Professional Documents

Culture Documents

Assignment Ii

Uploaded by

Noor AlamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

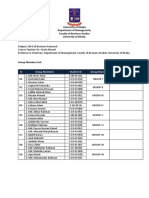

Assignment Ii

Uploaded by

Noor AlamCopyright:

Available Formats

Kernels Company manufactures four unique products A, B, C and D which are produced at five different

workstations V, W, X, Y and Z. Kernels company make and sell up to the limit of its demand per week.

Total amount of purchased raw materials for product A, B, C and D are tk.22, tk.18, tk.16 and tk.12.Each

worker paid tk. 25 per hour. Overhead costs are tk. 7000 per week. The plant operates 40 hours per

week. Five workers work in the company.

Manager of the organization believes that profitability can be improved if bottleneck resources were

exploited to determine the product mix. Price of product A, B, C and D are tk.85, tk.82, tk.45 and tk.40.

(i) Draw flowchart for each product from the following table.

Product A Product B Product C Product D

(Weekly Demand 65 (Weekly Demand 75 (Weekly Demand 85 (Weekly Demand

units ) units ) units ) 90 units )

Station minutes Station minutes Station minutes Station minutes

Step1:V 25 Step1:Y 10 Step1:W 8 Step1:W 13

Step2:y 12 Step2:X 18 Step 2:Z 10 Step 2:Z 12

Step3:X 13 Step3:V 4 Step 3:X 6 Step 3:Y 8

(ii) Calculate the profit margin per unit of each product and per unit of processing time at

bottleneck workstation.

(iii) Which workstation serves as the bottleneck according to workload?

(iv) Identify the best product mix according to traditional approach and bottleneck based

approach.

(iv) Calculate the change in profits by using the bottleneck based scheduling method

You might also like

- Group-I - Business-Research-Term-Paper (Chapter-10 - Collecting Data Using Attitudinal Scales)Document9 pagesGroup-I - Business-Research-Term-Paper (Chapter-10 - Collecting Data Using Attitudinal Scales)Noor AlamNo ratings yet

- Chapter Wise SummaryDocument2 pagesChapter Wise SummaryNoor AlamNo ratings yet

- 3-20-44-021 - Case Study On 'COW WOW CEREAL MILK'Document2 pages3-20-44-021 - Case Study On 'COW WOW CEREAL MILK'Noor AlamNo ratings yet

- EM-518 Business Research - Group NameDocument1 pageEM-518 Business Research - Group NameNoor AlamNo ratings yet

- EM-518 (3-20-44-021) Business Research - Research Report StructureDocument3 pagesEM-518 (3-20-44-021) Business Research - Research Report StructureNoor AlamNo ratings yet

- Cultural GlobalizationDocument7 pagesCultural GlobalizationNoor AlamNo ratings yet

- Capital Budgeting Decision - 05112021Document4 pagesCapital Budgeting Decision - 05112021Noor AlamNo ratings yet

- Md. Noor Alam - (3-20-44-021) - EM-559 Globalization and Strategy - Mid Term-IDocument13 pagesMd. Noor Alam - (3-20-44-021) - EM-559 Globalization and Strategy - Mid Term-INoor AlamNo ratings yet

- MBA (Evening), University of DhakaDocument3 pagesMBA (Evening), University of DhakaNoor AlamNo ratings yet

- EM-517-Advanced Management - Lecture-02Document6 pagesEM-517-Advanced Management - Lecture-02Noor AlamNo ratings yet

- Lecture 1 LEBDocument13 pagesLecture 1 LEBNoor AlamNo ratings yet

- EM-555 - LECTURE-4 - The Essential Elements of ContractDocument4 pagesEM-555 - LECTURE-4 - The Essential Elements of ContractNoor AlamNo ratings yet

- MID 2 LEB Spring22Document1 pageMID 2 LEB Spring22Noor AlamNo ratings yet

- MBA (Evening), University of Dhaka: Assignment - 01Document5 pagesMBA (Evening), University of Dhaka: Assignment - 01Noor AlamNo ratings yet

- Solution One Problem of Productivity, Decision Tree and Break-Even AnalysisDocument5 pagesSolution One Problem of Productivity, Decision Tree and Break-Even AnalysisNoor AlamNo ratings yet

- Introduction To Operations and Production: DR S. Sridhar AimitDocument94 pagesIntroduction To Operations and Production: DR S. Sridhar AimitNoor AlamNo ratings yet

- Chapter-1 Nature of Financial ManagementDocument32 pagesChapter-1 Nature of Financial ManagementNoor AlamNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)