Professional Documents

Culture Documents

WIKA Pressure Transmitter

Uploaded by

paulo maximoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WIKA Pressure Transmitter

Uploaded by

paulo maximoCopyright:

Available Formats

Electronic

pressure measurement

Process transmitter

Model UPT-20, with pressure port

Model UPT-21, with flush diaphragm

WIKA data sheet PE 86.05

®

for further approvals

see page 10

Applications

■■ Control and process technology

■■ Machine building and plant construction

■■ Pharmaceutical and hygienic industries

■■ Food industry

■■ Chemical, petrochemical industry

Special features

■■ Multi-functional display

■■ Simple menu navigation

■■ Conductive plastic case or stainless steel case (optionally

with electropolished surface)

■■ Large LC display, rotatable

■■ Approvals for hazardous areas

Process transmitter, model UPT-20

Fig. left: Plastic case

Fig. right: Stainless steel case with electropolished

surface

Description

Instrument construction HART protocol

The model UPT-2x process transmitter has been developed The process transmitter can be installed both in applications

for applications which require an intelligent sensor. Particu- using analogue technique and modern systems communicat-

larly the integrated temperature compensation makes the ing via the HART protocol.

process transmitter interesting for a wide range of applica-

tions. Via the display and operating module or the HART interface

this process transmitter can be configured directly on site or

The measuring cell is made of stainless steel 316L or of a remotely via a process control system.

combination with high-quality Elgiloy.

Turndown

The case is rotatable by 330° and the LC display can be An adjustable turndown allows to register exact process

mounted in different positions, displaceable in 90° steps. The values with optimised limits of the measuring values and

LC display is easy to read in any mounting position, even from without major restrictions of the accuracy.

a distance of up to 5 m.

WIKA data sheet PE 86.05 ∙ 04/2016 Page 1 of 14

Data sheets showing similar products:

Process transmitter; models IPT-10 and IPT-11; see data sheet PE 86.11

Measuring ranges

Gauge pressure

bar 0 ... 0.4 0 ... 1.6 0 ... 6 0 ... 16 0 ... 40 0 ... 100

0 ... 250 0 ... 600 0 ... 1,000

psi 0 ... 10 0 ... 15 0 ... 30 0 ... 100 0 ... 300 0 ... 500

0 ... 1,500 0 .... 5,000 0 ... 10,000 0 ... 15,000

1) 1) For model UPT-20: The value specified in the table applies only when sealing is made using a sealing ring below the hexagon. Otherwise max. 1,600 bar applies.

Absolute pressure

bar 0 ... 1.6 0 ... 6 0 ... 16 0 ... 40

psi 0 ... 30 0 ... 100 0 ... 300 0 ... 500

Vacuum and +/- measuring ranges

bar -1 ... 0 -0.2 ... +0.2 -1 ... +0.6 -1 ... +5 -1 ... +15 -1 ... +40

psi -14.5 ... 0 -14.5 ... +15 -14.5 ... +100 -14.5 ... +300 -14.5 ... +600

Other measuring ranges can be set via turndown.

For measuring ranges above 600 bar only the model UPT-20

is available.

Vacuum tightness

Vacuum resistance is provided, except for instruments for

oxygen applications.

Overpressure limit

Measuring range ≤ 16 bar/300 psi: 3 times

Measuring range > 16 bar/300 psi: 2 times

Output signals Voltage supply (for non-Ex)

Selectable versions Power supply U+

Standard 4 ... 20 mA

DC 12 ... 36 V

Option 4 ... 20 mA with HART® signal

Voltage supply (for Ex)

Load in Ω

Power supply U+: DC 12 ... 30 V

≤ (U+ - Umin) / 0.023 A

Maximum voltage Ui: DC 30 V

U+ = Applied power supply (see “Power supply”) Maximum current Ii: 100 mA

Umin = Minimum power supply (see “Power supply”) Maximum power Pi (gas): 1,000 mW

Maximum power Pi (dust,

Damping depending on the max.

0 ... 99.9 s, adjustable ambient temperature): 750/650/550 mW

Effective internal capacitance: 11 nF

After the set damping time the instrument outputs 63 % of the Effective internal inductance: 100 μH

applied pressure as output signal.

Settling time t90

60 ms without HART®

80 ms with HART®

Refresh rate

20 ms without HART®

50 ms with HART®

Page 2 of 14 WIKA data sheet PE 86.05 ∙ 04/2016

Accuracy specifications Reference conditions (per IEC 61298-1)

Accuracy at reference conditions Temperature

Including non-linearity, hysteresis, zero offset and end value 23 °C ± 2 °C

deviation (corresponds to measured error per IEC 61298-2).

Power supply

Selectable versions DC 23...25 V

Standard 0.15 % of span

Option 1 0.10 % of span Atmospheric pressure

860 ... 1,060 mbar (86 ... 106 kPa, 12.5 ... 15.4 psig)

Option 2 0.20 % of span

Humidity

Mounting correction 35 ... 95 % r. h.

-20 ... +20 %

Characteristic curve determination

Non-repeatability Terminal method per IEC 61298-2

≤ 0.1 % of span

Curve characteristics

Behaviour with turndown Linear

For measuring spans ≥ 1.6 bar

■■ TD ≤ 5:1 No influence on the accuracy Reference mounting position

■■ TD > 5:1 ... ≤ 100:1 GES = GG x TD / 5 Vertical, diaphragm points downward

For measuring spans < 1.6 bar

■■ TD = 1:1 No influence on the accuracy

■■ TD > 1:1 ... ≤ 100:1 GES = GG x (TD + 4) / 5

Long-term stability

Measuring range < 1 bar: 0.35 %/year

Measuring range ≥ 1 bar: 0.15 %/year

Measuring range ≥ 1.6 bar: 0.1 %/year

Measuring range ≥ 40 bar: 0.05 %/year

Thermal change zero point / span (reference

temperature 20 °C)

In compensated range 10 ... 70 °C:

No additional temperature error

Outside compensated range:

Typical < 0.1 %/10 K

Thermal change of the current output (reference

temperature 20 °C)

< 18 °C and > 28 °C

0.1 %/10 K (max. 0.15 %)

Legend

GES: Overall accuracy via turndown

GG: Accuracy (e.g. 0.15 %)

TD: Turndown factor (e.g. 4:1 corresponds to TD factor 4)

WIKA data sheet PE 86.05 ∙ 04/2016 Page 3 of 14

Operating conditions

Range of applications

The process pressure transmitter is suitable for internal and external operation. Direct

exposure to sunlight is permitted.

Permissible humidity

≤ 93 % r. h.

Permissible temperature ranges (for non-Ex)

Ambient temperature

Instrument with display and -20 ... +60 °C

operating unit

Instrument without display -40 ... +80 °C 1)

and operating unit

1) Instrument with angular connector or circular connector: -30 ... +80 °C

Storage temperature

Instrument with display and -40 ... +80 °C

operating unit

Instrument without display -40 ... +80 °C

and operating unit

Medium temperature

Oxygen application -20 ... +60 °C

Model UPT-20 -40 ... +85 °C

-40 ... +105 °C at max. 40 °C ambient temperature

-40 ... +120 °C at max. 30 °C ambient temperature

UPT-21 without cooling 85 °C at max. 80 °C ambient temperature

element

105 °C at max. 40 °C ambient temperature

120 °C at max. 30 °C ambient temperature

UPT-21 with cooling element 85 °C at max. 80 °C ambient temperature

120 °C at max. 50 °C ambient temperature

150 °C at max. 40 °C ambient temperature

Permissible temperature ranges (for Ex)

Temperature class / surface temperatures for all variants without cooling element:

Temperature class / surface temperature Ambient and medium temperature (°C)

T5, T6 -40 ≤ Ta ≤ +60

T4 -40 ≤ Ta ≤ +80

T135 °C -40 ≤ Ta ≤ +40 for Pi = 750 mW

-40 ≤ Ta ≤ +70 for Pi = 650 mW

-40 ≤ Ta ≤ +80 for Pi = 550 mW

Temperature class / surface temperatures for all variants with cooling element:

Temperature class Max. medium temperature Ambient temperature (°C)

(°C)

T4 120 -40 ≤ Ta ≤ +50

T3 150 -40 ≤ Ta ≤ +40

Page 4 of 14 WIKA data sheet PE 86.05 ∙ 04/2016

Restrictions to medium temperature due to sealing

(only for model UPT-21)

Selectable versions

Material Max. medium temperature

Standard NBR -20 ... +105 °C

Option 1 FKM -20 ... +105 °C

Option 2 FKM -20 ... +150 °C 2)

Option 3 EPDM 1) -40 ... +105 °C

Option 4 EPDM 1) -40 ... +150 °C 2)

1) EPDM only with hygienic process connection

2) Process connection with cooling element

Vibration resistance

4 g (5 ... 100 Hz) per GL characteristic curve 2

Shock resistance

150 g (3.2 ms) per IEC 60068-2-27

Ingress protection

IP66/67

IP65 for versions with circular connector, angular connector

or overvoltage protection

Ingress protection only applies with closed case head and

closed cable glands.

Explosion protection

see approvals

Display and operating unit, model DI-PT-U

(option)

Display type

LC display

For the process transmitter only this display may be used. For

order number see accessories.

Refresh rate

200 ms

Main display

4 ½-digit

Additional display

Selectable via menu, three-line scale range

Bar graph display

20 segments, radial, pressure gauge simulation

Colours

Background: Light grey

Digits: Black

Operating state

Display via symbols

WIKA data sheet PE 86.05 ∙ 04/2016 Page 5 of 14

Process connections

With pressure port (for model UPT-20)

Selectable versions

Per standard Thread size Possible measuring

ranges

EN 837 G⅜B ≤ 0 ... 1,000 bar

≤ 0 ... 15,000 psi

G½B ≤ 0 ... 1,000 bar

≤ 0 ... 15,000 psi

M20 x 1.5 ≤ 0 ... 1,000 bar

≤ 0 ... 15,000 psi

ANSI / ASME B1.20.1 ½ NPT ≤ 0 ... 1,000 bar

≤ 0 ... 15,000 psi

½ NPT, female ≤ 0 ... 1,000 bar

≤ 0 ... 15,000 psi

¼ NPT ≤ 0 ... 1,000 bar

≤ 0 ... 15,000 psi

With flush diaphragm (for model UPT-21)

Selectable versions

Per standard Thread size Possible measuring

ranges

- G½B 0 ... 6 to 0 ... 600 bar

0 ... 50 to 0 ... 5,000 psi

G1B ≤ 0 ... 1.6 bar

≤ 0 ... 100 psi

G1½B ≤ 0 ... 16 bar

≤ 0 ... 100 psi

G 1 hygienic 1) 2) ≤ 0 ... 16 bar

≤ 0 ... 100 psi

G 1 hygienic with cooling ≤ 0 ... 40 bar

element ≤ 0 ... 500 psi

M44 x 1.25 with union nut ≤ 0 ... 40 bar

≤ 0 ... 500 psi

Tri-clamp DN 1½ ≤ 0 ... 40 bar

≤ 0 ... 500 psi

DN 2 ≤ 0 ... 40 bar

≤ 0 ... 500 psi

Clamp DIN 32676 DN 40 ≤ 0 ... 40 bar

≤ 0 ... 500 psi

Grooved union nut DIN 11851 DN 25 ≤ 0 ... 40 bar

with conical coupling 3) ≤ 0 ... 500 psi

DN 50 ≤ 0 ... 40 bar

≤ 0 ... 500 psi

NEUMO BioConnect® DN 40 form V ≤ 0 ... 40 bar

≤ 0 ... 500 psi

VARIVENT® Form N ≤ 0 ... 40 bar

≤ 0 ... 500 psi

Form F ≤ 0 ... 40 bar

≤ 0 ... 500 psi

BioConnect® is a registered trademark of the company NEUMO.

VARIVENT® is a registered trademark of GEA Tuchenhagen GmbH.

1) Also available as a high-temperature version up to 150 °C.

2) Suitable for WIKA adapter system model 910.61, see data sheet AC 09.20

3) For a 3-A conform connection of process connections with milk thread fittings per DIN 11851, profile sealings from SKS Komponenten BV

or Kieselmann GmbH have to be used.

Page 6 of 14 WIKA data sheet PE 86.05 ∙ 04/2016

Pressure transmission medium

Model Medium

Model UPT-20 Measuring range ≤ 40 bar/500 psi: Synthetic oil, halocarbon oil

Measuring range > 40 bar/500 psi: Dry measuring cell

Model UPT-21 Synthetic oil, halocarbon oil

In general, halocarbon oil for oxygen applications.

Optionally FDA-listed media for the food industry are available.

Diaphragm seals

The model UPT-20 process transmitter can be adapted to the harshest conditions in the

process industry by using diaphragm seals. Thus, the transmitter can be used at extreme

temperatures, and with aggressive, corrosive, heterogeneous, abrasive, highly viscous or

toxic media. As a result of the wide variety of aseptic connections (such as clamp, threaded

pipe or DIN 11864 aseptic connections) measuring assemblies meet the high demands of

sterile process engineering.

Materials

Wetted parts

Selectable versions

Model Measuring Process con- Materials

ranges nections

UPT-20 ≤ 40 bar All Standard Process connection: Stainless steel 1.4404

Sensor: Stainless steel 1.4404

> 40 bar All Standard Process connection: Stainless steel 1.4404

Sensor: Elgiloy® 2.4711

Option Process connection: Hastelloy® HC276

Sensor: Elgiloy® 2.4711

UPT-21 All All Standard Process connection: Stainless steel 1.4435

Diaphragm: Stainless steel 1.4435

G½ Option 1 Process connection: Hastelloy® HC276

G1 Diaphragm: Hastelloy® HC276

G½ Option 2 Process connection: Gold-plated

G1 Diaphragm: Gold-plated

Sealing material

see table under Operating conditions, medium temperature

Case

Selectable versions

Option 1 Plastic (PBT) with conductive surface per EN 60079-0:2012

Colour: Night blue RAL5022

Option 2 Stainless steel case, precision-cast (suitable for chemical, petrochemical industries)

Option 3 Stainless steel case with electropolished surface

(suitable for pharmaceutical, food and hygienic industries)

WIKA data sheet PE 86.05 ∙ 04/2016 Page 7 of 14

Electrical connections

Selectable versions

Connection Ingress protection Wire cross-section

Plastic cable gland IP66/67 max. 2.5 mm2 (AWG 14)

Nickel-plated brass cable gland IP66/67 max. 2.5 mm2 (AWG 14)

Stainless steel cable gland IP66/67 max. 2.5 mm2 (AWG 14)

Stainless steel cable gland in hygienic design IP66/67 max. 2.5 mm2 (AWG 14)

Angular connector DIN 175301-803A with mating connector IP65 max. 1.5 mm2

Circular connector M12 x 1 (4-pin) without mating connector IP65 -

The stated ingress protection only applies when plugged in using mating connectors that have the appropriate ingress

protection.

Electrical safety

Reverse polarity protection

Connection diagrams

Cable gland M20 x 1.5 and spring-loaded terminals

Outlet for connection cable Pin assignment

Cable gland

Shield

Positive power supply terminal

Negative power supply terminal

Angular connector DIN 175301-803 A Circular connector M12 x 1 (4-pin)

U+ 1 U+ 1

1 4 3

3 U- 2 U- 3

2 1 2

Shield GND Shield 4

Legend

U+ Positive power supply terminal

U- Negative power supply terminal

Page 8 of 14 WIKA data sheet PE 86.05 ∙ 04/2016

Dimensions in mm

Process connections for model UPT-20

G L1 G L1 G L1 L2 D1

G⅜B 16 ¼ NPT 13 Measuring ranges ≤ 40 bar

G½B 20 ½ NPT 19 ½ NPT, female 20 19 26.5

M20 x 1.5 20 Hexagon dimension: 12 mm Measuring ranges > 40 bar

Spanner width: 27

Hexagon dimension: 12 mm ½ NPT, female 20 19 40.5

Spanner width: 27

Measuring ranges ≤ 40 bar

Hexagon dimension: 10 mm

Spanner width: 27

Measuring ranges > 40 bar

Hexagon dimension: 12 mm

Spanner width: 41

Process connections for model UPT-21

G L1 L2 L3 D1 G L1 L2 L3 D1 G L1 L2 D1

G½B 23 20.5 10 18 G1B 23 20.5 10 30 G1½B 25 22 55

Hexagon dimension: 12 mm Hexagon dimension: 13 mm Hexagon dimension: 14 mm

Spanner width: 27

Hygienic Hygienic

G L1 L2 L3 L4 D1 G L1 L2 L3 L4 D1

G 1 B 25 9 19 46.5 29.5 G1B 25 9 19 74.5 29.5

Hexagon dimension: 13 mm Hexagon dimension: 13 mm

WIKA data sheet PE 86.05 ∙ 04/2016 Page 9 of 14

Clamp connection ØD Ød

(clamp) Tri-clamp 1) DN 1 1/2 50.5 43.5

DN 2 64 56.6

DIN 32676 DN 40 50.5 43.5

1) Process connections per ASME BPE

Grooved union nut G Ød3

DIN 11851 DIN 11851 DN 25 Rd 52 x 1/6 44

with conical coupling

for pipes per DN 50 Rd 78 x 1/6 61

DIN 11850

For a 3-A conform connection of process connections with

® milk thread fittings per DIN 11851, profile sealings from

SKS Komponenten BV or Kieselmann GmbH have to be

used.

VARIVENT® ØD

VARIVENT® Form F 50

Form N 68

®

NEUMO Ød2 Ød4 ØD Øk FB

BioConnect® Flange form V BioConnect® DN 40 4x9 44.2 100 80 10

Page 10 of 14 WIKA data sheet PE 86.05 ∙ 04/2016

Process transmitter with plastic case, models UPT-20 and UPT-21

Process transmitter with stainless steel case, models UPT-20 and UPT-21

ca. 102 ca. 126

ca. 114

ca. 121

ca. 143

ca. 17

M20x1.5

36

WIKA data sheet PE 86.05 ∙ 04/2016 Page 11 of 14

Accessories

Description Order no.

Display module, model DIH52-F on request

5-digit display, 20-segment bar graph, without separate power supply, with additional HART®

functionality. Automatic adjustment of measuring range and span.

Secondary-master functionality: Setting the measuring range and unit of the connected trans-

mitter using HART® standard commands possible.

Optional: Explosion protection per ATEX

HART® modem

USB interface, model 010031 11025166

RS-232 interface, model 010001 7957522

Bluetooth® interface [EEx ia] IIC, model 010041 11364254

HART® modem, PowerXpress 14133234

USB interface 2.0

Voltage supply via USB or AC 100/250 V, 50/60 Hz power supply unit

Requires Windows 98, 2000, XP (32-bit), VISTA (32-bit), Windows 7(32/64-bit)

Hand-held, model FC475HP1EKLUGMT 14025585

HART® protocol, Li-Ion battery, voltage supply AC 100 ... 240 V, colour display with backlight-

ing, Bluetooth® and infrared interface, ATEX, FM, CSA and IECEx(i)

Hand-held, model FC475FP1EKLUGMT 14025730

HART® protocol and FF Bus, Li-Ion battery, voltage supply AC 100 ... 240 V, colour display

with backlighting, Bluetooth® and infrared interface, ATEX, FM, CSA and IECEx(i)

Hand-held, model MFC5150X 14104078

HART® protocol, universal voltage supply, cable set with 250 Ω resistance, with DOF upgrade,

ATEX and cULus

Welding socket

for process connection G ½ flush 1192299

for process connection G 1 flush 1192264

for process connection G 1 ½ flush 2158982

for process connection G 1 hygienic flush 2166011

Instrument mounting bracket 14058660

for wall or pipe mounting, stainless steel

Overvoltage protection 14002489

for transmitters, 4 ... 20 mA, M12 x 1.5, series connection

Display and operating unit, model DI-PT-U 14090181

The display and operating unit can be attached in 90° steps. The display and operating unit

features a main display and an additional display.

The main display shows the output signal. The additional display shows different values, at the

same time as the main display - these values can be selected by the user.

The process pressure transmitter can be configured through the display and operating unit.

Only this display may be used for installation into the process transmitter.

Barstock valve, model 910.81

See data sheet AC 09.18

Hygienic cable gland M20 x 1.5 11348691

Page 12 of 14 WIKA data sheet PE 86.05 ∙ 04/2016

Approvals (option)

Logo Description Country

EC declaration of conformity European Community

■■ EMC directive, interference emission (group 1, class B) and immunity per EN 61326-1:2013

(industrial application), EN 61326-2-3:2013 1)

■■ Pressure equipment directive

■■ ATEX directive

- Ex i Zone 1 gas [II 2G Ex ia IIC T4/T5/T6 Gb]

Zone 1 connection to zone 0 gas [II 1/2G Ex ia IIC T4/T5/T6 Ga/Gb]

Zone 2 gas [II 3G Ex ic IIC T4/T5/T6 Gc]

Zone 21 dust [II 2D Ex ia IIIC T135 °C Db]

Zone 21 connection to zone 20 dust [II 1/2D Ex ia IIIC T135 °C Da/Db]

IECEx IECEx member states

Hazardous areas

- Ex i Zone 1 gas [Ex ia IIC T6 ... T3 Gb]

Zone 1 connection to zone 0 gas [Ex ia IIC T6 ... T3 Ga/Gb]

Zone 2 gas [Ex ia IIC T6 ... T3 Gc]

Zone 21 dust [Ex ia IIIC T135 °C Db]

Zone 21 connection to zone 20 dust [Ex ia IIIC T135 °C Da/Db]

EAC Eurasian Economic

■■ Pressure equipment directive Community

■■ Electromagnetic compatibility

■■ Hazardous areas

- Ex i Zone 0 gas [0ExiaIICT4/T5/T6 X]

Zone 1 gas [1ExiaIICT4/T5/T6 X]

Zone 2 gas [2ExiaIICT4/T5/T6 X]

Zone 21 dust [Ex iaD 20 T135 °C X]

Zone 20 dust [Ex iaD 21 T135 °C X]

MTSCHS Kazakhstan

Permission for commissioning

BelGIM Belarus

Metrology, measurement technology

DNOP_MakNII Ukraine

■■ Mining

■■ Hazardous areas

- Ex i Zone 1 connection to zone 0 gas [II 1/2G EEx ia IIC T4/T5/T6 Ga/Gb]

Zone 21 connection to zone 20 dust [II 1/2D IP6X T130 °C/T95 °C/T80 °C]

Uzstandard Uzbekistan

Metrology, measurement technology

INMETRO Brazil

■■ Metrology, measurement technology

■■ Hazardous areas

- Ex i Zone 1 gas [Ex ia IIC T6 ... T3 Gb]

Zone 1 connection to zone 0 gas [Ex ia IIC T6 ... T3 Ga/Gb]

Zone 2 gas [Ex ia IIC T6 ... T3 Gc]

Zone 21 dust [Ex ia IIIC T135 °C Db]

Zone 21 connection to zone 20 dust [Ex ia IIIC T135 °C Da/Db]

3-A International

®

Food

This instrument is 3-A marked, based on a third party verification for conformance to the 3-A standard.

1) During interference, increased measuring deviations of up to 0.15 % of the set measuring range can occur.

WIKA data sheet PE 86.05 ∙ 04/2016 Page 13 of 14

Manufacturer‘s information and certifications

■■ NAMUR NE21:2011

■■ NACE

■■ FDA conform filling and sealing

Certificates (option)

■■ 2.2 test report

■■ 3.1 inspection certificate

■■ DKD/DAkkS calibration certificate

■■ Calibration

■■ 3.1 calibration certificate per DIN EN 10204

Approvals and certificates, see website

Ordering information

Model / Explosion protection / Case version / Digital display / Window / Output signal / Electrical connection / Measuring range /

Process connection / Sealing / Wetted parts / Accuracy / Certificates / Scaling

© 2014 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

Page 14 of 14 WIKA data sheet PE 86.05 ∙ 04/2016

04/2016 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- RTS Automatic Transfer Switch - Technical Manual - GENERAC PDFDocument28 pagesRTS Automatic Transfer Switch - Technical Manual - GENERAC PDFpevare100% (2)

- DVR2000E Training - SECT #8 (Troubleshooting)Document18 pagesDVR2000E Training - SECT #8 (Troubleshooting)Anonymous uEt1sNhU7lNo ratings yet

- Uen R 63900001Document8 pagesUen R 63900001ivanNo ratings yet

- P94-2057 Wipers, HornDocument3 pagesP94-2057 Wipers, HornGonzalo Galvez100% (1)

- Tuc 6 WF ManualDocument92 pagesTuc 6 WF ManualSunil Singh86% (7)

- Ansi C37.21-1985Document24 pagesAnsi C37.21-1985Jairo WilchesNo ratings yet

- Hidraulico 246d ImplementosDocument4 pagesHidraulico 246d ImplementosIboy Eslin Alvarado Paredes50% (2)

- Process Transmitter Model UPT-20, With Pressure Port Model UPT-21, With Flush DiaphragmDocument8 pagesProcess Transmitter Model UPT-20, With Pressure Port Model UPT-21, With Flush DiaphragmPercy CordovaNo ratings yet

- Caudalimetro Coriolis Kobold TmuDocument13 pagesCaudalimetro Coriolis Kobold TmuBase SistemasNo ratings yet

- DPT-R8-Series - Datasheet-9.0 - Delta P SensorDocument2 pagesDPT-R8-Series - Datasheet-9.0 - Delta P SensorLê Xuân AnNo ratings yet

- Microcal P20Document2 pagesMicrocal P20ctmtectrolNo ratings yet

- 6110 - Eng - A - W FlukeDocument2 pages6110 - Eng - A - W FlukeVito PuertoNo ratings yet

- Ds Pe8161 en CoDocument13 pagesDs Pe8161 en Comohamadhosein mohamadiNo ratings yet

- Wika Pgt23.1001 DatasheetDocument5 pagesWika Pgt23.1001 DatasheetongquangthaiNo ratings yet

- Kde en 923 0862Document32 pagesKde en 923 0862joseloaiza378No ratings yet

- Hauser Endress: Pressure Transducer Cerabar T PMP 131Document8 pagesHauser Endress: Pressure Transducer Cerabar T PMP 131CardonettiNo ratings yet

- Ultra High Purity Transducer For Explosion-Protected Areas, Ex Na Ic Models WUC-10, WUC-15 and WUC-16Document8 pagesUltra High Purity Transducer For Explosion-Protected Areas, Ex Na Ic Models WUC-10, WUC-15 and WUC-16MohammadNo ratings yet

- Pressure Transmitter For Applications in Hazardous Areas Model IS-3Document17 pagesPressure Transmitter For Applications in Hazardous Areas Model IS-3alexiel1806No ratings yet

- Pol955 60Document12 pagesPol955 60AssaadNo ratings yet

- Twintex Datasheet DC Power Supply PPS 202111revDocument6 pagesTwintex Datasheet DC Power Supply PPS 202111revPaolo CristianiNo ratings yet

- Eyc GHM - Pi Ho - DR Omni p1 - e - Datasheet 20181224Document3 pagesEyc GHM - Pi Ho - DR Omni p1 - e - Datasheet 20181224pieter.salimansNo ratings yet

- cảm biến chân ty 2Document5 pagescảm biến chân ty 2Trần Quốc ĐôngNo ratings yet

- Pressure Transmitter For Precision Measurements Model P-30, Standard Version Model P-31, Flush VersionDocument8 pagesPressure Transmitter For Precision Measurements Model P-30, Standard Version Model P-31, Flush VersionAnonymous 4MwmDaNbNo ratings yet

- P502CIDocument5 pagesP502CIDaniel SolerNo ratings yet

- Hand-Held Pressure Calibrator With Integrated Pump Model CPH6600Document6 pagesHand-Held Pressure Calibrator With Integrated Pump Model CPH6600Nabeel AhmedNo ratings yet

- Multimetro Norman EM420B - enDocument25 pagesMultimetro Norman EM420B - enNelson BavaNo ratings yet

- Pressure Transmitter Model ECO-1: ApplicationsDocument4 pagesPressure Transmitter Model ECO-1: ApplicationsМихаил БеребердинNo ratings yet

- Product Catalogue Differential Pressure TransmitterDocument28 pagesProduct Catalogue Differential Pressure Transmitterprasana balajiNo ratings yet

- Dew Point Sensor Fa 500Document2 pagesDew Point Sensor Fa 500CORE2 MK TEK1No ratings yet

- DeltaOHM BAROsense Manual ENGDocument24 pagesDeltaOHM BAROsense Manual ENGDaniel Hermida VaqueroNo ratings yet

- 1 DS - EWK - 3010-3015 - 10 - 20kg 型錄Document4 pages1 DS - EWK - 3010-3015 - 10 - 20kg 型錄Abhishek DuttaNo ratings yet

- Certificados Internacionais HPK 1 500Document11 pagesCertificados Internacionais HPK 1 500JeanMacedoNo ratings yet

- Belimo 22ADP-184.. Datasheet En-GbDocument7 pagesBelimo 22ADP-184.. Datasheet En-GbMuhammad Faris MazleyNo ratings yet

- WIKA Sensors - A10 Datasheet - DS - PE8160 - en - Co - 1631Document8 pagesWIKA Sensors - A10 Datasheet - DS - PE8160 - en - Co - 1631chipulinoNo ratings yet

- 1 2020 ROW CatalogDocument214 pages1 2020 ROW CatalogBryan BaringNo ratings yet

- Ultrasonic SensorsDocument7 pagesUltrasonic Sensorsl1f3b00kNo ratings yet

- AI523 Data Sheet, 2, en USDocument12 pagesAI523 Data Sheet, 2, en USJozz LivelyNo ratings yet

- WIKA Ecco 1Document4 pagesWIKA Ecco 1Chandra NugrahaNo ratings yet

- Technical Specifications: SUA3000RMI2UDocument2 pagesTechnical Specifications: SUA3000RMI2UDodai アルド SaputraNo ratings yet

- Apc 2000alw PDFDocument5 pagesApc 2000alw PDFvan_dall_2No ratings yet

- Mgcplus: Measuring Amplifier SystemDocument44 pagesMgcplus: Measuring Amplifier SystemvikryaNo ratings yet

- Model PSD-30 Pressure Transmitter With Integral LED Display and Programmable Solid State SwitchesDocument4 pagesModel PSD-30 Pressure Transmitter With Integral LED Display and Programmable Solid State SwitchesAndhika PramanaNo ratings yet

- Belimo 22ADP-184Document7 pagesBelimo 22ADP-184Vũ Đức GiangNo ratings yet

- RTS DC Servo DriveDocument4 pagesRTS DC Servo DriveJunaid YNo ratings yet

- PXU PID Controller: Temperature/Process ControllersDocument3 pagesPXU PID Controller: Temperature/Process ControllersGaryNo ratings yet

- APFC Epcos 6Document8 pagesAPFC Epcos 6Sriman ChinnaduraiNo ratings yet

- Kuebler - Codix 553, 48x96 MM: Area of UseDocument3 pagesKuebler - Codix 553, 48x96 MM: Area of UseActividades UnadNo ratings yet

- Senzorul de Nivel ProgramDocument36 pagesSenzorul de Nivel ProgramAlexandra GrigoreNo ratings yet

- DPT CTRL Datasheet-5.0Document2 pagesDPT CTRL Datasheet-5.0Alejandro CorsiNo ratings yet

- DenA2240X000 Monitor AMI OxytraceDocument2 pagesDenA2240X000 Monitor AMI OxytracefazliNo ratings yet

- Unimano 1000 - Brochure 1434064681 PDFDocument2 pagesUnimano 1000 - Brochure 1434064681 PDFHatake KakashiNo ratings yet

- DCBD AY1415-Bai Tap On Thi Cuoi KyDocument4 pagesDCBD AY1415-Bai Tap On Thi Cuoi KyErik ChanNo ratings yet

- TRIO-20.0/27.6-TL-OUTD 20 To 27.6 KW: ABB String InvertersDocument4 pagesTRIO-20.0/27.6-TL-OUTD 20 To 27.6 KW: ABB String InvertersVarazhdinecNo ratings yet

- Powertronix CatalogueDocument44 pagesPowertronix Catalogueahmad rehmanNo ratings yet

- APC Smart-UPS RT 2000VA 230V: Home Products Uninterruptible Power Supply (UPS) Smart-UPS On-LineDocument4 pagesAPC Smart-UPS RT 2000VA 230V: Home Products Uninterruptible Power Supply (UPS) Smart-UPS On-LineMarius BaltariuNo ratings yet

- Apr 2000alwDocument5 pagesApr 2000alwhandlitoNo ratings yet

- DS PV1502 en Co 8052Document6 pagesDS PV1502 en Co 8052SERDINA FFNo ratings yet

- High-Quality Pressure Transmitter For General Industrial Applications Model S-10Document8 pagesHigh-Quality Pressure Transmitter For General Industrial Applications Model S-10gliga vasileNo ratings yet

- Ficha Tecnica Transmisor de Presión Turck Pt3000psig-2003-I2-H1143Document4 pagesFicha Tecnica Transmisor de Presión Turck Pt3000psig-2003-I2-H1143Gustavo EgasNo ratings yet

- Insulation Tester: Rs-232 DataloggerDocument42 pagesInsulation Tester: Rs-232 DataloggervlkodlakschwartzNo ratings yet

- EYL220Document9 pagesEYL220ghared salehNo ratings yet

- Ds Pe8185 Archived en CoDocument8 pagesDs Pe8185 Archived en CoLuu Van KhueNo ratings yet

- Product Data Sheet: Tracer UC600 Programmable ControllerDocument4 pagesProduct Data Sheet: Tracer UC600 Programmable ControllermodvillamancaNo ratings yet

- TWDLCAE40DRFDocument3 pagesTWDLCAE40DRFalexfmiNo ratings yet

- Magnetic Switch For Bypass Level Indicators Model BGU: ApplicationsDocument10 pagesMagnetic Switch For Bypass Level Indicators Model BGU: ApplicationschauNo ratings yet

- In-Line Diaphragm Seal With Sterile Connection For Sanitary Applications Models 981.22, 981.52 and 981.53, Clamp ConnectionDocument5 pagesIn-Line Diaphragm Seal With Sterile Connection For Sanitary Applications Models 981.22, 981.52 and 981.53, Clamp ConnectionchauNo ratings yet

- Appendix: Cross Reference BFTDocument7 pagesAppendix: Cross Reference BFTchauNo ratings yet

- Valve Manifold For Differential Pressure Gauges Model 910.25Document4 pagesValve Manifold For Differential Pressure Gauges Model 910.25chauNo ratings yet

- Diaphragm Pressure Gauge For The Process Industry Models 432.50, 433.50, Up To 10-Fold Overload Safety, Max. 40 BarDocument4 pagesDiaphragm Pressure Gauge For The Process Industry Models 432.50, 433.50, Up To 10-Fold Overload Safety, Max. 40 BarchauNo ratings yet

- Thermowell With Flange (Fabricated) Version Per DIN 43772 Form 2F, 3F Models TW40-8, TW40-9Document3 pagesThermowell With Flange (Fabricated) Version Per DIN 43772 Form 2F, 3F Models TW40-8, TW40-9chauNo ratings yet

- Threaded Process Connection, Diaphragm Seals Model 990.31, Plastic DesignDocument2 pagesThreaded Process Connection, Diaphragm Seals Model 990.31, Plastic DesignchauNo ratings yet

- Machine Glass Thermometers Model 32, V-Form: ApplicationsDocument5 pagesMachine Glass Thermometers Model 32, V-Form: ApplicationschauNo ratings yet

- Diaphragm Seal With Flange Connection With Internal Diaphragm, Threaded Design Model 990.41, Large Working VolumeDocument7 pagesDiaphragm Seal With Flange Connection With Internal Diaphragm, Threaded Design Model 990.41, Large Working VolumechauNo ratings yet

- Threaded Process Connection, Diaphragm Seals Model 990.34, Welded DesignDocument4 pagesThreaded Process Connection, Diaphragm Seals Model 990.34, Welded DesignchauNo ratings yet

- Bimetal Thermometer Model 52, Industrial Series: ApplicationsDocument6 pagesBimetal Thermometer Model 52, Industrial Series: ApplicationschauNo ratings yet

- Bimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55Document11 pagesBimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55chauNo ratings yet

- Bimetal Thermometer Model 54, Industrial Series: ApplicationsDocument7 pagesBimetal Thermometer Model 54, Industrial Series: ApplicationschauNo ratings yet

- Blade 360 Sensor Posicion Rotativo SensovantDocument2 pagesBlade 360 Sensor Posicion Rotativo SensovantGianfranco JulcaNo ratings yet

- 5069 Compact I/O Modules Specifications: Technical DataDocument68 pages5069 Compact I/O Modules Specifications: Technical DataGomz RubNo ratings yet

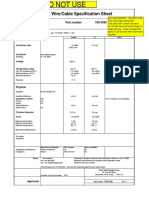

- Wire, 10 AWG, 5000 V, Tefzel - Focal 3393Document1 pageWire, 10 AWG, 5000 V, Tefzel - Focal 3393Marilton SiqueiraNo ratings yet

- THR 400 W Solar System SchematicR1Document5 pagesTHR 400 W Solar System SchematicR1IkhwanNo ratings yet

- Connectors F Solenoid Valv - Canfield PDFDocument2 pagesConnectors F Solenoid Valv - Canfield PDFhebert perezNo ratings yet

- Wire Harness Repair: MaintenanceDocument164 pagesWire Harness Repair: MaintenanceLuis Gustavo FernandesNo ratings yet

- Min-Com Installation GuideDocument2 pagesMin-Com Installation GuideAmy ChanNo ratings yet

- 2x16 AWG TC 600V Overall Shielded Control Cable - 8KDP102109 - V - 1 - R - 11Document2 pages2x16 AWG TC 600V Overall Shielded Control Cable - 8KDP102109 - V - 1 - R - 11Daniel ArgumedoNo ratings yet

- MolexDocument3 pagesMolexDeddy WilopoNo ratings yet

- Figure 1. Hydraulic Schematic SymbolsDocument20 pagesFigure 1. Hydraulic Schematic Symbolsamin chaabenNo ratings yet

- Rectangular Connectors: FCN360 SeriesDocument32 pagesRectangular Connectors: FCN360 Seriespavan goyalNo ratings yet

- Airbus EurocopterDocument12 pagesAirbus EurocopterrafiNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document32 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768CarlosNo ratings yet

- 2108 - ECTR330-4 - Paxar BangladeshDocument46 pages2108 - ECTR330-4 - Paxar Bangladeshkhondakarmasud.hasanNo ratings yet

- Dekoron Cable Product Specification SheetDocument1 pageDekoron Cable Product Specification SheetgrandpaNo ratings yet

- Csi S 270553 I C S: Ection Dentification FOR Ommunications YstemsDocument16 pagesCsi S 270553 I C S: Ection Dentification FOR Ommunications YstemsYogeshSharmaNo ratings yet

- Siga-Cc1 12-22-2010Document6 pagesSiga-Cc1 12-22-2010Felipe LozanoNo ratings yet

- Aquanet PDFDocument4 pagesAquanet PDFTMorera VMaritzaNo ratings yet

- Scotchcast Flexible Power Cable Jointing Kits: 82-F and 82-BF Series Data SheetDocument4 pagesScotchcast Flexible Power Cable Jointing Kits: 82-F and 82-BF Series Data SheetVaaDNo ratings yet

- Model 4425: Instruction ManualDocument27 pagesModel 4425: Instruction ManualKeithcar Llang MayoNo ratings yet

- Universal, Commercial, and .140 MATE-N-LOK Contact and Housing Selection ChartsDocument4 pagesUniversal, Commercial, and .140 MATE-N-LOK Contact and Housing Selection ChartsaustintanNo ratings yet

- Verasys™ Bacnet® MS/TP Communications: Technical BulletinDocument24 pagesVerasys™ Bacnet® MS/TP Communications: Technical BulletinMegaHyperMaxNo ratings yet

- Delco Charging Cable Flyer 9 18Document1 pageDelco Charging Cable Flyer 9 18dima65No ratings yet