Professional Documents

Culture Documents

SW652 1 OP Manual

SW652 1 OP Manual

Uploaded by

Irawan Budi Santosa0 ratings0% found this document useful (0 votes)

194 views94 pagesOriginal Title

SW652-1-OP-Manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

194 views94 pagesSW652 1 OP Manual

SW652 1 OP Manual

Uploaded by

Irawan Budi SantosaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 94

No,__2498-96190-0__

A Read this handbook thoroughly and understand the whole information

contained before trying to operate, inspect and service your machine!

OPERATING &

MAINTENANCE

INSTRUCTIONS

MODEL

SW652-.-1sSeries

VIBRATING SW652-1 SW652B.:

Ws SW652ND-1

From SW6521 — 1SW47 — 20101

SW652B.1 — 1SW47 - 20101

SW652ND-1 — 1SW47 - 20101

SAKAI

ee

PREFACE

PREFACE |

This operator's manual serves as a guide for the use of your Sakai SW652-1 Series Vibrating

Roller for those who are new to the machine, and also for the people who have experience in

using the Machine and want to refresh their knowledge for the machine.

Read this manual thoroughly and try to fully understand the information before operating your

machine, Keep this handbook at hand whenever you do your work.

The main subjects of this manual are:

(1) Basic precautions for safety, (2) Operation, (3) Daily maintenance and (4) Specifications.

For operation and maintenance of the engine, refer to the Engine Instruction Manual

furnished separately. Descriptions in this manual can differ from the machine instructions

of your machine due to the results of the invest gation and improvement in its design. If you

have any inquiry regarding your Machine or this manual, contact our distributors.

[contents

CONTENTS

PREFACE

MACHINE AND ENGINE IDENTIFICATION NUMBERS.

SAFETY NOTICES, ae zi

4. BASIC PRECAUTIONS FOR SAFETY .

1.1 General Precautions

4.2 Preparation for Safe Operation ..

13 Before Starting the Engine.

1.4 After Starting the Engine...

45 During Operation ......

4.6 Loading and Unloading...

1.7 Transportation .

118 Handling the Battery...

19 Towing

1.10 Before Servicing

4.11 During Servicing

1.12. Safety Decals...

2. OPERATION.

2.1 Instruments and Controls,

2.1.1 Operator's station...

2.12 Gauges, indicator lamps and warning lamps ..

Switches. :

Operating lovers and pedals ....

Unloader valve ...1.m

16 Fuse box...

2.2 Handling and Adjustments

.2.1 Seat adjustment. ia

2.2 Adjustment and replacement of scraper.

2.3 Disengaging the brake when towing

2.3 Operation.

Before-starting inspection

Starting the engine.

After starting the engin

Traveling

Stopping / Parking.

Stopping the engine...

Check after stopping the engine.

24 Vibratory Operation .nrnnnrn

aca oreeeeecee a __ CONTENTS |

25 Sprinkler

2.6 Precautions for Work...

2.6.1 Compaction operation

2.6.2. When going downhill

2.6.3 Ona slope.

2.7 Applicable Jobs

2.8 After Operation.

2.9 Loading and Unloading...

2.9.1 Use of a trailer equipped with a winch

2.9.2 Self-propeliing .. +

2.10 After Loading the Machine.

2.11 Transportation... i

2.12 Operation in Cold Weather.

2.12.1 Fuel oil and grease..

2.12.2 Coolant

2.12.3 Battery.

2.13 When the Cold Season is Over.

2.14 For a Long Storage Period.

2.15 During the Storage Period ..

2.16 When the Battery Has Discharge <

2.16.1 Connection and disconnection of booster cables.

3. PERIODICAL MAINTENANCE

3.1 Precautions.

3.4.1 Lifting the machine on a hoist ..

3.2 Walk-Around Checking

3.3 Periodical Maintenance P

3.4 Maintenance Procedure.

(1) Every 10 hours or daily.

(2) Every 50 hours

(3) Every 250 hours.

(4) Every 500 hours.......

(6) Every 1000 hours

(6) As required...

3.5 Consumable Parts...

3.6 Feeding Water and Lubricants

3.7 Electric Wiring Diagram ...

4. SPECIFICATIONS.

MACHINE AND ENGINE I

MACHINE AND ENGINE IDENTIFICATION NUMBERS.

When ordering parts or making inquiries about your machine, the following information is

requested:

(1) Machine model

Indicated on the dashboard in the operator's sfation.

Ko

er

(2) Machine serial number

‘SW652-1 7]

swes2B-1 | 18w47-COOOO

SW652ND-1

(3) Engine serial number Te

/

Location

SAFETY NOTICES

For the safe use of your machine, correct handling and periodical maintenance are of utmost

importance. Thoroughly read the safety precautions described in this manual. Do not attempt

to operate and maintain your machine until you gain a full understanding of these safety

statements.

This manual covers the proper and safe method of driving and handling of this machine for its

intended use. When this machine is used a manner, other than that covered in this manual,

you must assume responsibility for your own persoral safety.

In this manual and on the machine, you will find safety notices. Each safety notice starts with

a signal word as shown below:

Adancer Denotes that there is an extreme hazard. If you fail to

take proper precautions, itis highly likely that you could

be killed or seriously injured (The color of the symbol 4

is red).

Aiwarning Denotes that there is a hazard. If you fall to take proper

precautions, you could be killed or seriously injured

(Symbol Abs orange).

Acaution Calls attention to safety practices. If you fail to take

proper precautions, you could be injured or cause

damage to the machine (Symbol & is yellow).

a SAFETY NOTICES

Itis almost impossible for the safety notices in this manual and or the machine to cover all the

potential dangers. Keep alert to possible dangers not mentioned in this manual and on the

decales.

Awarninc

Do not operate your machine before you read its operator's

manual thoroughly.

Incorrect operation can kill or cause injury.

It is your responsibility to operate the machine safely.

‘+£ Non-approved modifications can pose safety-related problems. Before making any

modifications, consult your distributor. For an injury or damage to the machine caused by

non-approved modifications, Sakai accepts no responsibility

+ Basic precautions for safe operation of your machine are discussed begi

© To operate and work with your machine, you must be qualified.

ws ___ WARNING: Nealigence of these i

[1 BASIC PRECAUTIONS FOR SAFETY

1. BASIC PRECAUTIONS FOR SAFETY

1.1 General Precautions

1 Read thoroughly the operator's manual.

Inderstand the functions of the controls and gauges.

Familiarize yourself with their location and how to Nl I

operate them. Understand the meaning of all the.

symbols,

Ml Obey the worksite rules.

* Follow the worksite rules such as matters forbidden or to be attended to, and working

procedures.

I Wear protective clothing to suit the work.

Wear clothing, safety shoes and hard hat to suit your work.

* Do not wear clothing and accessories that tend to get caught in the controls or protruded

portions of the machine. Do not wear oily clothing.

According to the type of jobs, wear safety goggles or mask.

SOvwORe

+ Know the terrain, geology and conditions of the road surface at the worksite. Start working

after securing safety such as stationing a guardsman or putting up barriers where there is a

risk of falling of the machine or collapse of shoulder.

I Provide against an accident.

* Decide in advance the means of communication in an emergency. Know the location and

use of an extinguisher and first-aid kit.

IW Know the capability of the machine.

* Thoroughly understand the performance of your machine and correctly operate the

machine to meet the requirements of the job site, Operating the machine beyond its

capabilities may lead to an accident. Use your machine within its capability.

‘A WARNING: Negligence of these instruct

jis =

Do not use a machine which has not been serviced correctly at regular intervals.

+ Before working, perform necessary inspections. Start operation only after making

certain the machine is in good operating condition. if found to be abnormal, report to the

responsible person and have the fault corrected. Operate the machine after making sure

that itis safe to operate.

Ins can lead to accidents. i

“1. BASIC PRECAUTIONS FOR SAFE

Do not allow anyone to enter the work area except for authorized personnel.

* Always conduct the work paying attention to the

workers around the machine.

Be careful of hot parts.

* After your machine has operated for some time, the

coolant, engine oil and hydraulic fluid will become hot

and the pressure will build up. If, in this state, you try to

remove the filler caps, drain the oil or replace the filters,

you can get burned, Perform this work in accordance

with the correct procedures with the machine cooled ‘ili

down:

+ To remove the radiator cap, slowly loosen the cap to

relieve the pressure with the engine shut down and the

coolant cooled down. (For the radiator cap with a lever,

lift the lever to release the trapped pressure.)

+ When removing the filler cap on the hydraulic tank, release the trapped pressure by turning

it out slowly to prevent the oil from gushing out.

* Do not touch the muffler while the engine is running or immediately after it has been shut

down. You can get burned.

Be careful with fi

* The fuel, oil, and anti-freeze will catch fire if open

flames or ignition sources are used close to them

Particularly, the fuel is highly flammable.

* Do not smoke or use a match or cigarette lighter close

to inflammables (combustibles).

+ When refueling, stop the engine and do not smoke.

+ The filler caps of the fuel and oil tanks must be kept

tight.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Vibratory Tandem RollerDocument2 pagesVibratory Tandem RollerIrawan Budi SantosaNo ratings yet

- SW TW502 Op ManualDocument101 pagesSW TW502 Op ManualIrawan Budi SantosaNo ratings yet

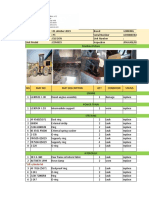

- Surat Pengiriman Barang (Delivery Notes) : PT PP Presisi Doc. No: ... /PD/XI/2021Document3 pagesSurat Pengiriman Barang (Delivery Notes) : PT PP Presisi Doc. No: ... /PD/XI/2021Irawan Budi SantosaNo ratings yet

- RPL - Main Pump PC70-8Document15 pagesRPL - Main Pump PC70-8Irawan Budi SantosaNo ratings yet

- Category Fast Moving20211123 - 18160290Document1 pageCategory Fast Moving20211123 - 18160290Irawan Budi SantosaNo ratings yet

- Series: Vibratory Tandem RollerDocument2 pagesSeries: Vibratory Tandem RollerIrawan Budi SantosaNo ratings yet

- PRS Lonking 833 CilegonDocument4 pagesPRS Lonking 833 CilegonIrawan Budi SantosaNo ratings yet

- 01.permohonan Pengecekan Alat Titipan Rev.01Document2 pages01.permohonan Pengecekan Alat Titipan Rev.01Irawan Budi SantosaNo ratings yet