Professional Documents

Culture Documents

Adidas Self Assessment - Security System (C-TPAT)

Uploaded by

Isyalendra Surya AlamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adidas Self Assessment - Security System (C-TPAT)

Uploaded by

Isyalendra Surya AlamCopyright:

Available Formats

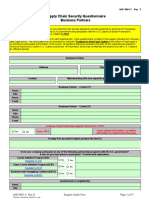

adidas Group Factory Security Self-Assessment

As you are aware, U.S Customs and Border Protection (CBP) and the importing trade community have collaborated to

develop the Customs-Trade Partnership Against Terrorism (C-TPAT), to protect the global supply chain from terrorism.

The adidas Group is a proud member of C-TPAT and is committed to securing the integrity of its supply chain.

As a foreign business partner of the adidas Group you are required to complete and sign this self-assessment committing

yourself to remedying any shortcomings and affirming your commitment to the adidas Group Supply Chain Security

Program. Should you have any questions on the content of this self-assessment, please contact Debora Situmorang on

deborasitumorang@omegacompliance.com or +62-21-576-0933.

VENDOR NAME AKA / (Other Name)

Address

Vendor Representative Title

Vendor ID Number

Fax No Phone

Vendor worked with Factory since (insert year) E-mail

FACTORY NAME AKA / (Other Name)

Address

:City State/Province Country Postal Code

Factory Contact Title E-Mail

Telephone (Country Code) (City Code) (Area Code) Phone Ext.

Mobile (Country Code) (City Code) (Area Code) Phone

Fax (Country Code) (City Code) (Area Code) Fax

Has this factory previously undergone a C-TPAT evaluation for another US importer?

If so, list the names of each importer

Size of the facility Building Area: Total Area:

No. of entrances/exits to the facility?

No. of employees Permanent: Temporary: Total:

Yes No N/A

Are the security guards company employees? If not, please specify which company they work for? ______________________

OTHER INFORMATION

Business relationship with adidas Group began in:

The five main customers in decreasing order are (percentage of business) ( %)

( %)

( %)

( %)

( %)

The largest countries of export are:

Business Partner Requirement

1. Does the factory have written and verifiable processes for the selection of trucking companies who are

Yes No N/A

responsible for moving merchandise from your site to the CFS/Terminal/Port?

2. Are there key criteria / requirements for selecting a business partner in terms of supply chain security,

Yes No N/A

such as security control, financial stability, corporate history and hiring practices?

3. Does the factory require trucking companies to demonstrate that they are meeting the C-TPAT security

criteria via written/electronic confirmation? Examples include a contractor indicate security

requirements including use of specific transit routes, designed meal and rest stops, reporting any

attempt to tamper with the container, attempted hijack incident, a letter from the trucking company's

Yes No N/A

senior officer attesting to compliance; a written statement from the trucking company demonstrating

compliance with C-TPAT security criteria or an equivalent World Customs Organization (WCO)

accredited security program administered by a customs authority; or a completed security

questionnaire.

4. Are there any legally binding contracts with the contractors covering the specific routes of delivery? Yes No N/A

adidas Group Factory Security Self-Assessment

Effective: 2012/5/14

Form: OC-FS-032

Version: 3 Omega Compliance is

Accredited by US Customs

5. Are written and verifiable processes in place to conduct security checks (announced and Yes No N/A

unannounced) to all contractors to comply with C-TPAT security criteria eg. security controls, corporate

history and hiring practices (background checks) etc..?

CONTAINER AND TRAILER SECURITY

6. Are written procedures in place stipulating how seals are to be controlled and affixed to loaded

Yes No N/A

containers and trucks?

7. Do you maintain written procedures for recognizing and reporting compromised seals and/or

Yes No N/A

containers/trailers to U.S. Customs and Border Protection or the appropriate foreign authority?

8. Are procedures in place to maintain the integrity of the shipping containers / trucks including how to

Yes No N/A

report and neutralize unauthorized entry into containers / trucks or container / truck storage areas?

9. Are there documented procedures for affixing, replacing, recording and tracking the seals placed on

containers, trailers, trucks, and/or railcars? (applicable to FCL or seals used by facility or carrier to Yes No N/A

secure shipments via LCL).

10. Prior to loading, does the factory inspect the reliability of the locking mechanism of the doors of the

Yes No N/A

containers / trucks?

11. Is there a seventeen-point inspection process in place to verify the physical integrity of the container

structure prior to loading: bumper, engine, tires, floors of the cab, fuel tanks, outside & inside of the cab,

air tank, driver shafts, fifth wheel area, outside/undercarriage, floors of container / box of the truck,

Yes No N/A

inside/outside doors of the container / box of the truck, side walls of the container / box of the truck,

inside ceiling & outside roof of the front wall, front wall of the container / box of the truck, refrigeration

unit and exhaust?

12. Does the security guard, shipping manager and driver (if present for loading) verify the 17-point

Yes No N/A

inspection by signing off on the inspection checklist?

13. Are procedures in place to outline how purchased seal are stored, logged and handled? Yes No N/A

14. Is a high grade security seal which meets or exceeds the PAS ISO 17712 standard affixed to all loaded

Yes No N/A

containers / trucks bound for the United States or to forwarder’s CFS warehouse?

15. After the container / truck are loaded, does the factory take a digital photo of the back of the

Yes No N/A

container/trailer before the doors are closed and sealed?

16. After the container / truck are sealed, does the factory take digital photos of the seal and all sides of the

Yes No N/A

container / truck?

17. Are only designated employees authorized to distribute seals for integrity purposes, including handling

Yes No N/A

of unused seals?

18. Is the loading and unloading of containers / trucks supervised by a security officer or another

Yes No N/A

designated person?

19. Are containers / trucks stored in a secure area to prevent unauthorized access and/or manipulation? Yes No N/A

20. Does the containers / trucks stored or parked an adequate distance away from the perimeter walls or

Yes No N/A

fencing?

21. Is there any measurement in place to monitor and track the conveyance of cargos by trucks or

containers when they are on the ways to CFS warehouse / port? eg. conveyance tracking log, describe

Yes No N/A

how to know the cargos are delivered within a reasonable time frame, build up the channel of

communication between driver and factory representative on the way of travel, etc?

PHYSICAL ACCESS CONTROLS

22. Are all employees given an identification badge including new recruits? Yes No N/A

23. Does the employee identification badge include the following information?

-Employee photo

-Employee name Yes No N/A

-Department

-Employee ID, if applicable

24. Is employee's access to restricted areas (such as cargo handling/storage area, packing area, IT server

Yes No N/A

room and document control room) limited to access needed for the performance of their duties?

25. Is the issuance and removal of employee identification badges adequately controlled? Yes No N/A

26. Do employees wear an identification badge while on the premises? Yes No N/A

27. Does the factory in place system to verify the employee identity, and required all employee Yes No N/A

identification badges be reviewed on an annual basis, and are renewed if necessary?

28. Is a list of names and photos of terminated employees given to security to aid them in the access

Yes No N/A

control to the factory?

adidas Group Factory Security Self-Assessment

Effective: 2012/5/14

Form: OC-FS-032

Version: 3 Omega Compliance is

Accredited by US Customs

29. Are there documented procedures for the issuance, removal and changing of access devices (e.g.

Yes No N/A

keys, key cards, etc.)?

30. Do guards have standing operating procedures (SOP) indicates the security performance, such as the

monitoring hour 24/7, the dress code, the issuance of security equipments, how to verify and control of Yes No N/A

the identification badges for the employees, visitors and vendors, etc?

31. Do guards locked all factory entrance and manned during non-operating hours? Yes No N/A

32. Do guards conduct inspection for the personal belongings carried by employee or visitors? Yes No N/A

33. Do security guards log and report incidents including any security violation and compromised seals

Yes No N/A

and/or containers/trailers to appropriate management and/or local authorities?

34. Do security guards receive specific training and update periodically including terrorism threat

Yes No N/A

awareness and unauthorized access?

35. Are there procedures in place to identify, challenge and address unauthorized/unidentified persons? Yes No N/A

36. Do visitors / vendors need to present photo identification for documentation purpose upon arrival at the

Yes No N/A

factory?

37. Do visitors / vendors need to go through entrance separated from the factory employee? Yes No N/A

38. Are visitors / vendors required to wear temporary identification badges while on the factory premises? Yes No N/A

39. Do visitors / vendors badges in place a system to identify missing or theft, such as numbering or

Yes No N/A

colored code and logging of issuing and returning?

40. Does the factory have an up-to-date list for all on-site contractors, vendors and repairer including their

Yes No N/A

names, company and address?

41. Are visitors escorted by an authorized person while on the factory premises? Yes No N/A

42. Are arriving packages and mail periodically screened before dissemination? Yes No N/A

43. Is advance information from a visitor / vendor required before the visit? Yes No N/A

PERSONNEL SECURITY

44. Do the factory in place written and verifiable processes to screen prospective employee including

Yes No N/A

permanent or temporary?

45. Is employee applications and interview required before hired? Yes No N/A

46. Is employee application information such as employment history and reference verified prior to

Yes No N/A

employment?

47. Does the facility retain copies of each employee's official identification? Yes No N/A

48. Does the factory conduct background checks and investigations upon prospective employees

consistent with federal, state and local regulations? Examples include criminal record checks and Yes No N/A

verifications of former addresses?

49. For factories located in a country where local law prohibits criminal background checks, does the

factory use alternative methods to investigate potential employees:

Asking probing yet noninvasive questions to stimulate conversation with the applicant including in-

depth questions regarding gaps in employment?

Verifying an applicant’s background by conducting in-depth reference checks and requesting

additional references from those personal references? Yes No N/A

Conducting personal visits to references and applicant’s homes?

Verifying driving records (as relevant)?

Verifying current and previous addresses?

Requesting educational transcripts directly from schools?

Checking the applicant’s reputation through local associations?

50. Does the factory perform periodic checks and reinvestigations based on cause and/or the sensitivity of

the employee’s position? Employees working in the shipping and receiving areas, packing area, Yes No N/A

security, IT and HR are considered sensitive positions.

51. Are there procedures in place to remove identification, facility and system access for terminated

Yes No N/A

employees?

52. Does the factory have written employee termination procedures? Yes No N/A

53. Upon termination of employment, does the factory utilize a checklist to ensure that the employee no

Yes No N/A

longer has access to the factory premise and that all company property has been returned?

54. Is the issuance of facility employee identification centralized and controlled by a specific department? Yes No N/A

55. Are lost IDs replaced and recorded as missing? Yes No N/A

56. Is security staff informed of lost ID badges (name, ID number, etc.)? Yes No N/A

57. Is there any guards monitor access on restricted area by checking employee identification? Yes No N/A

adidas Group Factory Security Self-Assessment

Effective: 2012/5/14

Form: OC-FS-032

Version: 3 Omega Compliance is

Accredited by US Customs

PROCEDURAL SECURITY

58. Are there procedures in place to ensure that all information used in the clearing of merchandise/cargo

is legible, complete, accurate and protected against the exchange, loss or introduction of erroneous Yes No N/A

information?

59. Are all business documents, including purchase orders, invoices, manifests and customer information

Yes No N/A

kept under lock and key when the factory is not operating?

60. To help ensure the integrity of cargo, are there procedures in place to ensure that information received

Yes No N/A

from business partners is reported in an accurately and timely manner?

61. Is departing cargo reconciled against information on the cargo manifest? Yes No N/A

62. Is departing cargo accurately described with weight, labels, marks and piece count and also verified? Yes No N/A

63. Is departing cargo checked against purchase or delivery orders? Yes No N/A

64. Does the factory conduct random documented examinations of cartons prior to palletizing? Yes No N/A

65. After cartons are examined, are they stamped “EXAMINATED” and resealed with tape? Yes No N/A

66. Does the factory send goods to forwarder’s CFS warehouse by using closed top truck with a lockable

Yes No N/A

door?

67. Does the factory have a written contract with trucking companies which indicate the security

requirements, such as using specific transit routes, designated meals and rest stops, reporting any Yes No N/A

attempt to tamper with container / trailer, attempt hijack incident?

68. Are drivers delivering or receiving cargo positively identified before the cargo is received or released? Yes No N/A

69. Are procedures established to track the timely movement of outgoing goods, cargos, containers and

Yes No N/A

truck?

70. Are all shortages, overages, and other significant discrepancies or anomalies resolved and/or

Yes No N/A

investigated appropriately?

71. Are U.S. Customs and Border Protection and/or other appropriate law enforcement agencies notified if

Yes No N/A

anomalies, illegal or suspicious activities are detected?

72. Is dangerous cargo, including hazardous materials, ammunition and explosives, secured and stored

Yes No N/A

separately?

73. Is dangerous cargo labeled when necessary? Yes No N/A

74. Does the facility have a documented policy that requires all security procedures to be documented? Yes No N/A

75. Does the facility have a designated chief / head staff member responsible for overall site security? Yes No N/A

76. Has an internal, second or third party site security assessment been conducted? Yes No N/A

77. Does the facility require the contractors to conduct periodical self assessment of their security policies

Yes No N/A

and procedures and to share the results with the facility?

78. Does the facility or a third party auditor conduct on-site inspections on the contractors whether they has

Yes No N/A

followed the implementation of the standards/procedures set by the facility?

79. Are both incoming and outgoing cargo vehicles checked / inspected for illegal cargo or an unregistered

Yes No N/A

visitor?

80. Are delivery drivers required to show a truck manifest on entry and/or exit? Yes No N/A

81. Does the facility keep records for all incoming and outgoing containers / trucks about the drivers name,

truck license / registration number, container security seal number (if any), shipping documentation Yes No N/A

check, guard's name, time and date of entry with container number?

82. Are seals / padlocks on either incoming containers/trailers or outgoing shipment inspected? Yes No N/A

83. Are seal numbers recorded for incoming container / truck seals? (applicable to FCL or seal used by

facility or carrier to secure shipments via LCL, non applicable to padlock used by facility or carrier to Yes No N/A

secure shipments via LCL)?

84. Are seal numbers recorded for outgoing container / truck seals? (applicable to FCL or seal used by

facility or carrier to secure shipments via LCL, non applicable to padlock used by facility or carrier to Yes No N/A

secure shipments via LCL)?

85. Are seal numbers verified at the time of final sealing before departure? (applicable to FCL or seals

Yes No N/A

used by facility or carrier to secure shipments via LCL)?

86. Any written procedure in place to verify seal number against facility documentation when the container /

truck are turned over to the next supply chain link (applicable to trucks and closed vans)? (applicable to Yes No N/A

FCL or seal used by facility or carrier to secure shipments via LCL)?

adidas Group Factory Security Self-Assessment

Effective: 2012/5/14

Form: OC-FS-032

Version: 3 Omega Compliance is

Accredited by US Customs

87. Any written procedure in place to report case of broken seals / padlocks (if any), when broken seals /

padlocks (including cargo hold locks) are discovered, is there an examination of the container / truck Yes No N/A

contents (applicable to trucks and closed vans)?

88. Does the facility conduct the inventory upon receipt of seals and track the issuance of seals in a seal

Yes No N/A

log book?

89. Is seal inventory count conducted at least once per year during the internal audit? Yes No N/A

90. Any documented system in place to ensure that management be informed of and investigates all

Yes No N/A

anomalies found in shipments and / or the accompanying documents?

91. Any documented procedure for contractors to report security violations to facility management? Yes No N/A

92. Is loading dock access restricted to authorized personnel only? Yes No N/A

93. Is the cargo moved directly from the storage facility/assembly line to the conveyance without

Yes No N/A

intermediate staging?

94. Are trucks sealed after loading is complete? (applicable to FCL / LCL) Yes No N/A

95. For pick-ups from multiple manufacturers, does the facility require transportation providers to use

Yes No N/A

secure locking devices (e.g. padlocks) for less-than-full-load containers?

96. Does the facility assign a designated representative responsible for providing accurate products

Yes No N/A

information to the carriers?

97. Has the said representative been trained on the information requirements for shipments to the United

Yes No N/A

Stated?

98. Does the facility keep all shipment records? Yes No N/A

99. Are the shipment records made in an electronic format?

100. Any documented procedure to conduct periodic unannounced security checks to ensure that all of the

Yes No N/A

above security procedures are being performed properly?

101. Any documented security improvement plan that summarizes or identifies vulnerabilities and

Yes No N/A

corresponding corrective actions?

SECURITY TRAINING AND THREAT AWARENESS

102. Does the factory have a threat awareness program maintained by security personnel to recognize and

foster awareness of the threat posed by terrorists and contraband smugglers at each point along the Yes No N/A

supply chain?

103. Does the factory made employees aware of the security procedures the company has in place and how

to report suspicious activities and/or security violations, such as publicizing the security policy Yes No N/A

throughout the facility (use posters, bulletin board etc)?

104. Is additional training provided to employees in the shipping and receiving areas, as well as to those

Yes No N/A

receiving and opening mail?

105. Is specific training offered to assist employees in maintaining cargo integrity, recognizing internal

Yes No N/A

conspiracies and protecting access controls?

106. Does the factory integrate all security training into employee orientation and hold periodic refresher

Yes No N/A

training sessions?

107. Does the facility conduct new employee orientation? Yes No N/A

108. Does the factory offer incentives for participation in the above security programs? Yes No N/A

109. Does the facility have and maintain an employee code of conduct such as an employee handbook? Yes No N/A

110. Are periodic meetings held with guards to discuss the factory security and alerts? Yes No N/A

111. Is all security program training documented (including information such as subject, date, attendees,

Yes No N/A

photos, training material)?

adidas Group Factory Security Self-Assessment

Effective: 2012/5/14

Form: OC-FS-032

Version: 3 Omega Compliance is

Accredited by US Customs

PHYSICAL SECURITY

112. Does perimeter fencing (physical barriers and deterrents that guard against unauthorized access)

Yes No N/A

enclose the cargo handling and storage facilities?

113. Are domestic, international, high value and hazardous cargos segregated by interior fencing? Yes No N/A

114. Do you regularly inspect all fencing for integrity and damage? Yes No N/A

115. Are gates through which vehicles and/or personnel enter or exit manned and/or monitored? Yes No N/A

116. Are private passenger vehicles and parking lots separated from the cargo handling and storage areas? Yes No N/A

117. Are all buildings in the factory constructed of materials which prevent unlawful entry? Yes No N/A

118. Are factory buildings periodically inspected and repaired? Yes No N/A

119. Are inspection records related to infrastructure integrity kept (including inspection dates, reported

Yes No N/A

damages, and completed repairs)?

120. Are all external and internal windows, gates and fences secured with locking devices? Yes No N/A

121. Is a lost, misplaced or stolen key reported immediately to the factory management? Yes No N/A

122. Do management or security personnel control the issuance of all locks and keys? Yes No N/A

123. Does the facility have an automatic intrusion detection or automatic alarm system? And test regularly? Yes No N/A

124. Is there a back-up power source for the alarm system? Yes No N/A

125. Are intrusions reported? (This is to ascertain whether the intrusion system is effective when triggered) Yes No N/A

126. Are locking devices used to control access to restricted areas? And test regularly? (This depends on

Yes No N/A

how well the facility is established in terms of physical / electronic security measures)

127. Is there an individual responsible for distributing and maintaining cards / codes / other mechanisms for

Yes No N/A

activating locking devices?

128. Are both managers and security personnel provided with an up-to-date list of all personnel access

Yes No N/A

privileges on a regular schedule?

129. Any alarm systems and video surveillance cameras monitor activities inside / outside the facility

Yes No N/A

including those sensitive areas eg. cargo handling and storage areas? If so, by whom?

130. If applicable, does a substantial physical barrier surround the perimeter of the property? Yes No N/A

131. Are underground access points, culverts, utility tunnels, sewers, etc. secured to prevent unauthorized

Yes No N/A

access?

132. Do guards patrol the interior and exterior of buildings in the facility? Yes No N/A

133. Are CCTV records kept for at least 45 days? Yes No N/A

134. Is access to CCTV monitors controlled? Yes No N/A

135. Is there adequate lighting inside and outside the factory? This includes all entrances, exits, cargo

Yes No N/A

handling areas, storage areas, parking areas and fences? Any back up power supply?

136. Is access to the lighting switches restricted to authorized personnel only? Yes No N/A

137. Is the lighting switched on automatically (with light sensor or a timer) / manually as the natural light on

Yes No N/A

the entire facility dims?

138. If available, are the parking lots for visitors separated from those for employees? Yes No N/A

139. Are vehicles prohibited / prevented from parking near the perimeter fencing? Yes No N/A

140. If allowed to enter the facility, are vendor and visitor vehicles inspected? Yes No N/A

141. Are employee parking lots and visitor parking lots set apart from entrances and exits? (sizable facility -

keep a distance; small facility - suggested keep them outside of facility or N/A if this is a tiny facility e.g Yes No N/A

home facility)

142. Are the parking lots monitored? Yes No N/A

143. Any visual identification for employee / visitor parking be required (e.g. a coded parking sticker, tag,

Yes No N/A

decal)?

144. Are there security measures in place to prevent tampering of goods during production, the introduction

Yes No N/A

of foreign material(s) into the assembly area and packing area?

adidas Group Factory Security Self-Assessment

Effective: 2012/5/14

Form: OC-FS-032

Version: 3 Omega Compliance is

Accredited by US Customs

INFORMATION TECHNOLOGY SECURITY

145. Are there IT security policies, procedures and standards in place and trained to all employees? Yes No N/A

146. Any designated system administrator? Yes No N/A

147. Does the factory limit access to its computers and other information systems via individually assigned

Yes No N/A

accounts that require a periodic change of password?

148. Are individual passwords used consisting of a combination of letters, numbers and symbols that cannot

Yes No N/A

be personal identifiers?

149. Are IT passwords deactivated and changed once every 90 days? Yes No N/A

150. Are the user and IT administrator locked out of the system after 3 unsuccessful attempts to login? Yes No N/A

151. Do computers lock after a short period of inactivity? Yes No N/A

152. Does the facility have documented procedures for identifying which employees are allowed access to

Electronic information systems, including; Shipping forms / Shipping Data / Cargo Movement / Security Yes No N/A

Seals?

153. Does the facility have any documented procedures to adjust or rescind such access? Yes No N/A

154. Is there a system in place to identify the abuse of information technology including improper access,

tempering or the altering of business data? And the system data be kept and reviewed weekly including Yes No N/A

invalid password attempts and files access?

155. Are system violators subject to appropriate disciplinary actions? Yes No N/A

156. Is all computer information saved on a back-up system and that the backup data stored in a fire

Yes No N/A

resistant safe or at an off-site facility?

157. Any network security system be implemented e.g. Firewall(s) / Intrusion Warning System / Anti-Virus? Yes No N/A

158. Does the factory regularly hold meetings attended by senior management which address IT security

Yes No N/A

issues?

ACKNOWLEDGEMENT

By completing and signing this document, you are committing to developing and maintaining a security

program in line with the requirements of the adidas Group, as described above.

Please sign and chop this document and return to Omega Compliance by email

deborasitumorang@omegacompliance.com within 7 days. Your full cooperation is expected.

Print Name: __________________________

Print Title: __________________________

Signed: __________________________

Date: __________________________

adidas Group Factory Security Self-Assessment

Effective: 2012/5/14

Form: OC-FS-032

Version: 3 Omega Compliance is

Accredited by US Customs

You might also like

- Customs Trade Partnership Against Terrorism (C-Tpat) Vendor Security Questionnaire Effective: January 29, 2019Document3 pagesCustoms Trade Partnership Against Terrorism (C-Tpat) Vendor Security Questionnaire Effective: January 29, 2019Carlos MorenoNo ratings yet

- Section/Control Description Security Management System: C-TPAT Self-Assessment - Manufacturing & WarehousingDocument5 pagesSection/Control Description Security Management System: C-TPAT Self-Assessment - Manufacturing & Warehousingaprilia retno0% (1)

- Best Security PracticesDocument38 pagesBest Security Practicesneil926100% (1)

- 01-CTPAT Security Questionnaire PDFDocument8 pages01-CTPAT Security Questionnaire PDFSudeesha Wenura Bandara100% (1)

- INT0010A: Corporate C-TPAT Procedure Manual Revised 2015Document7 pagesINT0010A: Corporate C-TPAT Procedure Manual Revised 2015Carlos MorenoNo ratings yet

- Security Risk Assessment - MamelodiDocument5 pagesSecurity Risk Assessment - MamelodiGasa Security100% (1)

- Is-906 - Workplace Security Awareness Course OverviewDocument20 pagesIs-906 - Workplace Security Awareness Course OverviewmattbettNo ratings yet

- Study Unit 5: Key Risk Indicators Key Performance IndicatorsDocument23 pagesStudy Unit 5: Key Risk Indicators Key Performance IndicatorsThato SechoaroNo ratings yet

- Project Security Compliance Assessment ChecklistDocument33 pagesProject Security Compliance Assessment ChecklistOancea Mircea Ion0% (1)

- Standard Operating Manual for Private Security Companies in Sierra LeoneDocument19 pagesStandard Operating Manual for Private Security Companies in Sierra LeonebharatheeeyuduNo ratings yet

- APSRTC Official Website For Online Bus Ticket Booking - APSRTConlineDocument2 pagesAPSRTC Official Website For Online Bus Ticket Booking - APSRTConlineDominic ChalmersNo ratings yet

- New Joining Kit V4Document50 pagesNew Joining Kit V4Ayush SinghNo ratings yet

- Supply Chain Security Questionnaire Business Partners: InstructionsDocument17 pagesSupply Chain Security Questionnaire Business Partners: InstructionsCarlos MorenoNo ratings yet

- CTPAT Importer Security Questionnaire: Page 1 of 9Document9 pagesCTPAT Importer Security Questionnaire: Page 1 of 9San ThisaNo ratings yet

- C-TPAT Vendor Security QuestionnaireDocument10 pagesC-TPAT Vendor Security QuestionnaireCarlos MorenoNo ratings yet

- C-TPAT Glossary of TermsDocument9 pagesC-TPAT Glossary of TermsnghiaNo ratings yet

- C-TPAT Security AwarenessDocument27 pagesC-TPAT Security Awarenessferesza100% (1)

- C-TPAT Requirements For Import Suppliers - v3 (English Version)Document12 pagesC-TPAT Requirements For Import Suppliers - v3 (English Version)zoomerfins22No ratings yet

- IT, HR, Welfare, Store, Security RecordsDocument3 pagesIT, HR, Welfare, Store, Security RecordsNakibur RahmanNo ratings yet

- C-TPAT Questionnaire For Manufacturer 2020Document5 pagesC-TPAT Questionnaire For Manufacturer 2020r0yalgirlNo ratings yet

- Basic Security Measures For Guards in FacilityDocument18 pagesBasic Security Measures For Guards in FacilitySaltedBananaNo ratings yet

- CTPAT Required Document List and Security GuidelinesDocument19 pagesCTPAT Required Document List and Security GuidelinesLoan Huynh100% (1)

- CTPAT Questionnaire 1.3Document10 pagesCTPAT Questionnaire 1.3Faruque UddinNo ratings yet

- Physical Security Assessment Form PDFDocument17 pagesPhysical Security Assessment Form PDFMohamed ZhranNo ratings yet

- Seal Integrity: Customs-Trade Partnership Against TerrorismDocument38 pagesSeal Integrity: Customs-Trade Partnership Against TerrorismCarlos MorenoNo ratings yet

- C-TPAT INTERNAL AUDIT CHECKLIST REVIEWDocument15 pagesC-TPAT INTERNAL AUDIT CHECKLIST REVIEWmoctieudinh100% (1)

- Ctpat Documentation RequirementsDocument6 pagesCtpat Documentation RequirementsAkhil Sharma100% (1)

- C-TPAT Risk Assessment-Finished CartoonDocument2 pagesC-TPAT Risk Assessment-Finished CartoonFaruque UddinNo ratings yet

- Security Policy (Including The Prevention and Control of Violence & Aggression)Document19 pagesSecurity Policy (Including The Prevention and Control of Violence & Aggression)ahmed100% (1)

- Ctpat Security QuestionnaireDocument8 pagesCtpat Security QuestionnaireCarlos MorenoNo ratings yet

- WRAP Audit Procedure - (06.09.2022)Document1 pageWRAP Audit Procedure - (06.09.2022)Abdur Rahman SohagNo ratings yet

- Travel - Safety and SecurityDocument50 pagesTravel - Safety and SecurityLaura SurduNo ratings yet

- C-TPAT's Five Step Risk Assessment ProcessDocument44 pagesC-TPAT's Five Step Risk Assessment ProcessMarco SanchezNo ratings yet

- Information Security Risk Assessment The Qualitative Versus Quantitative DilemmaDocument6 pagesInformation Security Risk Assessment The Qualitative Versus Quantitative Dilemmamohammad.mamdooh9472No ratings yet

- Security Policy 02Document3 pagesSecurity Policy 02prabir_kalna5601No ratings yet

- Baseline Security Controls PolicyDocument5 pagesBaseline Security Controls PolicyClyde Ben BaleteNo ratings yet

- SASDOC-22 - General Documents Checklist For CTPAT or Security or SCAN Audit PDFDocument1 pageSASDOC-22 - General Documents Checklist For CTPAT or Security or SCAN Audit PDFFaruque Uddin0% (1)

- WRAP's 12 PrinciplesDocument3 pagesWRAP's 12 PrinciplesEmdad YusufNo ratings yet

- Access Control PolicyDocument5 pagesAccess Control PolicyClyde Ben BaleteNo ratings yet

- CTPAT Highway CarriersDocument48 pagesCTPAT Highway Carrierslezaa23No ratings yet

- 11 Security OrganisationsDocument21 pages11 Security OrganisationsZoltan NagyNo ratings yet

- Security Awareness Workshop: This Summary Paper Is Divided Into Five Sections, CoveringDocument22 pagesSecurity Awareness Workshop: This Summary Paper Is Divided Into Five Sections, Coveringralph3horses7192No ratings yet

- DIPLOMA IN ENFORCEMENT MANAGEMENT ASSIGNMENT 1 & 2 PRINCIPLES OF PHYSICAL SECURITYDocument17 pagesDIPLOMA IN ENFORCEMENT MANAGEMENT ASSIGNMENT 1 & 2 PRINCIPLES OF PHYSICAL SECURITYNEERESH KUMAR SRI DEVANNo ratings yet

- RohitDocument75 pagesRohitRobin PalanNo ratings yet

- Security Compliance Audit ReportDocument14 pagesSecurity Compliance Audit ReportAjiWidyartaNo ratings yet

- Physical Security ChecklistDocument7 pagesPhysical Security ChecklistdexterNo ratings yet

- Division of Information Technology Policy 18.2aDocument3 pagesDivision of Information Technology Policy 18.2aBara DanielNo ratings yet

- Riskassessment PDFDocument3 pagesRiskassessment PDFSecurity_Minded100% (1)

- Security Rules and Procedures June 17Document24 pagesSecurity Rules and Procedures June 17Sumitra RadhikaNo ratings yet

- Physical SecurityDocument20 pagesPhysical SecurityJudielyn CualbarNo ratings yet

- CTPAT Requirements: C-TPAT Means Customs Trade Partnership Against Terrorism Which Is The Result of September 11Document7 pagesCTPAT Requirements: C-TPAT Means Customs Trade Partnership Against Terrorism Which Is The Result of September 11honey zmeuyNo ratings yet

- Safety & Property Risk ManagementDocument46 pagesSafety & Property Risk ManagementzaidoNo ratings yet

- Ctpat AssessmentDocument20 pagesCtpat AssessmentchacovatolawNo ratings yet

- Physical Security 121013Document40 pagesPhysical Security 121013Myrick HongitanNo ratings yet

- Mobile Patrolling of GuardsDocument6 pagesMobile Patrolling of GuardsMuhammadShahidKhakiNo ratings yet

- EM01Document20 pagesEM01Anonymous B7pghh100% (1)

- C-TPAT Facility QuestionnaireDocument15 pagesC-TPAT Facility QuestionnaireShafiqulHasanNo ratings yet

- Physical Security: AttackerDocument20 pagesPhysical Security: AttackerRaf BelzNo ratings yet

- 2157 EISF June 2017 Security Risk Management A Basic Guide For Smaller NGOsDocument80 pages2157 EISF June 2017 Security Risk Management A Basic Guide For Smaller NGOsHabibullah MirhazarNo ratings yet

- Security Awareness Programs A Complete Guide - 2019 EditionFrom EverandSecurity Awareness Programs A Complete Guide - 2019 EditionNo ratings yet

- Security And Risk Management Tools A Complete Guide - 2020 EditionFrom EverandSecurity And Risk Management Tools A Complete Guide - 2020 EditionNo ratings yet

- Abbott C-TPAT Supply Chain Security QuestionnaireDocument7 pagesAbbott C-TPAT Supply Chain Security QuestionnaireCarlos MorenoNo ratings yet

- Itt AcknowledgementDocument1 pageItt Acknowledgementsiddharth jainNo ratings yet

- Detailed Advertisement For Recruitment of Security Guard Cum PeonDocument12 pagesDetailed Advertisement For Recruitment of Security Guard Cum PeonArunNo ratings yet

- Rop 133Document4 pagesRop 133msyan1965No ratings yet

- Borang Mohon VisaDocument4 pagesBorang Mohon Visanadirah400No ratings yet

- Quote: Indian Oil Corporation LimitedDocument4 pagesQuote: Indian Oil Corporation Limitedaj joshiNo ratings yet

- Job Advert-Technical Projects CoordinatorDocument3 pagesJob Advert-Technical Projects CoordinatorKenn MatibaNo ratings yet

- Registration For Enrollment FormDocument1 pageRegistration For Enrollment FormReno EsteroNo ratings yet

- Getting To Know You: Your Account Opening JourneyDocument1 pageGetting To Know You: Your Account Opening JourneyScribd AccountNo ratings yet

- PROJECT REPORT On Housing Loans at State Bank of IndiaDocument23 pagesPROJECT REPORT On Housing Loans at State Bank of IndiaDebjyoti Rakshit100% (2)

- ASAR New Reg FormDocument2 pagesASAR New Reg FormReshmiNo ratings yet

- Ticket 19674360399Document2 pagesTicket 19674360399abhay tiwariNo ratings yet

- PMAY Annexure B and C SBI BankDocument6 pagesPMAY Annexure B and C SBI BanktpchowoNo ratings yet

- Dualcitizenship ChecklistDocument1 pageDualcitizenship ChecklistTanya IñigoNo ratings yet

- The Real Cause of Being a Legal Fiction and the RemedyDocument20 pagesThe Real Cause of Being a Legal Fiction and the RemedyMalcolm Wilhelm100% (1)

- The Impact of Investigated The Current System of ID-card Processing System in IMT EnuguDocument35 pagesThe Impact of Investigated The Current System of ID-card Processing System in IMT EnuguIbrahim BasiruNo ratings yet

- West Virginia Drivers Handbook - West Virgina Drivers ManualDocument88 pagesWest Virginia Drivers Handbook - West Virgina Drivers ManualpermittestNo ratings yet

- MDocument175 pagesMDanielle Kiara ZarzosoNo ratings yet

- Microsoft® Corporation BoardDocument2 pagesMicrosoft® Corporation BoardTomy Firdaus GusasiNo ratings yet

- PENSDocument3 pagesPENSPraveen KumarNo ratings yet

- Starting Your Own BusinessDocument48 pagesStarting Your Own BusinessamfipolitisNo ratings yet

- Applicable: HQP-HLF-860 (V01, 08/2021)Document3 pagesApplicable: HQP-HLF-860 (V01, 08/2021)mskanne divineNo ratings yet

- Fa8 en Residence Permit Accompanying SpouseDocument13 pagesFa8 en Residence Permit Accompanying SpouseRaji ShankarganeshNo ratings yet

- CSSD Handbook Update-1-2019Document17 pagesCSSD Handbook Update-1-2019صفاء ساتيNo ratings yet

- Documents Required for a Housing Loan ApplicationDocument5 pagesDocuments Required for a Housing Loan ApplicationGajendra AudichyaNo ratings yet

- CPLP Handbook May2018 PDFDocument48 pagesCPLP Handbook May2018 PDFsrivenramanNo ratings yet

- 16630/malabar Express Third Ac (3A)Document2 pages16630/malabar Express Third Ac (3A)Joby ThomasNo ratings yet

- Welcome Circular No 4 2016-2017Document3 pagesWelcome Circular No 4 2016-2017api-262668586No ratings yet

- Postal Id FormDocument1 pagePostal Id FormRachelle Anne CuevasNo ratings yet