Professional Documents

Culture Documents

Min-Ft-Phoenix-Paquete 3-Ots-221

Uploaded by

Alfredo SecceOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Min-Ft-Phoenix-Paquete 3-Ots-221

Uploaded by

Alfredo SecceCopyright:

Available Formats

Project Shougang, 812-CB-210/240

splice layout 1200 ST3150 10,5/5,5 X/EOB

04.11.2014

belt running direction B.v.Heimburg

1 1

2 2

3 3

4 4

5 5

. .

. .

. .

. .

34 34

35 35

36 36

37 37

38 38

39 39

40 40

41 41

42 42

43 43

44 44

. .

. .

. .

. .

73 73

74 74

75 75

76 76

77 77

150 650 (50) 650 150

1650

Drawing not true to scale

© Copyright PHOENIX Conveyor Belt Systems GmbH

Project Shougang, 812-CB-210/240

splice layout 1200 ST3150 10,5/5,5 X/EOB

04.11.2014

cable pattern left side belt running direction B.v.Heimburg

1

2

3

4

5

.

.

.

.

34

35

36

37

38

39

40

41

42

43

44

.

.

.

.

73

74

75

76

77

800

1500

Drawing not true to scale

© Copyright PHOENIX Conveyor Belt Systems GmbH

Project Shougang, 812-CB-210/240

splice layout 1200 ST3150 10,5/5,5 X/EOB

04.11.2014

belt running direction cable pattern right side B.v.Heimburg

1

2

3

4

5

.

.

.

.

34

35

36

37

38

39

40

41

42

43

44

.

.

.

.

73

74

75

76

77

800

1500

Drawing not true to scale

© Copyright PHOENIX Conveyor Belt Systems GmbH

Project Shougang, 812-CB-210/240

splice layout 1200 ST3150 10,5/5,5 X/EOB

04.11.2014

B.v.Heimburg

splice assembly

9,0 mm top cover rubber

2,0 mm bonding rubber

7,6 mm cords + intermediate rubber 2,3 x 8,5 mm

2,0 mm bonding rubber

4,0 mm bottom cover rubber

nominal belt thickness: 23,6 mm

condition of cable surface

Drawing not true to scale

© Copyright PHOENIX Conveyor Belt Systems GmbH

Project Shougang, 812-CB-210/240

splice layout 1200 ST3150 10,5/5,5 X/EOB

04.11.2014

B.v.Heimburg

T [°C]

vulcanisation

temperature

press

dismounting

temperature

curing time t [min]

vulcanization parameters for PHOENIX splice rubber

pressure: 12...14 bar

temperature: 155 °C (+/- 5 K)

vulcanization time: 75 min

press dismounting temperature: < 60°C

Drawing not true to scale

© Copyright PHOENIX Conveyor Belt Systems GmbH

You might also like

- Angels in The Bleak Midwinter-TrompetaDocument1 pageAngels in The Bleak Midwinter-Trompetajorge farquezNo ratings yet

- FMOD Transition - Violin IIDocument2 pagesFMOD Transition - Violin IISergio de MiguelNo ratings yet

- 5 Chan Chan TrumpetDocument2 pages5 Chan Chan Trumpetcamilolopera87No ratings yet

- Cruisin Susan - OboeDocument2 pagesCruisin Susan - Oboejojo burroNo ratings yet

- Moliendo Cafe 3 - Tenor-SaxofoonDocument2 pagesMoliendo Cafe 3 - Tenor-SaxofoonmcamposamievaNo ratings yet

- Sentenced - MournDocument3 pagesSentenced - Mournamin bakiNo ratings yet

- Radioactive - Paul - Murtha ClarinetDocument1 pageRadioactive - Paul - Murtha ClarinetmabekNo ratings yet

- Drum - I Do It For YouDocument1 pageDrum - I Do It For YouUrloliberoNo ratings yet

- Who Growth Chart Girls - Birth To 2 YearsDocument5 pagesWho Growth Chart Girls - Birth To 2 YearsReylinge Relia MargouwNo ratings yet

- Ramones - The KKK Took My Baby AwayDocument2 pagesRamones - The KKK Took My Baby AwayImportaciones e Inversiones CYH100% (1)

- Killing in The Name Distortion Guitar 2Document2 pagesKilling in The Name Distortion Guitar 2AKSAR HIBURNo ratings yet

- Aida Sax Alto FDocument1 pageAida Sax Alto FLumevi 76No ratings yet

- 3rd Technical Analysis Training by Ayman WakedDocument25 pages3rd Technical Analysis Training by Ayman WakedKaushik ShahNo ratings yet

- 4831586-I Say A Little PrayerDocument1 page4831586-I Say A Little PrayerSimone MedaglianiNo ratings yet

- Answer Sheet SHADINGDocument2 pagesAnswer Sheet SHADINGRACHEL ABENo ratings yet

- D6R Track-Type Tractor Differential Steering 1RW00001-UP (MACHINE) POWERED BY 3306 Engine (SEBP2616 - 79) - Por Palabra ClaveDocument4 pagesD6R Track-Type Tractor Differential Steering 1RW00001-UP (MACHINE) POWERED BY 3306 Engine (SEBP2616 - 79) - Por Palabra ClaveDey MayNo ratings yet

- Daftar Hadir PrintDocument9 pagesDaftar Hadir PrintWiky Asri IswandiNo ratings yet

- Maranata 16 PDFDocument1 pageMaranata 16 PDFElias AraujoNo ratings yet

- Maranata 16 PDFDocument1 pageMaranata 16 PDFElias AraujoNo ratings yet

- Sax AltoDocument1 pageSax AltoLumevi 76No ratings yet

- Accidental Blues - Alto SaxDocument1 pageAccidental Blues - Alto Saxjojo burroNo ratings yet

- 03 Mini-Basketball Scoresheet GuidelinesDocument2 pages03 Mini-Basketball Scoresheet GuidelinesRichard Merck Mendoza100% (1)

- E.T. - ViolaDocument3 pagesE.T. - ViolaOmarSalazarHidalgoNo ratings yet

- Ele Não Desiste de Você SIBELIUS 5 Violin 1Document1 pageEle Não Desiste de Você SIBELIUS 5 Violin 1Adeilton santosNo ratings yet

- Aida Trompeta FDocument1 pageAida Trompeta FLumevi 76No ratings yet

- Vehicle Ides of March Alto SaxDocument1 pageVehicle Ides of March Alto SaxPim van Harten0% (1)

- Daftar Hadir PesertaDocument5 pagesDaftar Hadir PesertaWiky Asri IswandiNo ratings yet

- Just The Two of Us: Alto SaxophoneDocument1 pageJust The Two of Us: Alto SaxophoneOlesyaKosarevaNo ratings yet

- Pepper March: BB Trombone 1Document3 pagesPepper March: BB Trombone 1rui fragataNo ratings yet

- Moderate 180 Intro 1: Standard TuningDocument4 pagesModerate 180 Intro 1: Standard TuningZombieMrCazNo ratings yet

- Rob Cantor - Sheet Music - SHIA LABEOUF - LIVE - Full Score - Drum SetDocument2 pagesRob Cantor - Sheet Music - SHIA LABEOUF - LIVE - Full Score - Drum SetFake AccountNo ratings yet

- Angra - Spread Your Fire - Partitura BateriaDocument9 pagesAngra - Spread Your Fire - Partitura BateriawiLLiam ParedesNo ratings yet

- Tinh Thoi Xot Xa - Strings-GuitarDocument3 pagesTinh Thoi Xot Xa - Strings-Guitarson anhNo ratings yet

- El Condor Pasa PDFDocument2 pagesEl Condor Pasa PDFBohi StarNo ratings yet

- La Dama Del Lago Fantasma Cap 5 Brass-Tenor SaxophoneDocument3 pagesLa Dama Del Lago Fantasma Cap 5 Brass-Tenor SaxophoneLuis MardonesNo ratings yet

- Cant Take My Eyes Off You - Frankie Valli Jazz Band Arrangement-Trombone 1Document3 pagesCant Take My Eyes Off You - Frankie Valli Jazz Band Arrangement-Trombone 1Gabriel Jiménez (GrabrielJiménezTrova)No ratings yet

- Himno A La AlegriaDocument4 pagesHimno A La AlegriaBeltran Colque TrujilloNo ratings yet

- Vehicle Ides of March TrumpetDocument1 pageVehicle Ides of March TrumpetPim van Harten100% (1)

- Meu TributoDocument1 pageMeu TributoKarolineNo ratings yet

- Sway (Quien Sera) - Saxofón Alto 1Document2 pagesSway (Quien Sera) - Saxofón Alto 1jhojanNo ratings yet

- Highly Strung: Orianthi BelieveDocument2 pagesHighly Strung: Orianthi BelievePaul CruzNo ratings yet

- TRP Melodias Tarijeñas-1Document2 pagesTRP Melodias Tarijeñas-1AlvaroNo ratings yet

- Bajo Melodias Tarijeñas-1Document2 pagesBajo Melodias Tarijeñas-1AlvaroNo ratings yet

- 02 Oye Lo Que Te Conviene 8 y Mas Drums PDFDocument3 pages02 Oye Lo Que Te Conviene 8 y Mas Drums PDFLeonardo Rafael GonzálezNo ratings yet

- Report & Assessment Sheet For The Month of - Report & Assessment Sheet For The Month ofDocument2 pagesReport & Assessment Sheet For The Month of - Report & Assessment Sheet For The Month ofPrakash SantraNo ratings yet

- Users RecordDocument2 pagesUsers RecordPrakash SantraNo ratings yet

- Liberanos - CornoDocument1 pageLiberanos - CornoLorena MuzzilliNo ratings yet

- Fire Ring Lead GuitarDocument3 pagesFire Ring Lead GuitarMinmaw SoeNo ratings yet

- Plantilla TelarDocument1 pagePlantilla TelarCatherine PintoNo ratings yet

- Cruisin Susan - Clarinet in BB 2Document2 pagesCruisin Susan - Clarinet in BB 2jojo burroNo ratings yet

- To The Bone - KeysDocument4 pagesTo The Bone - KeysJavier Jimenez VillatoroNo ratings yet

- BOE Transportation Presentation 11-17-21Document4 pagesBOE Transportation Presentation 11-17-21MarianNo ratings yet

- Lintasan Pengukuran Kebugaran Jasmani Methode Single Test Lari 1.000 M / 1.600 MDocument12 pagesLintasan Pengukuran Kebugaran Jasmani Methode Single Test Lari 1.000 M / 1.600 MAndy KurniantoNo ratings yet

- Who Do You Think You Are: Not For Sale - Free Bass Transcription For The Studies and Private Use OnlyDocument3 pagesWho Do You Think You Are: Not For Sale - Free Bass Transcription For The Studies and Private Use OnlyGabriel Forlani ZaraNo ratings yet

- Blue Whale by NecruSDocument4 pagesBlue Whale by NecruSJuan MarinNo ratings yet

- Oipl2009 - Ap0901010 Multimo 360 UkDocument2 pagesOipl2009 - Ap0901010 Multimo 360 UkAdrianNo ratings yet

- Blue Whale by NecruSDocument4 pagesBlue Whale by NecruSpaula acostaNo ratings yet

- O Rosto de Cristo - Alto Sax 1Document1 pageO Rosto de Cristo - Alto Sax 1Matheus Domingues BorgesNo ratings yet

- The Toyota Kata Practice Guide: Practicing Scientific Thinking Skills for Superior Results in 20 Minutes a DayFrom EverandThe Toyota Kata Practice Guide: Practicing Scientific Thinking Skills for Superior Results in 20 Minutes a DayRating: 4.5 out of 5 stars4.5/5 (7)

- BMR Calamine CreamDocument5 pagesBMR Calamine Creamzaraorganics99No ratings yet

- Chimney Sizing Chart For Fireplaces: 100 50 30 20 15 10 8 Flue Area, inDocument1 pageChimney Sizing Chart For Fireplaces: 100 50 30 20 15 10 8 Flue Area, inBen ZithaNo ratings yet

- 3 PlasticsDocument33 pages3 Plasticsabhijit bhattacherjeENo ratings yet

- Mse 21604Document4 pagesMse 21604chandsixNo ratings yet

- Engineering Materials by RK RajputDocument528 pagesEngineering Materials by RK Rajputmv599766No ratings yet

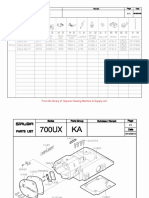

- Siruba 700UX Parts ListDocument23 pagesSiruba 700UX Parts Listgarciac12No ratings yet

- Summary of Micro-ManufacturingDocument7 pagesSummary of Micro-ManufacturingUrgie KuNo ratings yet

- RW Ti Product Catalog Prorox IndiaDocument36 pagesRW Ti Product Catalog Prorox IndiaPro ariaNo ratings yet

- Finals 2Document15 pagesFinals 2Ghonel RootNo ratings yet

- Ratlam 30 KLD STP Along With Extra TankDocument1 pageRatlam 30 KLD STP Along With Extra TankPrabal singhNo ratings yet

- 2019 Jot FallDocument86 pages2019 Jot Fallahmed kabelNo ratings yet

- Eutectic Eutronic Arc Spray 4 HFDocument4 pagesEutectic Eutronic Arc Spray 4 HFjhonatan VBNo ratings yet

- Car Park ShadeDocument2 pagesCar Park ShadeG RajakumarNo ratings yet

- History of MetalockDocument8 pagesHistory of MetalockJefferson RojasNo ratings yet

- Ni Electroless Plating of ABS Polymer by Palladium and Tin-Free ProcessDocument9 pagesNi Electroless Plating of ABS Polymer by Palladium and Tin-Free ProcessAleksandr BykovNo ratings yet

- RHEWUM QuestionnaireDocument2 pagesRHEWUM QuestionnairePrashanth ChinthallapallyNo ratings yet

- Abdelwahab 2017Document6 pagesAbdelwahab 2017DivyaNo ratings yet

- WM 1210Document32 pagesWM 1210Nisa KgNo ratings yet

- Internship ReportDocument27 pagesInternship Reportwww.chandangowda1128No ratings yet

- 8 Wastes of Lean Manufacturing - DOWNTIME - TIMWOODSDocument20 pages8 Wastes of Lean Manufacturing - DOWNTIME - TIMWOODStemaquijaNo ratings yet

- MobicatDocument44 pagesMobicatImnotresulNo ratings yet

- ASTM A789 Duplex Stainless TubingDocument10 pagesASTM A789 Duplex Stainless Tubingmathew holeyNo ratings yet

- Report Project g03 - Motorcycle Clutch HubDocument4 pagesReport Project g03 - Motorcycle Clutch HubMUHAMMAD FARIZ ZAINUDDINNo ratings yet

- TDS Resichim R812 - RompolimerDocument1 pageTDS Resichim R812 - RompolimerdanNo ratings yet

- (1-2) and 1111. (1-2) - 2015 - ISO Meteric Hexagon Bolts and ScrewsDocument88 pages(1-2) and 1111. (1-2) - 2015 - ISO Meteric Hexagon Bolts and ScrewsMark Carroll-ChiltsNo ratings yet

- GBM Scaffolding Catalogue 2019Document16 pagesGBM Scaffolding Catalogue 2019Vas SteelNo ratings yet

- Heavy-Duty Metal Repair Compound: Trust Corium FORDocument2 pagesHeavy-Duty Metal Repair Compound: Trust Corium FORchem KhanNo ratings yet

- Main Changes in BV Rules On Materials and Welding For The Classification of Marine UnitsDocument3 pagesMain Changes in BV Rules On Materials and Welding For The Classification of Marine UnitshamzaNo ratings yet

- Surface Cleaning Brush Maintenance ToolDocument1 pageSurface Cleaning Brush Maintenance Toolkamal_khan85No ratings yet

- 3M Infrastructure Coating - EMD Overview For Indonesia TeamDocument38 pages3M Infrastructure Coating - EMD Overview For Indonesia TeamYohanes Dimas PriambodhoNo ratings yet