, May 1998

You might also like

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedFrom EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNo ratings yet

- Paper - Sociedad PetroleraDocument6 pagesPaper - Sociedad PetroleraGeraldine BazanNo ratings yet

- Experimental Analysis of Pressure Drop in CTUDocument39 pagesExperimental Analysis of Pressure Drop in CTUVirginia SitompulNo ratings yet

- Drag Reduction Characteristics in Straig PDFDocument10 pagesDrag Reduction Characteristics in Straig PDFoswaldo58No ratings yet

- Fluid Flow in Perforated PipesDocument10 pagesFluid Flow in Perforated PipesapitbhuNo ratings yet

- The Effects of Bundle Geometry On Heat Exchanger Tube Vibration in Two-Phase Cross FlowDocument7 pagesThe Effects of Bundle Geometry On Heat Exchanger Tube Vibration in Two-Phase Cross FlowdhirendarjiNo ratings yet

- Walter2003 UnlockedDocument13 pagesWalter2003 UnlockedLorena CamposNo ratings yet

- Hajajs HSJD FDocument11 pagesHajajs HSJD FRohan PrajapatiNo ratings yet

- River Crossing Pipeline - PaperDocument6 pagesRiver Crossing Pipeline - PaperJoko NugrohoNo ratings yet

- Localized Corrosion in Multiphase pipelines@NACE-04381Document11 pagesLocalized Corrosion in Multiphase pipelines@NACE-04381Mahfoud AMMOURNo ratings yet

- Experimental investigation of laminar turbulent intermittency in pipe flow interaction distanceDocument17 pagesExperimental investigation of laminar turbulent intermittency in pipe flow interaction distanceالاسمر الجنوبيNo ratings yet

- Research Article: An Experimental Study of Flow Behavior of Coiled Tubing Drilling SystemDocument9 pagesResearch Article: An Experimental Study of Flow Behavior of Coiled Tubing Drilling Systemerdal aydinNo ratings yet

- Pressure-Driven Water Ows in Trapezoidal Silicon MicrochannelsDocument12 pagesPressure-Driven Water Ows in Trapezoidal Silicon MicrochannelsRam MurtyNo ratings yet

- Effect of Release Coefficient on Water Flow SystemsDocument12 pagesEffect of Release Coefficient on Water Flow Systemschristian.canaleNo ratings yet

- Nuclear Engineering and Design 342 (2019) 10-19Document10 pagesNuclear Engineering and Design 342 (2019) 10-19viveksingh061No ratings yet

- 1-s2.0-S187638041260072X-main (1)Document6 pages1-s2.0-S187638041260072X-main (1)Hareesh MaranNo ratings yet

- Hutagalung 2019 J. Phys. Conf. Ser. 1230 012087Document11 pagesHutagalung 2019 J. Phys. Conf. Ser. 1230 012087JulioRaNo ratings yet

- Friction Factor of Perforation Roughness in Pipes MeasuredDocument13 pagesFriction Factor of Perforation Roughness in Pipes MeasuredFernando LimaNo ratings yet

- SPE 89334 Analysis of The Effects of Major Drilling Parameters On Cuttings Transport Efficiency For High-Angle Wells in Coiled Tubing Drilling OperationsDocument8 pagesSPE 89334 Analysis of The Effects of Major Drilling Parameters On Cuttings Transport Efficiency For High-Angle Wells in Coiled Tubing Drilling OperationsmsmsoftNo ratings yet

- Dean Vortices in Pipe FlowDocument5 pagesDean Vortices in Pipe Flowgaurav agarwalNo ratings yet

- Drilling Fluid Flow in Circular and Annular TubesDocument15 pagesDrilling Fluid Flow in Circular and Annular TubesTalis TemNo ratings yet

- SW41256 Flow of Synthetic Drilling Fluids 1999 MayDocument40 pagesSW41256 Flow of Synthetic Drilling Fluids 1999 Mayipixuna0% (1)

- 27 Hagedorn 1965 PDFDocument10 pages27 Hagedorn 1965 PDFDexter CastilloNo ratings yet

- SPE 77951 Multirate Test in Horizontal Wells: SurcolombianaDocument12 pagesSPE 77951 Multirate Test in Horizontal Wells: SurcolombianaJorge RochaNo ratings yet

- ChE 220 Mod 5 Flow of Incompressible Fluid 2020-2021Document73 pagesChE 220 Mod 5 Flow of Incompressible Fluid 2020-2021Claire G. MagluyanNo ratings yet

- Ravi HEFATfullpaperDocument5 pagesRavi HEFATfullpaperRavi PrakashNo ratings yet

- A Review On Turbulent Flow Through Pipe A State of Art IJERTCONV3IS20094Document4 pagesA Review On Turbulent Flow Through Pipe A State of Art IJERTCONV3IS20094newworldosemwegieNo ratings yet

- PressureDrop IJFMRDocument18 pagesPressureDrop IJFMRThinh Tran HungNo ratings yet

- IEIC July 2016Document9 pagesIEIC July 2016Dr. Sandeep Rangrao DesaiNo ratings yet

- Spe 64647 Experimental Study On Friction Pressure Drop For Nonnewtonian Drilling Fluids in Pipe and Annular FlowDocument11 pagesSpe 64647 Experimental Study On Friction Pressure Drop For Nonnewtonian Drilling Fluids in Pipe and Annular Flowmauro87065458No ratings yet

- Spe 107013 MSDocument11 pagesSpe 107013 MSOscarNo ratings yet

- Preliminary Study of Polymer Melt Rheological Behavior Flowing Through Micro-ChannelsDocument10 pagesPreliminary Study of Polymer Melt Rheological Behavior Flowing Through Micro-Channelsvandna kushwahaNo ratings yet

- SlipDocument8 pagesSlipsseagal_2No ratings yet

- Model Need PDFDocument16 pagesModel Need PDFmucoNo ratings yet

- Aic 690020121Document6 pagesAic 690020121Rishi SNo ratings yet

- Cross-Flow Vibrations of A Pipe Close To A Rigid Boundary: V.JacobsenDocument7 pagesCross-Flow Vibrations of A Pipe Close To A Rigid Boundary: V.Jacobsen李智No ratings yet

- Browne 1995 Fluid Dyn. Res. 15 A04Document29 pagesBrowne 1995 Fluid Dyn. Res. 15 A04enrique.ovlNo ratings yet

- 74SmithKlineTransitoryStall PDFDocument6 pages74SmithKlineTransitoryStall PDFmyskyshepherdNo ratings yet

- SPE-167950-PA YPL Rot Ecc BuckledDocument15 pagesSPE-167950-PA YPL Rot Ecc BuckledAdam LyleNo ratings yet

- Artículo 1Document11 pagesArtículo 1valentinaNo ratings yet

- Liang 2020Document13 pagesLiang 2020sandips123No ratings yet

- Fluid-Elastic Instability Tests On Parallel Triangular Tube Bundles With Different Mass Ratio Values Under Increasing and Decreasing Flow VelocitiesDocument21 pagesFluid-Elastic Instability Tests On Parallel Triangular Tube Bundles With Different Mass Ratio Values Under Increasing and Decreasing Flow VelocitiesMattNo ratings yet

- Numerical Modelling of Vortex Induced VibrationsDocument6 pagesNumerical Modelling of Vortex Induced VibrationscteranscribdNo ratings yet

- SPE-16083 Transprte de Cutting en DireccionalDocument11 pagesSPE-16083 Transprte de Cutting en DireccionalCamila PalaciosNo ratings yet

- Capillary Viscometer and Vibrating Tube Densimeter For Simultaneous Measurements Up To 70 Mpa and 423 KDocument11 pagesCapillary Viscometer and Vibrating Tube Densimeter For Simultaneous Measurements Up To 70 Mpa and 423 KAraceli SalinasNo ratings yet

- Numerical Study On Dynamic Behavior of Entrapped Air in A Partially Filled PipeDocument10 pagesNumerical Study On Dynamic Behavior of Entrapped Air in A Partially Filled Pipesherio amrousyNo ratings yet

- Computational Investigation, On Thermohydraulic Characterization of Liquid Hydrogen and Liquid Nitrogen in MicrochannelsDocument14 pagesComputational Investigation, On Thermohydraulic Characterization of Liquid Hydrogen and Liquid Nitrogen in MicrochannelsTJPRC PublicationsNo ratings yet

- Dimensional Analysis of Droplet Size and Ligament Length During High-Speed Rotary Bell AtomizationDocument7 pagesDimensional Analysis of Droplet Size and Ligament Length During High-Speed Rotary Bell AtomizationEmilio HipolaNo ratings yet

- Hagedorn and Brown 1965Document10 pagesHagedorn and Brown 1965LIDIA PUGLIESSANo ratings yet

- Characteristics of Secondary Flow Induced by 90° Elbow in Turbulent Pipe FlowDocument12 pagesCharacteristics of Secondary Flow Induced by 90° Elbow in Turbulent Pipe FlowthiagofbbentoNo ratings yet

- Imaging The Velocity Profiles in Tubeless Siphon Ow by NMR MicrosDocument4 pagesImaging The Velocity Profiles in Tubeless Siphon Ow by NMR MicrosLeonardo JaimesNo ratings yet

- Well Testing and Interpretation For Horizontal WellsDocument6 pagesWell Testing and Interpretation For Horizontal Wellsmiguel_jose123No ratings yet

- HY B00030 Hydraulic Characteristics and Discharge Control of Sluice GatesDocument10 pagesHY B00030 Hydraulic Characteristics and Discharge Control of Sluice GatesFelipe VillegasarangoNo ratings yet

- Journal of Hydrology: Shanshan Yao, Fanhua Zeng, Hong Liu, Gang ZhaoDocument12 pagesJournal of Hydrology: Shanshan Yao, Fanhua Zeng, Hong Liu, Gang ZhaoJuan MNo ratings yet

- Hydrodynamics Characterization of Rotor-Stator Mixer With Viscous FluidsDocument10 pagesHydrodynamics Characterization of Rotor-Stator Mixer With Viscous FluidsRaul DionicioNo ratings yet

- POF Flow Characterization in Convergingdiverging MicrochannelsDocument8 pagesPOF Flow Characterization in Convergingdiverging MicrochannelsChirodeep BakliNo ratings yet

- Sahar Et Al. - 2017 - Effect of Hydraulic Diameter and Aspect Ratio On SDocument22 pagesSahar Et Al. - 2017 - Effect of Hydraulic Diameter and Aspect Ratio On Smosab.backkupNo ratings yet

- Water Hammer in Irrigation Systems: G. A. Clark and D. Z. HamanDocument6 pagesWater Hammer in Irrigation Systems: G. A. Clark and D. Z. HamanJitendraHatwarNo ratings yet

- Ie061304i - Artigo Pneumatic TransportDocument18 pagesIe061304i - Artigo Pneumatic TransportScheylaNo ratings yet

- Frączek 2016 J. Phys. Conf. Ser. 760 012004Document11 pagesFrączek 2016 J. Phys. Conf. Ser. 760 012004Ayouba FOFANANo ratings yet

- Coal Runoff Analysis Complete ReportDocument32 pagesCoal Runoff Analysis Complete ReportArif SusetyoNo ratings yet

- 7D162B Pressure Drop For Double Pipe Heat Exchanger SiDocument4 pages7D162B Pressure Drop For Double Pipe Heat Exchanger SiparagmhamunkarNo ratings yet

- Manual Programa ALLIEVIDocument165 pagesManual Programa ALLIEVIKenny Marcos AtocheNo ratings yet

- Fluid Mechanics and Hydraulics Proceedings of 26th InternationalDocument601 pagesFluid Mechanics and Hydraulics Proceedings of 26th InternationalSwan Zay AungNo ratings yet

- Laminar and Turbulent Flow CharacteristicsDocument13 pagesLaminar and Turbulent Flow CharacteristicsAbhishek ChauhanNo ratings yet

- Chapter 12 - Water DistributionDocument51 pagesChapter 12 - Water Distributionsalt2009No ratings yet

- Chilled Water Supply and Pressure DropDocument10 pagesChilled Water Supply and Pressure DropgothdaddeeNo ratings yet

- Review of Fluid Review of Fluid MechanicsDocument40 pagesReview of Fluid Review of Fluid MechanicsNebiyou KorraNo ratings yet

- Answer Any Two QuestionsDocument11 pagesAnswer Any Two QuestionsKirtismita TalukdarNo ratings yet

- Chemical Engineering Fluid Flow ReviewDocument32 pagesChemical Engineering Fluid Flow ReviewJohn P. BandoquilloNo ratings yet

- Keffer, 1999Document14 pagesKeffer, 1999Sinta NucleaNo ratings yet

- Resistance Coefficient KDocument14 pagesResistance Coefficient KNestor S. ReEyesNo ratings yet

- Venturi EffectDocument21 pagesVenturi Effectmuhammad ridNo ratings yet

- RRB Junior Engineer Civil Solved Model Question Paper 4Document21 pagesRRB Junior Engineer Civil Solved Model Question Paper 4Naruttam DasNo ratings yet

- ESFR Cold Storage Manual A4 UD March 2008Document111 pagesESFR Cold Storage Manual A4 UD March 2008jantonio1952No ratings yet

- TPG 4140 CALCULATIONSDocument6 pagesTPG 4140 CALCULATIONSpatrickandreas77No ratings yet

- W7L2 - Transportation of Natural Gas-IDocument25 pagesW7L2 - Transportation of Natural Gas-IJay patelNo ratings yet

- Lab Experiments Losses in PipeDocument14 pagesLab Experiments Losses in Pipesawmag123No ratings yet

- Boundary Layer Flow and Pipe Network AnalysisDocument18 pagesBoundary Layer Flow and Pipe Network AnalysisnkchandruNo ratings yet

- A New Model For Laminar, Transitional, and Turbulent Flow of Drilling MudsDocument14 pagesA New Model For Laminar, Transitional, and Turbulent Flow of Drilling MudsLeidy Laura Álvarez BerríoNo ratings yet

- Kalkulasi TeknisDocument7 pagesKalkulasi TeknisArsyil Dwinda PutraNo ratings yet

- Microirrigation Theory and Practice GuideDocument23 pagesMicroirrigation Theory and Practice GuideJuan Carlos Cruz ENo ratings yet

- FDM260S Printed PackDocument146 pagesFDM260S Printed PackTefelo TsimaneNo ratings yet

- Automated Monitoring of Torque and Drag in Real TimeDocument87 pagesAutomated Monitoring of Torque and Drag in Real TimeNaoufel EnitNo ratings yet

- Ref45 54810207 Thesis BoonkaewDocument69 pagesRef45 54810207 Thesis BoonkaewbaronNo ratings yet

- 8.6.1 The Moody DiagramDocument3 pages8.6.1 The Moody DiagramAganon AristotleNo ratings yet

- Fluid FrictionDocument18 pagesFluid Frictioncakhoa100% (2)

- CHEN403-Unit Operation 1 Fluid Flow and Mechanical Operations, 25th Edition-KA Gavhane-2015 PDFDocument381 pagesCHEN403-Unit Operation 1 Fluid Flow and Mechanical Operations, 25th Edition-KA Gavhane-2015 PDF521 Balaji ONo ratings yet

- 2022 PE NAME Reference Handbook - ERRATA - 0Document17 pages2022 PE NAME Reference Handbook - ERRATA - 0nothankyouNo ratings yet

- Wall Bounded Turbulent Part 2Document25 pagesWall Bounded Turbulent Part 2Jack HughesNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Pharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryFrom EverandPharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryOtilia M. Y. KooNo ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)