Professional Documents

Culture Documents

Intake Pressure Tester For 2.7T Engine: Parts List: Tool List

Intake Pressure Tester For 2.7T Engine: Parts List: Tool List

Uploaded by

cpspam1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intake Pressure Tester For 2.7T Engine: Parts List: Tool List

Intake Pressure Tester For 2.7T Engine: Parts List: Tool List

Uploaded by

cpspam1Copyright:

Available Formats

Intake Pressure Tester for 2.

7T Engine

Variations in boost production, air/fuel mixture, and drivability can often be traced to leaks in the in-

take system of the 2.7T engine, especially when equipped with larger fuel injectors. Finding and

eliminating leaks makes your 2.7T ownership and any long distance trouble shooting with your tuner

a much better experience.

We came up with an inexpensive method that works like a charm to pressurize the pre-throttle body

side of the intake system of the 2.7T. Feel free to source the parts on your own or you can pur-

chase the entire kit from us for a nominal price. If you want to make your own, we suggest using

www.mcmaster.com as a source for the parts. We have included the part numbers below.

A regulated compressed air source is required to operate this tester. As with all compressed air ap-

plications, take care during operation as the system will be under pressure.

Parts list: Tool list:

1 3” rubber straight joining clamp 9/16” box end wrench

McMaster # 4511K78 31/64” drill bit

1 3” PVC cap Drill

McMaster # 9102K223

Flat head screwdriver

1 7/8” vinyl cap

McMaster # 9753K86 Regulated compresser air source

1 1/4” air coupler, industrial shape Pliers

McMaster # 6534K46

1 Hose clamp

McMaster # 5388K18

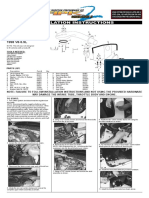

Using the 31/64” drill bit, drill a hole in the center of the PVC cap.

Thread the air coupler fitting into the cap using the 9/16” box end

wrench. The threads on the fitting will cut into the cap and make an

air tight seal. Thread the fitting down until flush with the cap, as in

Figure 1.

Install the PVC cap into the rubber joining clamp and tighten down the

large hose clamp fully.

Figure 1: Fitting installed in PVC cap

Any questions or comments, let us know: AWE-Tuning.com 215-658-1670 Page 1 of 2

Copyright 2002, AWE Tuning. No part of this document may be reused or duplicated without the express permission of AWE Tuning/Secor Ltd. All rights reserved.

Installation of the tester requires removal of the

intake hose running between the MAF and Y-pipe

(at point A in Figure 2. AWE RSK04 components

shown in Figure 2, but OEM look similar). Use pli-

ers to unload the springs clamps at each end of the

hose (flathead screwdriver with AWE RSK04 hose).

Remove the side engine covers (removed in Figure

2).

Unclip the PCV damper from Y-pipe (at point B in

Figure 2) by squeezing the clip. Figure 2 shows a

2000 and early 2001 configuration, late 2001 and

2002 will appear similar.

Figure 2: Engine bay

Close the PCV (Positive Crankcase Ventilation) branch off

the Y-pipe with the vinyl cap and hose clamp. Slip the

hose clamp over the cap and tighten fully.

Figure 3 shows 2000 and early 2001 configuration. Late

2001 and 2002 will appear slightly different.

Remove the oil filler cap, as this will eliminate a hiss noise

as air pressurizes the crankcase during testing.

Figure 3: Capping off PCV branch

Slide the rubber clamp assembly over the inlet of the

Y-pipe and tighten down the second large hose

clamp fully.

With air pressure turned off, attach the end of an air

hose to the air fitting on the PVC cap as in Figure 4.

SLOWLY increase the air pressure to the system via

a regulator. No more than 15 psi is needed to ex-

pose any leaks in the system. Be sure to stand clear

in case the tester pops off.

With pressure in the system, listen for any leaks

coming from the intake and fix as needed. Common

leaks are at hose junctions and intercooler end caps.

Figure 4: Tester installed

While this tester pressurizes only the portion of the intake before the throttle body, that is usually

enough to expose any of the common intake leaks that occur on the 2.7T engine.

Any questions or comments, let us know: AWE-Tuning.com 215-658-1670 Page 2 of 2

Copyright 2002, AWE Tuning. No part of this document may be reused or duplicated without the express permission of AWE Tuning/Secor Ltd. All rights reserved.

You might also like

- Tecbrake Installation Guide For Caterpillar 3406, 3406B and 3406CDocument18 pagesTecbrake Installation Guide For Caterpillar 3406, 3406B and 3406CJunior Lester100% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Detroit 8.2 v8Document25 pagesDetroit 8.2 v8Jose Juan Davila100% (3)

- 2008 7 8Document8 pages2008 7 8Peps Ren100% (2)

- Opel Corsa Aircon InstallationDocument18 pagesOpel Corsa Aircon InstallationJohan DiscoBiscuit PrinslooNo ratings yet

- Service Manual 300050007500 PermconDocument19 pagesService Manual 300050007500 PermconMiguel Angel Santos PintadoNo ratings yet

- Connect Series AccesoriesDocument15 pagesConnect Series AccesoriesPablo Gaspar D'Agostini AmengualNo ratings yet

- Lecture-6 Types of Electrical Wiring SystemDocument32 pagesLecture-6 Types of Electrical Wiring Systemaditya0% (1)

- C Molo TM003 eDocument8 pagesC Molo TM003 ejcclaNo ratings yet

- Electronic Unit Injector - Install: Disassembly and AssemblyDocument5 pagesElectronic Unit Injector - Install: Disassembly and Assemblysxturbo100% (1)

- Air Hydrilic PumpDocument6 pagesAir Hydrilic Pumpcampa150No ratings yet

- Lesson One - Candle, Color, and Petition MagicDocument20 pagesLesson One - Candle, Color, and Petition MagicEleonora TorresiNo ratings yet

- 428ebackhoe Loader Electrical SystemDocument4 pages428ebackhoe Loader Electrical Systemwtn2013100% (1)

- JEE Advanced Sample Papers 2 (Paper 1 & 2) by FIITJEEDocument71 pagesJEE Advanced Sample Papers 2 (Paper 1 & 2) by FIITJEEAvneesh GautamNo ratings yet

- TM 5-3800-205-23-3 Model 613CWDDocument344 pagesTM 5-3800-205-23-3 Model 613CWDAdvocateNo ratings yet

- Bs 7671 2018 Corrigendum Dec 2018 PDFDocument11 pagesBs 7671 2018 Corrigendum Dec 2018 PDFSimon Rae100% (2)

- Cummins Serie K Calibracion de ValvulasDocument63 pagesCummins Serie K Calibracion de Valvulasfrank_16100% (1)

- Compressor WabcoDocument6 pagesCompressor Wabcoruben_cruz_34No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- F16 AvionDocument26 pagesF16 AvionJuan Carlos AlvaradoNo ratings yet

- Tecbrake Installation Guide For Caterpillar 3406, 3406B and 3406CDocument18 pagesTecbrake Installation Guide For Caterpillar 3406, 3406B and 3406Cdimitriap100% (1)

- Imperial AutoDocument14 pagesImperial Autotajju_121No ratings yet

- Gate Valve MaintenanceDocument8 pagesGate Valve Maintenancechar_lynNo ratings yet

- Fuel SistemDocument55 pagesFuel SistemRodolfo AlbertoNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- E870-82 (Reapproved 2006) Standard Test Methods For Wood FluelsDocument2 pagesE870-82 (Reapproved 2006) Standard Test Methods For Wood FluelsChoirun Nisa100% (1)

- Alkylation Technology StudyDocument41 pagesAlkylation Technology StudyGabriel ManavellaNo ratings yet

- Valvework Usa. Model M MSGDocument7 pagesValvework Usa. Model M MSGLuis Enrique RicoNo ratings yet

- Unit Injector - Install: Disassembly and AssemblyDocument5 pagesUnit Injector - Install: Disassembly and AssemblyJoze 23No ratings yet

- Pump Repair ManualDocument17 pagesPump Repair ManualSergiSerrano100% (1)

- Strut Tower Brace For 2005-2008 Ford Mustang GT Catalog #5223 Installation InstructionsDocument1 pageStrut Tower Brace For 2005-2008 Ford Mustang GT Catalog #5223 Installation Instructionsdannydarko521613No ratings yet

- Injector InstalacionDocument6 pagesInjector Instalacionjose luis herreraNo ratings yet

- Prosedure Installation Eui c9Document5 pagesProsedure Installation Eui c9Un'galluNo ratings yet

- Coolaire Installation InstructionsDocument15 pagesCoolaire Installation Instructionsgeorgemesfin@gmailNo ratings yet

- G300 Brake BleederDocument7 pagesG300 Brake BleederluisNo ratings yet

- Installation and Maintenance Instructions Figure C67 Fabri-Valve Bi-Directional Knife Gate ValveDocument6 pagesInstallation and Maintenance Instructions Figure C67 Fabri-Valve Bi-Directional Knife Gate Valveعبدالرحمن عمرNo ratings yet

- 05-3087 - New Crankshaft PlugsDocument2 pages05-3087 - New Crankshaft PlugsManish patelNo ratings yet

- 57-0057 InstDocument3 pages57-0057 Instvolvo297No ratings yet

- Vectra Pipe RetrofittingDocument2 pagesVectra Pipe RetrofittingPrudzNo ratings yet

- Manual Sc32.PDF Prenza Hidraulica GatesDocument16 pagesManual Sc32.PDF Prenza Hidraulica GatesEsteban Sándiga GrandaNo ratings yet

- Unit Injector - InstallDocument4 pagesUnit Injector - InstallJose PichinteNo ratings yet

- 99-00 FM2 Two Cat Turbo KitDocument27 pages99-00 FM2 Two Cat Turbo KitDavid CahillNo ratings yet

- AEM 21 821 - Inst PDFDocument12 pagesAEM 21 821 - Inst PDFGeoff ThomasNo ratings yet

- SERVICE BULLETIN No. 012-2009 21-12-2009Document13 pagesSERVICE BULLETIN No. 012-2009 21-12-2009Bert SmitNo ratings yet

- Air CylinderDocument4 pagesAir Cylindersimbua720% (1)

- Paso de Gases Motor E-TechDocument4 pagesPaso de Gases Motor E-TechJuan José LopezNo ratings yet

- Turbo Systems Installation InstructionsDocument17 pagesTurbo Systems Installation InstructionsAndrew DavisNo ratings yet

- Breakage of The Tightening Stud of Cyl - CoverDocument5 pagesBreakage of The Tightening Stud of Cyl - Coverstergios meletisNo ratings yet

- 1.6L 4cyl Diesel & Turbo DieselDocument18 pages1.6L 4cyl Diesel & Turbo DieselLeomir BrandaoNo ratings yet

- MEGA Operating InstructionsDocument14 pagesMEGA Operating InstructionsSumit SinghaNo ratings yet

- User's Manual: Precision Pump ApplicatorDocument9 pagesUser's Manual: Precision Pump ApplicatorVishal VajatNo ratings yet

- Governor PinDocument2 pagesGovernor PinFrank FurmanNo ratings yet

- KNN 57 1506 2 - InstDocument2 pagesKNN 57 1506 2 - InsthavvkxjNo ratings yet

- K Series Throttle Body Install GuideDocument11 pagesK Series Throttle Body Install GuideHybrid Racing100% (1)

- Clinical Pelvimetry - HZ Undergraduate Obstetrics & GynaecologyDocument24 pagesClinical Pelvimetry - HZ Undergraduate Obstetrics & GynaecologyErica AlabanNo ratings yet

- 04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation InstructionsDocument10 pages04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation Instructionstrimoca_234178616No ratings yet

- Service Bulletin PDFDocument8 pagesService Bulletin PDFamrjheyNo ratings yet

- Kit Number 57-0668: Honda Civic 1.8i 16v I-Vtec 2005Document5 pagesKit Number 57-0668: Honda Civic 1.8i 16v I-Vtec 2005Thor BertNo ratings yet

- Technical Information Bulletins Ajax # 010717Document28 pagesTechnical Information Bulletins Ajax # 010717harley florezNo ratings yet

- Pp10 CCGT Power Station: Operation and Maintenance Manual Sootblower Seal Air FansDocument13 pagesPp10 CCGT Power Station: Operation and Maintenance Manual Sootblower Seal Air Fansanbesivam87_49857255No ratings yet

- TW580Document2 pagesTW580Ghassan ALkikiNo ratings yet

- 295 18EN - New Crankcase Ventilation System For Kalmar 44 AWF Straddle Car...Document3 pages295 18EN - New Crankcase Ventilation System For Kalmar 44 AWF Straddle Car...abdelghani abdelhadiNo ratings yet

- Trane Mini Split Normal InstalacionDocument12 pagesTrane Mini Split Normal InstalacionAnonymous ApjtcZ6YT6100% (1)

- Hyper-Charger Installation Instructions For YamahaDocument3 pagesHyper-Charger Installation Instructions For YamahaTaizenziggyNo ratings yet

- 4756 Civic 96-2000 D16y8 Performer XDocument3 pages4756 Civic 96-2000 D16y8 Performer XRafael Isaac Lòpez Vargas100% (1)

- 4 3 Vortec Engine Manual Powerdyne Automotive Products IncDocument6 pages4 3 Vortec Engine Manual Powerdyne Automotive Products Incgarrett86No ratings yet

- PilotSystem Gas15Gal 1BBL - V5Document21 pagesPilotSystem Gas15Gal 1BBL - V5antonio alberto gutierrez suarezNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Oil WhirlDocument2 pagesOil WhirlJitendra KumarNo ratings yet

- Metallurgy: Phase Diagram F-CDocument11 pagesMetallurgy: Phase Diagram F-CLusi MustikaNo ratings yet

- 7 - Eccentricity, Hydraulic and AerodynamicDocument13 pages7 - Eccentricity, Hydraulic and Aerodynamickurniuawan6723No ratings yet

- Aa Vq-1: Zvcmwzwe' V: 'Ywu Nl©Ynxb Wc÷Bhy Wmwjûv I 2atm PV C I 27 CDocument15 pagesAa Vq-1: Zvcmwzwe' V: 'Ywu Nl©Ynxb Wc÷Bhy Wmwjûv I 2atm PV C I 27 CAdrita KhanomNo ratings yet

- DRW ManualDocument120 pagesDRW Manualhniwan40No ratings yet

- Degraded Decryptor by Anshi Nanavati Armaann Bhansali and Ishaan RaghavanDocument7 pagesDegraded Decryptor by Anshi Nanavati Armaann Bhansali and Ishaan Raghavanapi-541981758No ratings yet

- Company Profile Manufacturer PT BMIDocument17 pagesCompany Profile Manufacturer PT BMIBayumi Tirta JayaNo ratings yet

- Why Is Mercury A Liquid at STPDocument2 pagesWhy Is Mercury A Liquid at STPZain KhanNo ratings yet

- On Indian Railway GorakhpurDocument20 pagesOn Indian Railway Gorakhpuranushka singhNo ratings yet

- Fues 1Document3 pagesFues 1ragkaraNo ratings yet

- Speedcut: Diamond Wire Cutting Machine For Marble, Granite, Sandstone and Limestone in The Dimension Stone IndustryDocument5 pagesSpeedcut: Diamond Wire Cutting Machine For Marble, Granite, Sandstone and Limestone in The Dimension Stone IndustryJose Lozano PiscoNo ratings yet

- 18002-ED-EVD-001-03-Module Datasheet PDFDocument3 pages18002-ED-EVD-001-03-Module Datasheet PDFVenkataramanan SNo ratings yet

- HKIE Seminar 18-1-2008Document120 pagesHKIE Seminar 18-1-2008Tommy Wan100% (1)

- Local Site Effects and Design Ground Motions (Lectures 23 To 26)Document8 pagesLocal Site Effects and Design Ground Motions (Lectures 23 To 26)YHTRTRNo ratings yet

- Manual Do Usuário YAMAHA PSR S900 S700 PDocument51 pagesManual Do Usuário YAMAHA PSR S900 S700 PbcsitersNo ratings yet

- Kapasitor TRVDocument7 pagesKapasitor TRVkuliah ikaNo ratings yet

- 23 Numerical-Prediction-Of-Centrifugal-Compressor-Noise PDFDocument10 pages23 Numerical-Prediction-Of-Centrifugal-Compressor-Noise PDFAnonymous zXVPi2PlyNo ratings yet

- GE2152 BCM Power Plant Engineering Notes 2Document13 pagesGE2152 BCM Power Plant Engineering Notes 2Alagar SamyNo ratings yet

- Non-Conventional Energy Sources - G. D. RaiDocument41 pagesNon-Conventional Energy Sources - G. D. RaiHari Kishan10% (10)

- Gas Assisted Injection MoldingDocument32 pagesGas Assisted Injection MoldingYuvaraj YuvarajNo ratings yet