Professional Documents

Culture Documents

RED WHITE Cast Iron Gate Valve - 125 LB.: Features

Uploaded by

Sergio DjbucaneroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RED WHITE Cast Iron Gate Valve - 125 LB.: Features

Uploaded by

Sergio DjbucaneroCopyright:

Available Formats

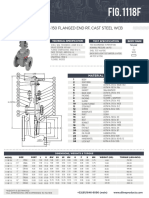

RED WHITE Cast Iron Gate Valve – 125 lb.Fig. No.

511

Features 22 21

3

• Outside Screw and Yoke

• Rising Stem

• Solid Wedge Disc

• Bronze Trimmed

15

• Flanged Ends

18

• Conforms to Specifications of MSS-SP-70 2

Cast Iron

Working Pressures Fig. 1

Working Pressure Non-Shock (psi) Test Pressure (psi)

Saturated Steam Cold Water, Oil, Gas Shell (Water) Seat (Water)

125 200 350 220

5

23 11

12

10

Materials & Specifications

Item Description Material Specification 17

1 Body Cast iron ASTM A126 Class B 14 9

2 Bonnet Cast iron ASTM A126 Class B 19

2

3 Yoke Cast iron ASTM A126 Class B

4 Disc Cast iron ASTM A126 Class B 8

16

5 Handwheel Ductile iron ASTM A536 Grade 60-40-18 20

13

6 Body seat ring Stainless Steel A182 Grade F6a

7 Disc seat ring Stainless Steel A182 Grade F6a

8 Stem Stainless Steel A182 Grade F6a 6

9 Gland Stainless Steel A182 Grade F6a 4

10 Yoke sleeve Cast bronze ASTM B62-C83600

11 Wheel nut Steel ASTM A36

12 Washer Brass plate ASTM B36-C2600 7

13 Bonnet bolt Steel ASTM A307 Grade B*

1

14 Gland bolt Steel ASTM A307 Grade B*

15 Yoke bonnet bolt Steel ASTM A307 Grade B*

D1

16 Bonnet bolt nut Steel ASTM A563 Grade A*

17 Gland bolt nut Steel ASTM A563 Grade A*

18 Yoke bonnet bolt nut Steel ASTM A563 Grade A*

19 Gland packing Non-asbestos

20 Gasket Non-asbestos

21 Sleeve nut Cast iron ASTM A126 Class B

H

22 Knock pin Steel ASTM A36

23 Nameplate Aluminum plate ASTM B209-1100

D

*Zinc plated

“G” Bolt Dia

“N” holes

eq spaced

Dimensions & Weights (inches-lbs.) T on “C” BC

L “h” Hole Dia

Size 1-1/2 2 2-1/2 3 4 5 6 8 10 12 14

L - 7.00 7.50 8.00 9.00 10.00 10.50 11.50 13.00 14.00 15.00 Notes:

1. Face to face dimensions for flanged gate valves conform to ANSI B16.10.

H - 13.90 16.2 18.60 21.70 25.80 29.80 37.70 46.10 53.70 59.90

2. End flange dimensions and drilling conform to ASME B16.1.

D1 - 7.10 7.10 7.10 7.90 9.10 9.80 11.00 14.20 15.70 19.70 End flanges are fully flat faced and smooth finished on the joint side in

D - 6.00 7.00 7.50 9.00 10.00 11.00 13.50 16.00 19.00 21.00 accordance with MSS-SP-6.

C - 4.75 5.50 6.00 7.50 8.50 9.50 11.75 14.25 17.00 18.75 3. Pressure-temperature ratings conform to those specified in

T - 0.62 0.69 0.75 0.94 0.94 1.00 1.12 1.19 1.25 1.38 MSS-SP-70.

4. Disc seat rings in all sizes are pressed into discs.

N - 4 4 4 8 8 8 8 12 12 12

5. Bodies are reinforced with a lateral rib in sizes 10" and larger.

h - 0.75 0.75 0.75 0.75 0.88 0.88 0.88 1.00 1.00 - 6. For sizes 4" and larger, by-pass bosses are provided at A, B, E & F

G - 0.62 0.62 0.62 0.62 0.75 0.75 0.75 0.88 0.88 - positions in accordance with MSS-SP-45.

Wt. - 31 44 53 80 105 138 225 371 513 828 7. For sizes 10", 12", & 14", yoke is separated from bonnet as Fig. 1.

Imfluid RED-WHITE

WHITE

VALVE CORP.

IMFLUID LTD. Compania 1973 Santiago Chile Tel: (+56-02) 6967479 E-mail: ventas@imfluid.cl www.imfluid.cl

-59-

You might also like

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- GL 125 150Document1 pageGL 125 150FABIONo ratings yet

- Cast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Document4 pagesCast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Sushil ChauhanNo ratings yet

- Cast Steel Gate Valve Class 150 & 300 SpecificationsDocument4 pagesCast Steel Gate Valve Class 150 & 300 Specificationsarmin heidariNo ratings yet

- Technical Data Sheet: Series 4200 Type W Pressure GateDocument2 pagesTechnical Data Sheet: Series 4200 Type W Pressure GateJayNo ratings yet

- Non Return Valves Cast Steel APIDocument4 pagesNon Return Valves Cast Steel APILinson GeorgeNo ratings yet

- Globe Valves - ASME Class 900 & 1500: Flanged EndDocument1 pageGlobe Valves - ASME Class 900 & 1500: Flanged EndMunishTrichyNo ratings yet

- Series 45114 Flanged Globe ValveDocument4 pagesSeries 45114 Flanged Globe Valveeduardo goveaNo ratings yet

- FNW FigDocument1 pageFNW Fighamzabayat2338No ratings yet

- Hidrante Seco Mod F0733Document1 pageHidrante Seco Mod F0733Julio FloresNo ratings yet

- Cast Steel Globe Valve Pressure Seal Class 1500, 2500Document3 pagesCast Steel Globe Valve Pressure Seal Class 1500, 2500Andri AjaNo ratings yet

- Relief ValveDocument2 pagesRelief ValveRobertoNo ratings yet

- KITZ - Cast Iron - 125FCL&125FCYDocument2 pagesKITZ - Cast Iron - 125FCL&125FCYdanang hadi saputroNo ratings yet

- LT Ci Web PDFDocument6 pagesLT Ci Web PDFjaihindNo ratings yet

- ES Model W-M115-3Document2 pagesES Model W-M115-3moekimo3No ratings yet

- Gate Valve Materials ListDocument2 pagesGate Valve Materials ListJavier FernandezNo ratings yet

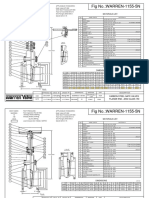

- Valvula Warren-2155-5nDocument2 pagesValvula Warren-2155-5nFernando castellano castroNo ratings yet

- Walworth 5202F 150lb GatesDocument5 pagesWalworth 5202F 150lb GatesAnthonyNo ratings yet

- V3-GAN-A125 Gate Valve SpecificationDocument1 pageV3-GAN-A125 Gate Valve SpecificationArthur DeiparineNo ratings yet

- K-601-Ip, Ind PSTDocument1 pageK-601-Ip, Ind PSTamir shokrNo ratings yet

- Data Sheet PSVDocument12 pagesData Sheet PSVDiego RuanoNo ratings yet

- Fig No.:WARREN-1155-5N: Materials ListDocument2 pagesFig No.:WARREN-1155-5N: Materials ListDiego OrtegaNo ratings yet

- Plummech Post IndicatorDocument1 pagePlummech Post IndicatorNguyễn Đăng PhúcNo ratings yet

- Delta Pacific Valve Mfg. Co.: New York, U.S.ADocument1 pageDelta Pacific Valve Mfg. Co.: New York, U.S.ALê Tuấn AnhNo ratings yet

- Gate Valve Drawing and SpecificationsDocument1 pageGate Valve Drawing and SpecificationsismailNo ratings yet

- Gala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BDocument7 pagesGala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BChhomNo ratings yet

- Class 150 Cast Carbon Steel Gate ValveDocument1 pageClass 150 Cast Carbon Steel Gate Valvearief sugiartoNo ratings yet

- 0sc Wtran 004395 (Bin Mat Qas 000195 00) B Approved With CommentsDocument44 pages0sc Wtran 004395 (Bin Mat Qas 000195 00) B Approved With Commentskhalidusman1984No ratings yet

- MV Sub R 2365 6Document1 pageMV Sub R 2365 6Harold David Gil MuñozNo ratings yet

- Flanged Gate Valves PDFDocument20 pagesFlanged Gate Valves PDFnishadNo ratings yet

- Red White Bronze Gate Valve Specs & DetailsDocument1 pageRed White Bronze Gate Valve Specs & DetailsSergio DjbucaneroNo ratings yet

- 207AB Válvulas RWVDocument1 page207AB Válvulas RWVПабло Рамирес РамиресNo ratings yet

- Van Cổng OS & Y GATE VALVE KVS-4150Document1 pageVan Cổng OS & Y GATE VALVE KVS-4150Nguyễn Kỳ TúNo ratings yet

- FMAE31Document2 pagesFMAE31Amr ATTIANo ratings yet

- Fig 4923 GDocument1 pageFig 4923 GAsmaaNo ratings yet

- Warren 1155 8 Valvulas Compuert Api600 Trim 8Document4 pagesWarren 1155 8 Valvulas Compuert Api600 Trim 8Luis ArenasNo ratings yet

- ES - Model W-M110-10.Document2 pagesES - Model W-M110-10.SANRAJ TECHNONo ratings yet

- Walworth Cast Stainless Steel SPCL AlloyDocument2 pagesWalworth Cast Stainless Steel SPCL AlloySamano ComercializadoraNo ratings yet

- R 2361 6Document2 pagesR 2361 6Angelo100% (1)

- 280B Válvulas RWVDocument1 page280B Válvulas RWVПабло Рамирес РамиресNo ratings yet

- MDT 2021 Bro Gtfe 10K FCDocument1 pageMDT 2021 Bro Gtfe 10K FCsuwono radukNo ratings yet

- Valvulas OS&YDocument1 pageValvulas OS&Ydaniel manuel garces davilaNo ratings yet

- Bronze Safety Relief Valves-Models SV5601 SV5708-Technical InformationDocument5 pagesBronze Safety Relief Valves-Models SV5601 SV5708-Technical InformationMarco ChablaNo ratings yet

- ROBINET SERTAR PANA CORP PLAT TECOFI Model V3200 - Fisa TehnicaDocument1 pageROBINET SERTAR PANA CORP PLAT TECOFI Model V3200 - Fisa TehnicaVasi ChiriacNo ratings yet

- 1118F 1318F 1618F SeriesDocument4 pages1118F 1318F 1618F SeriesĐức Thiện HuỳnhNo ratings yet

- 600scjs#cy 2-12 - 15Document2 pages600scjs#cy 2-12 - 15MohamadIbnuHassanNo ratings yet

- Series 6700 Combo GateDocument2 pagesSeries 6700 Combo GateBasadi GassamaNo ratings yet

- Flanged Resilient OS&Y Gate Valve (XZ41X), UL/FM ApprovedDocument1 pageFlanged Resilient OS&Y Gate Valve (XZ41X), UL/FM ApprovedRoman UgarteNo ratings yet

- Swagelok Pipe FittingsDocument24 pagesSwagelok Pipe Fittingsgacm98100% (1)

- Pipe Fittings - SwagelokDocument24 pagesPipe Fittings - SwagelokJagadish KumarNo ratings yet

- MS 01 147Document24 pagesMS 01 147Nabil ShaikhNo ratings yet

- Lead Free: Series 405-NRS-RWDocument2 pagesLead Free: Series 405-NRS-RWEstefanía MárquezNo ratings yet

- 504 Milwaukee Valve AngleDocument1 page504 Milwaukee Valve Anglemax_powerNo ratings yet

- Swing Check Valve 900 Class SpecDocument1 pageSwing Check Valve 900 Class SpecMunishTrichyNo ratings yet

- 03b Check Valves Preesure SealDocument2 pages03b Check Valves Preesure SealAndri AjaNo ratings yet

- Fig 4930G 5930G 4930BS Hattersley DS 1219 P36Document1 pageFig 4930G 5930G 4930BS Hattersley DS 1219 P36Prithvi DhakalNo ratings yet

- F1111 14 In. 24 In. Ul FM Data SheetDocument1 pageF1111 14 In. 24 In. Ul FM Data SheetAhmed SamirNo ratings yet

- 47XU Gate CraneFS DS p103 0620Document1 page47XU Gate CraneFS DS p103 0620Younis JanNo ratings yet

- 02.T Throttle Type Globe Valve Bonnetless: FeaturesDocument1 page02.T Throttle Type Globe Valve Bonnetless: Featureskamal arabNo ratings yet

- Two Orifice Float Trap TOFT GuideDocument4 pagesTwo Orifice Float Trap TOFT GuideHiranthaNo ratings yet

- SR 100 Eam-Tb-8100Document6 pagesSR 100 Eam-Tb-8100Sergio DjbucaneroNo ratings yet

- Elster American Meter Standards ComplianceDocument5 pagesElster American Meter Standards ComplianceJorge Hernan Castro QuintanaNo ratings yet

- 51 51 16U 81 Issue 16Document3 pages51 51 16U 81 Issue 16Boris SergantNo ratings yet

- Ficha Tecnica 1813 BDocument12 pagesFicha Tecnica 1813 BnicolasuribeNo ratings yet

- Cast Carbon Steel Check Valve: Class 150Document1 pageCast Carbon Steel Check Valve: Class 150Mina MagdyNo ratings yet

- Red White Bronze Gate Valve Specs & DetailsDocument1 pageRed White Bronze Gate Valve Specs & DetailsSergio DjbucaneroNo ratings yet

- Exothermics Stainless Steel Heat Exchangers: 3/20/2015 Installation Guide 500Document16 pagesExothermics Stainless Steel Heat Exchangers: 3/20/2015 Installation Guide 500Sergio DjbucaneroNo ratings yet

- Exothermics Heat Exchangers: Transfer Energy With Greater EfficiencyDocument4 pagesExothermics Heat Exchangers: Transfer Energy With Greater EfficiencySergio DjbucaneroNo ratings yet

- Exothermics Aluminum Heat Exchangers: 3/20/2015 Installation Guide 550Document16 pagesExothermics Aluminum Heat Exchangers: 3/20/2015 Installation Guide 550Sergio DjbucaneroNo ratings yet

- Maxon Pscheck: Partial Stroke Technology With Series 8000 Pneumatic Safety Shut-Off ValveDocument8 pagesMaxon Pscheck: Partial Stroke Technology With Series 8000 Pneumatic Safety Shut-Off ValveSergio DjbucaneroNo ratings yet

- Exothermics Tubular Heat Recuperators: 3/20/2015 Installation Guide 545Document12 pagesExothermics Tubular Heat Recuperators: 3/20/2015 Installation Guide 545Sergio DjbucaneroNo ratings yet

- Exothermics Heat Exchangers: Transfer Energy With Greater EfficiencyDocument4 pagesExothermics Heat Exchangers: Transfer Energy With Greater EfficiencySergio DjbucaneroNo ratings yet

- Cryogenic Bola Ac. Inox.Document2 pagesCryogenic Bola Ac. Inox.Sergio DjbucaneroNo ratings yet

- 02-00017 SMARTLINK DS BrochureDocument8 pages02-00017 SMARTLINK DS BrochureSergio DjbucaneroNo ratings yet

- ST441manual SpecDocument5 pagesST441manual SpecSergio DjbucaneroNo ratings yet

- Simple Phenomena of Magnetism 1 MSDocument4 pagesSimple Phenomena of Magnetism 1 MSnssNo ratings yet

- III - D S BDTM921 - T V M: ATA Heet WO Alve AnifoldDocument2 pagesIII - D S BDTM921 - T V M: ATA Heet WO Alve Anifoldrob.careyNo ratings yet

- HoW To Dispose Outdated ElectronicsDocument10 pagesHoW To Dispose Outdated ElectronicsNoel JosephNo ratings yet

- DH WorkshopDocument17 pagesDH Workshopaan monNo ratings yet

- Tungsram-LED-Bright-Stik-DataSheet-EN - SASODocument3 pagesTungsram-LED-Bright-Stik-DataSheet-EN - SASORoudy J. MhawasNo ratings yet

- OS06Document19 pagesOS06Asghar Khattak FDCPNo ratings yet

- File System OperationsDocument2 pagesFile System OperationsRobert FavourNo ratings yet

- DIGI Usecases MAIN DOC V20 enDocument18 pagesDIGI Usecases MAIN DOC V20 enZine eddine Hadj mokhnachrNo ratings yet

- Democratising Digital Commerce in India: ONDC's Vision and RoadmapDocument160 pagesDemocratising Digital Commerce in India: ONDC's Vision and RoadmapAnuragNo ratings yet

- 2.5G 850nm 550m SFP TransceiverDocument6 pages2.5G 850nm 550m SFP TransceiverGLsun MallNo ratings yet

- Allyvensia Binti Dohiuil 65385Document4 pagesAllyvensia Binti Dohiuil 65385ALLYVENSIA DOHIUILNo ratings yet

- PE CurriculamDocument145 pagesPE Curriculamavula43No ratings yet

- SASY60 IDocument50 pagesSASY60 IAlisson Duarte MoreiraNo ratings yet

- The Studio 3T Field Guide To MongoDB AggregationDocument148 pagesThe Studio 3T Field Guide To MongoDB AggregationF ZaidiNo ratings yet

- Online Banking Authentication System Using QR-code and Mobile OTPDocument6 pagesOnline Banking Authentication System Using QR-code and Mobile OTPግሩም ሽ.No ratings yet

- 300+ Angular Interview QuestionsDocument64 pages300+ Angular Interview QuestionsAmit Naik100% (1)

- La Maison RadaDocument7 pagesLa Maison RadaAbelardo BrazilNo ratings yet

- Mini Split MlaDocument8 pagesMini Split MlaAmbar JuarezNo ratings yet

- G3-160T DataSheet 245Document2 pagesG3-160T DataSheet 245Henry Esteban MesiasNo ratings yet

- Ecgr3155 Experiment 8 Mosfet Amplifiers Configurations and Input Output ImpedancesDocument9 pagesEcgr3155 Experiment 8 Mosfet Amplifiers Configurations and Input Output ImpedancesdrhammoudaNo ratings yet

- Ashwin ProjectDocument35 pagesAshwin ProjectShraddha WagheNo ratings yet

- Paradigms of HMIDocument23 pagesParadigms of HMITiến PhạmNo ratings yet

- PEOPLECERT 106 MoP Foundation PEOPLECERT 106 Exam Exam DumpsDocument6 pagesPEOPLECERT 106 MoP Foundation PEOPLECERT 106 Exam Exam DumpsThomas WilliamNo ratings yet

- From a CDS View to an OData Service for AnalyticsDocument18 pagesFrom a CDS View to an OData Service for AnalyticsParesh GanganiNo ratings yet

- Final Report OMNI WING AIRCRAFTDocument51 pagesFinal Report OMNI WING AIRCRAFTPrithvi AdhikaryNo ratings yet

- My First Ttcn-3 Project With TtworkbenchDocument19 pagesMy First Ttcn-3 Project With TtworkbenchPramod KumarNo ratings yet

- Math 8 Unit 1Document12 pagesMath 8 Unit 1api-114939020No ratings yet

- Profilesiteneng9 161007045623Document31 pagesProfilesiteneng9 161007045623Aditya SinghNo ratings yet

- Parts Book: TA25/TA27 Articulated TruckDocument536 pagesParts Book: TA25/TA27 Articulated TruckYeison RamirezNo ratings yet

- Crafco Matrix Bridge Joint Mastic BrochureDocument2 pagesCrafco Matrix Bridge Joint Mastic BrochureElisa Silva BohorquezNo ratings yet