Professional Documents

Culture Documents

21 Casting Defects and How To Prevent Them in Your Products

Uploaded by

mkmkhairiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

21 Casting Defects and How To Prevent Them in Your Products

Uploaded by

mkmkhairiCopyright:

Available Formats

!

"

21 CASTING

DEFECTS AND HOW

TO PREVENT THEM

IN YOUR PRODUCTS

MANUFACTURING AND QC

BLOG

By Sunny Wong 18 Sep 2018

Home › Manufacturing And QC Blog ›

21 Casting Defects And How To Prevent

Them In Your Products

Your cast iron metal pan leaves the factory

with pinholes, leading to a slew of

complaints from your customers. What

happened? How could you have prevented

this from happening?

Foundry production is a complex multi-

step process. The technical level of each

process varies greatly. Skills of the

operator, quality management and

equipment can all a"ect the !nal quality of

the casting.

The key to preventing product defects in

your casted products is to set clear

expectations and tolerances for quality

issues with your supplier (related: How

Experienced Importers Limit Product Defects

in 3 Stages [eBook]).

But before you can do that, you need to

have a clear understanding of the di"erent

types of casting defects and their causes.

Only then can you prevent casting defects

and avoid sending defective products to

your customers.

Read on or click the links below to jump to

the section for each of these types of

casting defects.

Pinholes Run out Cold

Subsurface Swells shut/lap

blowhole Drops Misruns

Open holes Rat tails, Cold shots

Open veins and Slag

shrinkage buckles inclusion

Closed Metal (scab)

shrinkage penetration

Cuts and Hot Shift/mismatc

washes tear/crack h

Fusion Hot/Hard Flash, !n

spots and burrs

Warping

GAS POROSITY

CASTING DEFECTS AND

CAUSES

Gas porosity occurs when the metal traps

gas (most often nitrogen, oxygen or

hydrogen) during casting.

When the casting cools and solidi!es,

bubbles form because the solid form of

the metal cannot hold as much gas as the

liquid form. These bubbles appear on a

casting as rounded, circular cavities or

holes.

There are three types of casting defects

related to gas porosity:

1. Pinholes

Pinholes, also sometimes referred to as

porosities, are very tiny holes (about 2

mm) usually found in the cope (upper)

part of the mold, in poorly vented pockets.

They usually appear in large numbers

together, either at the surface or just

below the surface of the casting. They are

always visible to the naked eye and don’t

require equipment to identify.

2. Subsurface blowhole

Blowholes, or simply blows, are larger

cavities than pinholes.

A subsurface blowhole appears on the

inside of a cast and usually isn’t visible

until after machining.

Subsurface blowholes can be di#cult to

detect before machining, requiring

harmonic, ultrasonic, magnetic or x-ray

analysis.

3. Open holes

These blowholes appear on the surface of

the cast and are easier to detect than

subsurface blowholes.

Causes and prevention of gas porosity

There are several causes of cavity defects.

Poor venting of mold and cores

Insu#cient drying of mold and cores

How can you prevent gas porosity?

Scars are shallow blows that appear on a

$at surface, while blisters are scars

covered with a thin layer of metal.

Excessive moisture content of molding

sand

Inadequate gas permeability of molding

sand

Potential solutions include:

Incorporate good $uxing and melting

practices: melt metal in a vacuum, in an

environment of low-solubility gases or

under a $ux that prevents contact with the

air

Increase gas permeability of sand:

coarser sands have a higher permeability

Increase permeability of mold and

cores. Allow air and gas to escape from the

mold cavity

Dry out molds and cores before use and

store dry

Increase rate of solidi!cation by

reducing metal temperature during

casting

SHRINKAGE CASTING

DEFECTS AND CAUSES

Shrinkage occurs because metals are less

dense as a liquid than a solid.

A shrinkage cavity is a depression in a

casting which occurs during the

solidi!cation process. Shrinkage porosity

appears with angular edges, compared to

the round surfaces of gas porosity.

Cavities might also be paired with

dendritic fractures or cracks.

Large shrinkage cavities can undermine

the integrity of the casting and may cause

it to eventually break under stress.

Shrinkage can result in two types of

casting defects.

4. Open shrinkage defects

These are open to the atmosphere. Air

compensated as the shrinkage cavity

forms.

Pipes are open shrinkage defects that

form at the surface and burrow into the

casting. Caved surfaces are shallow, open

shrinkage defects that form across the

surface of the casting.

5. Closed shrinkage defects

Also known as shrinkage porosity, closed

shrinkage defects form within the casting.

Macro shrinkage can be viewed with the

naked eye, but micro shrinkage cannot.

Closed shrinkage defects usually appear at

the top of hot spots, or isolated pools of

hot liquid.

Prevent shrinkage cavities by improving

casting structure

Alloys always shrink when changing from

molten to solid. This is because the density

of a casting alloy in the molten state is

lower than that in the solid state.

You should expect some shrinkage during

solidi!cation. Factor a shrinkage allowance

into the pattern design before casting.

You can prevent shrinkage casting defects

by improving the overall casting structure:

Design a running (gate) system with

risers that ensure a continuous $ow of

molten metal

Increase local heat dissipation by

inserting internal chills, cooling ribs or

cooling coils

Reduce casting temperature to limit the

total volume de!cit

MOLD MATERIAL CASTING

DEFECTS AND CAUSES

Mold material casting defects are related

to the mold material, which is most

commonly sand. You and your supplier

can typically address these casting defects

and causes by modifying the mold.

6. Cuts and washes

Cuts and washes are areas of excess

metal. These appear when the molten

metal erodes the molding sand.

A cut appears as a low projection along

the surface of the drag face, decreasing in

height as it extends from one side of the

casting to the other.

Causes and prevention of cuts and washes

Cuts and washes can be caused by molten

metal $owing at a high velocity, causing

too much metal to $ow through the gate.

You

can

prevent cuts and washes easiest by:

Designing the gating system properly

Improving mold and core strength

Adding more binders to the facing and

core sand

7. Fusion

Fusion occurs when sand grains fuse with

molten metal. It appears as a thin crust

with a brittle, glassy appearance !rmly

adhered to the casting.

Causes and prevention of fusion

Two main factors can cause fusion:

Low refractoriness of clay or sand

Too high pouring temperature of

molten metal

Refractoriness is the ability of the molding

material to resist the temperature of the

liquid so it doesn’t fuse with the metal.

Silica sand has the highest refractoriness.

Improving the refractoriness of the

molding material and/or reducing the

pouring temperature of the molten metal

will help prevent fusion.

8. Run out

Run out is when liquid metal leaks out of

the mold, leading to an incomplete or

missing casting.

A faulty mold or $ask is responsible for

run out.

Prevention of run out and incomplete

castings

To prevent this casting defect, design the

casting mold with precision. Inspect and

replace any defective molds before

casting.

High temperatures can lead to excess

wear and tear of the mold. Use quality raw

materials for your mold that can resist

high temperatures.

9. Swells

Swells are an enlargement of the casting.

Swells typically take on the shape of a

slight, smooth bulge on the vertical face of

castings.

Causes and prevention of swells

Swell is usually caused by improper or soft

ramming of the mold or a low strength

mold.

Molds should be built to withstand liquid

metal pressure. Otherwise, the mold wall

may give way or move back, causing

swelling.

Using a strong, properly rammed mold

prevents swells.

10. Drops

Drops occur when pieces of sand fall into

metal casting when it’s still liquid. Drops

appear as an irregularly shaped projection

on the cope (top) surface of a casting.

Causes and prevention of drops

Four potential

causes for drops

and their

preventions

include:

Low sand

strength: Use sand

of a higher strength if this your culprit

Soft ramming: Provide harder

ramming

Insu!cient "uxing of molten metal:

Properly $uxing molten metal removes

impurities

Insu!cient reinforcement of sand

projections in the cope: Reinforce sand

projections using nails or gaggers to !x

this issue

11. Rat tails, veins and buckles

Rat

tails, or veins, appear as an irregular line

or crack on the casting, when the surface

of the molding sand buckles up. Rat tails

usually occur on the surface of the mold

bottom, an area covered with molten

material.

Buckles are a more severe form of rat

tails.

Causes and prevention of rat tails and

buckles

Rat tails and buckles occur when excessive

heat of the metal causes the sand to

expand. This may be caused by:

Poor expansion properties of the

sand: Add combustible additives to sand.

A hot pouring temperature: Reduce

pouring temperature of metal.

Poor mold design: Large and $at

sections are more prone to rat tails. The

mold also should not be too hard, as it

must allow for proper expansion.

12. Metal penetration

Metal penetration occurs when liquid

metal penetrates gaps in the molding

sand. The penetration is visible to the

naked eye as a rough and uneven surface

!nish of the casting.

Causes and prevention of metal penetration

Metal penetration is due to:

Use of sand with low strength and high

permeability

Use of large or coarse sand grain: the

coarser the sand grains, the more severe

the metal penetration

Lack of mold wash

Soft ramming of sand

Prevent metal penetration by !xing these

areas. Use high strength, small grain size,

low permeability and hard ramming of

sand. Ensure a protective barrier against

metal penetration by coating the surface

of molds with a mold wash.

You can typically remove metal

penetration by grinding down the rough

surface of the casting.

METALLURGICAL CASTING

DEFECTS AND CAUSES

There are two types of metallurgical

defects to watch out for.

13. Hot tear/crack

Cracks appear in the form of irregular

crevices in a branched pattern.

Some cracks are obvious and easily seen,

while others can require magni!cation.

Cracks occur as the casting cools, towards

the end of solidi!cation.

Causes and prevention of hot tears and

cracks

If the solidifying metal does not have

su#cient strength to resist tensile forces

during solidi!cation, hot tears will appear.

Hot tears are mostly caused by poor mold

design. Modifying the mold to improve

collapsibility can easily resolve these

issues.

14. Hot/hard spots

Hot spots are spots that are harder than

the surrounding area. This is because they

cooled more quickly than the surrounding

material.

Hard spots can interfere with machining

and increase tool wear.

Causes and prevention of hot spots

Hot spots are a direct result of improper

cooling practices. There are two potential

solutions if hot spots are your problem:

Start by correcting cooling practice

Also consider changing the metal’s

chemical composition

POURING CASTING DEFECTS

AND CAUSES

Pouring metal defects arise during the

process of pouring metal into the mold. If

you have a pouring metal defect, it will fall

into one of these categories:

15. Cold shut/lap

Cold shut is a type of surface defect. You’ll

see a line or crack with a round edge on

the casting surface.

This defect is visible to the naked eye and

often results in rejecting the cast, as it

creates a weak spot.

Causes and prevention of cold shut

When molten metal enters the mold from

two gates, the streams will meet at a

junction. Low temperatures can prevent

fusion at the junction, causing the streams

to solidify before fusion, creating a cold

shut.

Cold shut is usually a result of a lack of

$uidity of the molten metal, or a poor

design of the gating system.

The best way to prevent cold shuts is to

increase $uidity of the molten metal. This

can be done in a few ways:

Optimize gating system to minimize

narrow cross-paths and ensure short $ow

paths

Increase the pouring temperature to

prevent premature solidi!cation

Improve gas permeability of the mold

(through coarser grain size, etc.)

16. Misruns are closely related to

cold shuts

Misruns occur when the liquid metal is too

cold to $ow to the extremities of the mold

cavity before freezing and solidifying.

The

liquid

metal

does not

completely !ll the mold cavity. The misrun

is the un!lled portion or space in the

mold.

Causes and prevention of misruns

The reasons for premature solidi!cation

are similar to those for cold shut. If you

have a misrun, check:

Mold design

Gating system design and

Molten metal $uidity

17. Cold shots

Splattering during pouring of a liquid can

cause solid globules to form.

As

these globules freeze, they become

entrapped in the casting.

Cold shots are typically ball, drop or pearl

shaped and loosely attached to the metal.

Causes and prevention of cold shots

To prevent splattering and cold shots,

consider

Modifying pouring procedures to

minimize turbulence

Adjusting gating system designs to

reduce gate speed

18. Slag inclusion (scab)

These irregular metallic crusts are found

on the casting surface. Scabs are typically

only a few millimeters thick but can be

seen by the naked eye. They usually have

sharp edges, irregular shapes and are

!rmly bonded to the casting.

You might also like

- Casting Defects & CausesDocument15 pagesCasting Defects & CausesAbhinav Pratap MauryaNo ratings yet

- Casting Defects & CausesDocument15 pagesCasting Defects & CausesAbhinav Pratap MauryaNo ratings yet

- 21 Types Casting DefectsDocument94 pages21 Types Casting DefectsNarayanakumar A.PNo ratings yet

- Casting DefectsDocument14 pagesCasting Defectsadbsalman734No ratings yet

- Typical Casting DefectsDocument16 pagesTypical Casting DefectsSeah Ying ZhiNo ratings yet

- Casting Defects GuideDocument8 pagesCasting Defects GuideAll In OneNo ratings yet

- Casting DefectsDocument9 pagesCasting DefectsRao YasirNo ratings yet

- Metal Casting Is A Complex Process That Involves The Application of High Pressure To Molten MetalDocument7 pagesMetal Casting Is A Complex Process That Involves The Application of High Pressure To Molten MetalMaria SarwatNo ratings yet

- Casting DefectsDocument2 pagesCasting DefectsNaman ShethNo ratings yet

- WINSEM2020-21 MEE1007 ETH VL2020210506859 Reference Material I 09-Apr-2021 Lec 8-MEE1007-MP-Casting Defect and InspectionDocument57 pagesWINSEM2020-21 MEE1007 ETH VL2020210506859 Reference Material I 09-Apr-2021 Lec 8-MEE1007-MP-Casting Defect and InspectionSmita AshturkarNo ratings yet

- Casting DefectsDocument24 pagesCasting DefectsRadheshyam Suwalka100% (1)

- Defects in CastingDocument4 pagesDefects in CastingArjun Singh MarjaraNo ratings yet

- Casting DefectsDocument5 pagesCasting DefectsNayeem pashaNo ratings yet

- Part-C Defects - Nptel PDFDocument5 pagesPart-C Defects - Nptel PDFLakhwant Singh KhalsaNo ratings yet

- SeminarDocument38 pagesSeminarManohara ErlaNo ratings yet

- Experiment No. 8 Casting Defects: Aim: TheoryDocument5 pagesExperiment No. 8 Casting Defects: Aim: TheoryDhananjay ShimpiNo ratings yet

- Foundry DefectsDocument74 pagesFoundry DefectsdanielsasikumarNo ratings yet

- Casting DefectsDocument7 pagesCasting Defectsmannu_riderNo ratings yet

- Casting DefectsDocument35 pagesCasting DefectsYaser Mohamed AbasNo ratings yet

- Foundry DefectsDocument74 pagesFoundry DefectsdanielsasikumarNo ratings yet

- Casting DefectsDocument8 pagesCasting DefectsJavier Escalante VillanuevaNo ratings yet

- Discussion MoldingDocument4 pagesDiscussion MoldingNur' Ayuni100% (1)

- Shrinkage DefectsDocument11 pagesShrinkage DefectsMohsin Abbas100% (1)

- Casting DefectsDocument5 pagesCasting DefectsChinmay Das89% (9)

- Pemilba CastingDocument8 pagesPemilba CastingRefky FNo ratings yet

- Defects WeldingDocument206 pagesDefects WeldingJayesh100% (1)

- 2 Defects and DiscontinutiesDocument33 pages2 Defects and DiscontinutiesSandip GhimireNo ratings yet

- NDT Discontinuities - World of NDTDocument51 pagesNDT Discontinuities - World of NDTHòa NguyễnNo ratings yet

- Casting DefectsDocument12 pagesCasting Defectssushil.vgiNo ratings yet

- Welding Defect: Hydrogen EmbrittlementDocument8 pagesWelding Defect: Hydrogen EmbrittlementShajin Mohammed ShamsudhinNo ratings yet

- Casting DefectsDocument38 pagesCasting DefectsAhmad Raza TararNo ratings yet

- Identifying Casting DefectsDocument4 pagesIdentifying Casting Defectsdarwin_huaNo ratings yet

- Pouring of MetalDocument6 pagesPouring of Metalرسول ناصر كريم خريبطNo ratings yet

- Casting DefectsDocument5 pagesCasting DefectskuttachicheraiNo ratings yet

- Casting Processes CompleteDocument49 pagesCasting Processes CompleteRavi KumarNo ratings yet

- REQUIRME_ASSIGNMENT3Document4 pagesREQUIRME_ASSIGNMENT3Cyber RoseNo ratings yet

- Welding DefectsDocument94 pagesWelding DefectsesamhamadNo ratings yet

- Welddefects As Per Iso 5817Document40 pagesWelddefects As Per Iso 5817shruthiNo ratings yet

- Identifying Casting DefectsDocument5 pagesIdentifying Casting Defectsrajeevkv4No ratings yet

- Hot tears and spots defects in castingsDocument4 pagesHot tears and spots defects in castingsKamran KhalidNo ratings yet

- Defects in WeldsDocument6 pagesDefects in WeldsSaran KumarNo ratings yet

- Experiment No. 6: Casting Is ADocument6 pagesExperiment No. 6: Casting Is AArun kumar rouniyarNo ratings yet

- Casting DefectDocument25 pagesCasting Defectravikataria02No ratings yet

- Types of Welding Defects PDFDocument12 pagesTypes of Welding Defects PDFDhiab Mohamed AliNo ratings yet

- Inherent: They Are Usually Related To Discontinuities Found in TheDocument10 pagesInherent: They Are Usually Related To Discontinuities Found in TheBhadresh PatelNo ratings yet

- Metal CastingDocument69 pagesMetal CastingMohd Mansoor HasanNo ratings yet

- Weld Defect - WikeepidiaDocument5 pagesWeld Defect - Wikeepidiapuri16No ratings yet

- castingDocument12 pagescastingS V Garata ReddyNo ratings yet

- Welding Defects: Their Causes and PreventionDocument18 pagesWelding Defects: Their Causes and PreventionsanjaykumarmauryaNo ratings yet

- Basic Mechanical EngineeringDocument70 pagesBasic Mechanical EngineeringHemachandran100% (6)

- Defect in Casting For Amie Manufacturing Technology and Manufacturing ScienceDocument33 pagesDefect in Casting For Amie Manufacturing Technology and Manufacturing ScienceparameshwaranpraveenNo ratings yet

- Defect Related FailuresDocument24 pagesDefect Related FailuresAhmad AloudahNo ratings yet

- Factors Affecting CastingDocument6 pagesFactors Affecting CastingMuhammad BilalNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Farm and Workshop Welding, Third Revised Edition: Everything You Need to Know to Weld, Cut, and Shape MetalFrom EverandFarm and Workshop Welding, Third Revised Edition: Everything You Need to Know to Weld, Cut, and Shape MetalNo ratings yet

- The Home Blacksmith: Tools, Techniques, and 40 Practical Projects for the Blacksmith HobbyistFrom EverandThe Home Blacksmith: Tools, Techniques, and 40 Practical Projects for the Blacksmith HobbyistRating: 4 out of 5 stars4/5 (1)

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforFrom EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNo ratings yet

- Bahasa English - The Coronavirus Exposes EducationDocument3 pagesBahasa English - The Coronavirus Exposes EducationmkmkhairiNo ratings yet

- ISO 03714-1980 ScanDocument4 pagesISO 03714-1980 ScanmkmkhairiNo ratings yet

- Jumper LineDocument2 pagesJumper LinemkmkhairiNo ratings yet

- Jumper LineDocument2 pagesJumper LinemkmkhairiNo ratings yet

- Parker PM50 Permanent Magnetic Yoke SetDocument1 pageParker PM50 Permanent Magnetic Yoke SetmkmkhairiNo ratings yet

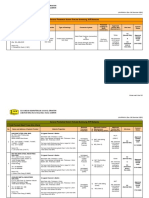

- Project Quality PlanDocument43 pagesProject Quality Planmkmkhairi100% (4)

- Iron AlloysDocument6 pagesIron AlloysHieu NguyenNo ratings yet

- Grinding MachineDocument15 pagesGrinding MachineTan Jun Zhe0% (1)

- Construction Specification 781-Metal Fabrication and InstallationDocument3 pagesConstruction Specification 781-Metal Fabrication and InstallationJing JingNo ratings yet

- Fixed Fastener Tolerance Calculation ASME Y14.5M-1994 APPENDIX B4Document7 pagesFixed Fastener Tolerance Calculation ASME Y14.5M-1994 APPENDIX B4jowarNo ratings yet

- Metric Steel Sheet SpecsDocument4 pagesMetric Steel Sheet SpecsNurNo ratings yet

- CNC lathe frame for DIY CNC machineDocument13 pagesCNC lathe frame for DIY CNC machineMujjo SahbNo ratings yet

- Using Caterpillar Replacement Thread Inserts (0676) : Instrucción EspecialDocument9 pagesUsing Caterpillar Replacement Thread Inserts (0676) : Instrucción EspecialMiguel Gutierrez50% (2)

- Tapping Size Clearence HoleDocument7 pagesTapping Size Clearence HoledeepakanoorNo ratings yet

- Kinematic Structures and Machining Possibilities of Some CNC Machine ToolsDocument9 pagesKinematic Structures and Machining Possibilities of Some CNC Machine ToolsmusthakmechNo ratings yet

- 52 - ApprovedTrussSystem List 09 Disember 2020 - 0Document13 pages52 - ApprovedTrussSystem List 09 Disember 2020 - 0Ana RozaininaidaNo ratings yet

- Automation, Prouction Systems and CIM MP GROOVER CHAPTER 7 SolutionDocument24 pagesAutomation, Prouction Systems and CIM MP GROOVER CHAPTER 7 SolutionMuhammad Adeel Ahsen100% (1)

- MOMENT EndplateDocument8 pagesMOMENT Endplatemoseslugtu6324No ratings yet

- Forming questions (1)Document6 pagesForming questions (1)ibrahimtalal702No ratings yet

- Machinery and Equipment List for Plastic Processing LabDocument17 pagesMachinery and Equipment List for Plastic Processing LabParitosh DiwasaliNo ratings yet

- BN 4850Document2 pagesBN 4850Alexandros KarasmanoglouNo ratings yet

- BS en 14399-7-2018 - TC - (2021-05-23 - 05-17-06 PM)Document67 pagesBS en 14399-7-2018 - TC - (2021-05-23 - 05-17-06 PM)EmreNo ratings yet

- ALRO MetalsGuidePDFCatalogJune2013LRDocument544 pagesALRO MetalsGuidePDFCatalogJune2013LRIsmael ZavalaNo ratings yet

- DAFTAR HARGA SUKU CADANG HYUNDAI PRICE-16514YG1Document1,438 pagesDAFTAR HARGA SUKU CADANG HYUNDAI PRICE-16514YG1andrew candraNo ratings yet

- Aalco Aluminium PlateDocument2 pagesAalco Aluminium PlateJose MatosNo ratings yet

- Pdvsa: Engineering Design ManualDocument4 pagesPdvsa: Engineering Design ManualnoxleekNo ratings yet

- Basic Mechanical - Engineering-Soldering Brazing and WeldingDocument10 pagesBasic Mechanical - Engineering-Soldering Brazing and WeldingRavichandran GNo ratings yet

- HSFG bolting specification for bridgesDocument12 pagesHSFG bolting specification for bridgesRadha KrishnanNo ratings yet

- Term Paper-Sheet Metal WeldingDocument6 pagesTerm Paper-Sheet Metal Welding11gargdinesh7No ratings yet

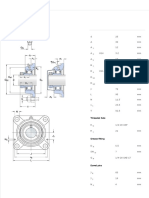

- Y-Bearing Square Flanged Units - FY 25 FM PDFDocument2 pagesY-Bearing Square Flanged Units - FY 25 FM PDFEmin SoftićNo ratings yet

- Iso 20crmo4Document2 pagesIso 20crmo4Kumar SanthanamNo ratings yet

- Turnbuckle Hook To EyeDocument1 pageTurnbuckle Hook To EyeeraswastaNo ratings yet

- 42CrMo4 steel product specificationDocument3 pages42CrMo4 steel product specificationeduardomanar1224No ratings yet

- 0108eng PDFDocument36 pages0108eng PDFsanthoshNo ratings yet

- Weldability of P91 SteelsDocument9 pagesWeldability of P91 SteelsAkshay KumarNo ratings yet

- CNC ExercisesDocument51 pagesCNC ExercisesMinh Lam100% (10)