Professional Documents

Culture Documents

ERIES 549 High-Accuracy, Non-Contact 2D Encoder

Uploaded by

MedoBoudyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ERIES 549 High-Accuracy, Non-Contact 2D Encoder

Uploaded by

MedoBoudyCopyright:

Available Formats

MICSYS

SERIES 549 High-accuracy, Non-contact 2D Encoder

SPECIFICATIONS

Order No. 549-701A

FEATURES

Model MICSYS-SA1 • Simultaneous, non-contact measurement of

Detection method Laser speckle image correlation X-Y position.

Effective range ±100μm (2D) • Nano-resolution measurement.

Resolution 1 nm

Accuracy (20°C) ±100 nm • Suitable for applications such as stage

Data update period 20Hz position repeatability, strain measurement,

deflection measurement, etc.

Applications • Applies the image correlation of a speckle

1. Evaluation of stages used in manufacturing equipment and inspection systems pattern.

Measure displacement caused by

temperature, humidity, voltage

fluctuation or other factors

• No scales needed—can detect on any

Actuator

optically rough surface.

• Detector can be completely removed from

surface and replaced to continue reading.

•Drawings are available on request.

a) Evaluation of position repeatability b) Evaluation of standstill stability and drift

2. Highly accurate positioning of workpieces

Setting and removal

Actuator

3. Measurement of minute displacement

Load

Measure displacement caused by

Structure (beam) temperature or humidity fluctuations or

other factors and displacement caused during

a material attachment process, etc.

a) Measurement of minute displacement of a structure b) Measurement of minute displacement of a workpiece

DIMENSIONS

Detector Mass : 300g

Standard target Mass : 10g

.63”(16)

1.89”(48)

1.10”(28) 2-ø3.4, through hole

.39”(10) .35”(9) ø6.5Countersunk,depth3

.19”(5)

.39”(10)

1.61”(41)

.59”(15) .59”(15) .59”(15) 2-M4x0.7, depth 6 Measuring surface .79”(20) ±0.2 .15”(4)

.62”(16)

(ø5.8)

.23”

1.62”(41.2)

.24”(6.1)

.06”(1.6)

.54”(39)

.31”(8) .55”(4) ±0.1

1.18”(30)

.39”(10)±0.2

.06”(1.6)

39”(1000) 0.1

(10 ±0.2)

.39”

1.82”(46.3)

Standard target

I/F unit Mass : 1700g

8.5”(216)

7.87”(200) 8.03”(204)

2.83”(72)

3.05”(77.6)

H-18

You might also like

- V Anvil MicrometerDocument1 pageV Anvil MicrometerMedoBoudyNo ratings yet

- Setting RingsDocument1 pageSetting RingsMedoBoudyNo ratings yet

- ABSOLUTE Digimatic Bore GaugeDocument1 pageABSOLUTE Digimatic Bore GaugeMedoBoudyNo ratings yet

- Digimatic Tubular Inside MicrometerDocument1 pageDigimatic Tubular Inside MicrometerMedoBoudyNo ratings yet

- Series 154 - Small Hole Gauge SetDocument1 pageSeries 154 - Small Hole Gauge SetMedoBoudyNo ratings yet

- Bore Gauge CheckerDocument1 pageBore Gauge CheckerMedoBoudyNo ratings yet

- Dro Abs Linear Scales At715Document1 pageDro Abs Linear Scales At715MedoBoudyNo ratings yet

- EyepiecesDocument1 pageEyepiecesMedoBoudyNo ratings yet

- Quick Vision ELF SeriesDocument1 pageQuick Vision ELF SeriesMedoBoudyNo ratings yet

- Paper Rolls, Ink Ribbons, BulbsDocument1 pagePaper Rolls, Ink Ribbons, BulbsMedoBoudyNo ratings yet

- Fiber Scale ST-F11Document1 pageFiber Scale ST-F11MedoBoudyNo ratings yet

- Quantum IkeDocument1 pageQuantum IkeMedoBoudyNo ratings yet

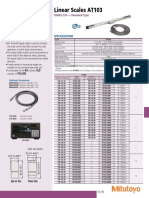

- Linear Scales AT103: Specifications FeaturesDocument1 pageLinear Scales AT103: Specifications FeaturesMedoBoudyNo ratings yet

- Hub MicrometersDocument1 pageHub MicrometersMedoBoudyNo ratings yet

- Outside MicrometersDocument1 pageOutside MicrometersMedoBoudyNo ratings yet

- NDTD Series: Isolated 3W Wide Input Dual Output DC/DC ConvertersDocument6 pagesNDTD Series: Isolated 3W Wide Input Dual Output DC/DC ConvertersMedoBoudyNo ratings yet

- Carbide Wear BlockDocument1 pageCarbide Wear BlockMedoBoudyNo ratings yet

- Features: EconolineDocument3 pagesFeatures: EconolineMedoBoudyNo ratings yet

- Can Seam MicrometersDocument1 pageCan Seam MicrometersMedoBoudyNo ratings yet

- Absolute Digimatic AOS CaliperDocument1 pageAbsolute Digimatic AOS CaliperMedoBoudyNo ratings yet

- Clear Loupe MagnifierDocument1 pageClear Loupe MagnifierMedoBoudyNo ratings yet

- Op 177Document16 pagesOp 1778m7s8y_scribdNo ratings yet

- Low Noise, Low Drift Single-Supply Operational Amplifiers OP113/OP213/OP413Document16 pagesLow Noise, Low Drift Single-Supply Operational Amplifiers OP113/OP213/OP413MedoBoudyNo ratings yet

- Bandwidth Sample Rate Nyquist TheoremDocument2 pagesBandwidth Sample Rate Nyquist TheoremMedoBoudyNo ratings yet

- Op Amps SG 2011-12 SG Apps PDFDocument13 pagesOp Amps SG 2011-12 SG Apps PDFMedoBoudyNo ratings yet

- Op Amps SG 2011-12 GlossaryTechnologyDocument4 pagesOp Amps SG 2011-12 GlossaryTechnology陳曉君No ratings yet

- OPA333 OPA2333: Features DescriptionDocument24 pagesOPA333 OPA2333: Features DescriptionMedoBoudyNo ratings yet

- Low Cost, 300 MHZ Voltage Feedback Amplifiers: ÷HZ AmaxiDocument12 pagesLow Cost, 300 MHZ Voltage Feedback Amplifiers: ÷HZ AmaxiMedoBoudyNo ratings yet

- AN699 - Anti-Aliasing, Analog Filters For Data Acquisition Systems-00699bDocument13 pagesAN699 - Anti-Aliasing, Analog Filters For Data Acquisition Systems-00699bRicky CoxNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The High Voltage Homopolar GeneratorDocument6 pagesThe High Voltage Homopolar Generatorapi-241035124No ratings yet

- Kathrein Antennen 1998Document161 pagesKathrein Antennen 1998Sebastian Schille100% (1)

- Electrical CalloutsDocument9 pagesElectrical CalloutsJason d HernandezNo ratings yet

- T-DM-008-D Alpha Prius VDocument30 pagesT-DM-008-D Alpha Prius VHameed BangishNo ratings yet

- Parameters of A Multiple-Arm Spiral Antenna From Single-Arm MeasurementsDocument5 pagesParameters of A Multiple-Arm Spiral Antenna From Single-Arm MeasurementsMadeline CurryNo ratings yet

- S7 Power System EarthingDocument11 pagesS7 Power System EarthingBisal Sarker JoyNo ratings yet

- MECO 2017: University of Health Sciences, LahoreDocument2 pagesMECO 2017: University of Health Sciences, LahoreSmith 4allNo ratings yet

- Project Eye...Document40 pagesProject Eye...Vijayudu MahezaNo ratings yet

- Institutional AssessmentDocument6 pagesInstitutional AssessmentShairrah Claire Bañares BatangueNo ratings yet

- CD Spectroscopy PPT FinalDocument20 pagesCD Spectroscopy PPT FinalMukesh Yadav0% (1)

- Electric Shock Hazard of Manual Electric Arc Welding Work: Guide For Safety at WorkDocument12 pagesElectric Shock Hazard of Manual Electric Arc Welding Work: Guide For Safety at WorkmechanikyNo ratings yet

- Adaptive Algorithm For Calibration of Array CoefficientsDocument8 pagesAdaptive Algorithm For Calibration of Array CoefficientsIJAET JournalNo ratings yet

- Cyber PowerDocument17 pagesCyber PowerArky KhanNo ratings yet

- 03 CMOS DC Characteristics PDFDocument28 pages03 CMOS DC Characteristics PDFbalukiran2008No ratings yet

- 02 Folien 2012-02-20 We, PD TheoryDocument65 pages02 Folien 2012-02-20 We, PD TheoryAlberto VegaNo ratings yet

- Q4 GenPhysic2 USLeM3 Week-3 Jayar Version-3Document10 pagesQ4 GenPhysic2 USLeM3 Week-3 Jayar Version-3Arjen Lei VillafuerteNo ratings yet

- C7884 SeriesDocument5 pagesC7884 Seriestbuckup2175No ratings yet

- Lazo Direccionable GamewellDocument52 pagesLazo Direccionable GamewellEstheban LeyNo ratings yet

- NCP1399AA, NCP1399BA, NCP1399AC, NCP1399AF High Performance Current Mode Resonant Controller With Integrated High-Voltage DriversDocument44 pagesNCP1399AA, NCP1399BA, NCP1399AC, NCP1399AF High Performance Current Mode Resonant Controller With Integrated High-Voltage DriversGoensNo ratings yet

- Electrical Machines-II Unit 1Document35 pagesElectrical Machines-II Unit 1Krishna KumarNo ratings yet

- Physics Investigatory Project-1Document30 pagesPhysics Investigatory Project-1Horrible WorldNo ratings yet

- Guia de Producto Rev615 - AbbDocument60 pagesGuia de Producto Rev615 - Abbper47No ratings yet

- Water Level Controller Using Microcontroller and BuzzerDocument65 pagesWater Level Controller Using Microcontroller and Buzzermohit73% (11)

- 蒸汽调节阀Document26 pages蒸汽调节阀陈浩祥100% (1)

- Marshall Cabinets ManualDocument12 pagesMarshall Cabinets ManualDioy PalloneNo ratings yet

- General Notes: Schedule of Loads and ComputationsDocument1 pageGeneral Notes: Schedule of Loads and ComputationsPH GAMINGNo ratings yet

- Data Sheet - 1600kVADocument2 pagesData Sheet - 1600kVAhammad1290% (1)

- Acharya Input Zero-1Document10 pagesAcharya Input Zero-1Nishanth NishanthNo ratings yet

- DP 85 Train PackDocument112 pagesDP 85 Train Packdann222No ratings yet

- FLIR FC Series S Installation ManualDocument66 pagesFLIR FC Series S Installation Manualreivin27No ratings yet