Professional Documents

Culture Documents

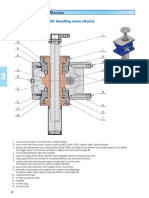

1.6. The Assembly of Fluid End Parts

Uploaded by

Sadegh AhmadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.6. The Assembly of Fluid End Parts

Uploaded by

Sadegh AhmadiCopyright:

Available Formats

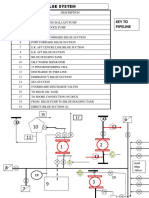

⑴Oil level indicator (2) Plug (3) Spray pump (4) Regulating valve (5) Water tank

1.6. The assembly of Fluid End Parts

A cross-section through the fluid end for F-1300/1600 is shown in Fig, 8. With reference to Fig 8,

clean and assemble the fluid end parts in the following manner:

Note: All of the parts in this fluid end assembly are designed with metal to metal seating to alleviate

friction wear from breathing action encountered in modern high pressure pump operation. For this

reason it is essential that all parts be clean and free of rust, nicks and burrs before being

assembled.

6 7 8 10 9 11 18 20 13 12

15

14

16

17

19

5 4 3 2 1

Fig. 8 F-1300/1600Fluid end assembly

(1) Wear plate seal (2) Wear plate (3) linear flange (4) linear sealing ring (5) linear lock (6) Linear

(7) linear locking ring (8) piston rod (9) piston (10) piston sealing (11) nut (12) Allocation disc (13)

valve rod guider (14) plug board (15) cylinder head sealing ring(16) Cylinder head

plug(17)-cylinder head(18) Valve covers sealing ring (19)-mud apron (20) Valve cover

14

You might also like

- Husqvarna LC 151s Használati UtasításDocument572 pagesHusqvarna LC 151s Használati UtasításSzarvas IstvánNo ratings yet

- FRMP13-16S-SPB289 - 2Document39 pagesFRMP13-16S-SPB289 - 2jyapias_1No ratings yet

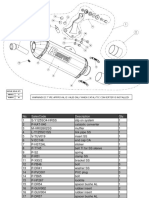

- Eng Akrapovic Spec S-Y125SO4-HRSSDocument2 pagesEng Akrapovic Spec S-Y125SO4-HRSSclinic carsNo ratings yet

- 320dl Swivel SystemDocument2 pages320dl Swivel SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- WXseries Manual 2021 CompressionDocument187 pagesWXseries Manual 2021 CompressionAlexandre RodriguesNo ratings yet

- Hyosung Manual de Taller GT650-S-RDocument122 pagesHyosung Manual de Taller GT650-S-RLandrich Trosky100% (1)

- Hydraulic System and Gear Pump RepairDocument11 pagesHydraulic System and Gear Pump RepairTrần Đức PhiNo ratings yet

- Preaction System With Model DV-5 Deluge Valve Double Interlock - Electric/Pneumatic Actuation 1-1/2 Thru 8 Inch (DN40 and DN200)Document16 pagesPreaction System With Model DV-5 Deluge Valve Double Interlock - Electric/Pneumatic Actuation 1-1/2 Thru 8 Inch (DN40 and DN200)PhuNguyenHoangNo ratings yet

- Angle CockesDocument4 pagesAngle CockescoolmaleankurNo ratings yet

- Fireloock31 80Document7 pagesFireloock31 80Jorge Alberto Velazquez CortesNo ratings yet

- Steering Unit: EH Electro Proportional Hydraulic Valve In-Line VersionDocument20 pagesSteering Unit: EH Electro Proportional Hydraulic Valve In-Line VersionbrunosamaeianNo ratings yet

- Air System Air PipingDocument1 pageAir System Air PipingCalon KayaNo ratings yet

- Service Manual SM01 - 076 - 021.00: Collector Ring, ReconditionDocument4 pagesService Manual SM01 - 076 - 021.00: Collector Ring, ReconditionJorge YuniorNo ratings yet

- 3 1 PDFDocument1 page3 1 PDFMichael DavenportNo ratings yet

- Catalog of Replacement Parts: CL44e AND CL54e Series DishwashersDocument40 pagesCatalog of Replacement Parts: CL44e AND CL54e Series DishwashersAndres RiveraNo ratings yet

- PC40MR-1 Main Pump Parts ListDocument1 pagePC40MR-1 Main Pump Parts ListOecox Cah DjadoelNo ratings yet

- Buyers Spreader ManualDocument4 pagesBuyers Spreader Manualtrailerman0000No ratings yet

- Re10460 PDFDocument20 pagesRe10460 PDFINVESTIGACION Y DESARROLLONo ratings yet

- Koblenz TP-2015 User ManualDocument12 pagesKoblenz TP-2015 User ManualCarmina Pineda GonzálezNo ratings yet

- Resourcesmediakey &language Code En&type DocumentDocument8 pagesResourcesmediakey &language Code En&type DocumentdarkoNo ratings yet

- Sp15 Accelerator ManualDocument8 pagesSp15 Accelerator ManualkerwinNo ratings yet

- Summary Type Series Booklet SPnorm SPblocDocument13 pagesSummary Type Series Booklet SPnorm SPblocRuddy Fabrizio Galvez JustinianoNo ratings yet

- Group 4 Disassembly and Assembly Group 4 Disassembly and AssemblyDocument9 pagesGroup 4 Disassembly and Assembly Group 4 Disassembly and AssemblyREMZONANo ratings yet

- Acme Screw Jacks-MA-seriesDocument36 pagesAcme Screw Jacks-MA-seriesDermot BrennanNo ratings yet

- Generated PDFDocument2 pagesGenerated PDFLuciano De PasquaNo ratings yet

- Group 6 RCV Pedal: 1. StructureDocument6 pagesGroup 6 RCV Pedal: 1. StructureالمهندسوليدالطويلNo ratings yet

- Hyosung Motors Cylinder Head Parts ListDocument124 pagesHyosung Motors Cylinder Head Parts ListJason CumbieNo ratings yet

- PM - HL 4150CDN 4570CDW 4570CDWTDocument42 pagesPM - HL 4150CDN 4570CDW 4570CDWTleo_lnetoNo ratings yet

- Hyp 7560GM Parts List PDFDocument1 pageHyp 7560GM Parts List PDFRaúl FigueroaNo ratings yet

- Ev FH M525 2067BDocument1 pageEv FH M525 2067Bdweight000No ratings yet

- SCM80R Spare PartsDocument1 pageSCM80R Spare PartsStephen BlommesteinNo ratings yet

- Essential Bilge System ComponentsDocument23 pagesEssential Bilge System ComponentsvivekNo ratings yet

- Eq PrimeDocument64 pagesEq PrimeIanosi SorinNo ratings yet

- 4 4. Nivo: Posamezni Sestavni Deli ISO, Pisava 2: Opis Sap Koda Revizija / IteracijaDocument2 pages4 4. Nivo: Posamezni Sestavni Deli ISO, Pisava 2: Opis Sap Koda Revizija / IteracijaAnonymous KdnOsd9No ratings yet

- W A U K E S H A: 60 FORM 6302 First EditionDocument2 pagesW A U K E S H A: 60 FORM 6302 First Editiondiego yecid millan mendozaNo ratings yet

- Sherwood P Series 17000Document6 pagesSherwood P Series 17000Crespo JorgeNo ratings yet

- Buffalo 2 Plus Parts CatalogDocument160 pagesBuffalo 2 Plus Parts CatalogPrita Shofi100% (1)

- Despeice LF168F - LF168F-2Document16 pagesDespeice LF168F - LF168F-2Edwin TtitoNo ratings yet

- Chapter 14 - Valve Mechanism and CamshaftDocument12 pagesChapter 14 - Valve Mechanism and CamshaftsezarNo ratings yet

- Piston Pump 420E, Backhoe Loaders Hydraulic and Steering System CatDocument21 pagesPiston Pump 420E, Backhoe Loaders Hydraulic and Steering System CatEdwar Julian100% (1)

- 30 Ton Capacity Puller Set: Parts List ForDocument2 pages30 Ton Capacity Puller Set: Parts List ForriinNo ratings yet

- Wednesday, April 9, 2014: Travel Parking BrakeDocument3 pagesWednesday, April 9, 2014: Travel Parking Brakejohn ayengahNo ratings yet

- Despiece Hyosung Aquila GV 125Document119 pagesDespiece Hyosung Aquila GV 125Oriel Merino CortesNo ratings yet

- dcP-9055CDN DCP-9270CDN MFC-9460CDN MFC-9465CDN MFC-9560CDW MFC-9970CDW PDFDocument42 pagesdcP-9055CDN DCP-9270CDN MFC-9460CDN MFC-9465CDN MFC-9560CDW MFC-9970CDW PDFStefanGarnetNo ratings yet

- Manual de Partes Finisher InternoDocument41 pagesManual de Partes Finisher InternoAlex RendonNo ratings yet

- Manual pc130Document495 pagesManual pc130Farhat100% (1)

- Repair Part Sheet - RJ84A, RJ85A, RJ86A - 54048 - eDocument2 pagesRepair Part Sheet - RJ84A, RJ85A, RJ86A - 54048 - eGerardo RodríguezNo ratings yet

- Group 7 Main Control Valve: 1. Removal and InstallDocument7 pagesGroup 7 Main Control Valve: 1. Removal and InstallTaha RdmanNo ratings yet

- Power Wheel Service Manual Model 8 Double Reduction Shaft and Spindle Output DrivesDocument4 pagesPower Wheel Service Manual Model 8 Double Reduction Shaft and Spindle Output DrivesFreddy Martínez AvendañoNo ratings yet

- Hyosung Comet Gt250fi Part CatalogueDocument112 pagesHyosung Comet Gt250fi Part Catalogueinrope100% (1)

- Service Manual SM01 - 076 - 024.00: Collector Ring, ReconditionDocument4 pagesService Manual SM01 - 076 - 024.00: Collector Ring, ReconditionJorge YuniorNo ratings yet

- Compass R Volute Replacement InstructionsDocument6 pagesCompass R Volute Replacement InstructionsGOWTHAMNo ratings yet

- Hydraulic and Transmission Schematics for Lift TrucksDocument20 pagesHydraulic and Transmission Schematics for Lift Trucksamin chaabenNo ratings yet

- GV125 cylinder head parts listDocument118 pagesGV125 cylinder head parts listCaptain444No ratings yet

- 05-12-02 5000B Accessory (Buzzer)Document2 pages05-12-02 5000B Accessory (Buzzer)yanandar.dpNo ratings yet

- Replacement Parts List: Fairhurst Single-Handle Pull-Down Sprayer Kitchen FaucetDocument1 pageReplacement Parts List: Fairhurst Single-Handle Pull-Down Sprayer Kitchen FaucetKilty ONealNo ratings yet

- PC 695SR 18 EUDocument32 pagesPC 695SR 18 EUДима ТукачNo ratings yet

- 1 s2.0 S2451904918302749 MainDocument14 pages1 s2.0 S2451904918302749 MainSadegh AhmadiNo ratings yet

- 1 s2.0 S0360319920329396 MainDocument13 pages1 s2.0 S0360319920329396 MainSadegh AhmadiNo ratings yet

- 1 s2.0 S0360544213004921 MainDocument11 pages1 s2.0 S0360544213004921 MainSadegh AhmadiNo ratings yet

- Thermo FormulaDocument1 pageThermo FormulaSadegh AhmadiNo ratings yet

- 1 s2.0 S0378775321006595 MainDocument17 pages1 s2.0 S0378775321006595 MainSadegh AhmadiNo ratings yet

- CFD Simulation of Precession in Sudden Pipe Expansion Ows With Low Inlet SwirlDocument15 pagesCFD Simulation of Precession in Sudden Pipe Expansion Ows With Low Inlet SwirlSadegh AhmadiNo ratings yet

- 1 s2.0 S0082078404003339 MainDocument26 pages1 s2.0 S0082078404003339 MainSadegh AhmadiNo ratings yet

- 1 s2.0 S1572665719305831 MainDocument36 pages1 s2.0 S1572665719305831 MainSadegh AhmadiNo ratings yet

- EI Tender Part B Technical Amendment ff7386 PDFDocument44 pagesEI Tender Part B Technical Amendment ff7386 PDFjosejohn1No ratings yet

- 1 s2.0 S0360319921019510 MainDocument13 pages1 s2.0 S0360319921019510 MainSadegh AhmadiNo ratings yet

- Emch 751 HW 04Document2 pagesEmch 751 HW 04Sadegh AhmadiNo ratings yet

- Well Testing: Super Green BurnerDocument2 pagesWell Testing: Super Green BurnerSadegh AhmadiNo ratings yet

- Mot Mos CatalogDocument9 pagesMot Mos CatalogSadegh AhmadiNo ratings yet

- 1 s2.0 S0196890421013510 MainDocument47 pages1 s2.0 S0196890421013510 MainSadegh AhmadiNo ratings yet

- ASME B36 10M-2015 Welded and Seamless Wrought Steel PipeDocument30 pagesASME B36 10M-2015 Welded and Seamless Wrought Steel PipeDaniel Diaz PrietoNo ratings yet

- Concentrate Control System: Operating, Maintenance, and Filling ManualDocument24 pagesConcentrate Control System: Operating, Maintenance, and Filling ManualSadegh AhmadiNo ratings yet

- Oil Gas 1st StageDocument13 pagesOil Gas 1st StageRome John Francisco100% (2)

- 2016 Art StrengthAnalysisofShippingContainer SentDocument11 pages2016 Art StrengthAnalysisofShippingContainer SentSadegh AhmadiNo ratings yet

- Design Calculation Offshore BasketDocument14 pagesDesign Calculation Offshore BasketSadegh AhmadiNo ratings yet

- Bladder Tank Proportioning System Pre-Piped: HD Fire Protect Pvt. Ltd. Technical DataDocument8 pagesBladder Tank Proportioning System Pre-Piped: HD Fire Protect Pvt. Ltd. Technical DataSadegh AhmadiNo ratings yet

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Document242 pagesNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- Evergreen: Minimal Environmental Impact Well Effluent BurnerDocument2 pagesEvergreen: Minimal Environmental Impact Well Effluent BurnerSadegh AhmadiNo ratings yet

- TEC SPEC 10OFFSHORE Oct17 - Rev2Document16 pagesTEC SPEC 10OFFSHORE Oct17 - Rev2Sadegh Ahmadi100% (1)

- Operation and Maintenance Manual: Skum Bladder Tank Type VerticalDocument8 pagesOperation and Maintenance Manual: Skum Bladder Tank Type VerticalSadegh AhmadiNo ratings yet

- Green Dragon High-Efficiency BurnerDocument1 pageGreen Dragon High-Efficiency BurnerSadegh AhmadiNo ratings yet

- Anti Collision System: Unique FeaturesDocument2 pagesAnti Collision System: Unique FeaturesSadegh AhmadiNo ratings yet

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Document242 pagesNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- Quiz PT3Document3 pagesQuiz PT3Sadegh AhmadiNo ratings yet

- Engineering Standard: IPS-E-PR-340Document22 pagesEngineering Standard: IPS-E-PR-340Sadegh AhmadiNo ratings yet

- ASNT Level II Study Guide Liquid Penetrant Testing MethodDocument49 pagesASNT Level II Study Guide Liquid Penetrant Testing MethodIsrael Riquelme100% (21)