Professional Documents

Culture Documents

Grease MSDS

Uploaded by

Altoz DequitoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grease MSDS

Uploaded by

Altoz DequitoCopyright:

Available Formats

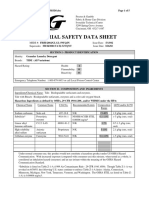

Komatsu Grease G2-LI

Safety Data Sheet

Komatsu Grease G2-LI

1. IDENTIFICATION OF THE SUBSTANCE/PREPARATION AND COMPANY/UNDERTAKING

Name Komatsu Grease G2-LI

Issued Date 16-06-2009

Product Type/Use Automotive and industrial grease.

Part numbers KG-EPLI-400, KG-EPLI-180KG

Company

Komatsu Europe International n.v Telephone: + 32 2 2552 499 (from 9:00 to 17:00)

Mechelsesteenweg 586 Fax: + 32 2 2552 540

1800 Vilvoorde Email address: sds.be@komatsu.eu

Belgium

2. HAZARDS IDENTIFICATION

EC Classification Not classified as Dangerous under EC criteria.

Health Hazards

Not expected to be a health hazard when used under normal conditions. Prolonged or repeated skin contact

without proper cleaning can clog the pores of the skin resulting in disorders such as oil acne/folliculitis.

High-pressure injection under the skin may cause serious damage including local necrosis. Used grease

may contain harmful impurities.

Signs and Symptoms

Local necrosis is evidenced by delayed onset of pain and tissue damage a few hours following injection. Oil

acne/folliculitis signs and symptoms may include formation of black pustules and spots on the skin of

exposed areas. Ingestion may result in nausea, vomiting and/or diarrhoea.

Safety Hazards

Not classified as flammable but will burn.

Environmental Hazards

Not classified as dangerous for the environment.

3. COMPOSITION/INFORMATION ON INGREDIENTS

Preparation description

A lubricating grease consisting of highly-refined mineral oil and additives.

Additional Information

The highly refined mineral oil contains <3% (w/w) DMSOextract, according to IP346.

4. FIRST AID MEASURES

General Information

Not expected to be a health hazard when used under normal conditions.

Inhalation

No treatment necessary under normal conditions of use. If symptoms persist, obtain medical advice.

Skin Contact

Remove contaminated clothing. Flush exposed area with water and follow by washing with soap if available.

If persistent irritation occurs, obtain medical attention. When using high pressure equipment, injection of

Version 3.0 16-06-2009 Page 1 of 6

Komatsu Grease G2-LI

product under the skin can occur. If high pressure injuries occur, the casualty should be sent immediately to

a hospital. Do not wait for symptoms to develop. Obtain medical attention even in the absence of apparent

wounds.

Eye Contact

Flush eye with copious quantities of water. If persistent irritation occurs, obtain medical attention.

Ingestion

In general no treatment is necessary unless large quantities are swallowed, however, get medical advice.

Advice to Physician

Treat symptomatically. High pressure injection injuries require prompt surgical intervention and possibly

steroid therapy, to minimise tissue damage and loss of function. Because entry wounds are small and do not

reflect the seriousness of the underlying damage, surgical exploration to determine the extent of involvement

may be necessary. Local anaesthetics or hot soaks should be avoided because they can contribute to

swelling, vasospasm and ischaemia. Prompt surgical decompression, debridement and evacuation of foreign

material should be performed under general anaesthetics, and wide exploration is essential.

5. FIRE FIGHTING MEASURES

Clear fire area of all non-emergency personnel.

Specific Hazards

Hazardous combustion products may include: A complex mixture of airborne solid and liquid particulates and

gases (smoke). Carbon monoxide. Unidentified organic and inorganic compounds.

Suitable Extinguishing Media

Foam, water spray or fog. Dry chemical powder, carbon dioxide, sand or earth may be used for small fires

only.

Unsuitable Extinguishing Media

Do not use water in a jet.

Protective Equipment for Firefighters

Proper protective equipment including breathing apparatus must be worn when approaching a fire in a

confined space.

6. ACCIDENTAL RELEASE MEASURES

Avoid contact with spilled or released material. For guidance on selection of personal protective equipment

see Chapter 8 of this Material Safety Data Sheet. See Chapter 13 for information on disposal. Observe all

relevant local and international regulations.

Protective measures

Avoid contact with skin and eyes. Use appropriate containment to avoid environmental contamination.

Prevent from spreading or entering drains, ditches or rivers by using sand, earth, or other appropriate

barriers.

Clean Up Methods

Shovel into a suitable clearly marked container for disposal or reclamation in accordance with local

regulations.

7. HANDLING AND STORAGE

General Precautions

Use local exhaust ventilation if there is risk of inhalation of vapours, mists or aerosols. Properly dispose of

any contaminated rags or cleaning materials in order to prevent fires. Use the information in this data sheet

as input to a risk assessment of local circumstances to help determine appropriate controls for safe handling,

storage and disposal of this material.

Handling

Version 3.0 16-06-2009 Page 2 of 6

Komatsu Grease G2-LI

Avoid prolonged or repeated contact with skin. Avoid inhaling vapour and/or mists. When handling product in

drums, safety footwear should be worn and proper handling equipment should be used.

Storage

Keep container tightly closed and in a cool, well-ventilated place. Use properly labelled and closeable

containers. Storage Temperature: 0 - 50°C / 32 - 122°F

Recommended Materials

For containers or container linings, use mild steel or high density polyethylene.

Unsuitable Materials

PVC.

Additional Information

Polyethylene containers should not be exposed to high temperatures because of possible risk of distortion.

8. EXPOSURE CONTROLS, PERSONAL PROTECTION

Occupational Exposure Limits

Material Source Type ppm mg/m3 Notation

TWA

Oil mist, mineral OEL (BE) 5 mg/m3

[Mist.]

STEL

OEL (BE) 10 mg/m3

[Mist.]

Additional Information

Due to the product's semi-solid consistency, generation of mists and dusts is unlikely to occur.

Exposure Controls

The level of protection and types of controls necessary will vary depending upon potential exposure

conditions. Select controls based on a risk assessment of local circumstances. Appropriate measures

include: Adequate ventilation to control airborne concentrations. Where material is heated, sprayed or mist

formed, there is greater potential for airborne concentrations to be generated.

Personal Protective Equipment

Personal protective equipment (PPE) should meet recommended national standards. Check with PPE

suppliers.

Respiratory Protection

No respiratory protection is ordinarily required under normal conditions of use. In accordance with good

industrial hygiene practices, precautions should be taken to avoid breathing of material. If engineering

controls do not maintain airborne concentrations to a level which is adequate to protect worker health, select

respiratory protection equipment suitable for the specific conditions of use and meeting relevant legislation.

Check with respiratory protective equipment suppliers. Where air-filtering respirators are suitable, select an

appropriate combination of mask and filter. Select a filter suitable for combined particulate/organic gases and

vapours [boiling point >65 °C (149 °F)] meeting EN141.

Hand Protection

Where hand contact with the product may occur the use of gloves approved to relevant standards (e.g.

Europe: EN374, US: F739) made from the following materials may provide suitable chemical protection: PVC,

neoprene or nitrile rubber gloves. Suitability and durability of a glove is dependent on usage, e.g. frequency

and duration of contact, chemical resistance of glove material, glove thickness, dexterity. Always seek advice

from glove suppliers. Contaminated gloves should be replaced. Personal hygiene is a key element of

effective hand care. Gloves must only be worn on clean hands. After using gloves, hands should be washed

and dried thoroughly. Application of a non-perfumed moisturizer is recommended.

Eye Protection

Wear safety glasses or full face shield if splashes are likely to occur. Approved to EU Standard EN166.

Protective Clothing

Skin protection not ordinarily required beyond standard issue work clothes.

Version 3.0 16-06-2009 Page 3 of 6

Komatsu Grease G2-LI

Monitoring Methods

Monitoring of the concentration of substances in the breathing zone of workers or in the general workplace

may be required to confirm compliance with an OEL and adequacy of exposure controls. For some

substances biological monitoring may also be appropriate.

Environmental Exposure Controls

Minimise release to the environment. An environmental assessment must be made to ensure compliance

with local environmental legislation.

9. PHYSICAL AND CHEMICAL PROPERTIES

Appearance Brown. Semi-solid at ambient temperature.

Odour Slight hydrocarbon.

pH Not applicable

Initial Boiling Point and Boling Range Data not available.

Dropping Point > 180 °C / > 356 °F

Flash Point Typical > 180 °C / > 356 °F

Upper / lower Flammability or Explosion limits: Typical 1 - 10 %(V) (based on mineral oil)

Auto-Ignition Temperature > 320 °C / 608 °F

Vapour pressure < 0,5 Pa at 20 °C / 68 °F (estimated value(s))

Density Typical 900 kg/m3 at 15 °C / 59 °F

Water solubility Negligible.

n-octanol/water partition coefficient (log Pow) > 6 (based on information on similar products)

Kinematic Viscosity Not applicable.

Vapour Density (air=1) > 1 (estimated value(s))

Evaporation rate (nBuAc=1) Data not available

10. STABILITY AND REACTIVITY

Stability

Stable.

Conditions to Avoid

Extremes of temperature and direct sunlight.

Materials to Avoid

Strong oxidising agents.

Hazardous Decomposition Products

Hazardous decomposition products are not expected to form during normal storage.

11. TOXICOLOGICAL INFORMATION

Basis for Assessment

Information given is based on data on the components and the toxicology of similar products.

Acute Oral Toxicity

Expected to be of low toxicity: LD50 > 5000 mg/kg, Rat

Acute Dermal Toxicity

Expected to be of low toxicity: LD50 > 5000 mg/kg, Rabbit

Acute Inhalation Toxicity

Not considered to be an inhalation hazard under normal conditions of use.

Skin Irritation

Expected to be slightly irritating. Prolonged or repeated skin contact without proper cleaning can clog the

pores of the skin resulting in disorders such as oil acne/folliculitis.

Version 3.0 16-06-2009 Page 4 of 6

Komatsu Grease G2-LI

Eye Irritation

Expected to be slightly irritating.

Respiratory Irritation

Inhalation of vapours or mists may cause irritation.

Sensitisation

Not expected to be a skin sensitiser.

Repeated Dose Toxicity

Not expected to be a hazard.

Mutagenicity

Not considered a mutagenic hazard.

Carcinogenicity

Product contains mineral oils of types shown to be noncarcinogenic in animal skin-painting studies. Highly

refined mineral oils are not classified as carcinogenic by the International Agency for Research on Cancer

(IARC). Other components are not known to be associated with carcinogenic effects.

Reproductive and Developmental Toxicity

Not expected to be a hazard.

Additional Information

Used grease may contain harmful impurities that have accumulated during use. The concentration of such

harmful

impurities will depend on use and they may present risks to health and the environment on disposal. ALL

used grease should be handled with caution and skin contact avoided as far as possible. High pressure

injection of product into the skin may lead to local necrosis if the product is not surgically removed.

12. ECOLOGICAL INFORMATION

Ecotoxicological data have not been determined specifically for this product. Information given is based on a

knowledge of the components and the ecotoxicology of similar products.

Acute Toxicity

Poorly soluble mixture. May cause physical fouling of aquatic organisms. Expected to be practically non

toxic: LL/EL/IL50 > 100 mg/l (to aquatic organisms) (LL/EL50 expressed as the nominal amount of product

required to prepare aqueous test extract). Mineral oil is not expected to cause any chronic effects to aquatic

organisms at concentrations less than 1 mg/l.

Mobility

Semi-solid under most environmental conditions. Floats on water. If it enters soil, it will adsorb to soil

particles and will not be mobile.

Persistence/degradability

Expected to be not readily biodegradable. Major constituents are expected to be inherently biodegradable,

but the product contains components that may persist in the environment.

Bioaccumulation

Contains components with the potential to bioaccumulate.

Other Adverse Effects

Product is a mixture of non-volatile components, which are not expected to be released to air in any

significant quantities. Not expected to have ozone depletion potential, photochemical ozone creation

potential or global warming potential.

13. DISPOSAL CONSIDERATIONS

Material Disposal

Recover or recycle if possible. It is the responsibility of the waste generator to determine the toxicity and

physical properties of the material generated to determine the proper waste classification and disposal

Version 3.0 16-06-2009 Page 5 of 6

Komatsu Grease G2-LI

methods in compliance with applicable regulations. Do not dispose into the environment, in drains or in water

courses.

Container Disposal

Dispose in accordance with prevailing regulations, preferably to a recognised collector or contractor. The

competence of the collector or contractor should be established beforehand.

Local Legislation

Disposal should be in accordance with applicable regional, national, and local laws and regulations.

EU Waste Disposal Code (EWC): 12 01 12 spent waxes and fats. Classification of waste is always the

responsibility of the end user.

14. TRANSPORT INFORMATION

ADR

This material is not classified as dangerous under ADR regulations.

RID

This material is not classified as dangerous under RID regulations.

ADNR

This material is not classified as dangerous under ADNR regulations.

IMDG

This material is not classified as dangerous under IMDG regulations.

IATA (Country variations may apply)

This material is not classified as dangerous under IATA regulations.

15. REGULATORY INFORMATION

The regulatory information is not intended to be comprehensive. Other regulations may apply to this material.

EC Classification Not classified as dangerous under EC criteria.

EC Symbols No Hazard Symbol required.

EC Risk Phrases Not classified.

EC Safety Phrases Not classified.

EINECS All components listed or polymer exempt.

TSCA (USA) All components listed.

16. OTHER INFORMATION

MSDS Regulation

Regulation 1907/2006/EC

Restrictions

This product must not be used in applications other than recommended without first seeking the advice of the

Komatsu technical department.

List of R Phrases in Section 3

Not classified.

Disclaimer

This information is based on our current knowledge and is intended to describe the product for the purposes

of health, safety and environmental requirements only. It does not constitute a guarantee for any specific

property of the product.

... End Of SDS ...

Version 3.0 16-06-2009 Page 6 of 6

You might also like

- Grade 6 First Periodical Test in EPPDocument6 pagesGrade 6 First Periodical Test in EPPPrecilla Halago88% (8)

- Legacy - Wasteland AlmanacDocument33 pagesLegacy - Wasteland AlmanacВлад «Befly» Мирошниченко100% (3)

- Magazine of The U.S. Navy February 1990Document52 pagesMagazine of The U.S. Navy February 1990Fred NoeyesNo ratings yet

- NIPPON PYLOX PAINT Technical SpecificationDocument8 pagesNIPPON PYLOX PAINT Technical SpecificationhudaNo ratings yet

- MsdsDocument6 pagesMsdsAlta Danty Putri GahartiNo ratings yet

- Sample Staff Development PlanDocument2 pagesSample Staff Development PlanBlessie Maranan100% (2)

- MSDS 3017 Servosystem HLP 32Document4 pagesMSDS 3017 Servosystem HLP 32Udit Jain100% (1)

- MSDS Carpet ShampooDocument3 pagesMSDS Carpet ShampooachmadNo ratings yet

- MSDS400Document3 pagesMSDS400adebukNo ratings yet

- MSDS PropanDocument4 pagesMSDS PropanYayak AmanNo ratings yet

- Mop Strip 1217 MSDSDocument2 pagesMop Strip 1217 MSDSSage Chemical InternationalNo ratings yet

- Safety Data Sheet Tellus Oil 68Document7 pagesSafety Data Sheet Tellus Oil 68Isabela BoceanuNo ratings yet

- Tellus 68 MsdsDocument7 pagesTellus 68 MsdsMalou Castillo UmaliNo ratings yet

- MSDS Turalik 48Document4 pagesMSDS Turalik 48satriaNo ratings yet

- Dettol Anti-Bacterial Laundry Sanitizer MSDSDocument10 pagesDettol Anti-Bacterial Laundry Sanitizer MSDSMark DunhillNo ratings yet

- Separol, Msds 040411Document3 pagesSeparol, Msds 040411Alejandro Pereira BerríosNo ratings yet

- ENERGOL GR-XP 200 msds 영문Document4 pagesENERGOL GR-XP 200 msds 영문thisbaboNo ratings yet

- Aquasorb 3005 KL - MSDS PDFDocument5 pagesAquasorb 3005 KL - MSDS PDFFlavio Jorge Miranda PimentelNo ratings yet

- SKF MSDS LGHP 2 PDFDocument5 pagesSKF MSDS LGHP 2 PDFMunkhnasan MonaNo ratings yet

- Safety Data Sheet: 1. Identification of The Material and Supplier Aluminium Sulfate SolidDocument6 pagesSafety Data Sheet: 1. Identification of The Material and Supplier Aluminium Sulfate SolidrezaNo ratings yet

- Msds Cypergard 100 Ec Reg BaruDocument3 pagesMsds Cypergard 100 Ec Reg BaruFumigasi100% (1)

- MSDS Modacon Semen Acian Anti AlkaliDocument5 pagesMSDS Modacon Semen Acian Anti AlkaliWidia YpnNo ratings yet

- Komatsu Eo 15W040 LC CK-4 - 2021Document19 pagesKomatsu Eo 15W040 LC CK-4 - 2021theunauthorisedNo ratings yet

- CBA MSDS Fipronil (Eng & Indo)Document8 pagesCBA MSDS Fipronil (Eng & Indo)anon_763578539No ratings yet

- Red BWS - SDSDocument2 pagesRed BWS - SDSRezoanul Haque50% (2)

- Date of Construction: June 2007 Date of Revision: - : 1 of 8Document8 pagesDate of Construction: June 2007 Date of Revision: - : 1 of 8Rizky Pandu WigunaNo ratings yet

- MSDS NPK Blue FertiliserDocument4 pagesMSDS NPK Blue Fertiliserhary budiman0% (1)

- Msds NPKDocument38 pagesMsds NPKKamilaNo ratings yet

- Material Safety Data Sheet: Manufacturer Pt. Bital AsiaDocument3 pagesMaterial Safety Data Sheet: Manufacturer Pt. Bital Asiaedi100% (1)

- Damar ResinDocument3 pagesDamar ResinKukuh Satrio WibowoNo ratings yet

- Msds Na2S2O3.5H2ODocument6 pagesMsds Na2S2O3.5H2OLuthfi Prananta WibawaNo ratings yet

- MSDS Tide Granular Laundry DetergentDocument5 pagesMSDS Tide Granular Laundry DetergentFarhanNo ratings yet

- MSDS PC 22 Radiator CoolantDocument4 pagesMSDS PC 22 Radiator CoolantAldiNo ratings yet

- N 9905Document7 pagesN 9905yuda anggiNo ratings yet

- 39000322e548cce7 1585837070Document2 pages39000322e548cce7 1585837070Ahmad Sohili AkbarNo ratings yet

- Envi Wall Putty MSDSDocument4 pagesEnvi Wall Putty MSDSrumahsketchNo ratings yet

- MSDS Nuvet Plus 600 ECDocument5 pagesMSDS Nuvet Plus 600 ECI Gusti PradanaNo ratings yet

- Final Msds Hand SanitizerDocument4 pagesFinal Msds Hand SanitizerAngga Putra MargaNo ratings yet

- MSDS Cement Tiga Roda - Dec 2019Document5 pagesMSDS Cement Tiga Roda - Dec 2019noto.sugiartoNo ratings yet

- MSDS 009 - enDocument3 pagesMSDS 009 - enindah50% (2)

- MSDS Gel KecoaDocument6 pagesMSDS Gel KecoaMaulida UlfahNo ratings yet

- Sikadur® 752 Comp. ADocument9 pagesSikadur® 752 Comp. Aashley.susalumNo ratings yet

- MSDS Amistartop325SCDocument13 pagesMSDS Amistartop325SCRangga BaladikaNo ratings yet

- A-201 MSDSDocument11 pagesA-201 MSDSt509No ratings yet

- MSDS Methyl Orange PDFDocument5 pagesMSDS Methyl Orange PDFAngga Pamilu Putra0% (1)

- N Spec 120 Cleaner Data SheetDocument11 pagesN Spec 120 Cleaner Data SheetSergio Alejandro Loza EscobarNo ratings yet

- Sds 108 Polyethylene TerephthalateDocument3 pagesSds 108 Polyethylene TerephthalateAida FatmawatiNo ratings yet

- Hoja Seguridad Dromus BLDocument7 pagesHoja Seguridad Dromus BLClaudia hernandezNo ratings yet

- Fosroc - Nitocote PE 135Document8 pagesFosroc - Nitocote PE 135guru sathya bharathyNo ratings yet

- Msds Epoxy ResinDocument4 pagesMsds Epoxy ResinSrinivasan ReddyNo ratings yet

- Oil - Pertamina Meditran Sae40Document4 pagesOil - Pertamina Meditran Sae40dk_moehammedNo ratings yet

- DIG Wash and Block Buffer Set 1 PC: Safety Data SheetDocument21 pagesDIG Wash and Block Buffer Set 1 PC: Safety Data SheetGEINER ANDRES OSSA GALVIS0% (1)

- MSDS PamDocument5 pagesMSDS Pama.hasan670No ratings yet

- MSDS TegDocument7 pagesMSDS TegRandy Ip100% (1)

- EC Safety Data Sheet: PRESEPT™ Disinfectant Tablets & Granules (Product Packed in Tubs)Document8 pagesEC Safety Data Sheet: PRESEPT™ Disinfectant Tablets & Granules (Product Packed in Tubs)Yotin Bayu MerryaniNo ratings yet

- Sodium Hypochlorite 12% PDFDocument6 pagesSodium Hypochlorite 12% PDFTaufiq Nur RachmanNo ratings yet

- MSDS Gum DamarDocument3 pagesMSDS Gum DamaryudirahdianNo ratings yet

- MSDS PhenolphthaleinDocument6 pagesMSDS PhenolphthaleinAstri Aisyah RahmiNo ratings yet

- MSDS PE Foam PDFDocument4 pagesMSDS PE Foam PDFmamaze ilmania100% (1)

- MSDS Soda Ash PDFDocument3 pagesMSDS Soda Ash PDFSarker Choton100% (1)

- Safety Data Sheet: Lutensol® TO 8Document10 pagesSafety Data Sheet: Lutensol® TO 8eggy mushadiNo ratings yet

- Sds - Cat Deo 15w-40 Engine Oil (2014)Document10 pagesSds - Cat Deo 15w-40 Engine Oil (2014)MichaelNo ratings yet

- Safety Data Sheet Omala F320Document7 pagesSafety Data Sheet Omala F320Isabela BoceanuNo ratings yet

- Gadinia 30 - MSDSDocument7 pagesGadinia 30 - MSDSBeryl FernandesNo ratings yet

- Whare Group Final PresentationDocument19 pagesWhare Group Final PresentationAruna MadasamyNo ratings yet

- Loading Ericsson GPEH Files - Into ANALYZER - Tech NotesDocument9 pagesLoading Ericsson GPEH Files - Into ANALYZER - Tech Notesbmaia18No ratings yet

- Podar School HomeworkDocument7 pagesPodar School Homeworkerr64wxh100% (1)

- Vanicek Et Al CGG 42 1 Geoid&QuasiGeoidDocument17 pagesVanicek Et Al CGG 42 1 Geoid&QuasiGeoidLeni HelianiNo ratings yet

- Decision Mathematics D1 January 2023 Question Paper Wdm11-01-Que-20230126Document28 pagesDecision Mathematics D1 January 2023 Question Paper Wdm11-01-Que-20230126VisakaNo ratings yet

- Budget Preparation: Lesson 3.2Document24 pagesBudget Preparation: Lesson 3.2JOSHUA GABATERONo ratings yet

- LG Neon2Document4 pagesLG Neon2LorenzoNo ratings yet

- Worst Practices TrollDocument41 pagesWorst Practices TrollsaviomoreiraNo ratings yet

- The Teaching ProfessionDocument119 pagesThe Teaching ProfessionhelmaparisanNo ratings yet

- TQ G10 POST TEST CompleteDocument2 pagesTQ G10 POST TEST CompleteLorenz Gallo VillaseranNo ratings yet

- Waruna FernandoDocument5 pagesWaruna FernandowarunafernandoNo ratings yet

- Major Orientation Reflection PaperDocument2 pagesMajor Orientation Reflection PaperNessNo ratings yet

- 2112 Filipino Thinkers PDFDocument4 pages2112 Filipino Thinkers PDFHermie Rose AlvarezNo ratings yet

- Architecture Firms: CCBA DesignsDocument1 pageArchitecture Firms: CCBA DesignspallaviNo ratings yet

- CPDDocument9 pagesCPDMeigy NitalessyNo ratings yet

- Moxa Iologik E1200 Series Manual v15.2Document129 pagesMoxa Iologik E1200 Series Manual v15.2yeng menNo ratings yet

- Jun 2003 - Qns Mod BDocument13 pagesJun 2003 - Qns Mod BHubbak KhanNo ratings yet

- KZR 12247564Document3 pagesKZR 12247564Jan MulderNo ratings yet

- Kaitlyn Duron ResumeDocument2 pagesKaitlyn Duron Resumeapi-453866596No ratings yet

- Hci - Web Interface DesignDocument54 pagesHci - Web Interface DesigngopivrajanNo ratings yet

- SEMINARS AND FIELDTRIPS (59041, 59042, 59071) : Electronics Engineering DepartmentDocument3 pagesSEMINARS AND FIELDTRIPS (59041, 59042, 59071) : Electronics Engineering DepartmentDaniel TamisenNo ratings yet

- Disassembly and Assembly: 1106D Industrial EngineDocument185 pagesDisassembly and Assembly: 1106D Industrial EnginefranNo ratings yet

- TH I Gian Làm Bài: 180'Document17 pagesTH I Gian Làm Bài: 180'Duy HảiNo ratings yet

- Cs-Stan Issue 4Document180 pagesCs-Stan Issue 4Jan JíchaNo ratings yet

- BañadosHenneaux-1993-Geometry of The 2+1 Black HoleDocument52 pagesBañadosHenneaux-1993-Geometry of The 2+1 Black HoleGuido FranchettiNo ratings yet

- Maximus Price ResumeDocument2 pagesMaximus Price Resumeapi-491233681No ratings yet