Professional Documents

Culture Documents

HR Model 4 Speed Short Drop

HR Model 4 Speed Short Drop

Uploaded by

HERNAN0 ratings0% found this document useful (0 votes)

47 views16 pagesOriginal Title

28000 HR Model 4 Speed Short Drop

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views16 pagesHR Model 4 Speed Short Drop

HR Model 4 Speed Short Drop

Uploaded by

HERNANCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

Maintenance and Service Manual

L Powershift @

7) Transmission &

Ct He HR MODEL 4 SPEED SHORT DROP Ill

See

COMPONENTS

CLARICHURTEH> ‘

‘SM HR28410 (Rev. 2-80)

Service Publications

1-77 at 1-40, Rt. 18, Box 38

Statesville, NC 28677

TOWING OR PUSH STARTING

Before towing the vehicle, be sure to lift the NOTE: If the transmission has 4 wheel drive,

rear wheels off the ground or disconnect the disconnect both front and rear drivelines.

driveline to avoid damage

mission during towing.

to

the trans- Because of the design of the hydraulic

system, the engine cannot be started by

pushing or towing

‘Copyright Clark Equipment Company, 1891

npublahod mera A ight reve

mit Distibuton

No pat of this work maybe reread in any form under

fy mare wot tect wren pemision of Cla

Equpment Comesny.

CLARK CLARK

MAINTENANCE & SERVICE MANUAL CORRECTIONS

FOR THE

28000 SERIES, 32000 SERIES & 34000 SERIES

Please keep this sheet with any 28000, 32000 or 34000 Mi

tenance and Service Manuals.

Use the following torque chart for the self locking elastic stop nut used on the input, output, idler

and P.T.O. shafts when repairing any of the above series transmissions.

Corrections will be made at the next individual Maintenance and Service Manual printing.

SELF LOCKING ELASTIC STOP NUT TORQUE

THREAD SIZE FT. LBS, TORQUE NEWTON METERS (N.m.)

1” - 20 150 - 200 203.4 - 271,1

| 1%" - 18 200 - 250 271,2 - 338,9 oh

1H" -18 300 - 350 406.8 - 474.5

I 1H" -12 7 400 - 450 542,4 - 610,1

9-172 3-08

TABLE OF CONTENTS

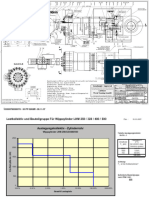

HR CONVERTER AND TRANSMISSION CASE GROUP... FIG. A

FOUR SPEED CLUTCH AND GEAR GROUP (SHORT DROP). . “FIG. B

28,000 FOUR SPEED SHORT DROP

ASSEMBLY INSTRUCTION SHEET =. se. ee IG

DISASSEMBLY OF TRANSMISSION =. - se eT

FOUR SPEED SHORT DROP POWER FLOW. =. 0. wwe

NOTE: Metric Dimensions Shown in Brackets [ 1.

CLARK

Figure A

CLARK

ITEM

u

12

13

4

5

16

”7

18

19

20

a

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

4

42

HR28000 CONVERTER AND TRANSMISSION CASE GROUP

(SHORT DROP OUTPUT)

DESCRIPTION

Suction Tube Assembly

Converter Housing and Tube Assembly

Tube Sleeve

Tube Sleeve

Converter Housing Sleeve

Converter Housing Sleeve Lock

Converter Housing Sleeve Screw

Lockwasher

Converter Housing Sleeve Screw

Converter Housing Sleeve Screw

Converter Housing Sleeve Screw

Lockwasher

Converter Housing Sleeve Lock

Converter Housing Sleeve

Breather

Street Ell

Reducing Bushing . ae

Tube Sleeve

Pipe Plug

Converter Housing to Transmission

Housing Screw Lockwasher

Converter Housing to Transmission

Housing Screw

Converter Housing to Transmission

Housing Lockwasher

Converter Housing to Transmission

Housing Screw

Lube Tube Retaining Screw

Lube Tube Retaining Screw Lockwasher

Valve Oil Supply Tube ...

3rd Speed Tube “O” Ring

Grd Speed Tube Assembly

Tube Clip

Tube Clip Serew Lockwasher

Tube Clip Screw

Lube Tube Assembly .

Lube Tube Retainer Screw Lockwasher

Lube Tube Retainer Screw

Reverse Tube “O" Ring

Reverse Tube Assembly

Tube Clip

Tube Clip Serew Lockwasher

Tube Clip Screw

Suction Tube “O” Ring

Retainer Screw Lockwasher

Suction Tube Retainer Screw

Tube Sleeve

Pressure Tube “O" Ring

ary.

ITEM

43

44

45

46

47

48

a

50

51

52

53

54

55

56

87

58

59

60

6

62

63

64

65

66

o7

638

0

70

n

72

73

74

75

76

7

78

79

80

al

82

DESCRIPTION ary.

Converter Housing to Transmission

Case Gasket nn : seve V

Converter Housing to Transmission

Case Dowel Pin ... aoe

Low Speed Clutch Pressure Tube ..... 1

Transmission Case to Converter

Housing Screw Lockwasher wl

Transmission Case to Converter

Housing Screw 10

Transmission Case Assembly occ

Transmission Case to Rear Cover

Dowel Pin’ 2

Transmission Case to Rear Cover

Gasket sevens V

Transmission Caso Rear Cover 1

Rear Cover to Case Serow Lockwasher ...13

Rear Cover to Case Serew nnn 13

Rear Cover Pipe Plug 1

Rear Cover to Transmission Case

Stud Nut . 2

Rear Cover to Transmission Case

Lockwasher

0" Ring =

Tube Sleeve 7

Transmission Case to Rear Cover Stud

Drain Plug .

Oil Level Plug . -

Screen Assembly Gasket...

Screen Assembly

Suction Tube Assembly ...

Suction Tube "O” Ring ..

2

Tube Sleeve 1

1

2

1

2

1

1

1

1

Suction Tube Retainer Washer coe

2

1

1

1

1

1

1

1

1

1

1

Suction Tube Retainer Washer Screw

Oil Distributor Retainer Ring ..

Distributor Lock Ball

Distributor and Plug Assembly

Distributor Retainer Ring

4th Clutch Lube Tube

Tube Sleeve .

Tube Sleeve “O" Ring -

Tube Sleove

Ath Speod Pressure Tube

4th Speed Pressure Tube “O" Ring

Control Valve Mounting Plate

(Remote Mounting)

Valve Plate Serew —

Valve Plate Screw Lockwasher

Valve Plate Plug

Valve Cover Plate

Figure B

CLARK

Tem

o

CLARK

28000 SERIES FOUR SPEED CASE AND CLUTCH GROUP

(SHORT DROP OUTPUT)

DESCRIPTION

Clutch Shaft Piston Ring

Cluich Shaft Front Bearing Retainer Ring

Clutch Shaft Front Bearing

Clutch Shaft Front Bearing Retainer Ring

Clutch Griven Gear Bearing—Shield

must face out

Clutch Driven Gear Bearing Locating

Ring

Clutch Driven Gear

Clutch Driven Gear Oil Baffle Ring

Clutch Driven Gear Bearing Locating

Ring

Clutch Driven Gear Bearing .

Spring Retainer Snap Ring

Spring Retainer

Piston Return Spring

Spring Retainer

Reverse and 3rd Clutch Shaft and Drum

Spring Retainer 7

Piston Return Spring

Spring Retainer

Spring Retainer Snap Ring .

3rd Gear Bearing

3rd Gear Bearing Snap Ring ..

3rd Gear Oil Baffle Ring .

3rd Gear

3rd Gear Bearing Spacer

3rd Gear Bearing Snap Ring

3rd Gear Bearing—Shield must face out.

Reverse and 3rd Shaft Rear Bearing...

2nd Gear wo

Clutch Hub Oil Baffle Ring

2nd Gear Retainer Ring :

Spring Retainer Snap Ring .

Spring Retainer

Piston Return Spring

Spring Retainer

Forward and 2nd Clutch Shaft and Drum .

Spring Retainer

ston Return Spring

Spring Retainer

Spring Retainer Snap Ring - 7

Clutch Driven Gear Bearing ....

Clutch Driven Gear Bearing Snap Ring

Clutch Hub Oil Baffle Ring

Clutch Driven Gear

Bearing Snap Ring

Clutch Driven Gear Bearing—Shield

must face out

Front Bearing Retainer Ring

Front Bearing Locating Ring ....

Forward and 2nd Front Bearing

Front Bearing Retainer Ring 7

Clutch Shaft Piston Ring

Low Speed Clutch Shaft Pilot Bearing

2nd Gear Bearing End Plate

2nd Gear Bearing

Low Speed Gear Bearing Ret:

low Speed Gear Bearing Assembly .....

avy.

3

i

1

1

oT

ITEM

109,

110

Mm

12

113

DESCRIPTION

Low Speed Gear

Clutch Hub Oil Baffle Ring

Bearing Retainer Ring

Spring Retainer Snap Ring

Spring Retainer

Piston Return Spring

Spring Retainer

Low Speed Clutch Shaft and Drum

Low and 4th Clutch Drive Gear

Gear Retainer Ring

Low Speed Shaft Rear Bearing

Low Speed Shaft Rear Bearing

Retainer Ring

Clutch Shaft Piston Ring

Clutch Shaft Piston Ring,

Rear Bearing Cap Gasket

Rear Bearing Cap

Rear Bearing Cap Screw Lockwasher

Rear Bearing Cap Screw

Rear Bearing Cap Plug

Output Shaft Bearing Cap

Speedo Gear Tube Nut

Speedo Gear

Rear Bearing Cap “O" Ring

Bearing Cap Gasket

Lock Ball

Output Shaft Rear Bearing Assembly

Rear Bearing Locating Ring

Speedo Drive Gear

Bearing Cap Screw

Bearing Cap Screw Lockwasher

Flange Oil Seal

Ovtput Flange

Flange “O" Ring

Flange Washer

Flange Nut

4th Gear Piston Ring

4th Gear Bearing Retaining Ring

Output Shaft Front Bearing :

4th Gear Front Bearing Locating Ring

4th Gear Bearing

4th Gear Spacer

4th Gear

4th Gear Bearing

Spring Retainer Snap Ring :

Spring Retainer

Return Spring ae

Clutch Hub Oil Baffle Ring

Backing Plate Snap Ring

Clutch Dise Backing Plate

Clutch Inner Dise

Clutch Outer Dise

Clutch Piston Assembly

Clutch Piston Outer Seai Ring

Output Shaft Gear :

Output Shaft :

4th Cluich Drum and Hub Assembly

4th Cluich Drum Locating Ring

Clutch Piston Inner Seal Ring

ary.

CLARK CLARK

CLARK CLARK

HR MODEL 4-SPEED (SHORT DROP)

INTEGRAL TRANSMISSION AND CONVERTER

To be used in conjunction with HR 28000 Series 3-Speed Manual

Number SMHR28310

‘The 4-tpeed information contained herein must be used in conjunction with the HR28310 Series 3-Speed Short

Drop Maintenance and Service Manual, the difference being in the output shaft. The 4-speed unit has a clutch

added to the output shaft.

DISASSEMBLY

Use Figures 1 thru 49 and Figure 51 in the HR 28000

Series 3-Speed Short Drop Output Manual.

Figure 50 shows the 3-speed output shaft and gear

assembly. The 4-speed unit has the fourth speed clutch

con the output shaft. See Figure 50A

Figure 2

Remove low speed gear taper be

retainer ring.

Figure 50A

Remove output shaft and 4th speed clutch assembly.

CLUTCH DISASSEMBLY

NOTE: DO NOT MIX THE FRICTION DISCS IN

THE LOW CLUTCH WITH THE FRICTION DISCS

OF ANY OF THE OTHER CLUTCHES. (SEE NOTE

FOLLOWING FIGURE 8.)

Figure 3

LOW CLUTCH DISASSEMBLY Remove low speed gear and outer taper bearing.

—— Figure 4

‘woe?

Remove clutch end plate retainer ri

Figure 1 Remove tlutch end plate and inner and outer clutch

Remove low clutch shaft front bearing inner race. discs.

Remove low gear inner taper bearing.

Figure 6

Remove clutch piston return spring. A sieeve with a

portion removed is recommended for removing the

clutch piston return spring, washer, and retainer ring.

Sleeve shown is a common pipe, with a 1-1/2" wide

x 1" high opening. The pipe is 6” long 3-1/4 0.0.

2.3/4 1.D. Compress spring retainer washer. Through

‘opening remove spring retainer snap ring. Release

fension on spring retainer. Remove spring retainer

and spring. Turn clutch over and tap clutch shaft on

a block of wood to remove clutch piston.

LOW CLUTCH REASSEMBLY

Figure 7

Install new clutch piston inner and outer sealing ring.

Insert piston into clutch drum using caution as not to

damage seals. Position piston return spring, spring

retainer and retainer snap ring. Compress spring and

retainer and install snap ring.

Figure 8

Install low gear inner taper bearing,

Install one steel disc.

Install one friction dise, NOTE: The friction dises in

the low clutch has a higher co-efficient rating than the

friction dises in the othor clutches, therefore the dises

must not be mixed. The low clutch inner dise can be

identified by an “X" stamped on one side of the inner

teeth, The low clutch inner disc also has a strip of

non-soluble yellow paint sprayed on the outer edge

of the dise. Alternate steel and friction discs until the

proper amount of discs are installed. First disc next

to the piston is steel, last dise is friction.

%

Figure 9

Install end plate and retainer ring.

Figure 10

ww clutch taper bearing spacer. NOTE: When

installing the 3rd gear in the 3rd speed clutch a bear-

ing spacer is used between the inner and outer 3rd

gear bearing also.

Instal

CLARK CLARK

< at +

Ww

Figure 11

Install low gear Into clutch drum. Align splines on ;

low gear with internal teeth of fricion discs. Tap geer Figure 14

1 een Delnst focce this operation, Gear foimes Install low clutch shaft front bearing inner race with

must be in full position with internal teeth of all fric- large diameter of race down.

tion discs.

¥ 4th CLUTCH DISASSEMBLY

Na

Figure 12

Install low gear outer taper bearing.

Figure 15

Remove clutch shaft piston rings.

Figure 13

Install low clutch taper bearing retainer ring.

NOTE: Retainer ring is selected at assembly for proper

Variable thickness rings are used in snap :

ring grooves to assure proper taper bearing tightness. Figure 16

Check ring 38 shown for fight ring to bearing fi. Remove front bearing retainer ring and front bearing.

CLARK

m

Figure 17.

Remove front bearing locating ring,

Figure 18

Remove 4th gear from clutch drum.

LG

ne |

a,

vd

Pa

,

igure 19

Remove inner bearing spacer and inner bearing. Dis-

assemble clutch discs and piston as explained in Figure

65 through Figure 69 in 3 Speed Short Drop Manual.

4th CLUTCH REASSEMBLY

Install piston, piston return spring and inner and outer

discs as explained in Figure 70 through 75 in 3 Speed

Short Drop Manual.

Figure 20

Install 4th speed gear inner be:

Part Number must go down. See

=_—"

19. NOTE: Bearing

igure 22-A.

Figure 21

Install beering spacer between inner and outer 4th

speed gear bearings.

Install 4th speed gear into clutch drum. Align splines

on clutch gear with internal teeth of frietion dises. Tap

gear into position. Do not force this operation. Gear

splines must be in full position with internal teeth of

all friction discs.

Pe

Figure 22

Install 4th speed gear outer bearing. NOTE: Bearing

Part Number must go up. See Figure 22-A. It is recom-

mended a rubber band be used to hold outer bearing

rollers in position when installing bearing.

OUTER BEARING

Par NUMBER

BEARING SPRCER.

INNER BEARING PART NUMBER MUST BE DOWN:

Figure 228

Figure 23

Install front bearing locating ring.

Figure 24

Install front bearing and bearing retai

+ ring,

CLARK

Figure 25

Install clutch shaft piston rings.

Proceed with Figure 92 in 3-speed Short Drop Manval.

Figure 938

Install output shaft and 4th speed clutch assembly in

housing.

Proceed with Figure 94 in 3-speed Short Drop Manual,

to complete reassembly.

NOTE: On the 4-speed short drop transmission, a bear-

ing end plate must be positioned between the 2nd

speed bearing and 2nd speed gear.

CLARK

CLARK

COLOR KEY e—

== 1ST (LOW) cc

Sa =

==> snp Cee —

eat oi ] =

SSE)

4 SPEED (SHORT DROP) TRANSMISSION

CLARICHURTEH>

Statesville, North Carolina

Brugge, Belgium

Arco, Italy

Sao Paulo, Brazil Price $8.00

59-905.0007

PRINTED IN U.S.A.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Clark 13.2MHR2442 HR18000-24000Document49 pagesClark 13.2MHR2442 HR18000-24000HERNANNo ratings yet

- Plano de Caja Lieberth 70 Ton.Document84 pagesPlano de Caja Lieberth 70 Ton.HERNANNo ratings yet

- Cilindro de T4Document3 pagesCilindro de T4HERNANNo ratings yet

- Acumulador SadesaDocument20 pagesAcumulador SadesaHERNANNo ratings yet

- 4 Speed LDDocument150 pages4 Speed LDHERNAN100% (1)

- Komatsu D60-65 Ae010Document63 pagesKomatsu D60-65 Ae010HERNAN100% (1)

- Manual Clark 24000Document52 pagesManual Clark 24000HERNANNo ratings yet

- Tester HidraulicoDocument2 pagesTester HidraulicoHERNANNo ratings yet

- R and HR 3, 6, & 8 LDDocument156 pagesR and HR 3, 6, & 8 LDHERNANNo ratings yet

- Transmision Clarkoht-5000Document62 pagesTransmision Clarkoht-5000HERNANNo ratings yet

- UntitledDocument1 pageUntitledHERNANNo ratings yet

- R 3 Speed Long DropDocument55 pagesR 3 Speed Long DropHERNANNo ratings yet

- 3 - 6 - Long DropDocument126 pages3 - 6 - Long DropHERNANNo ratings yet

- Transmision 6 WG 115Document72 pagesTransmision 6 WG 115HERNANNo ratings yet

- SMV M7707-12993Document387 pagesSMV M7707-12993HERNAN100% (1)

- Clark 36000Document45 pagesClark 36000HERNAN50% (2)

- Clark C 16000Document40 pagesClark C 16000HERNANNo ratings yet

- Clark 20000Document190 pagesClark 20000HERNANNo ratings yet

- R-HR & LFHR Model 3 Speed Long DropDocument123 pagesR-HR & LFHR Model 3 Speed Long DropHERNANNo ratings yet

- HR 4 Speed Long DropDocument97 pagesHR 4 Speed Long DropHERNANNo ratings yet