Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 viewsRCD 2 Besavillapdf PDF Free

RCD 2 Besavillapdf PDF Free

Uploaded by

KristelleCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ojt Narrative - Degracia, Arianne Joyce ADocument48 pagesOjt Narrative - Degracia, Arianne Joyce AKristelleNo ratings yet

- KaraokeDocument1 pageKaraokeKristelleNo ratings yet

- Share DEGRACIA, ARIANNE JOYCE A.Document2 pagesShare DEGRACIA, ARIANNE JOYCE A.KristelleNo ratings yet

- Job Information: Job No Sheet No RevDocument63 pagesJob Information: Job No Sheet No RevKristelleNo ratings yet

- Performance Criteria For Water Distribution SystemDocument7 pagesPerformance Criteria For Water Distribution SystemKristelleNo ratings yet

- Ever Joy Acob Rivera House Final-S6Document1 pageEver Joy Acob Rivera House Final-S6KristelleNo ratings yet

- Ever Joy Acob Rivera House Final-S4Document1 pageEver Joy Acob Rivera House Final-S4KristelleNo ratings yet

- Degracia, Arianne Joyce A. Finals - WaterDocument15 pagesDegracia, Arianne Joyce A. Finals - WaterKristelleNo ratings yet

- 1st Sem Requested Unprogrammed SubjectDocument16 pages1st Sem Requested Unprogrammed SubjectKristelleNo ratings yet

- Activity 3Document2 pagesActivity 3KristelleNo ratings yet

- Ce 80 PrelimDocument12 pagesCe 80 PrelimKristelleNo ratings yet

- Degracia - Research ProposalDocument12 pagesDegracia - Research ProposalKristelleNo ratings yet

- Fluid Mechanics Lesson 3 PDF FreeDocument5 pagesFluid Mechanics Lesson 3 PDF FreeKristelleNo ratings yet

- Module 2: (3 Hours) Title: Knowing PhilippineDocument5 pagesModule 2: (3 Hours) Title: Knowing PhilippineKristelleNo ratings yet

- CE 76B - Midterm-Module 2.5Document24 pagesCE 76B - Midterm-Module 2.5KristelleNo ratings yet

- Open Channel Design: 4.4.1 OverviewDocument37 pagesOpen Channel Design: 4.4.1 OverviewKristelleNo ratings yet

- CE 76B - Midterm-Module 2.3bDocument7 pagesCE 76B - Midterm-Module 2.3bKristelleNo ratings yet

- CE Board Exam Results 2019Document36 pagesCE Board Exam Results 2019KristelleNo ratings yet

- Fluid Mechanics Lesson 3 PDF FreeDocument5 pagesFluid Mechanics Lesson 3 PDF FreeKristelleNo ratings yet

- CE 76B - Midterm-Module 2.4Document7 pagesCE 76B - Midterm-Module 2.4KristelleNo ratings yet

- This Study Resource Was: SCHEDULE: 9:30-11:00Document4 pagesThis Study Resource Was: SCHEDULE: 9:30-11:00KristelleNo ratings yet

- CE 76B-Midterm - Module 2.1Document8 pagesCE 76B-Midterm - Module 2.1KristelleNo ratings yet

- Cost-Volume-Profit Analysis: Additional Issues: Summary of Questions by Objectives and Bloom'S TaxonomyDocument37 pagesCost-Volume-Profit Analysis: Additional Issues: Summary of Questions by Objectives and Bloom'S TaxonomyKristelleNo ratings yet

- Design of PSC Members Basis Sign ConventionDocument32 pagesDesign of PSC Members Basis Sign ConventionKristelleNo ratings yet

- Design of SlabDocument18 pagesDesign of SlabKristelleNo ratings yet

- This Study Resource Was: 1/12/09 12:42 PM Flo76434 - Un0164Document2 pagesThis Study Resource Was: 1/12/09 12:42 PM Flo76434 - Un0164KristelleNo ratings yet

RCD 2 Besavillapdf PDF Free

RCD 2 Besavillapdf PDF Free

Uploaded by

Kristelle0 ratings0% found this document useful (0 votes)

6 views73 pagesOriginal Title

Pdfcoffee.com Rcd 2 Besavillapdf PDF Free

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views73 pagesRCD 2 Besavillapdf PDF Free

RCD 2 Besavillapdf PDF Free

Uploaded by

KristelleCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 73

————S—

424

use A, = Prin bd

‘A, =0,00509(1000)(75)

A =381.8mm"

Tan> (1000) - 991.8

raed

$= 205 say 200mm

of reinforcement for the

@ Spacing at the span bounded

positive moment

by BEFC

wit

14

_ 12(25)?

i

“Me

+M. = 6.36 kN.m.

M, = 0 bd? «(1 -0.590)

5.36x 10 = 0:90(20.7)(1000)(75)fa(1 - 0.590)

eo = 0.05279

opi

poke

{

¥

= 0.05279(20.7)

75 0.00397

Use p,, = at

oan

Ppp, = 0.00509

A= 0.00508(1000)¢75) = 981.8 mm?

Spacing of 10 mm:

1 (1000)

Zag 2

4 (10 3; 381.8

S= 205mm Say 200mm

Max. Spacing of 10 my

im diametey

Prescribed by des; t bas

Max, $= 3 y 450 i ses

Max. § = 3(100) = 399 $450 ok

Max. 8 = 300 mm o,¢,”

A

ithout interior beam,

For slabs without a

between the supports and having 8

of long to short span not Greater thang

1. Min. thickness of slabs Without 4,

panels= 125 mm ty

2, Min. thickness of slabs wit, ty

panels = 100 mm

For slabs with beams spanning betes

the supports on all. sides, the mi,

thickness shall be as follows:

4, For om equal to or less than On

without drop panels = 125 mm

with drop panels = 100 mm

2. For om greater than 0.2 but my

greater than 2.

f,

B+

tos 1500

~ 36+58(qy,,-0.2)

h should not be less than 125 mm

3. Forom greater than 2.0

L, (0.8 + Ae

is ( fa!

36498

h should not be less than 90 mm

where:

L ar span in long direction

ratio of clear span in long diredton®

Clear span in short direction

o=seh

El

l= gross moment of inertia of beam

5 9f0ss moment of inertia of slab

Ec= modulus of elasticity of beam

* = Modulus of elasticity of slab

% = Tatio of flexural stiffness of

Section to flexural stifiness of @

Of slab bounded laterally by oe”

Of adjacent panel.

&

AINFORCED CONCRETE

slabs Using Direct De

‘ Caster

425

10a]

Ultimate Uniform load:

v= 120. + 16LL

pe eT = 1214.3) + 1.6

Wu 14.764 kPa

ini . Qt

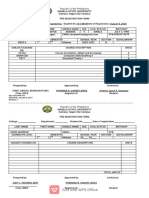

two way reinforced conerete building floor pat Static design moment for fe

: am

is cd of slab

ggsiem is composed of slab panels measur

gy mx 76 m. in plan supported by shay (lear span of Be:

coumn line beams cast monolithically with the =6.1-0.36

gab as shown. Thickness of slab is 180 mm, L=5.74

The typical exterior panel carries a service live Considerit

fad of 6000 Pa in addition to the sellveig ng 1 m. length of Bc:

ofthe floor. Assume unit weight of concrete to i 16 ;

te 24 kNim®. Beam BC has a dimension of }— 16.3 kPa

360x510 mm. Use Direct Design Method

Uniform load acting on BC:

w= 14.784(7.6)

w= 112.36 kN/m

1

M=3 ol?

M= —(112,36(5.74)°

M= 462.75 kN.m

@ Max. negative moment for beam BC:

NSCP specs for the distribution factors

applied to static moment for positive and

negative moments in end span.

ole

Clear span Ln _ Clears

Which of-the following gives the ultimate

0

uniform load acting on the slab in kPa. err

® i i SARS

Which of the following gives the total static SE

design moment for beam BC. 4 I

® Which of the following gives the max. wh sane Mu Vis Ma

Negative moment for beam BC: veggie"

Solution : pistribution factors:

gon the Interior negative moment = 0.65

© Utimate uniform load actin

Slab: , Positive moment = 0.35

Dead load = Max. negative moment for beam BC

ad = 0.18(24) = 0,65(462.75)

i Dead load = 4.32 kPa 4 = 300.79 KN.m

load = 6 kPa

RE

426

te Bake oe tC

OS aia rad

Ey Aian lou

i the suj

i ‘or beams spanning between the supports gp

5,9,5.3.2 Minimum thickness of slabs without interior petrnot be leSS than the following valueg alt

accordance with the provisions of Table 5.9.5(C) and st

it 425mm

(a) Slabs without drop panels .. out

(b) Slabs with drop panels ..

Table 5.9.5 (c) Minimum Thickness of Slabs Without Interior Beams

Yield ‘Without drop panels With drop panels

i i Interior

& Interior Exterior 7

pe eral Panels Panels Panels

Without ;

without | with edge ae With edge

edge edg beams

beams beams beams

275 Ln33 | Ln/36 Ln/36 Ln/36 Ln/40 Lni40

415 Ln/30 + Ln/33 Ln/33 Ln/33 Ln/36 Lni36

Ln = length of clear span in long direction of two-way construction, measured face to face of supporsia

slabs without beams and face to face of beams or other ‘supports in other cases.

From the given floor plan of the bldg. shown.

=

© Compute the min. thickness of slab S-1 if sg

Fy=415 MPa, =

® Compute the min. thickness of slab S-2 if & posts

Fy= 415 MPa. 8 Saf Tree

® Compute the min. thickness of slab $-3 if gf: 5?

Fy= 275 MPa, alm ciate a

Solution: 3 “__ :

© Min. thickness of slab S-1 if Fy = 415 MPa. 7.00. m 600m ame

6500

Min. t= “33 aif

- f © Min. thickness of slab $-3 if FY°

Min, t= 196.97 mm > 100 ok MPa ‘

Ln = 4000 -

® Min. thickness of slab S-2 if Fy = 415 MPa sa -

in 0 . Ly = 3500

uae a 3500

Min, t= a

Min, t= 152.78 > 100 ok Mi

lin. t= 97.22 < 100

Use t= 100 mm

CED CONCRETE

gp Problem:

seat ’

1s without drop panels

u aa with drop panels ..

125 mm

100 mm

Gina Without Interior Beams Without Drop Panels

427

532 Minimum thickness of slabs without interior beams spanning between the supports shall be in

59 ance with the provisions of Table 5.9.5(c) and shall not be less than the following values.

Table 5.9.5 (c) Minimum Thickness of Slabs Without Interior Beams

Yield Without drop panels With drop panels

Goss Fy | Exterior Interior | Exterior Interior

pa | Panels Panels | Panels Panels

clot With edge oe With edge

beams beams beams a

75 Ln/33 Lnfa6 | _ nia Ln/36 tno | Lniao

15 Ln30 unfa3_ | _Lnia3 Lni33 uns6 | Lni36

in= length of clear span in long direction of two-way construction, measured face to face of supports in

sabs without beams and face to face of beams or other supports in other cases.

From the glven floor plan of a bldg shown, Compute thé following using f= 27.6 MPa.

© Min. thickness of slab S-1 if Fy = 415 MPa.

® Min. thickness of slab S-2 if Fy = 415 MPa.

© Min. thickness of slab S-3 if Fy =415 MPa.

Solution:

© Min, thickness of slab S-1 if Fy = 415 MPa.

\

Min, == = 8500

aay = ap

Min. t= 216.67 mm > 125 “ok

© Win. ta

Min. thickness of stab S-2 if Fy = 415 MP2.

Min, t= 166.67 > 125 ok

a

e

5

:

g So aa

3

Z Paes ali

aR Sim a

@® Min. thickness of slab S-3 if Fy = 415 MPa.

in 12 3800

Min. t= 30

Min. t= 116.67 < 125

Use (= 125mm

aie

REINFORCED Co}

428

Solution:

peed ai @ Minimum thicknoss of fat

4 Plate,

(72) Lae Ou i late;

a)

Ei Problem: jn.206

Aan offco building is planned using 2 flat plate veo #20

column layout as shown

ims, dropped panels OF

mitted. Specified live :

d load will include the @ Factored design loads:

llowable of 0.96 Dead load of the slab = 23.5(0.22)

floor system with the

in the figure. No bea

column capitals are per

load is 4.8 kPa and deat

weight of the slab plus an al

KPa for frish oor plus suspended loads. The Deed load of the slab = 5.17 kPa

columns will be 450 mm square and the floor

tb floor height of the structure will be 3.6 ™. ;

fg = 2768 MPa, ty = 4147 MPa, Wt. of Factored design loads:

“eis2354Nnd 4.201 = 1.2(6.17 + 0.96) = 1.2(6.19)

sonvaste 8 28. 4.201 = 7.36 kPa

4.6LL = 1.6(4.8) = 7.68 kPa

Using equivalent frame method.

Total factored design load = 7.36 +7.65

Total factored design load = 15.04 kr

® Total loadings on panel D, (DL + Ll)

Factored live load of Sere) = 576K

Total loadings on panel D = 7.36 +516

Total loadings on panel D = 13.1217

Check:

Ratio of service live load to dead lost

48.

Ratio =

® Compute the minimum thicknes ot

ness .

plate forthe exeforpanelD. | Ratio'= 0,783 > 0.75 ok

®@ Compute the factored design loads,

@ Compute the total loadi ne “a!

csp N ratio is > 0.75, the patter 0

panel D to obtain max, ‘coli nd ee a

'egalive momenton panel D. | = ;

} Spans plus 4 factor live load on

RCED CONCRETE

a Fucus

b oy sab with interior beam is shown in

awe Wi yan with a slab thickness of 175 mm,

vette, f= 414.6 MPa. Assume both

yg? nd siab has the same value of

wots elesicly. E. All columns has 2

oeesin of 300 mm x 300 mm.

1 12

Section A-A

© Compute the effective width of the flange

ofthe T-beam section.

® Compute the flexural stiffness of the T-

beam section in terms of E.

Compute the required thickness of slab for

an interior panel as per NSCP Specs.

Solution:

9 Effective width of the flange of the T-

beam section.

fe

t=175

=375

429

Length of overhang:

xeh

X= 375

x=at

x=4(175)

x= 700

Use x= 375 mm

‘Width of flange = 300 + 2(375)

Width of flange = 1050 mm

® Flexural stiffness of the T-beam section

in terms of E,

[aes is

set9i98

693,

3

je 37535807

Locate the neutral axis of the T-section:

Ax = 1050(175) = 183750

Az= 375 (300) = 112500

A = 296250

AY =A.y, +A, Ye

296250 y = 183750(87.5) + 112500(362.5)

y= 191.93 mm

Moment of inertia about centroidal axis:

300(16.93)?

3

3

;

+ oaurey + 1050(175)(104.43)?

Flexural stiffness = E |

Flexural stiffness = 7064.3 x 10° E

430 REINFORCED G6iqj

® Required thickness of slab for an

interior panel as per NSCP Specs.

Gross moment of inertia of slab 6 m. wide

2 6000(175)*

* 12

|, =2679.7 x 10° mm*

E (7084.3) 10°

E (2679.7) 10°

@, = 2.64

1

Gross moment of inertia of slab 7.2 m. wide

= 72001757

2

3215.6 x 10° mmé

|, = 7064.3 x 10°

= E (7064.3) 10°

E (82156) 10°

a, =2.20

a

a, =242>20

Clear span:

Long span=7.2-0.3

Long span = 6.9 m.

Short span =6 - 0.3

Short span = 5.7 m.

long span

‘short span

69

aT =121

Slab thickness required by NSCP Spex

For ot, >2.0

t, (08+ 1.)

= —__1500"

36+98

but not less than 90 mm

414.6

6 oe

_ 200 (08+ 48)

36+ 9(1.21)

h= 158.4 mm< 175mm ok

FORCED CONCRETE

‘AMS SUBJECTED

to TORSION

enis that cause @ member to twist about

wormaitudinal exis iS called torsional

a pens oF frqUes.

4 fe me Ts

OUR Cll ea ery

ie

For 2010 NSCP:

_ BAR (Ag)?

Poet

where:

ross sectional area of the beam

Pop = perimeter of the beam

a) For rectangular beams:

‘stirrup

pr

i

Pay (300 + 500) 2 = 1600

Ap=500(300) = 150,000

4) For beams with overhang:

X= ley

Ons ion of overhang

x= 4(100) = 400

® x=h=500

Use x = 400 mm (smallest value)

Pop= 300 + 600 + 700 + 100 + 400 + 500

Poo = 2,600

‘Aca = 300(600) + 100(400)

Aco = 220,000

2) Conditions under which Torsion

eta

When actual torsion is less than this

value, torsion can be neglected.

Pee

1 cov Ae)”

«42P,

] 43. REINFORCED

1,

2af, A, Cot

AS

s

A, =0.85x, y,

{,, = refers to closed transverse

torsional reinforcement

{,, = refers to longitudinal torsional reinforcement

Value of 6(@ shall not be taken smaller

than 30° nor larger than 60°)

1) @ = 45° for non prestressed members

2) @ = 37.5" for prestressed members with

an effective prestress force not less than 40%

of the tensile strength of the longitudinal

reinforcement

Re Re eer ee Re

ECE TCR CEO

A, (total) =A, + 2A,

A, (total) A, | 2A,

s s

eAy

5

Oe Er ae ees closed)

Ue

ee

As2A, =P8

in

A,+2A, =0.062,/772eS

but not be less than (0.35),

ME acy Cur meh ey

reinforcement

6S) 4,

Verse Eo

Wax.8=" or 300 mm,

P=2(, +)

The spacing of _ transverse ‘ors

reinforcement shall not exceed the smale

B

= oF 300 mm.

30 im.

Or mir ee ta

required for torsion

PA fe

A =hn 2

ar i Cot? @

@ = 45° ifnot specified

err

LEE erie ues

Pees

BE Ay Arp &

A, (in fife “hy

7

A then At

EE shallnote less than 57

ORCED CONCRETE

eons

5 Me Ap he

alin) =f, 8

0.175b,

AA. chal notbe less than, =

s 1

er ret

g ee of the concrete shall be|

Ps

f omeoemsacselats

VY of ee]! sof ZF

(¢) Tatyl sla 3

ehh

© p=2x, *Y:)

(4) ab deol 22]

owes

V,=

eee

V, =0.174 Jf" b, d

ere

For th

e th

Hat "@® S80 shown, compite the

© The cracking torsional moment of section A.

The cracking torsional moment of section B.

cae torsional moment of section C.

Pee 276 MPa = 415 MPa

435

Section A

530

2 Set2 mm

x+|-0'6-@ 0-0

704

99-4

Section B

| ‘woo

480 ago

S32 nimi 0-

eo0e

Solution: .

© Cracking torsional moment of section A

A, = 400600)

A, = 240000

P., = (400 + 600)(2)

P, = 2000

3,

oT = 0.75 V27.6 (240000)?

* 3(2000) .

1, = 37.82 KN,

® Cracking torsional moment. of section B

b

350

350"

Length of overhang on each side:

x= 450 mm

x= 4t

x=4(100) >

400 mm

Use x = 400 mm.

Width of flange:

b= 400 + 350 + 400

b= 1150 mm

ep = 1150(100) + 350(450)

Aco = 272500 mm2

Pep = 1180 + 2(100) + 2(450) + 350 + (400)

Pep = 3400'mm :

~

REINFORCED CG)

Cracking torsional moment o¢

Seetig

Ce) ’

7 = O75 NITE (2725009

ole 3(3400)

AT, = 28.69 kN,

© Cracking torsional moment of

b=720

Sect

Length of overhang on one side:

xs at

x=4(150)

x= 600mm

x=370mm

Use x = 370 mm

Width of flange:

b=370 +350

b=720

Aca = 720(150) + 350(370)

Aep = 272500 mm?

Pep = 720 + 150 + 370 + 320 + 35080)

Pep = 2480 mm

Cracking torsional moment of section’:

ot, = CAL?

wat

ot = 005 276 (272500)

« 3(2480)

_- OT, = 29.88 kNm.

gGINBORCED COI INCRETE

way joist system sy

A rmposed factored dead load of TiPa ana

si yored live load of 8 kPa, totaling 15 kPa

4 total factored dead load of the beam and

factored loads applied directly to it ig 6

yin, Slab thickness is 125 mm, Assume the

ipst loads are transferred to the beam by the

jst webs

(227.6 MPa .

2415 MPa

cowumns supporting the beams = 600 x 600 mm

Wath of spandrel beam AB = 600 mm,

© Compute the max. ultimate design moment

ofthe end span beam AB,

@ Compute the max. ultimate shear of beam

AB.

@ If the.two ends of the beam AB are fixed

against rotation by the column, determine

the total torque of beam AB

AK. 600 pica column

Jou

Solution:

° Max. utimate design moment of the end

Span beam AB:

‘oist reaction Per meter length of joist.

B

Ms WE

16:5"

M =, 785(7.4)?

: 16

M, = - 261.82 kNum

M,=+ Mee

te

My=+ BSay

4

My = 299.22 kim

2

M, =.“

0

M, =. 765(7.4)"

10

M, =-418.91 km

Max. uniate design moment:

M, = 418.91 km

600 x 600 7

600 « 600

colunn

‘column

$ 74m. 4

Sm.

@ Max, ultimate shear of beam AB:

145 w, L

ME

= 1.45(76.5)(7.4)

2

Xv,

V, = 325.51 kN

436.8 | RT,

Exterior negative moment in the joist

ot

Mo

_15(9.4)

Mom

M, = 55.23 kN.m

Although this is a bending moment in the

joist, it act as a twisting moment on the

edge of the beam.

“nN

6kNIm > M=S55.23 kNum.

<1 0.3m

6.5 KNI

600 mm.

t= 55.23 + 70.5(0.3)

t= 76.38 kN.m/m of beam AB.

Total torque acting at both ends of

spandrel beam AB

7228 04)

T = 282.61 kKN.m

RCED CONCRETE

is subjected to torsional moment in

ide to the flexural moment and shear from

36st Joads at the cantilever frames,

the analysis, the following factored design

10M result Ms = 440 KN-m, Vo = 280 kN, T,

1 kN-m., width of beam, "b” = 499 mm,

= Andepth of beam, *h” = 500 mm, fe = 20,7

0a, fy = 275 MPa, f= 415 MPa, concrete

ul to the centroid of tension steel = 65 mm,

ae ratio at balanced condition, py = 0.02,

ywable concrete shear stress = 0.76 MPa,

igeral ties are 42 mm diameter.

8m

ie

| iF

i¢|

| 25m

IG)

1

\25m

: tt

|

BE

bs

© Which of the following gives the tension

reinforcement required for factored

moment, Mu.

© Which of the following gives the spacing of

transverse reinforcement for. factored

shear, Vu.

® Which of the ‘following gives the

longitudinal reinforcement required for

torsion, Tu. Assume 40 mm clear cover to

lateral ties,

Solution:

© Tension reinforcement required:

O85 je" nuns.

‘ae

¢

‘e=247 92

(a2) 1) 95208

TAS,

437

M, = £

aC (- 3)

C=085 (ap

Cs 0.85(20.7)(a)(400)

C=7038a

M = a!

.=00(4-3)

440.10 = 0.90 (7038) a (435- 3)

69464.18 = 4350-0 502

a? -870a+ 138928.36 = 0

870+ 448 54

2

a=210.73mm

a

CsT

O85f'ab=A, f

0.85 (20.7)(210.73)(400) = A, (415)

A, =3574 mm*

Check: if steel yields

a=he

210.73 = 0.85 ¢

c= 247.92

&, _ 0.003

25208 24792

€, = 0.00305

.

ee 415

200,000

€, = 0.002075

Steel yields: €, > €,

Use A, = 3574 mm?

438

i ont

@ Spacing of transverse reinforceme!

for factored shear Vix

v, 2076b, 4

v, =0,76 400\45)

v, =192240M

Mev +y,

may,

280 - 432.24+V,

85

V, = 197.472 KN

Atd

AF (127 Q)

A, =226.2 mm"

_ 226.2 (275)(435)

5° ertr2

$= 137 mm say 130 mm.

d

Max. S= =

2

Max. S=

Use S =130 mm

© Longitudinal reinforcement required for

torsion:

x1 40-80-12 40}

x= 308 VE

|

ys = 500-80 - 12

y=408 bs

A i;

8” 201, A, Coe

A 180x108

$

3" 3.64

REINFORCED Cok

Steel area required for torsion:

A, > Se cot? 45"

Aa gh ors

p,=2(%, +1)

p, = 2(308 + 408)

p= 1432

a Ap bt ott ag

ASSRT

_361(1432\275)(1)

A 45

A 126 men?

The cantilever beam has a span of 35 au

carries a uniformly distributed factored load ¢

22 kNim applied at 300 mm off centering y

the cross section as shown in the figure, Thy

beam has a cross section of 250 mm x4)

mm, with an effective depth of 387.5 mm.

fe = 20.68 MPa, f= 414.7 MPa

22kNim

|, 300 mm

4=387.0

© Compute the factored shear foe #

the critical section.

te

® Compute the factored torsional mone

at the critical section.

4 mo

® Determine the amount of torsion ve

reinforcement for torsion is requ?"

,

(NFORCED CONCRETE

Jution:

© tored shear force V, at the Critical

© Section.

sectio!

Was?

"-me6) PUL

y279.2kN { ate

vw

* 92125 40.895 sans

Ve2 70.675 KN ||. ——=

i 102

Factored torsional moment T. at the

critical section.

22 KN/m

|. 300 mm |

|d=387.50

3.6m

40.3875 3.2125

Max. 7y=23,76

Max. T, = 22(0.3)(3.6)

Max.T, = 23.76 kN.m

L _ 2376

32105 * “35

AG = 21.20 kN

————

439

Amount of torsion where no

felnforcomant for torsion is required,

A, = 450(250)

A, = 112500 mm?

450

= 250(2) + 450(2)

P= 1400 mm

250

KOay

12P,

1, = 275 20.68 (112500)

12(1400)

Ai = 2.58 x 10° Namm

The T-beam shown has a simple span of

10m. Itis supported by a hinged at A and a

roller at B. The beam is fixed against rotation

at support A only and B provides no torsional

restraint. The beam carries a uniform load of

12 KNim including its own weight at an

eccentricity “e" as shown, fc’ = 21 MPa.

Effective depth d = 540 mm,

12KNén

h =190

300 mm ~

at tesa

Wygst2 Ain

Wer

re

440

@ Compute the effective width of the

flange

® Compute the value of the cracking

torque. ——

co imum eccentricily “@

ute the maxi

° ported ifthe torsion does not have to be

considered.

Solution : .

© Effective width of flange:

=hedt

Use x = 480

b= 300 +2(480)

b= 1260mm

© Cracking torque:

1260

“480 Jo 480

500 ‘

300

Ace = 1260(125) + 300(480)

Acp = 301500 mm?

Pep = 1260 + 2(125) + 2(480)

+2(480) + 300

Pog = 3730 mm

Cracking torque:

=e vie (a)

o 3p,

3(3730)

Ter= 27.92 x 105 N.mm

REINFORCED OH

Ter= 27.92 KN.

not considered:

Wa 12k

T=12(10)€

T=120e

1, ae

946 10

Ty=113.52e kN.m

= ON al

. 12P,

075 V24 (015007

12 (3730)

Tu= 6.98 x 108 N.mm

Tu=6.98 kN.m

113.52 e = 6.98

e= 0.061 m.

e= 61mm

380, Problem:

A reinforced concrete beam has a widhol 3

mm and a total depth of 600 mm. 0

concrete cover is 40 mm.

f’=25MPa . fy=415 MPa. 4

Diameter of transverse. reinforcer! *

12mmo

Longitudinal reinforcement to ress! 56"*

= 28 mms arrange as shown: *

Spacing of vertical closed stirups= 1"

Use @ = 0.75 shear strength reduction

9 ori woo where torsion can be

ect

sed.

i rored torsional moment of 40 KN.m

é Lae M110 the beam is the section is

uate.

ba ine the design torsional strength of

yam section.

(io.

; soln id ‘ersional moment where

0 a acs Hsjon can be neglected:

ge (ace)

1? “4aPCp) «if

92 80600) son

ap = 180000

pep= (200 + 60012)

pep= 1800

Nba a:

1 sa(Pop)

076/25 (180000)

1*~49(1800)

1, 8625000 Nmm .

7, =5.625KNm

® Adequacy of the beam due to torsion

only.

x1=300- 80-12

= 208

= 600 - 80 - 12

Ph=2(208 + 508) °

Pre1gg2

Ao= 0.85 x1 ys

Ae = 0.85(208(508)

As nays = 105664

a

ORCED CONCRETE

jored torsional moment of |_|

44)

<

(et)

7M

(oF +7 <0 Ma Be

v, 20172/f,0,d

Vv, =0.17(1)V25

V, =0.85b,

40x108(1432)

eee 23.01

1.7(105664)

301 <0.75 Joes+3V25

3.01<3.14 (safe)

© Torsional strength of the beam.

MAL, 2°)

w, =a i

= (12)?

Ae 4(100)

OT, = 0.75|2(89814.4)(1.13)(415)cot 45")

=1.13

oT, = 63.2KNm

Eff A 61}

The figure shows a floor plan of a one way

slab system. The spandrel beam has the

following dimensions. All.column sizes are

300 mm x 300 mm. The spandrel beam is

subjected to a torsional moment Tu = 30 kKN.m

and a shear force Vu = 100 KN.

= 20.7 MPa, fy = 415 MPa. Diameter of

stirrups is 10 mm and the clear cover is

40 mm. Effective depth of spandrel beam is

387.5 mm fv = 275 MPa,

REINFORCED €@

442

Spundret

Beam

300 mm” 335 main

Acp= 120(630) + 300(339) = M43

Pen® 900+ 480+ 880 + 12059,

Pop = 2160 mm 4

: Limiting torque:

Ps "A

450 2 eve AS) a (As)

= RR

Soa 1, = 275 N27 (A746097

—— oy

Section A-A 12 (2160)

© Compute the limiting torque due to T, =4.01 x 108 Namm= 40H

faciored loads which does Alot require any ‘

longitudinal steel reinforcement for torsion. ® Spacing of 10 mmo Stirrups requ

® Compute the Spacing of the 10 mm 6 for shear and torsion: eh

stimups required for shear and torsion for

the spandrel beam. For shear:

® Compute the area of longitudinal steel A ied

‘equired for torsion for the spandrel beam’ S= we

Solution: Ay _Y,

© Limiting torque: v i wd

My

7 ove a.) suey,

. 12 Pa

V.=017A JE ba

¥, =017 ¥207 (300)(875)

V, =89914N

V, = 89.91 kN

feavsy,

100 |

a75 7899+,

V, =43.42 kN

CED CONCRETE

120 mm

320 mm

comm 330m

Al

3 20f, A, Cote

9=45' ifnot specified

x, = 300- 2(40) - 10

A, = 085 (x, y,)

A, = 0.85(210)(360)

A

8

AL 30x108

S 2(0.85)(275)(64260)

Keto

s

443

Combined shear and torsion:

Aus «Ae 2A

Ss

=0.407 + 2(1)

Ss

wen

Ss 2.407

Maog= F (10) @)

Agog = 157 mm

=65.22 say 60mm

Max. spacing of stirups allowed:

Max spacing =

P, =2(x, +y,)

P, =2(210 + 360)

P= 1140

Max. spacing = “40

Max. spacing = 142.5 mm

Use S= 60 mma.c.

Area of longitudinal steel required for

foto

AS * P, te Cot? 0

7 i sie

A=) 1

a5

A, = 756 min?

Min. area of longitudinal steel required for

torsion:

2 BE the) AL 5 by

= 124, 8 Ty

>

by 200

where Ai=t9> Pw -

Ss 6, 6(275) =O Nit

= S207 (174600) (1)(1140(275)

e 12(415) a5

on = 41.6 mm? <756 mm? ok

Use A, = 756 mm?

REINFORCED GG;

444

,=0C (4 )

Eye

a span of 4 m. and

fi m has n _

ee ca load of 25 kNim including its 200 x 10° = 0.90(5278 5a) (srs .

sorte ete | mseiase |

line of the cross Sé 5

cate ‘of 300 mm x 500 mm with an a? - 875a + 74199 = 0)

atecive depth f= 20.7 MPa, For longitudinal a= 110.07 mm

bars fy = 415 MPa of 437.50 mm. For shear

reinforcements fw = 275 MPa. Diameter of

‘shear reinforcements is 10 mm @. Use 40 mm

clear covering of concrele.

E 25 kNim

25kNin al

ese}:

| sors

Co} a=Bc

i 110.07 =0.85¢

® Determine the area of longitudinal steel esPadai

bars required for the beam to resist

bending moment only neglecting torsion.

Determine the spacing of the 10 mm @

stirrups required for shear and torsion.

© Determine the area of longitudinal stress

required for torsion.

Solution:

© Area of longitudinal steel bars required 2 - 0.003

for bending. 308.01 128.49

w=25KNim - &, = 0.00714 > 0.002075

8

[eee oo" game

110.07=0.85 ¢

4m

M= 25(4)(2) = 200 kN.m ¢= 129.49 mm

C=0.85f' ab &=

C= 0,85(20.7)(a)(300) = 5278.5 a 5

¥ 200,000

&, = 0.002075

E, _ 0.003

308.01 129.49

&, = 0.00714 > 0.002075

ho

ED CONCRETE

086

nt she A, (415)

AS? 21400 mm?

spacing of stirrups required for shear

© Fad torsion: W=25 kN

445

y,

“ev, -v,

8

V, =0.17 Jf bd

v, =0.17(1) 120.7 (300(437-6)

V, = 101.52KN

an

. am

oo

Me

55 ter

V2 89-1KN yo yto0us

20 ‘sage “S04. 4

Torsional moment

Check whether torsion could be neglected:

im

oi Ae)?

12P,, “E =|

=

A, = 300(500) = 150,000

P,, = 300(2) + 500(2) = 1600

(A)

Te nie (allowable torsion)

1 = 075.207 (160,000)*

¥ 12 (1600)

T, =4x 108 Nmm=4 kN.

Since actual torsion

Te= 17.81 kN.m> 4 KN.

Torsion should be considered.

tiups required for shear.

Yaysy,

°

2 = 10182+V,

V, = 17.28 KN

gz fed

yy

ASM

Ss fd

A, . 17280

=0.144

“s 275(437.5)

Stirrups required for torsion:

Ae

S204, A, colo

9=45" ifnot specified

=300-40-40

= 220

= 600 - 40-40

ys = 420

Ao = 0.85 x1 Yi

‘Ag = 0,85(220)(420)

Ao = 78540 mm

I,

s

A 17.81x 10°

1781x108

“3° 770.85)(275)(78540)

Aaa =F (10) (2)

Ag = 157 mm? area of U-stirups

et

Ae = 0.629

“gy 70628

S=249 mm say 240 mm

‘Max: spacing shall not exceed:

Su = 5 or 300mm

REINFORCED) €

P,=2(x, +y,)

* = 2(220 + 429)

Max, § = 1280

Max. S = 160 mm

Use S = 160mm

(Spacing of 10 mm & shear re

"ain

@® Area of ‘ongitudinay ‘

torsion: = ting

A= kp be cary

f

0.485(1280)(275)

ag)

A

A =411mm?

* Min, steel area required fr torsion:

-SVEAS A

MEAS “rp sph

“Mins, = $5./2077(180000) cesar

1285) a

Min. A, = 273.8 mm? <411 mn ck

‘Area of longitudinal bars required erst:

AS 411mm

jfEINFORCED CONCRETE

d= development length

La= basic development length

A)Development of deformed

bars and wire in tension

4. For deformed bars or de

ldo shall be as follows:

not be less than 300 mm.

formed Wire,

Sut Lo shall

Case @

Clear spacing of bars bein devel

spliced not less than dp eer eee

less than ds, and stirrups op ties

throughout Iy not less than the code

minimum or clear spacing of bars being

developed or spliced not less than 2 dy

and clear cover not less than ds.

a) 20 mm diameter and smaller bars and

deformed wires

L _ 12, BA

4 (25

b) 25mm diameter and larger bars

L, _ 34, @Ba

4 5 AY

Other Cases:

a) 20mm diameter and smaller bars and

deformed wires

181, BA

5 Jt

b) 25mm diameter and larger bars

, _9f, @BA

" 4 10 Jf"

447

For deformeg

laldy shat bo:

+. aka

4 °>—

® oye (“K)

,

in Which the term

bars or deformed wire,

(=) shall not be

Steater than 2.5

where:

©= spacing or cover dimension inmm

Kv = transverse reinforcement index

Af

oth

10sn

where:

S = maximum center to center spacing of

transverse reinforcement within Id,

mm.

<1 = number of bars or wires being spliced

or developed along the plane of

splitting.

Av = total cross-sectional area of all

transverse reinforcement which is

within the spacing s and which

crosses the potential plane of splitting

through the reinforcement being

developed in mm?,

fyt = specified yield strength of transverse

reinforcement in MPa.

The factors for use in the expression

for development of deformed bars and

deformed wires in tension:

4. a = reinforcement location factor

= 1.3 for horizontal reinforcement

so placed that more than

300 mm of fresh concrete is

cast in the member below

the development length or

splice.

= 1.0 for other reinforcement.

448

2, = coating factor

= 45 for epoxy-coale

oe h cover less than

fds, or clear spacing [eS

than 6d>

ge12 All other epoxy-coated bars

or wites.

y= 1.0 for uncoated re

However, the product ot

taken greater than 1.7

einforcement size

inforcerent.

need not be

factor

° for 20 mm aiameter ard

smaller bars and deformed

wires.

‘y=10 26 mm diameter and larger

bars

4, 1. lightweight aggregate concrete

factor

3.21.3 when-lightweight aggregate

concrete ig used, however,

when fais specified, % shall

be permitted to be 75 F-

but not less than 1.0

2.21.0 when — normal weight

concrete is used.

B)Development of deformed

bars in compression

Basic Development Length:

"0254, 5

ie

but not less than 0.04 do fy

Ld,

‘Multiplying factors:

4) Excess reinforcement - A, fequired

: A, furnished

- 0.75

2). Spirals and ties

Reinforcement enclosed within spiral

reinforcement not less than 10 mm

diameter and not more than 100 mm

pitch or within 12 mm.diameter ties in

conformance with NSCP specs and

spaced not more than 100 mm ofi

center

La= multiplier © x multiplier @ x Ld

REINFORCED CONC

C)Development of bundled

4) Increase development length, ba,

for 3 bar bundle, La= (1.20) [q %

2) Increase development length

for 4 bar bundle. L=1.33 tae %

D)Development of stand

hooks in tension ar

4) de shall not be less than 8

than 150 mm. » ot

Basic development length for hook

7

100d,

= Ee with, = 415 MPa

2)

be

Multiplying factors:

For different fy

3)

4

45

Concrete Cover 07

For 36 mm diameter bar anj

smaller, side cover (normal ip

plane of the hook) not less tan

65 mm, and for 90-degree hock,

cover on bar extension beyond

hook not less than 50 mm.

b)

Ties or stirrups 08

For 36 mm diameter bar and

smaller, hook enclosed vericaly

of horizontally within ties or sima

ties spaced along the fl

development length La

greater than 3do, where d & |

diameter.

¢)

f) Excess reinforcement A

xcess rein! forceme’ A, ‘ised

or develope

Where anchorage

for fy is not specifically "4"

reinforcement in excess ot

required by analysis

9) Lightweight agoreaae ts

concrete

ean?

Epoxy-coated reinforce ig

Li)

Hooked bars with epoxy’

é FORCED CONCRETE

jopment Lengths ina

ical Continuous Beam

sinc of

eiesten/ pein o

mney econ

os

or dp

nuey as compression

Seance

Development Lengths for

Cantilever Beams

Development Lengths

for Reaction which Confines

The Ends of Reinforcement

[he 13Mtala

sie Tf 1

Ct

i satlover beam is reinforced with top

» Ste Consisting of 3 - 34 mm a ina single row

’ er in the figure. Shear reinforcement is

teas sue 101mm o stimups. f= 27.6 MPa,

Section A-A

3a Ba

5

= 1.3 reinforcement location factor

= 1.0 epoxy-coated bars

4.= 4.0 normal weight concrete

© Determine the point at which the center

34 mm o bar can be theoretically

terminated.

® Considering NSCP specs for development

length requirements, determine the

minimum distance the 34 mm 9 bar must

extend outward from the support at A to

be safely anchored.

® Determine the moment capacity of the

beam at the point where the 3% 34 mm o

bar is terminated.

Solution:

® Point where the 34 mm » center bar can

be terminated.

Ly _ 3f, a BA

a SJ

Ly 3(4150(1.3)(1.0)(1.0)

4, 5 278

Ly =2095mm

2.095 m.

450

Cut off point:

Min Lg

= =

[ 0.83 m

— 5 3m

Cut off point is 0.83 from the support.

® Min. distance the 34 mm o must extend

outward from A,

Min. Ld = 300 mm

@ Moment capacity at the point where the

34 34 mm 9 bar is terminated.

Actual M= aa 17? 4301217)

M=3527, tin

2

[ee] ZA

‘2M ime

rr ie, E (d-al2)

LB

' rer

x

7 (34)? (2)

A, = 1816 mm?

C= T

085f'ab=A, f,

0.85(27.6)(a)(350) = 1816(415)

a= 91.78 mm

m=04,1 (4-5)

M, =0.90(1816)(445) (rs. 2178

M, =958.9 KN.m > 352.7 kN.m (safe)

91.78

® Determine the nominal shear stengt

@® Determine the nominal shear stew

© Determine the max. nominal SM

© Determine the distance from the om

® Determine the distance fens n up

REINFORCED 66)

A cantilever beam has a width op

an effective depth of 600 mm. 1ehhs

with 4 - 28 mm 9 top bars whic 2 i

as shown in the figure. It carr

load of 8800 Nim (including it sa

and a service live load of 4 ane

f= 20.7 MPa, f= 276.5 MPa,

3000

Section A-A Section B-B

© Determine the factored uniform load.”

® Determine the factored shear force at te

critical section.

provided by concrete.

provided by shear reinforcement.

strength provided by shear reinforcer

beyond which concrete can 2m

shear.

which minimum shear rei ment

be provided.

CED CONCRETE

mine ne min. fea of shear

p oaetoment if 10 mm o strups are

Good ‘at 300 mm 0.6

mine the development length for the

9 mage a= 13 A= 10, Bato

‘ermine the theoretical cut off point

g De the support of bars “b" “b’, based on

Jopment length requirements and

ok its adequacy. Assume uncoated

e

a cement and normal weight of

ren

concrete.

3, aba

5

= 3 reinforcement location factor

410 for uncoated reinforcement

4.21.0 normal weight concrete

‘ue t=

se

Solution:

© Factored uniform load.

Wo21.2DL 4 1.6LL

Wy=1.2(5.8) + 1.6(14.6)

Wu= 30.32 kN/m

© Factored shear force at the critical

section,

V= 30.32(4.6)

V= 139.47 KN

Vu= 139.47 - 30.32(0.6)

= 121.28 KN

w, =30.32 kN/m

TOT

®

451

Nominal shear strongth provided by

concrete.

V,=0.17A Jib, d

V, =0.17 20.7 (300)(600)

V, = 139.22 KN

Nominal shear strength provided by

‘Shear reinforcement.

yekey

:

vy = 12128

075

V, = 2249 KN

+ 139.22

Max, nominal shear strength provided

by shear reinforcement.

Max. V, = 0.66 /f' b, d

Max. V, = 0.66 /20.7 (300)(800)

Max. V, = 54,05 KN

Distance from the support beyond

which concrete can carry total shear.

46

4

641.56 - 139.47x= 104.42(4.8)

x= 1.04 m.

452

over which

rent must be

® Distance from support

minimum shear reinforcer

provided.

BV, _ 11602 _53.01

2. 2

151.52 _ 5801

46 48-y

£9699 151.52) = 286.85

y= 284m.

required

18 Min.stirups "| No stirrups ]

. 284 146

® Min. area of shear reinforcement if 10

mm 9 stirrups are placed at 300 mm

oc.

Min.&, = 062, fbys

4

0,062,/20.7(300)(300)

2165

Min. A, =

Min. A, = 91.82 mm?

“AS provided by 10mm @ U-stimups:

A= = a0

y= (10) 2)

A, = 157mm? > 91.82 mm? ok

Min. area of shear reinforcement = 91.82 mm?

o Development length for the to,

1. 3f,aBA Phan,

= reinforcement location factor

= 1.3 for hor. Reinforcement gp

more than 300 mm of fresh ogy

is cast in the member belo

development length. thy

= coating factor

= 1.0 for uncoated reinforcement

A= light weight aggregate concrete fat

3. = 1.0 when normal weight concrete,

used. 5

e

3276.5) (13)(1)(1)

ue

4, 5207

ud

Ld= 1.327 m.

® Theoretical cut off point from the

support of bars “b” “b”:

aoe ISB 2927

og eae

Moment capacity of beam at 4,673 m

from the support. |

AP ‘ (28)° (2)

A, = 1232 mm?

42302765) = 0185(207)(6)(300)

a= 644mm

w,20 (6-5)

6454

yy, 0.901232)2765) (600- a3)

wy, =174 Nm

‘Adual moment:

we

™

30.32(2.927)"

2

M, = 130 KN.m < 174 KN.m_ ok

eeu

Arsinfoced concrete beam has a span of.

fm. Itis reinforced with 2 - 22 mm @ and

2-25 mm o (uncoated reinforcements) as

infceted in the figure. The beam carries a

uniform ultimate load of 5 kN/m including its

wn weight. fe’ = 20.7 MPé. Normal weight

concrete f= 414.6 MPa,

® Determine the theoretical cut off: point at

which the 2 - 22 mm @ bars can be

terminated from the center of the beam.

® Considering the extension beyond the

Cutoff points required by the NSCP

Specifications, determine the minimum

distance the 2 - 22 mm g bars should

®xlend on each side of the center line.

0 kN/n

I

om

222 m0

2.25 mmo

@® Determine the required length’ of

anchorage or development length of the

22 mm @ bars from the center span and

check whether itis adequate or not.

Use the following formula and

development factors:

2. = 1.0 for normal weight concrete

= 1.0 for reinforcement location factor

= 1.0for uncoated reinforcement.

‘Y= 1.0 for reinforcement size factor

fa

Bay

FE

Sif

a

ale

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ojt Narrative - Degracia, Arianne Joyce ADocument48 pagesOjt Narrative - Degracia, Arianne Joyce AKristelleNo ratings yet

- KaraokeDocument1 pageKaraokeKristelleNo ratings yet

- Share DEGRACIA, ARIANNE JOYCE A.Document2 pagesShare DEGRACIA, ARIANNE JOYCE A.KristelleNo ratings yet

- Job Information: Job No Sheet No RevDocument63 pagesJob Information: Job No Sheet No RevKristelleNo ratings yet

- Performance Criteria For Water Distribution SystemDocument7 pagesPerformance Criteria For Water Distribution SystemKristelleNo ratings yet

- Ever Joy Acob Rivera House Final-S6Document1 pageEver Joy Acob Rivera House Final-S6KristelleNo ratings yet

- Ever Joy Acob Rivera House Final-S4Document1 pageEver Joy Acob Rivera House Final-S4KristelleNo ratings yet

- Degracia, Arianne Joyce A. Finals - WaterDocument15 pagesDegracia, Arianne Joyce A. Finals - WaterKristelleNo ratings yet

- 1st Sem Requested Unprogrammed SubjectDocument16 pages1st Sem Requested Unprogrammed SubjectKristelleNo ratings yet

- Activity 3Document2 pagesActivity 3KristelleNo ratings yet

- Ce 80 PrelimDocument12 pagesCe 80 PrelimKristelleNo ratings yet

- Degracia - Research ProposalDocument12 pagesDegracia - Research ProposalKristelleNo ratings yet

- Fluid Mechanics Lesson 3 PDF FreeDocument5 pagesFluid Mechanics Lesson 3 PDF FreeKristelleNo ratings yet

- Module 2: (3 Hours) Title: Knowing PhilippineDocument5 pagesModule 2: (3 Hours) Title: Knowing PhilippineKristelleNo ratings yet

- CE 76B - Midterm-Module 2.5Document24 pagesCE 76B - Midterm-Module 2.5KristelleNo ratings yet

- Open Channel Design: 4.4.1 OverviewDocument37 pagesOpen Channel Design: 4.4.1 OverviewKristelleNo ratings yet

- CE 76B - Midterm-Module 2.3bDocument7 pagesCE 76B - Midterm-Module 2.3bKristelleNo ratings yet

- CE Board Exam Results 2019Document36 pagesCE Board Exam Results 2019KristelleNo ratings yet

- Fluid Mechanics Lesson 3 PDF FreeDocument5 pagesFluid Mechanics Lesson 3 PDF FreeKristelleNo ratings yet

- CE 76B - Midterm-Module 2.4Document7 pagesCE 76B - Midterm-Module 2.4KristelleNo ratings yet

- This Study Resource Was: SCHEDULE: 9:30-11:00Document4 pagesThis Study Resource Was: SCHEDULE: 9:30-11:00KristelleNo ratings yet

- CE 76B-Midterm - Module 2.1Document8 pagesCE 76B-Midterm - Module 2.1KristelleNo ratings yet

- Cost-Volume-Profit Analysis: Additional Issues: Summary of Questions by Objectives and Bloom'S TaxonomyDocument37 pagesCost-Volume-Profit Analysis: Additional Issues: Summary of Questions by Objectives and Bloom'S TaxonomyKristelleNo ratings yet

- Design of PSC Members Basis Sign ConventionDocument32 pagesDesign of PSC Members Basis Sign ConventionKristelleNo ratings yet

- Design of SlabDocument18 pagesDesign of SlabKristelleNo ratings yet

- This Study Resource Was: 1/12/09 12:42 PM Flo76434 - Un0164Document2 pagesThis Study Resource Was: 1/12/09 12:42 PM Flo76434 - Un0164KristelleNo ratings yet