Professional Documents

Culture Documents

Doz0115-Unpriced Bid

Doz0115-Unpriced Bid

Uploaded by

MONER MANUS0 ratings0% found this document useful (0 votes)

18 views80 pagesOriginal Title

DOZ0115-UNPRICED BID

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views80 pagesDoz0115-Unpriced Bid

Doz0115-Unpriced Bid

Uploaded by

MONER MANUSCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 80

LIST OF ATTACHMENT

es agiconeat at wil not be epedaved, epic Nad vor wed

ae marly Toad on be borowe?s Og

ven bythe ener othe borrower fork intended ues EIL-164

This drawing and design covers we propery of ENGINEERS INDIA LIMITED. Tis

L588 A216 27

except inthe ited way and eve ue permite by writen conser,

FOR MR NO.3314

VENDOR DATA REQUIREMENTS FOR

BALL VALVES

1BO18-444-16-43-voR-

3314

REVISION

SRNO| DOCUMENT TITLE | DOCUMENT NO. es

= | DATE

ADDEFKONAL TECHNICAL 018-444-16-43-aTR- 33/09/2033

|neouimewezs St

TTECENICRL, NOTES FOR VALVES 6-44-0082 33/07/2017

INSPECTION AND TEST PLAN FOR 6-01-0004 37/06/2033

waves | i

STANDARD SPECIFICATION FOR 6-81-0001 39/03/2016

POSUEIVE MATERIAL

IDENITFICATION (PMZ) A

|suppuren's work

SPECIFICATION FOR QUALITY 6-78-0002, 12/03/2015

MANAGEMENT SYSTEM REQUIREMENTS

FROM BIDDERS |

| SPECIFICATION FOR DOCUMENTATION 6-78-0003 | 32/03/2015

| REQUIRENGITS FROM SUPDLZERS

VALVE MATERIAL SPECIPICATION | B018-6-44-0006-3314 37/09/2038

23/08/2018

ee ENGINEERS INDIA LIMITED

NEW DEL

88 4 of 129

Project; PETROCHENTCAL COMPLE

Requisition No,

Rev

BOL8-644-W-MR-2914

Page 2 of 6

mrsino | mem cove DESCRIPTION ay | vow

1__ | Saonazzzocazzzz72 \VLV BALL, SHEET S40RR, 05 NCH a

2 | ssoaczzz00azzz777 VLV BALL, SHEET 54000, 0.5 INCH 6 Nos

‘3 | s40aGzzz00s2z7z77 |VLV.BALL, SHEET 54000, 0.75 INCH, 4 Nos

'4__[s4000zz700822722z |VLV.BALL, SHEET 54000. 1.0 INCH 2 Nos

| ssoqnzzzo0szzzzz7 \VLV BALL, SHEET S40QN. 0.75 INCH 7” 2 NOs

7 | st0qNzz2006222222 \VLV.BALL, SHEET S400N, 1.0 INGH 2 Nos

2 [seavazzz0043 BALL, SHEET SA0VA. 0.5 INCH 60 | nos:

‘9 [ saavAZzz00 IVCV.BALL, SHEET S40VA, 0.75 INCH 3 Nos

30 |saiwozzzovazzzzzz|VLV.BALL, SHEET 541WD, 0.5 INCH 2 Nos

ii |satwozzzonszzzzzz VLV BALL, SHEET5¢1WD, 0.75 INCH 7 Nos

32__| seaovzzz008 VLV.BALL, SHEET 54G01,05.NCH 7 5 Nos

13__| sesoizzzooazz7zz7 WLV.BALL, SHEET 54321, 0.5 INGH “ae [nos

ia | sesoizzz00sz2zzzz LV BALL, SHEET 54321, 0.75 INCH 7 4 Nos

is] sasoizzzooezzzzzz NLV.BALL, SHEET 54321, 1.0 NCH 30 [ "nos

16 | S4s01272015222772 |VLV BALL, SHEET 54321, 6.0 NCH 23 | Nos,

17 | $494622700«272222 'VLV BALL, SHEET 54045, 0.5 INCH 1 NOS.

ae [ssaB07z700«% [VLV.BALL, SHEET 54960; 0.5 NOH. aa [ nos

38 s4sa0z27005272272 |VLV.BALL, SHEET 54380, 0.75 INCH? 7 OS.

20__[s4sabzz701" VLV.BALL, SHEET 54380. 80 NCH z HOS:

21 | $4980727018222772 |VLV.BALL SHEET 54980, 14.0 INCH 2 Nos

122 | SKSBEZZ70042Z2722 \VLV.BALL, SHEET 5A3BE, 05 INCH 30 [Hos

23 | $498E727005272727 |VLVBALL, SHEET S496, 0,75 INCH 7 Nos

2a SHOBEZZZONY VLVBALL, SHEETS«9BE,3.01NOH 7 1 Nos

25___ | 5430Azz200812zzz7 |VLV BALL, SHEET 5490A, 0.75 INCH, LOOK OPENZ 5 Nos

'26___| $490Az27005222222 |VLV.BALL SHEET 5490A, 0.75 INCH 7 rT Nos

127 | SKSCAZZ700SzZz7zz VLV.BALL, SHEET SAGA, 2.0 NCH 3 NOS:

28___| S42GAz2701 1222222 \VLV.BALL SHEET 5430, 3.0 INCH 13 [Nos

23 | s4a0Azz7016222222 \VWV.BALL, SHEET S49CA, 8.0 NCH 3 NOS:

31] S#aLPzzzsoezzzzzz (VLV.BALL, SHEET S4S1P, LT. 05 INCH Fa TS

32 | sei P777508222727 VLV.BALL, SHEET S43P, LT, 1.5\NCH7_ 3 Nos

'33__| 49LPZzz5111z2zzz |VLV.BALL, SHEET 6431P, LT, 3.0 INGH, LOOK OPEN: 2 NOS

'34__| Saotzzzooazzzzz7 |VLV.BALL, SHEET 51401, 05 INCH 301 | _nos.

'35___| 54401zz2005122272 |VLV.BALL, SHEET 54401, 0.75 INCH, LOOK OPEN 12 | "nos

[36] 64401222005222777 |VLV.BALL, SHEET 54401, 0.75 NCH. 30 |_nos,

'37__| S4401zzz00szzzzzz |VLV.BALL, SHEET 54401, 1.5 INCH 1 NOS.

‘38 | 64401272000122727 |VLV.BALL, SHEET 54401, 20 NCH, LOOK OPEN 6 NOS.

33 | Sedoizzzooezzzzzz |VLV.BALL, SHEET 54401, 20 INCH 20__[ Nos.

40 | 5440127201 1122277 (VLV.BALL, SHEET 64401, 3.0 INCH, LOCKOPEN 2 NOS.

‘at 644012201 1222227 |VLV BALL, SHEET 54401, 3.01NGH 73 nos

2 "54401222019122222 |VLV.BALL, SHEET 54401, 4.0 INCH, LOOK OPEN 7” 1 NOS

'43__| Sa40izzz0r9zzzzZz |VLV_BALL, SHEET 54401, 40 1NCH 240s.

“44 Sadoizzzorszzzzz7 WIN BALL, SHEET 54401, 6.01NCH 7 3 NOS,

a5] 64401272016722727 (VLVBALL, SHEET 54401, 8.0 1NGH 3 NOS.

46 | S4401zzz0172z2zzz VLV.BALL, SHEET 5@401, 10.01NCH 1 NOS,

‘a7__| 8i403zz75i3727772 |VLV.BALL, SHEET 54403, LT, 8.0 INCH 3 NOS,

‘a8__| 64403z27515722277 |VLV.BALL, SHEET 54609, LT, 6.0 INCH 2 NOS:

‘a9 | 54019222011122227 |VLVBALL, SHEET 54415, 3.0 INCH, LOOK OPEN 2 NOS:

‘50 | Seasszz70001Z2727 |VLV.BALL, SHEET 64446, 2.0 INCH, LOCK OPEN 2 OS.

‘S1___| S44asZ7z00772727 |VLV.BALL, SHEET 54445, 20 INCH 7 6 NOs

52 | Seeaszzza0stzzzzz |VLV.BALL, SHEET 54446, CRYO, 07SINCH LOGKOPEN”| 5 NOS

Si | BISTZZAOSZZZZZE LV BALL, SHEET 54446, CRYO, OTSINCH z NOS

‘54___ | 5eaa6Zz24 18222227 [VLV BALL, SHEET 54446, CRYO, 12.0 NCH 7 NOS.

'S5__| BA406ZZ700872727 [VLV BALL, SHEET 54465,0.5 NCH [wos] |

‘37 | 64408277005122222 [VLV BALL, SHEET 54466, 0.75 NCH, LOCKOPEN ~ 3 NOS.

58 | seseezzz00sz2zzzz VLV BALL, SHEETS4466, 0.75 INCH 3 NOS

35 [S44AAZZZ011222222 VLV BALL, SHEET 544A, 3.0 INCH z NOS

‘60. | S4ABZZZ 1057222777 [VLV BALL, SHEET 544AB, IR 0.751NCH, Ta [N05

1 | 544B0Z72004227277 NLV BALL, SHEET S440D,05 NCH 7 33] Nos:

52 | 544B0272005727277 LV BALL, SHEET 54450, 0.75 INCH a7 | nos,

3 | Se4B0ZZ2006727277 LV BALL, SHEET 54400, 1.0 NOH a8 __[ Nos

‘t__ | SaaB0zzz008z77727 LV BALL, SHEET 54460. 1.5 NOH 4 Nos

5 __| seaB0zzz000z27727 \VLV BALL, SHEET 54400,20 NCH Tr [nos

15___| S4BEZZZ005Z22227 |VLV.BALL, SHEET S€BE, 0.75 INGA 33__[ Nos,

(67 | AMBEZZ2000227277 |VLV BALL, SHEET 5448E,201NCH 3 OS.

‘8 | S44BEZZ201 1Z2Z277 |VLV BALL, SHEET S44BE, 80 INCH 2 Nos

| saBEZzzOTS 7LV BALL, SHEET S44BE, 4.0 INCH z NOS

70 | S44CAZZZ005i IVLV-BALL, SHEET 544CA, 0.75 INCH, LOOK OPEN 7 @ NOS.

Ti | Sa4GAZZ2005 ViVSALL, SHEET S44CA, O7SINCH 7 74 [Nos

72 | s4sAzzz006722722 [VLV.BALL, SHEET SUCA.1.0INCH 7 6 Nos

73___| S440A722008227272 [VLV.BALL, SHEET S4CA,1.5 INCH 7 3 Os

74___| S44CAZzz008222222 NLV.BALL, SHEET SHCA, 2.0 INCH 3 Nos

75__| SMOAZZZO1 1272772 [VLV.BALL, SHEET SUACA, 3.INCH z NOs

76___| SHIOAZZZ0152722Z2 |VLV.BALL, SHEET SEACA, 6.0 INCH 3 Nos

77 |54a0727008277722 |VLV.BALL, SHEET 5440D, 2.0 NCH 7 Nos

@__ | seatozza004 IVLV.BAL SHEET 54410, 0.5 NCH [N05

‘g3__| Seat zz200gzzzzzz [VLV.BALL, SHEET S¢4LD. 1.01NGH 3 NOS.

‘sé [SaniGzz7s06272727 \VLV.BALL, SHEET 564M, LT, 1.0 INO 3 Nos

‘ss ___[saaniczzzs00: /W BAL, SHEETS@4MO, LT, 2.0 NCH 3 Nos

'a6__|SeahiPzzzs06zz2722 |VLV.BALL, SHEET S44MP,LT, 1.01NCH. 3 NOS

157” | SaaPnizzz0051222Z7 |VLV BALL, SHEET 544PM, 0.75 INCH, LOOK OPEN 3 NOs

a8 [ SaaPntzz700 LV.BALL, SHEET S44PM, 0.75 NCH 7 NOS.

39___| s44Azzz0087z2772 VLV.BALL, SHEET SMOA 20 INCH 7 ‘ NOs

50 | S4S46222405127272 [VLV.BALL, SHEET 54546, CRYO, O.75.NOH,LOOKOPEN”| 5 NOs

‘91 | sassezzzaoszzzzzz [VLV.BALL, SHEET 54548, CRYO, 0.75 NCH 30 [Nos

‘92 S4SAGZ274007227277 |VLV.BALL, SHEET 54546, CRVO, 1.0 NCH 3 NOS

‘93 | $46467224092722272 |VLV.BALL, SHEET 54546, CRYO, 2.0 NCH 2 NOs

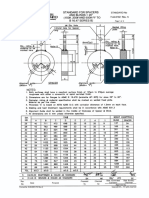

‘STANDARD SPECIFICATION No.

SHG Sy ENGINEERS TECHNICAL NOTES

ORR UMITED FOR VALVES S44, 0082 Rev. 7

aeat oh fee aartent fecfirat

TECHNICAL NOTES FOR VALVES

——

REVISED AND ISSUED AS STANGARS a

7 nora? Beareaton We NT

con 19 REVISED AND ISSUED AS STANDARD

10 SPECIFICATION Ry aro sc__ow_ND

REVISED AND ISSUEDAS STANDARD

5 040703 REVISED ANDIS ow sc DM ve

REVISED AND ISSUED AS STANDARD

4 151100 BEVSEDANDIS RN BRB NS o

3 O4GLS¢ ISSUEDINLINE WITH GENERAL REVISION AKG ONS RR 48

~ ‘Standards Standards

Commitee Bureau

E *urpose: Prepared Checked Zonvenor irman

No" Pate Purpos o by —Cenwener _chaleman

‘Approved by

Format No, €00-0001-F1 Rev. 0 ‘Copyright EL ~Alrigts reserved

a

SEONG TCU REgUREMenTS FoR smmomsrecrenton

eae Meceanwonel CRYOGENIC VALVES Page 1 of 2

‘SPECIAL REQUIREMENTS FOR LOW TEMPERATURE & CRYOGENIC VALVES

10 SCOPE

All valves of Low Temperature Carbon Steel (LTCS) and all grades of austenitic $S

(CRYO) material are categorized as cryogenic valves. All these valves shall have

extended bonnet as per BS 6364 except check valves.

Following qualification criteria shall be met by the valve vendors to quote valves for

cryogenic services:

2.0 QUALIFICATION CRITERIA

i) Both cryogenic test (clause 2.1) and reference list (clause 2.2) together shall be

considered for vendor qualification and vendor shall furnish the same, along with his

offer.

fi) Vendors who do not have cryogenic test reports and reference list covering valves of

all sizes, materials and ratings required by MR, should confirm / furnish the following

for consideration of their offer:

8. Evidence of having conducted successfully at least one cryogenic test as per

BS 6364. Test certificate shall be furnished with the offer.

'. Vendor shall confirm to conduct eryogenic test per clauses 2.1 & 2.3 for the

remaining valves not later than 12 weeks from the date of purchase order.

© Vendor shall also furnish reference list for valves supplied for non-cryo

service if reference list referred in 2.2.1 does not cover all the sizes of MR.

Offers of vendors who do not comply with above requirements would be rejected,

24 Cryogenic Test

‘Vendors to furnish copies of cryogenic test certificate for tests conducted as per details

given below:

2.1.1 Test shall be as per BS 6364,

2.1.2 Test temperature, unless specifically called for otherwise in the individual MR,

shall be -45°C for LTCS and -196°C for all grades of austenitic stainless steel.

2.1.3. Tests carried out on a particular size of one type of valve, pressure rating and

material shall qualify all sizes equal to and below the test valve size for the

same type, pressure rating and material. In case of austenitic SS any one grade

‘would qualify for all other grades of austenitic SS.

2.14. Tests should have been witnessed and certified by any one of the following

third party inspection agencies; M/s Lloyd, BV, DNV, TUV or BIL/ CEIL.

2.1.5. Cryogenic test need not be conducted for every order. Test conducted

previously and witnessed by inspection agencies listed above shall be

considered acceptable and need not be repeated.

Format No. 6-00-0001-F1 Rev. 0 ‘Copyright ETL ~ Alrighis reserved

Paae 26 of 129

ING SPECIAL REQUIREMENTS FOR STANDARD SPECIFICATION No.

INEERS

eateES@ NA “Lowrempearune 6-44-0082-A3 Rev.7

er dnaenare ‘CRYOGENIC VALVES Page 2 of?

22 Reference List

‘Vendor shall furnish reference list for valves supplied for eryogenic service indicating the

name of client, year of supply, size, material, pressure rating, type of valve and quantity.

23 Post Order Testing Procedure

23.1. Before conducting post order testing, vendor shall submit the following for

approval:

a, Test procedure (as per BS 6364),

b, Cross-section drawing of the valve with material of construction,

©. Schematic of test rig (as per BS 6364) with complete details,

2.32. Test has to be conducted irrespective of the service on largest size for each type of

valve and for each material and class rating. Vendor shall offer one, two or three

valves for selection of test valve by inspector depending upon whether quantity of

largest valve in the order is one, two or three and more than three respectively.

In the event of failure of the test valve to meet the specification requirements, the

vendor shall conduct test on two more valves. These two valves which pass test

successfully, are of lower size, then the qualification will be valid only to sizes

upto which test has been conducted successfully.

23.3. In case of non-conductance of cryogenic test(s) within 12 weeks or failure in the

test(s) conducted after receipt of order, the owner reserves the right to invoke any

of the provisions of the purchase order including cancellation of the purchase

order at the risk and cost of vendor.

30 Bonnet extension, wherever specified in the valve sheet to BS 6364 shall be for “non

cold box application” unless otherwise specified in the MR. Even if not ealled for in

valve sheet, valves indicated as “LT” or “CRYO” shall be supplied with bonnet

extension,

40 Bonnet and Gland extension joints shall be of butt welded/integrally cast construction,

50 Repair welding procedure for austenitic stainless steel valves in “CRYO” service shall

have to be qualified for impact test as per ASME B31.3. Minimum acceptable impact

‘energy shall be 20 J or lateral expansion of 0.38 mm at temperature of -196°C.

60 Wherever impact test of SS studs / nuts is called for in the data sheet, the impact value

shall be 27 J at the intended service temperature specified in the data sheets.

Format No. 6-00-0001-Fi Rev. 0 ‘Copyright EIL~ Alvighs esawed

Page 26 of 129

Paae 27 of 129

‘STANDARD SPECIFICATION No.

JENGINEERS SPECIAL REQUIREMENTS FOR,

Caer A ee ee er oe ee coszat Rev?

10

1

12

13

20

30

3

32

33

34

Format No. 600-0001-F1 Rev. 0

Page tof2

‘SPECIAL REQUIREMENTS FOR HYDROGEN SERVICE

GENERAL.

These requirements are applicable for valves used in Hydrogen service. These are in

addition to the requirements described in “Technical Notes for Valves” Spec. No. 6-44-

(0052, and shall be read in conjunction with this specification.

All cast valve flanges & bodies with flange rating of Class 900 or greater shall be

examined in accordance with paragraphs 7.2 through 7.5 of Appendix-VIT of ASME

SEC-VIIL, DIV.1, regardless of casting quality factor.

Body / bonnet / cover joints & stuffing box of all valves shall have low emission. One

valve per metallurgy, per rating, per size shall be helium leak tested as per ASME Sec.V,

Subsection A, Article 10 (Detector Probe Technique), Appendix IV at a minimum of

25% of the allowable (rated) cold working pressure. Selection of valves for helium leak

test shall be at random, Test duration shall be as follows:

Test Duration in Minutes

Pressure Class

Nominal Size

Upte300 | 600 | 8008900 | 1500 2500

Upto 2" 3 6 9 12 2

3" 06" 6 9 2 15 18

8" to 16" 9 9 2 15 18

18" to 24" 9 2 15 18 21

‘The valve shall show no leakage. No leakage is defined as a total leakage rate of less than

0.0001 mU/s of helium,

Only normalized and tempered material shall be use

the following specifications:

Castings ©: A217 Gr. WC1, A217 Gr.WC4, A217 Gr.WCS, A217 Gr.WC6, A217

Gr.WC9, A217 Gr.C5, A217 Gr.C12

Forgings : A182GrFIICL2

CS & AS VALVES

Bend test and Magnetic Particle inspection of the entire surface of body and bonnet

casting shall be in accordance with ASTM A2I7. Supplementary requirement $3 & S4

evaluation of magnetic particle, inspection shall be in accordance with MSS-SP-53

except that no linear discontinuities shall be allowed.

‘The Brinell hardness of heat treated casting shall not exceed 200 BHN for carbon steel &

225 for alloy steel.

Repair to defective casting shall be outlined in writing to the purchaser before repair

starts. Repait method to be approved prior to welding,

Casting shall be preheated to a minimum of 400°F prior to welding and all Chromium-

‘Molybdenum alloys shall be postweld heat Wreated after welding is complete, Stress

relieving is essential for welds. /./“\

Copyiight EL ~ AN Tans reserved

STANDARD SPECIFICATION No.

SSifetzIeT BS) ENGINEERS ‘SPECIAL REQUIREMENTS FOR

ei ONA UMITED

HYDROGEN SERVICE VALVES —-6~#4-0052-A4 Rev.7

Page 2 of2

35 Carbon steel shall be normalised and alloy steels shall be normalised & tempered.

36 Dye Penetrant test of welds shall be in accordance with ASTM BI165 Procedure B-2.

Interpretation as per Appendix-8 of ASME-VIII Div. 1.

37 ‘The tensile stress for AS shall be less than 100,000 psi.

38 Charpy V-notch impact testing is to be done for valve material (average 20 ft-lb for set of

3 [minimum value 15 ft-lb) at 30°F),

39 For radiography and acceptance criteria for valve castings, refer Cl. 4.2.

40 SS VALVES

44 Valve casting shall be in solution heat treated and pickled condi

42 Critical body and bonnet casing section typically defined by ASME B16.34 shall be

radiographed and shall meet ASTM E446 (upto 2" thick) Category A, B & CA Level 2,

Category CB, OC & CD Level 3, Category D, B & F Level 0. For wall thickness 2" to

4.5" comparable plates of ASTM E186 shall be used, ASTM E94 and ASTM E142 shall

be used for recommended practice & controlling quality of radiography as guide, The

‘entire surface of all castings shall be dye-penetrant inspected after pickling,

43 ‘Welds shall be 100% radiographed and evaluated in accordance with paragraph 344.5 of

ASME B31.3 with a minimum casting quality factor of 0.95, Dye Penetration test shall

be as per ASTM E165 Procedure B-2, Interpretation as per Appendix-8 of ASME-VIIL

Div.l.

Format No, 8-00-0001-F1 Rev. 0 ‘Copyright EIL ~All igh reserved

Pane 2808123

5 STANDARD SPECIFICATION STANDARD SPECIFICATION No.

SSH > ENGNEERS FOR POSITIVE MATERIAL

SHE SRARo eon wt eeromiRer3

SUPPLIER'S WORKS. Page 1 of8

faar orderen 4

POR UA Wea

& fey are farce

STANDARD SPECIFICATION

FOR

POSITIVE MATERIAL

IDENTIFICATION

(PMI)

AT SUPPLIER’S WORKS

wu tour oul | dee

(AE pe

2160076 REVISED AND REISSUED ew

2 ena REVISED ANO REISSUE ms soe

1 teorae REVISED AND REWOSUED wash wwe

00.7200 _ESUEDASSTANOAROSPEGRIGATON AKC

Sanaa — Sirs

: oped ected Commit bus

Be te Purpose Pgaree chased Com cea

Aoproved by

Format No, 8-00-0001-F1 Rev. 0 Copyright ElL— All righs reserved

Peoe 29 of 129

fa ponoiday la

cy TouoneS pexeoug

puNg _eaujuiwes spiepuers

osoding

Deane % canssr34 aNv Aas

a os on os ‘canssrau any @35nau

wa om ~ 995 L Gansst-3u ONY G3sMay

a 998 sxe iL canst aN aasinge

oo Cle a Lod - G2NSSI'3Y ONY G3SiA3y

rig oS")

SHUATVA

yor

NVId LSA.L GNV NOLLOAdSNI

Ibiole JobDh b InP!

RA) & [edlp

Tie rate

9°A0u 000-48-9 ‘S3A1vA enon sete mat

os qa Bas

ow nouvouteaae aware - Nv14.18a1 NV NolLOzdsM RRS:

panies suBu iy ~"a WBukdog

(stoaforg) mn yedooq

rea nysduewry “ayy

(doy OaW) weBuNEwEY MAY YAW

621 10 9¢ ave

APY L3-4000-00-9 ON YeWH0.

TERN expuoyeyy “1

anmpeyy fe120N “TW

ueuueyeeuey J “a

oUM ADDLEY IA,

ss19qU9

UUs YUN: a0mAU0D

aamrunuos spaepueyg wopsodsuy

ayeoyms9D a] Pua: OLN

oneaysjend souemuoyiog Sioplag, + dam Suysay apanieg onoutey— : Liaw

HEOYLoadg ammpaoo1g BUIpIaM — Sah : ODI

Jwattosnbay eyeq Jopus,, : yaa or

‘Bunsa, o1vosenyy) in : LHI

ously wonaadsuy Aviva part, Vid 20 fd uonomold ssaiBuy | dl

a 31 uwejq 1s9y pue vondodsuy—: aut

Suppers worsouod sang apiyding 208s ‘BupjoetD peonpuy wadoupAy OH

LY USUAL, OL LH

Ud YseASSY [ONYOD pry = Wd

Yd Asowsoge’] iso jeuo1Fy so1uos}s9¢q Waa

wa wawyeaLL WO} UaBospAy-oq —: Ha

uonez}ue310 Aapes Osdd ‘Sutyso] juensueg oq dd

Od SOOM WILL A]. aa

HSdN quayearnbg woqsey = go

LGN yoreasay Jong 7 Sumy Jo amynsuy enue = AID

LIA Pauw] JeuoHEWaqU] sraauiBug uOReIINIe> ‘1a,

ssuopemaaqqy

°: hostages SaATvA Te ae Ses

A 4Od

er. 1831 GN NoLtozasMt TENS gee

“ONNOWWoLsIOads GuvaNvIS

62410 6¢ 00

panasoySuBU Hy —"1a WBUKGOQ ono 241000008 ON WHOS

uoneotpoods aiqvonidde se

(ou) H - odoy aourdaooy aseyaing — | 389 JMO a1UdFoLI S389], uoNRoYtTEND-atg et

" id sad sy “ayes out

‘Buysixg -y . 7 i Prooay wOHLoIsITEn) “ ~

SON H Od Wd ‘Saar "4001 psmpunied Supe dam ¥ wda‘saM, zl

SaIpSsoId THD

squou a

a H - Sioa 6001 sompoooug patuownoog 9, 1627 WMH rt

Pe ‘yuauneas yop,

“say, onesoupéyy

aanpooorg or

‘wartadas

viauna | yariadns

gas quoome Tora | sousriaiovavio AUALLOV /dDVIS

NOLLOaASNT 40 2a098 |

SINAWAMINOME STL GNV NOLLOGASNI OE

“swuatnoop panauddy, suoneoysioods gor /ulazaxp pouigjau spuepurnsga/Od

SINSWA900 FONAUAITA 07

“soayeA Jo sjuswauynbas Suysoy winwwyurus atp sz9A09 uetg 3891. pus uoHOdsuT sy,

ad09S OT

Be,

2p Eee S3A1vA temonaenip won cerwmmtins

9°A0U yO00-1ES wOd aun WYO ee

ON NOLLVoIsIDads CHVONVIS: NV 1d 1 S41 GNV NOILO3dSNI

621 10 oF 20

onsasar uu ny ~"18 Ekiog 0.92% £4000-00-9 oN Jeuvos

ajqvondde

y Hl 4 polarons 4001 aiquotidde se sioremoy 92

| odoy qe » somsadoug 9 ‘sBuyoog 2

u 4 “y soaring iso %6001 teary /reasssyg | “purjgy‘siotse, ‘suum san ‘siyseg |S

podey ge S siscjeu puovew ws .

u u penmgneyice, | HYPE skleuy jeorwan Trusiew wig 405 sieg ve

wonsouroads war

qY y H wodas pur sui.y ‘asvypang, 7 a sBunsep iouuog pue Apog et

ydesB01poy

Pea ted Sy

tt Spot “w ‘i

- H H ody uonsadsuy KooL vorsuauic pensiy, | Ut! Pog ‘was edu | ez

ayquayidde se

os sapadoig 12410 7 201 | (Bu Apou ‘wars ‘os1q Souu0g “Kpog) |

x u Hu seiray99 wa, ‘001 “LGN ‘wwowsealy way sfurfiog 3 sSuns09 Ve

“jworumysoyy yootway>

oz

vain | wartaans | “Arians 32H 40 on

mioona Aatavap. | SOLSRIEOVEVHS ALIALIOV /t9VIS on

NOLID@ASNIdO 44098

a

ee sanrwn wm pene

7 Hos ign aes

Nvid.1sa1 GNY NoWOadSNI OREO wiaes

“ON NoWWorsioads auvaNWis

Ponosor sySu iy —"13 WUhde

62110 Lp 20

0new 2-1000-00-8 ON UIC

am z . todo 501, ‘soumunoysog sonea ey

4001 ‘Asororystreg porwisdo soyemoy 405 189, ouonouNg

(1 a10N). - joday 189, 29D uoisuaung / jens,

Me 4 odo 1994, 001 ios peo Cs 1eRs1 ee

jonvoyioads

(1310N) woneouioa aiqeonidde se 21 yeor] un

H - odoy 1894, aseying Ye249 4897 i +

Ant Faawiey. pur 1s9q sfeunoud / ae.soupAH

vopaodsay peu or

- H suoday uonoodsuy %001 woysuaunra J yenst, synpuodwoo jo 2u ze

aod

- fon ~ | svaiegeonstar | or | MORLSH.AE Boro ve

wopsedsuy ss9201g uy oe

maura | wariaans | ng" 30aHD JO oN

roan Waiavao | SOUSRIELOVEVED ALIALLOV /3DVLS Bs

NOLLOAASNI AO F409S

Le sete Sanwa

9804 000-189 wos

NV1d 182 ONY NOLLOZdSNI

ON Nouwvolstoges GuvaNvIS

onioseysyOu hy —713 yBUKdO9

szb 40 2p 20

0.A0y 3+1000-00-8 ON rewvoy

Or

5 Joanssy 3 suodoy 1504, on

H H - OL FO. seuddns, %001 ssuodey uoloadsuy | syeoyn299 uonsadsuy 7p uoneuauinsog | U9

Beg JO MaIAgY

1 P GonEsuWND0G 09

| |

- H = uodsy uonoadsuy 4001 PHD LIA / Tens, | aqquowidde se Supoo s0j05 pue Sunuieg | 1s

Bupureg os

gq Wisuema

( tonsadsuy | £4 P9559tn1m a6 Sea sduig yeu .

H - uodoy uonsedsuy | ua soja | padacoy jo Sudureag Buydurerg peur ov

jo Surdurag

(rion) H uodoy uonsodsuy q ia (arqeondde sy) y2040 ding sy

AL ig sed sy 3p squauiodwioy Ayu,

1000-18-9

AD H yoday uonsedsuj voads, Teorey PUD TN vp

‘Ta sad sy

viauna | wartaans | ¥ATTaas soaHD a0 on

aqioor WAINVOO SOLLSTHALIVAVHD ALIALLOV / FOVLS qs

NOLLOGdSNI AO FdOOS

be

: ou pono eo Sanwa Aemegpeon nares

“Ae Hi wos Cau ees

Nv1d 1832 GNV NOLLOadSNI MNN@ wees

“ON NoWWoisiozds cuvaNWIS

- ose 621 10 ey 20%

aniesay sy6u ly—"1a WBUKoo, 0am 14-1000-00% ON ewos

"stuauinoog panouddy/ uonwayroads gory ulasoip pauiajon SCAVCNVIS/Ud/Od 194 SP 9q I]EYS saNANOe amp Ile 209 sUON aoudoooy -¢

(uodn paaide asyaroypo

8 uy “syuaUtasinbes 369) 119U98 04} SaqUDSap INOUIMDOP SIM, -Z

9) Ha oiyddng ‘soqeo1yT390 89,1 Jat |ddng Jo mayaad uo paydoooe oq

1 dn saATeA 1883 JOKE WOQNED 2910198 uDBOIPSH UON 3 AQVN YON“)

ssojun) “o1geaydte 29 ost

JS Swuatundop yoesIUOD ut pely!dods 41 adoas oRoadsuy 30 980}

[ALT £9 pomataas 2q 01 stiodar dn yoeq ypIa Buope ay

MM S801 ISNV 008 ~4S"1 2215 0} dn sanjeA paBiog [901g YOQLED PuE SSeI ISNVOOE.ZI

s@iquonidde sy) SALON

4 “(utes 41g _ Jo 244 pure ozs Yow 30 “ou J-wrU) 9601 40 poyroods sy) ssouN!M WOPUEY - AVY “WIOJJ9d-d ‘“(leAosdde inompis peovoxd jou OG) PIOH -H :puadaT

L301 abeg

SAATVA a

9°04 000-18-9 wos

VION es

“on nouvatsoaes davannas vg sa GNV NoLLOZésNI ARENDS eae

‘SPECIFICATION FOR QUALITY STANDARD SPECIFICATION No.

SSifaizt MANAGEMENT SYSTEM

wanes ORR SNiiED REQUIREMENTS FROM Spt Rens

BIDDERS Page 1 of 7

aiefteaf @ quran yelers

wet stent tq fates

SPECIFICATION FOR QUALITY

MANAGEMENT SYSTEM

REQUIREMENTS FROM BIDDERS

1 120818 Goneral Revision

aus

© 04.06.09 ——_tssued as Standard Specticaton Standard

Commit

Rev,

Ree Date Purpose

Format No. 8-00-0001-F1 Rev. 0 ‘Copyright EIL— Alvighs reserved

—

‘SPECIFICATION FOR STANDARD SPECIFICATION No,

SSRfeRoTe le ENGINEERS DOCUMENTATION

S@aikits NDA UMTED REQUIREMENTS FROM zeit Revit

SUPPLIERS: Paget of

aromas & yea

atest tq fates

SPECIFICATION FOR

DOCUMENTATION REQUIREMENTS

FROM SUPPLIERS

OMS “OMS SP ~

1 120818 {Genora Revision Standards Standards so

Commitee Commitee

ows: ous

© 0406.09 Issued as Standard Specifeation Standards Standards, © SCT No

Commitee Commitee

‘Standards — Standards

committe Bureau

Prepared Checked

ey ty" _Convener__ chairman

Date Purpose

Format No, 8-00-000-F1 Rev. 0 Copyright EL — Allright reserves

DOCUMENT No.

INEERS ADDITIONAL TECHNICAL —8018-444-16-43-ATR-3314

LMTED REQUIREMENTS Rev. B

Page tol?

ADDITIONAL TECHNICAL

REQUIREMENTS

(BALL VALVES)

5 13.00.2019 ISSUED FOR BIDS RK SH ca

Rev. No Date Purpose Prepre’ checked by Approved by

Format No. EL. 1667-1024 Rev. 4 ‘Copyright EL —Alighs reserved

DOCUMENT No.

zi MiibiteD ADDITIONAL TECHNICAL po1g.444-1643-ATR-I914

sds CRN REQUIREMENTS Rev. B

Page 20f2

ADDITIONAL TECHNICAL REQUIREMENTS

(BALL VALVES)

1. Bidder to note that, no correspondence whatsoever shall be entered into or

entertained after the bid submission.

2, Bidder shall furnish quotations only for those items, for which he is approved by EIL

and which he can supply strictly as per MR specifications.

3. No technical details of any nature shall be included in the offer. If the offer contains

any technical deviation or clarification or stipulates any technical specifications

(even if in line with the MR requirements), the offer shall be liable for rejection.

However, Bidder to note that the MOU entered with EIL for any of the iter in the

requisition is NOT APPLICABLE,

4. The submission of prices by the bidder shall be construed to mean that he has

confirmed compliance with alll technical specifications of the corresponding item(s).

5. Bidders shall ensure compliance to the all specifications/documents as per ‘List

of Attachment" attached with the Material Requisition-B018-444-WB-MR-3314.

6. Valves specified as LO (Lock Open)/ LC (Lock Closed) shall be supplied with

arrangement suitable for locking in open as well as in closed position. Lock is

included in vendor's scope. Lock Open/ Lock Closed arrangement with chain is

not acceptable

7. Clause No. 5.17 of Specification for Quality Management System Requirements

from Bidders (6-78-0001) is not applicable.

8. Wherever valve ends specified as ONE END SCREWED in MR item description

shall be provided with one end screwed & other end socket welded. Screwed

Female end shall be as per ASME B1.20.1 (Taper) NPT & rating 3000#.

9. Wherever “FULL BORE" mentioned in MR item description, Ball valve shall be

designed for full bore requirement.

10. Valves with VMS sheet no. 543CA & 544CA, shall be furnished with suitable

bonnet gasket & stem packing to meet fugitive emission less than 100 PPMV,

11. For item specified under “IBR”, respective requirements as specified in Technical

Notes (6-44-0052) shall be applicable.

12. Bidder shall ensure / certify the suitability of all items for the intended service/

Process conditions as per the respective VMS Sheets(B018-6-44-0006-3314).

13. In case of any conflict amongst various documents enclosed with the MR, the most

stringent requirement shall govern and Owner/EIL decision in this regards shall be

final,

Format No. El. 1647-1924 Rev. 1 ‘Copyright BIL — Alvighis reserved

‘Aq panioddns) uoneayinads|

“squauiauinbay/suorypuo9 jeajuypa. pauonUaW anoge 943 03 UL

‘SUL "(G-Aau ‘VTEEAULY-£7-9T-7hP-BT08 Ul pasnposd squWrasynbay I

EW aNeA parejau sw wl pajerap as

pe ul aiqeanidde axe wasay paynuap! syuawa.inbay jeauypay [eDads

1u4924,[PUORIPPY PUE “L-A9Y’2500-v¥-9 U! PaDnPOIS SAAJEA 10} SION fe>IUYPaL

Inbug sia s9pun pazanoa ‘anjen Aur 40} Syuawiasinbay/suoNIpuED je>IUy>aL +.)

‘nen Bip WBOANA pakBAUOD

'8q Nm (G a4oys OZ SsaupseH)

931910

wuigs'9> azis pred yumse | SY anes | WSC iq -dnoup

2poh9 UL J9PMO4 UIA‘ EE 09942

“3591, uo}sswa anny T99 lav JO

‘voneoyuenb Jo} ualsaq payne piniy2uoydous | yyny vons| vee

am “Buppreg wars papeor

yo ‘ann yum papyoud aq ileus aNen ‘A-dnois |

Uuopeaystend 40) uBisaq payne) (0969 $4211) aumeiaduroy mor ww awves | Mca

aim “Buppeg wars papeer lj 2u04dosAd

anevs | cev

ann whim papinoud ag ileus anlen

‘SIWA Ui pouoquaus ‘aNBZN@ HIN Z visa

e891 uoyssiwg anna jo . noguyoowant OWS | vag

Loneowyenb 40 uBisaq payne soivosa1e8oupsea | NOSNOONe ne-dnosg

ain Bupeg wars papeen vous | Ya¥

enn yum papinasd ag ys aNeA “e ad

"W9] uopssIU3 DARIEN THO AW IO

lenb 04 uaisoq payisaD 5 yaisiaow

{ne “Bupjpeq wars papecT aunssaig YBIH 38 59 0D ants | VBC) ty dno

‘ann ym papiness 2g YeUs aAIeA

suey awe uo : as

i pewiay jepod somes ON

wonewuyuoy ssappia_| (.) siwowouinboy Jeo1uysos femads ‘Suewey 1epeds SWA | adig | dno

‘squowiaunbo

ods (Sane Hea) G.1NVA DTEE UW

Y-sinxouuy

Document No.

rT VENDOR DATA REQUIREMENTS anie.dae joes OR 314

aEORhio Rev.A

FOR BALL VALVES. Pa

VENDOR DATA REQUIREMENTS

FOR

FOR BALL VALVES

x 25AUG2019 ISSUED FOR BIDS RS SH Cy

fer Date Purpose Preparedby Checked by Approved by

Format No, 1642-826 Ret Copy EL -Aigs rerened

{JOB SPECIFICATION NO.

exonerss VALVE MATERIAL

ites OMAR ‘SPECIFICATION BO18 644006 Re

| Client: HMEL - DeptiSect.: 16/43

Projet? PETROCHEMICAL COMPLE

Tocation : BHATINDA | Tag No: S40AA SheetNo. 1 of 2

TAGNO. :540AA PIPING CLASS: IA, BIA ‘STANDARD:

RATING :#00 STANDARD; BSENISO 179 MPGRS GARG:

SIZE RANGE :05°T0 075" ENDS + SPCL.3000TO BAIT RATING: ENDS:

[aateoneu/ASTM A 10s

sree Javrravowour _|ssoi6 0 casTING)

fea foun [se

poor sear [RrTFE WitH SECONDARY METAL TO METAL

loam lsaureornevaien [sssie

NUTS WASHER

sre SeAL RENEWABLE wir [GRAFOILPREEs-Rmee-eRAFOT

VALVE OFEN ON

stReaNe

poo SEAL lGRAFOW reve

pony stub JAsTacaios ORB?

[BODY NUT. [ASTM A194 GR 2H L

lores REDUCED PORT

REQUIREMENT OF [REFER TECHNICAL NOTES FOR PURCHASE OF T

[GEAR OPERATION vatves.

fReQuiREMEnT OF IncrER TECHNICAL NOTES FOR FURCHASE OF

RADIOGRAPHY vats.

SPECIAL senvice y a Sy

[CONDITIONS Max tmp” | 206°C

seRasc fnconet x50 =

livorostanctest Jaopy:ansesio —[seaTs217se510

raessune

restrain faa V

wir a

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHINICAL NOTES FOR VALVES.

2 ONLY INTHE CASE OF CATEGORY - I MRS BIDDER SHALL CLEARLY WRITE ALL! ANY DEVIATION AGAINST

EACH PART/ MATERIAL OF VALVE IN THE SPACE PROVIDED FOR AND WHEREVER BIDDER AGREES WITH

'BILS SPC BIDDER SHALL INDICATE "AGREED

[NO CUTTING OVERWRITING BY BIDDER ON EIL'S SPEC IS ALLOWED.

"VALVES CAN ALSO BE SUPPLIED IN ACCORDANCE WITH APLAD. FOR API 6D VALVES.MIN BODY WALL

‘THICKNESS SHALL BE PER ASME B16. Tar

5. ALLVALVES SHALL BE FIRE SAFE DESIGNFIRE SAFE TEST SHALL BE AS PER (API 607 VIEDITION/(APL<07! | or nwt Tacronen |

ISO 10497)YAPI RP 6FA.

TESTING SHALL BE AS PER BS EN 12266-/APL6D.

ALL VALVES SHALL BE BIDIRECTIONAL.

BIDDER'S STAMPING ON THE VALVE SPECIFICATION SHEET SHALL BE CONSTRUED TO MEAN BIDDER'S

"ACCEPTANCE OF SUITABILITY OF VALVE AND VALVE SHEETS FOR SERVICE AND SPECIAL SERVICE.

‘CONDITIONS’ MENTIONED IN THE VALVE SPECIFICATION SHEETS.

9 STEM SEALBODY SEAL MATERIALS SHALL BE PROVIDED WITH CORROSION INHIBITOR.

fe ae 540AA

Pace 24'BPH48 No. 5-0000-0001-T2 Rev. 1 ‘Copyright ElL-All rights reserved

Jon eran Wo.

VALVE MATERIAL

ei SRA SPECIFICATION Bove4e006 ev

Cie HMEL

Project: PETROCHEMICAL COMPLE

‘Location : BHATINDA —

1

SheetNo. 2 of 2 |

NOTES

10. SOFT SEATED SW END BALL VALVES SHALL HAVE A 100MM SEAMLESS PIPE NIPPLE WELDED TO FACH END.

‘OFTHE VALVENIPPLES ARE TO BE WELDED PRIOR TO ASSEMBLING TEFLON SEATSSEALS. NIPPLE SHALL BE

[ASTM AIO6 GR B, SCHEDULE 0.25°T0 0.75"S160; "70 15°-XS,

1¢¥AEVECASTINOS SIRE UNDERGO RADIOGRAPHIC EXAMINATION,

12 FORTRUNNION MOUNTED BALL BODYSEAT SIIALLBE SPRING LOADED.

{3 THE SPCL ENDS INDICATED IN TiS VALVE SHEBT SHALL BE OFFERED AS PER FOLLOWING:INLET SHALL BE

WTO B-1611 AND OUTLETSHALL BE SCRD TO B 1.201

‘SHEET REV. NO. 0 OO — a

ome am | 540AA

ace ESGPHE NS. 5 0000-0001-T2 Rev. 4

“Copyright EILAI rights reserved

JOB SPECIFICATION NO.

sex VALVE MATERIAL

site ORAM ‘SPECIFICATION pores fe

Client: HMEL. | DeptSect.: 16/43

PIPING CLASS : 434 ‘STANDARD:

STANDARD: BSEN!S0 17292 SRS SARIS

{rch To ma631 TRATING: ENDS:

sHeGRveBASTC A Ts

brew caTarowour fsRI6NOCASTRO j

at pou fsa 7

pony sear pr WT SECONDARY ETAL TO WEA

Joc Inacsap naraneD [sre

brxerewasnen

preasaniRENEWARLE wr [oRAFOTLRREARESAGRATON

mueoneN on

Liar

foo sr nar ee

poor fstwavoRaT

poorer pst arn

omens RsbUGe Por

fecuRamroF EPR TECINGAL NOTES FOR URGHASEOF

GEaRORERATON facies

REQUIREMENT OF Ere Ton CnL NOTES FOR FURGIASEOF

fabian fauves

|SPECIAL SERVICE a 7

conorrions mee dernp” 204°C

exc fNconeL x0 oS

firowcsianctest poov-answio [SEAT arora

sone

hssrenessaxs foes

reas

NOTES

1 Ts YALE sc supe SHALL BE READIN CONLNCTION Wn TECHRICAL NOTES FOR VALVES

2 BMY Als exseor CATEGORY” ite siopeR SHALL CCEARLY WRITE ALL ANY DEVIATION ACAMST

SNE P ar nae OF VALVE THE PACE PROVIDED FOR AND WHEREVER DDER AGREES WITH

EILS SPEC BIDDER SHALL INDICATE "AGREED".

[NO CUTTING! OVERWRITING BY BIDDER ON EIL'S SPEC IS ALLOWED.

‘VALVES CAN ALSO BE SUPPLIED IN ACCORDANCE WITH API-SD. FOR API 6D VALVESMIN BODY WALL,

‘THICKNESS SHALL BE PER ASME B16

5) ALL VALVES SHALL BE FIRE SAFE DESIGN FIRE SAFE TEST SHALL BE AS PER (APL 607 VIEDITION/ (API 607!

150 10497))APIRP GFA.

"TESTING SHALL BE AS PER BS EN 12266-1/AP1 6D.

APL VALVES SHALL BE BIDIRECTIONAL.

BIDDERS STAMPING ON THE VALVE SPECIFICATION SHEET SIIALL BE CONSTRUED TO MEAN BIDDER'S

‘ACCEPTANCE OF SUITABILITY OF VALVE AND VALVE SHEETS FOR SERVICE AND SPECIAL SERVICE.

‘CONDITIONS MENTIONED IN THE VALVE SPECIFICATION SHEETS.

19. STEM SEAUBODY SEAL MATERIALS SHALL BE PROVIDED WITH CORROSION INHIBITOR,

[ieraev.no. | 0

aa 5400C

paca FEBPHIG¥© ©0000-0007 Rev. 1 “Copyright EILAighis reserved

4408 SPECIFICATION NO.

sae VALVE MATERIAL

@eatees ONAN ‘SPECIFICATION BOI8-6-44.0006 Rev.

Page 4 of

DeptiSeet.: 16/43 ]

Client: HMEL

Project: PETROCHEMICAL COMPLE

Location : BHATINDA Sheet No. 2 of 2

NOTES

10. SOFT'SEATED SW END BALL VALVES SHALL HAVE A 100MM SEAMLESS PIPE NIPPLE WELDED TO BACH END

‘OP THE VALVE NIPPLES ARE TO BE WELDED PRIOR TO ASSEMBLING TEFLON SEATS/SEALS. NIPPLE SHALL BE

‘ASTM Al06GR B, SCHEDULE 025°T0 0.3160; "TO L5-XS

11 TeteAAVE CASTINGS SHLXLE-NDERGO RADIOGRAPHIC EXAMINATION.

12. FOR TRUNNION MOUNTED BALL BODYSEAT SHALLBE SPRING LOADED.

1 THE SPCL ENDS INDICATED IN THIS VALVE SHEET SHALL BE OFFERED AS PER FOLLOWING:INLET SHALL BE

SW TO B-1611 AND OUTLET SHALL BE SCRD TO B1.20.1

°

Date wma | 540QC

Pago EP BPG No. §-0000-0001-T2 Rew. 1 ‘Copyright IL-l righis reserved

‘SHEET REV. NO.

Pa

JOB SPECIFICATION No.

ENGINEERS VALVE MATERIAL

aiRECiio ‘SPECIFICATION Ne

Client: HMEL | Depussect.: 16/43

Project PETROCHEMICAL COMPLE

| Tag No: S40QN Sheet No. 1 of 1

TAGNO. :540QN PIPING CLASS: 435

RATING :800 ‘STANDARD | :8SENISOI72

ENDS

[asta a 2 oR OH

sexe jevrarowour _[sssoaseais wo cASTING)

om fou isso0seae

lpopy sear JRPTFE WITH SECONDARY METAL TOMETAL

lexan jporreornerannen [sso

fpyNure WASHER

sre seaL Jeexewanue wrra[GRAFOIU Pree eRINGS--ORAFOR.

WvaLveoren on

frmeane

poy sat lorarowerre

jpopy stv fasta i GRD

poor wu [Astor a 1 oR

+

fontens Re duceot pol AE y

sreciat senvice Max. TEMP 201 De. c

[coNIONS.

sean fascont.x-750 —-

livorosrancTast fpoovemorsia — featsaiasesie

nessune

frst ssuxe _ porsic

ln ain

NOTES

| THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2 ONLY INTHE CASE OF CATEGORY - I MRs BIDDER SHALL CLEARLY WRITE ALL/ ANY DEVIATION AGAINST

EACH PART/ MATERIAL OF VALVE IN THE SPACE PROVIDED FOR AND WHEREVER BIDDER AGREES WITH

FILS SPEC BIDDER SHALL INDICATE "AGREED".

[NO CUTTING! OVERWRITING BY BIDDER ON EIL'S SPECIS ALLOWED,

'VALVES CAN ALSO BE SUPPLIED IN ACCORDANCE WITH APLD. FOR APL-6D VALVES, MIN BODY WALL

“THICKNESS SHALL BE AS PER ASME B16.34 Se

‘5. THE SPCL ENDS INDICATED IN THIS VALVE SHEET SHALL BE OFFERED AS FER FOLLOWING: ONE END (INLET) | oF MaUPXETURER |

‘SHALL BE SWTO B I6.11 AND OTHER END (OUTLET) SHALL BE SCRD TO B 1.20.1 seer ee

TESTING SHALL BE AS PER BS EN 12266-/API6D.

ALL VALVES SHALL BE BIDIRECTIONAL,

BIDDERS STAMPING ON THE VALVE SPECIFICATION SHEET SHALL BE CONSTRUED TO MEAN BIDDERS,

"ACCEPTANCE OF SUITABILITY OF VALVE AND VALVE SHEETS FOR SERVICE AND SPECIAL SERVICE.

‘CONDITIONS MENTIONED IN THE VALVE SPECIFICATION SHEETS.

9 STEN SEALIBODY SEAL MATERIALS SHALL BE PROVIDED WITH CORROSION INHIBITOR.

Io. SOFT SEATED SW END BALL VALVES SHALL HAVE A 100 MM SEAMLESS PIPE NIPPLE WELDED TO SW END OF

‘THE VALVENIPPLE IS TO BE WELDED PRIOR TO ASSEMBLING TEFLON SEATSSEALS. NIPPLE SHALL BE

ASIIGRITP30S, SCHDULE 05°70 0.75" 805, 10" TO 1.5405,

SHEET REV. NO. ]

me [a | 540QN

«Tgp BN 50000-00002 Rev 1 ‘Copyright EILAI rights reserved

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PTP Supports Catalog 2017 V5 v2 Reduce Size PDFDocument248 pagesPTP Supports Catalog 2017 V5 v2 Reduce Size PDFMONER MANUSNo ratings yet

- Suaval Lorven References - IndiaDocument2 pagesSuaval Lorven References - IndiaMONER MANUSNo ratings yet

- Metals 08 00932Document15 pagesMetals 08 00932MONER MANUSNo ratings yet

- Checklist For 3D Model ReviewDocument9 pagesChecklist For 3D Model ReviewMONER MANUS100% (1)

- 6-79-0013 Rev 2Document6 pages6-79-0013 Rev 2MONER MANUSNo ratings yet

- Molier Diagram ConceptDocument37 pagesMolier Diagram ConceptMONER MANUSNo ratings yet

- 6 44 0078 A3Document1 page6 44 0078 A3MONER MANUSNo ratings yet

- What Is Killed Carbon Steel For Piping MaterialDocument5 pagesWhat Is Killed Carbon Steel For Piping MaterialMONER MANUSNo ratings yet

- Ligar6wor iNDA: Ingimirs LimitedDocument3 pagesLigar6wor iNDA: Ingimirs LimitedMONER MANUSNo ratings yet

- What Is Difference Between Tempering, Annealing, Normalizing and QuenchingDocument1 pageWhat Is Difference Between Tempering, Annealing, Normalizing and QuenchingMONER MANUSNo ratings yet

- Tuvwxy Z (Y /) - 'Wxy Axwby C - Y D Ewy FC) Y Gy H Xy I - BajDocument6 pagesTuvwxy Z (Y /) - 'Wxy Axwby C - Y D Ewy FC) Y Gy H Xy I - BajMONER MANUSNo ratings yet