Professional Documents

Culture Documents

Damar Resin

Uploaded by

Kukuh Satrio WibowoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Damar Resin

Uploaded by

Kukuh Satrio WibowoCopyright:

Available Formats

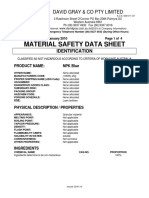

MSDS

MATERIAL SAFETY DATA SHEET

RUPERT, GIBBON & SPIDER PO BOX 425, HEALDSBURG CA, 95448 TEL: (707) 433-9577 FAX: (707) 433-4906

Damar Resin

MSDS No: # 9901511

Effective Date: 3/30/9

1. Product Identification

Product Name: Damar Resin

Product Code: 9901511

Chemical Family: Vegetable

2. Hazardous Ingredients

Hazardous Components: None

Other Components: Shorea Robusta Resin, CAS#9000-16-2,

Physical Hazards: This material may burn, but will not ignite readily. Keep away from

all sources of ignition.

NFPA Hazard Class: Health: 0 Flammability: 1 Reactivity: 0

3. Physical Data

Appearance: solid, brown nuggets

Color: brown

Solubility in Water: negligible

Odor: none to slight-characteristic

Vapor Pressure (mm Hg): No data

Vapor Density (air+1): No data

Boiling Point: N/A

Melting Point: 85-115 Deg. C

Specific Gravity: approximately .90

Percent Volatile: negligible

Bulk Density: approximately 7 pounds per gallon

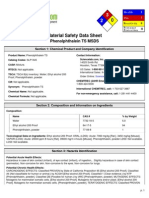

4. Fire and Explosive Data

Flash Point: >600 Deg F

Flammable/Explosive Limits (%): No data

Autoignition: no data

Burn Rate (solids only): no data

Flammable Properties: Flash Point: >600 degrees F, OSHA Flammability Class: not

regulated, LEL/UEL: No data, Autoignition Temperature: No data, Burn Rate (solids):

No data

Extinguishing Media: dry chemical, foam, water, sand or earth is recommended.

Unusual Fire & Explosion Hazards: This material may burn, but will not ignite readily.

Fire Fighting Procedures: Emergency responders in the danger area should wear bunker

gear and self-contained breathing apparatus for fires beyond the incipient state (29CFR

1910.156). In addition, wear other appropriate protective equipment as conditions

warrant. Isolate danger area, keep unauthorized personnel out. Contain spill if it can be

done with minimal risk. Move undamaged containers from danger area if it can be done

with minimal risk. With water, cool equipment exposed to fire if it can be done with

minimal risk.

5. Health Effects Data

Eye Effects: Solid material is not expected to be an eye irritant; however, contact with

molten wax may cause thermal burns. Vapors from molten wax may cause watering of

the eyes.

MSDS

MATERIAL SAFETY DATA SHEET

RUPERT, GIBBON & SPIDER PO BOX 425, HEALDSBURG CA, 95448 TEL: (707) 433-9577 FAX: (707) 433-4906

Skin Effects: Solid material is not expected to be a skin irritant; however, skin contact

with molten wax may cause thermal burns. No harmful effects from skin absorption are

expected.

Inhalations: Vapors emitted from molten wax are expected to have a low degree of

irritation by inhalation.

Ingestion: No harmful effects expected.

Human Effects of Overexposure: Effects of overexposure may include irritation of the

nose and throat.

6. Emergency and First Aid Procedures

Eye Contact: If irritation or redness develops from exposure to fumes generated during

hot-melt processing operations, move victim away from exposure and into fresh air.

Flush eyes with clean water. If irritation or redness persists, seek medical attention. For

contact with the molten material, gently open eyelids and flush affected eyes with cold

water. Seek immediate medical attention.

Skin Contact: For contact with molten material, leave material on skin and flush or

immerse affected areas using cold water. Seek medical attention.

Ingestion: First aid is not normally required for the solid material; however, if molten

material is swallowed, seek immediate medical attention.

Inhalation: If respiratory symptoms develop from exposure to fumes emitted by the

molten material, move victim away from source of exposure and into fresh air. If

symptoms persist, seek medical attention. If victim is not breathing, immediately begin

artificial respiration. If breathing difficulties develop, oxygen should be administered by

qualified personnel. See immediate medical attention.

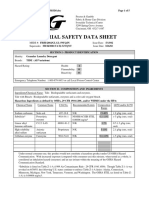

Employee Protection Recommendations

Eye Protection: Approved eye protection to safeguard against potential eye contact,

irritation or injury is recommended.

Skin Protection: Not normally required for solid material. The use of thermally-resistant

gloves is recommended when there is a potential for exposure to molten wax.

Respiratory Protection: No respiratory protection is required when working with the

solid material. If airborne concentrations of wax fumes, generated from molten wax are

expected, a NIOSH/MSHA approved air purifying respirator with a dust/mist/fume filter

should be used. Protection provided by air purifying respirators is limited (see

manufacturer's respiratory selection guide). Use a positive-pressure-air-supplied

respirator if there is a potential for an uncontrolled release, exposure levels are not

known, or any other circumstances where air-purifying respirators may not provide

adequate protection. A respiratory-protection program that meets OSHA's 29 CFR

1910.34 and ANSI Z88.2 requirements must be followed whenever workplace conditions

warrant a respirator's use.

Other: A source of clean water should be available in the work area for flushing eyes and

skin. Impervious clothing should be worn as needed.

7. Reactivity Data

Stability: Stable under normal conditions of storage and handling.

Polymerization: Will not occur

Incompatibility (materials to avoid): Avoid contact with strong oxidizing agents.

Hazardous Decomposition Products: Combustion can yield major amounts of oxides of

carbon and minor amounts of oxides of sulfur and nitrogen.

Conditions to Avoid: Avoid all possible sources of ignition.

MSDS

MATERIAL SAFETY DATA SHEET

RUPERT, GIBBON & SPIDER PO BOX 425, HEALDSBURG CA, 95448 TEL: (707) 433-9577 FAX: (707) 433-4906

8. Accidental Release Measures

This material may burn but will not ignite readily. Keep all sources of ignition away

from spill/release. Stay upwind and away from spill. Isolate danger area and keep

unauthorized personnel out. Contain spill if it can be done with minimal risk. Wear

appropriate protective equipment, including respiratory protection, as conditions

warrant. Prevent spilled material from entering sewers, storm drains, other unauthorized

treatment drainage systems and natural waterways. Notify fire authorities and

appropriate federal, state and local agencies. Cleanup under expert supervision is

advised. Minimize dust generation. Sweep up and package appropriately for disposal.

9. Handling and Storage

Handling: Wash thoroughly after handling. Do not wear contaminated clothing or shoes.

Use good personal hygiene practice. Empty containers retain residue (liquid and/or

vapor) and may be dangerous. Do not pressurize, cut weld, braze, solder, drill, grind or

expose such containers to heat, flame, sparks, or other sources of ignition. They may

explode and cause injury or death. All containers should be disposed of in an

environmentally-safe manner and in accordance with governmental regulations. Before

working o or in tanks which contain or have contained this material, refer to OSHA

regulations, ANSI Z49.1 and other governmental and industrial references pertaining to

cleaning, repairing, welding, or other contemplated operations.

Storage: Keep container(s) tightly closed. Use and store this material in cool, dry, wellventilated areas away from heat and all sources of ignition. Store only in approved

containers. Keep away from any incompatible material. Protect container(s) against

physical damage.

10. Disposal Considerations

This material, if discarded as produced, is not a RCRA listed or characteristic

hazardous waste. Use which results in chemical or physical change or contamination

may subject it to hazardous waste regulations. Along with properly characterizing all

waste materials, consult state and local regulations regarding the proper disposal of this

material.

11. Shipping Data

Hazardous Class or Division: Not classified as hazardous.

12. Regulatory Information

This material contains no chemicals subject to the reporting requirements of SARA 313

and 40 CFR 372.

This materials contains no none chemicals subject to Proposition 65.

This material has not been identified as a carcinogen by NTP, IARC, or OSHA.

No EPA (CERCLA) Reportable Quantity.

13. Toxicological Information

Please refer to CIR Review of Fossil and Synthetic Waxes published in 1983.

Notice to Reader

The information contained in this MSDS is based on data from sources considered to be reliable but Rupert,

Gibbon & Spider Inc. does not guarantee the accuracy or completeness thereof. Rupert, Gibbon & Spider Inc.

urges each customer or recipient of this MSDS to study it carefully to become aware of and understand the

hazards associated with this product. The reader should consider consulting reference works or individuals

who are experts in ventilation, toxicology or fire and understand the data in this MSDS.

You might also like

- MSDS Gum DamarDocument3 pagesMSDS Gum DamaryudirahdianNo ratings yet

- MSDS400Document3 pagesMSDS400adebukNo ratings yet

- MSDS 009 - enDocument3 pagesMSDS 009 - enindah50% (2)

- Material Safety Data Sheet Cold Ice +30 Gel Ice: Identification of Product and CompanyDocument2 pagesMaterial Safety Data Sheet Cold Ice +30 Gel Ice: Identification of Product and CompanyNur ChayatiNo ratings yet

- Pom MSDS PDFDocument3 pagesPom MSDS PDFebercueNo ratings yet

- Mop Strip 1217 MSDSDocument2 pagesMop Strip 1217 MSDSSage Chemical InternationalNo ratings yet

- PVC MSDSDocument9 pagesPVC MSDSSandry KesumaNo ratings yet

- Sanisol - SdsDocument6 pagesSanisol - SdsMohamad Arta100% (1)

- MSDS BTG Gashoun PDFDocument1 pageMSDS BTG Gashoun PDFEranda GraciellaNo ratings yet

- Gum Damar: Technical Data SheetDocument1 pageGum Damar: Technical Data SheetyudirahdianNo ratings yet

- Grease MSDSDocument6 pagesGrease MSDSAltoz DequitoNo ratings yet

- Msds NPKDocument38 pagesMsds NPKKamilaNo ratings yet

- Olive Oil MsdsDocument5 pagesOlive Oil Msdsshella168No ratings yet

- MSDS PC 22 Radiator CoolantDocument4 pagesMSDS PC 22 Radiator CoolantAldiNo ratings yet

- Red BWS - SDSDocument2 pagesRed BWS - SDSRezoanul Haque50% (2)

- MSDS Jotun Pilot QDDocument13 pagesMSDS Jotun Pilot QDHaryanto RNo ratings yet

- Msds Hydrogen PeroxideDocument2 pagesMsds Hydrogen PeroxideSlamet Ar100% (1)

- Safety Data Sheet Tellus Oil 68Document7 pagesSafety Data Sheet Tellus Oil 68Isabela BoceanuNo ratings yet

- MSDS NPK Blue FertiliserDocument4 pagesMSDS NPK Blue Fertiliserhary budiman0% (1)

- MSDS Prilled UreaDocument6 pagesMSDS Prilled UreaLutfi IsmailNo ratings yet

- MSDS Linalool PDFDocument7 pagesMSDS Linalool PDFSyafira Indah JulianaNo ratings yet

- Aquasorb 3005 KL - MSDS PDFDocument5 pagesAquasorb 3005 KL - MSDS PDFFlavio Jorge Miranda PimentelNo ratings yet

- Separol, Msds 040411Document3 pagesSeparol, Msds 040411Alejandro Pereira BerríosNo ratings yet

- MSDS PhenolphthaleinDocument6 pagesMSDS PhenolphthaleinAstri Aisyah RahmiNo ratings yet

- Hoja Seguridad Dromus BLDocument7 pagesHoja Seguridad Dromus BLClaudia hernandezNo ratings yet

- Msds Cypergard 100 Ec Reg BaruDocument3 pagesMsds Cypergard 100 Ec Reg BaruFumigasi100% (1)

- Safety Data Sheet: 1. Identification of The Material and Supplier Aluminium Sulfate SolidDocument6 pagesSafety Data Sheet: 1. Identification of The Material and Supplier Aluminium Sulfate SolidrezaNo ratings yet

- MSDS CarbomerDocument5 pagesMSDS CarbomerInsaf DaldoulNo ratings yet

- MSDS Tide Granular Laundry DetergentDocument5 pagesMSDS Tide Granular Laundry DetergentFarhanNo ratings yet

- White Oil MsdsDocument4 pagesWhite Oil MsdstopguitarNo ratings yet

- MSDS 280anDocument3 pagesMSDS 280anNur Ali Said100% (2)

- Tellus 68 MsdsDocument7 pagesTellus 68 MsdsMalou Castillo UmaliNo ratings yet

- Material Safety Data Sheet: 1. Identification of The Substance/Preparation and The Company/UndertakingDocument5 pagesMaterial Safety Data Sheet: 1. Identification of The Substance/Preparation and The Company/Undertakinghkc mathesonNo ratings yet

- MSDS PamDocument5 pagesMSDS Pama.hasan670No ratings yet

- Dettol Floor Cleaner NZ-V4.1-D8103889Document7 pagesDettol Floor Cleaner NZ-V4.1-D8103889Hana AlghamdiNo ratings yet

- Safety Data SheetDocument7 pagesSafety Data SheetGerman Chacon0% (1)

- MSDS AxSorb D EnglishDocument9 pagesMSDS AxSorb D EnglishMateus BanuthNo ratings yet

- Material Safety Data Sheet: Company: P.T. Kurita Indonesia Brandname: KURIFLOCK PA-322KDocument2 pagesMaterial Safety Data Sheet: Company: P.T. Kurita Indonesia Brandname: KURIFLOCK PA-322KMarcos DiazNo ratings yet

- Catalog Product Noka Indonesia - Compressed - CompressedDocument4 pagesCatalog Product Noka Indonesia - Compressed - CompressedSaBilScondNo ratings yet

- MSDS UV InkDocument4 pagesMSDS UV Inknorbertscribd0% (1)

- MSDS ParfumeDocument5 pagesMSDS ParfumeIlham NugrahaNo ratings yet

- Detergent (Accepta) PDFDocument6 pagesDetergent (Accepta) PDFNiluh Komang Putri PurnamantiNo ratings yet

- Msds FishmealDocument3 pagesMsds FishmealRamzy Badhawi100% (2)

- Dettol Anti-Bacterial Laundry Sanitizer MSDSDocument10 pagesDettol Anti-Bacterial Laundry Sanitizer MSDSMark DunhillNo ratings yet

- Levocol HCF - NLDocument3 pagesLevocol HCF - NLvinayakasis100% (1)

- Standard Sds-Palmerol 1214-Lauryl-Myristyl AlcoholDocument8 pagesStandard Sds-Palmerol 1214-Lauryl-Myristyl AlcoholNatalia EstupiñánNo ratings yet

- N 9905Document7 pagesN 9905yuda anggiNo ratings yet

- Company Profile - AG NutriceuticalDocument5 pagesCompany Profile - AG NutriceuticalNorina GenistonNo ratings yet

- Aflan Global - Coconut SpecialistDocument11 pagesAflan Global - Coconut SpecialistBismillah SugehNo ratings yet

- MSDS PC Duron Geo LD 15W-40 PDFDocument7 pagesMSDS PC Duron Geo LD 15W-40 PDFaliosk8799No ratings yet

- SL 1301 Eco FLZ 20Document8 pagesSL 1301 Eco FLZ 20alinus4yNo ratings yet

- Material Safety Data Sheet: CombitreatDocument5 pagesMaterial Safety Data Sheet: CombitreatJezrell JaravataNo ratings yet

- Msds HFDocument7 pagesMsds HFsagar1247No ratings yet

- Rp7-Aus SDSDocument7 pagesRp7-Aus SDSRùa ConNo ratings yet

- Msds - Marpozol W-505 (GHS) Eng 130409Document5 pagesMsds - Marpozol W-505 (GHS) Eng 130409Syafarul Mohammad100% (1)

- Jazeera Dhilal Primer-MsdsDocument5 pagesJazeera Dhilal Primer-MsdsMahmoud Flefil100% (1)

- Msds Penguard Midcoat B JotunDocument12 pagesMsds Penguard Midcoat B JotuncrysNo ratings yet

- DMDS Data SheetDocument7 pagesDMDS Data Sheetfarooq798100% (1)

- Paraffin Wax 2Document7 pagesParaffin Wax 2karthik1amarNo ratings yet

- Barite (Barium Sulfate)Document4 pagesBarite (Barium Sulfate)monarisosughisaNo ratings yet

- Cesium and Rubidium Salts of Keggin-TypeDocument146 pagesCesium and Rubidium Salts of Keggin-TypeChau MaiNo ratings yet

- The Following Tables Provide An Overview of The Key Advantages and Disadvantages of Different Types of Fertilisers On The Market TodayDocument3 pagesThe Following Tables Provide An Overview of The Key Advantages and Disadvantages of Different Types of Fertilisers On The Market TodayAbdullaNo ratings yet

- BelgJBotJansenetal1998 PDFDocument10 pagesBelgJBotJansenetal1998 PDFalexNo ratings yet

- TWI Current Practice For Welding P92 PDFDocument13 pagesTWI Current Practice For Welding P92 PDFpipedown456100% (1)

- Astm D1208 - 1 (En)Document3 pagesAstm D1208 - 1 (En)rezokaNo ratings yet

- EVA Resin 2018Document1 pageEVA Resin 2018AminulIslamNo ratings yet

- Oxidation-Reduction of Borneol PDFDocument8 pagesOxidation-Reduction of Borneol PDFRalston King Stulla ChambersNo ratings yet

- Metabolism Exam 2 - GIFT - Spring 2016Document9 pagesMetabolism Exam 2 - GIFT - Spring 2016shafa_nathani100% (2)

- Materials and Processes For Agricultural and Biosystems EngineeringDocument17 pagesMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioNo ratings yet

- Design of FRP-Profiles & All-FRP-Structures (2009) - Presentation PDFDocument67 pagesDesign of FRP-Profiles & All-FRP-Structures (2009) - Presentation PDFJulio Humberto Díaz RondánNo ratings yet

- Nitoseal 130Document2 pagesNitoseal 130Venkata RaoNo ratings yet

- Structure-Property Relationships of Flexible Polyurethane FoamsDocument10 pagesStructure-Property Relationships of Flexible Polyurethane Foamstoiec hocNo ratings yet

- Final Examination: Your Answer On The Space Provided For. (40 Points)Document5 pagesFinal Examination: Your Answer On The Space Provided For. (40 Points)Wichel AnnNo ratings yet

- Thermodynamic Analysis of EAF Electrical Energy deDocument17 pagesThermodynamic Analysis of EAF Electrical Energy deRafaela PradeNo ratings yet

- (Caustic Soda) : Material Safety Data SheetDocument2 pages(Caustic Soda) : Material Safety Data SheetKumbang KambingNo ratings yet

- Expansion Joint BasicsDocument114 pagesExpansion Joint Basicsrvrlonestar75% (4)

- Dehydration of AlcoholsDocument6 pagesDehydration of Alcoholsعبدالله هنيةNo ratings yet

- Jotun Penguard Express CF TDSDocument5 pagesJotun Penguard Express CF TDSnihad_mNo ratings yet

- Leaf Spring AnalysisDocument9 pagesLeaf Spring AnalysisThilli KaniNo ratings yet

- Azbil LX7000 Series (Switch) - M C 2Document12 pagesAzbil LX7000 Series (Switch) - M C 2phuoc leNo ratings yet

- Mobil Oil Dte 25 Ultra - Safety Data Sheet (SDS)Document10 pagesMobil Oil Dte 25 Ultra - Safety Data Sheet (SDS)ghyd artiagaNo ratings yet

- Basic Laboratory Glassware and EquipmentDocument11 pagesBasic Laboratory Glassware and EquipmentSheila Mae BaranganNo ratings yet

- Stefan Boltzmann Law PDFDocument3 pagesStefan Boltzmann Law PDFESAKKIMALA SNo ratings yet

- 3rd Quarter Science 8Document50 pages3rd Quarter Science 8John Ryan PiolNo ratings yet

- Development of The Model of The AtomDocument2 pagesDevelopment of The Model of The AtomshamshadNo ratings yet

- Supercritical Fluid Technology For Drug Product Development (2004)Document688 pagesSupercritical Fluid Technology For Drug Product Development (2004)Regiani Almeida Rezende100% (1)

- Catalogo de Valvula de RetenciónDocument15 pagesCatalogo de Valvula de RetenciónLeo NovoxNo ratings yet

- Innovation of LNGCDocument63 pagesInnovation of LNGCpadangiringNo ratings yet

- Jotafloor TC EDocument6 pagesJotafloor TC ERidwanSalminNo ratings yet

- FORMULATION AND EVALUATION OF GASTRO-RETENTIVE FLOATING TABLET OF QUETIAPINE FUMARATE Shanti Sagar, Srividya. L, B.K NanjawadeDocument14 pagesFORMULATION AND EVALUATION OF GASTRO-RETENTIVE FLOATING TABLET OF QUETIAPINE FUMARATE Shanti Sagar, Srividya. L, B.K NanjawadeiajpsNo ratings yet