Professional Documents

Culture Documents

Online Training - SIMATIC MANAGER and WINCC/SCADA Course For SIMATIC S7-300/400

Uploaded by

Adetunji Taiwo0 ratings0% found this document useful (0 votes)

9 views3 pagesOriginal Title

4_5771693987144403348

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views3 pagesOnline Training - SIMATIC MANAGER and WINCC/SCADA Course For SIMATIC S7-300/400

Uploaded by

Adetunji TaiwoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Online training - SIMATIC MANAGER and

WINCC/SCADA course for SIMATIC S7-300/400

FACILATOR: HOPE OFUKA

OBJECTIVE

Be able to recognize S7 hardware and be able to replace modules when a fault occurs.

Be able to operate the Step 7 software to make it perform certain tasks.

Understand basic S7 instruction set and be able to make minor modifications to software.

Be able to backup and restore a PLC program when required.

Be able to perform basic system diagnostics when a problem occurs.

Understand PLC to HMI communications

Make alterations to HMI screens

SIEMEN PLC Course Content:

Introduction to Siemens PLC

Architecture of Siemens PLC

Introduction to TIA Portal

Introduction to Simatic manager

Application and Advantage of PLC

Automation Concept and basic design

PLC programming

Introduction of Ladder Logic

Introduction of SFC

Introduction of Instruction list

Programmable Logic Controllers basic’s

Software / Hardware Introduction

Programming of PLC using 1131-3 Languages (LD, FBD, Ileto.)

Developing the PLC programming from Control Narratives

Creating & Editing Ladder Logic Program

Developing industry-oriented application programs using plc Programming Software

Interfacing PLC with various field input/output devices

PLC Fault Finding, Trouble Shooting

Forcing I/O’s

Detailed sequence of wiring

PLC Control Panel Wiring

Interfacing with Relay logic

Hands on Experience from Real time application

Detailed Functions blocks and Wiring concept of Digital & Analog I/O modules

Fundamental of Basic Process Control

Implementation of Control Narratives

Transmitters / Transducers / mA Sources connect with PLC

Overview of Flow, Pressure, Level, Temperature Transmitters

Overview of Control valve and ON/OFF valves.

Data types and parameter types, Bool etc.

Block types

Variable types (local and global)

How to monitor various blocks

Ladder, STL programs

Basic Instructions, contacts, Set, reset etc.

Timers, Counters

Comparators, Maths

How to make minor mods

Altering values in a VAT table

Back tracking through a program to establish where power flow stops

Overall reset procedure

Fault finding tips

SCADA:

Introduction to Siemens WinCC SCADA

Establishing master-slave control

Creating & Editing Objects

Creating Database / New SCADA Project

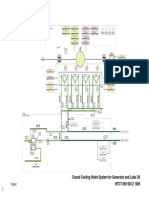

SCADA page design from P&ID Diagram

Alarm Configuration

Trends- Real Time & Historical

Database & DDE connectivity

Driver configuration

Live interfacing with PLC

Understanding P&ID diagram

Alarm / Events Configuration

Report generation

Modbus / Profibus / OPC

Data transfer from PLC/RTU , Report Generation

Process Graphics Development

SCADA Mimic page create from P&ID Diagram

Graphics Properties – Sizing,Filling,Blinking,Analog Entry,Visibility,Etc.

SCADA & PLC Interface used Different drivers

Dynamic Object / Display Creation

Cause & Effect Matrix creation

Dynamo creation for display

You might also like

- Online Training - SIMATIC MANAGER and WINCC/SCADA Course For SIMATIC S7-300/400Document3 pagesOnline Training - SIMATIC MANAGER and WINCC/SCADA Course For SIMATIC S7-300/400Adetunji TaiwoNo ratings yet

- DCS & Industrial Communication Protocals & ConfigurationDocument10 pagesDCS & Industrial Communication Protocals & ConfigurationAnbuselvamNo ratings yet

- Introduction to ABB 800xA DCSDocument15 pagesIntroduction to ABB 800xA DCSJebas ManovaNo ratings yet

- Introduction to Automation and PLC ProgrammingDocument37 pagesIntroduction to Automation and PLC ProgrammingHappy ShubhamNo ratings yet

- Course Content PCIDocument7 pagesCourse Content PCIgopinath87No ratings yet

- Training Viva PPT 4 YrDocument23 pagesTraining Viva PPT 4 YrAkanksha PatelNo ratings yet

- 2023322427-MasteringSiemensPLCsFromFundamentalstoAdvancedProgrammingDocument5 pages2023322427-MasteringSiemensPLCsFromFundamentalstoAdvancedProgrammingOussamaa AdjoudjNo ratings yet

- Delivery Release TIA Portal V15Document6 pagesDelivery Release TIA Portal V15Giovanni JacintoNo ratings yet

- PLC and Industrial Automation TrainingDocument6 pagesPLC and Industrial Automation TrainingAshok KumarNo ratings yet

- AutomationDocument3 pagesAutomationBharat SargarNo ratings yet

- Programmable Logic ControllerDocument27 pagesProgrammable Logic ControllerbimalishaNo ratings yet

- Training Proposal-Future 19-20-002 EE-StudentDocument8 pagesTraining Proposal-Future 19-20-002 EE-Studentmadhumita kunduNo ratings yet

- PLC Course ContentDocument5 pagesPLC Course ContentMahesh GonuguntlaNo ratings yet

- Plcpresentationnew 120411014249 Phpapp02Document27 pagesPlcpresentationnew 120411014249 Phpapp02Tran ThanhNo ratings yet

- Pristine Automation & TechnologiesDocument6 pagesPristine Automation & TechnologiesMohanNo ratings yet

- Home Automation Using PLC and ScadaDocument28 pagesHome Automation Using PLC and Scada544D GamingNo ratings yet

- PLC Presentation NewDocument27 pagesPLC Presentation NewEr. Piush Jindal100% (1)

- Programmable Logic Control Trainer IT-1200SDocument34 pagesProgrammable Logic Control Trainer IT-1200SImran ShaukatNo ratings yet

- Ipcs Automation: Preparing Students As Per The Industry DemandsDocument8 pagesIpcs Automation: Preparing Students As Per The Industry DemandsGince GeorgeNo ratings yet

- Basics of PLC Workshop - Day 1 AgendaDocument119 pagesBasics of PLC Workshop - Day 1 AgendaOwais Khan100% (2)

- PLC - Scada - Hmi - VFD - Training ContentsDocument6 pagesPLC - Scada - Hmi - VFD - Training ContentsJaya LawrenceNo ratings yet

- Seminar ON Scada & PLCDocument38 pagesSeminar ON Scada & PLCVikas ChoudharyNo ratings yet

- PLC Course Outline - WIADocument3 pagesPLC Course Outline - WIAAwais004No ratings yet

- Industrial Automation Brochure - Deepthi PDFDocument6 pagesIndustrial Automation Brochure - Deepthi PDFShivu5art workNo ratings yet

- PLC and SCADA Seminar - Control Systems OverviewDocument18 pagesPLC and SCADA Seminar - Control Systems OverviewSaurabh AggarwalNo ratings yet

- Industrial Automation SlideDocument40 pagesIndustrial Automation SlideAvid LearnerNo ratings yet

- Training BrochureDocument2 pagesTraining Brochuremrbundle3129No ratings yet

- 5 Ingredients That Make Scada Operation Delicious: Scada, Rtus, PLCS, ServersDocument18 pages5 Ingredients That Make Scada Operation Delicious: Scada, Rtus, PLCS, ServersAkram AshmawyNo ratings yet

- PLC/SCADA Presentation Automation Process ControlDocument39 pagesPLC/SCADA Presentation Automation Process ControlsaarjatNo ratings yet

- PLC Scada IndustrialDocument36 pagesPLC Scada IndustrialAnmolNo ratings yet

- PLC Workshop 1-2 DayDocument120 pagesPLC Workshop 1-2 DayHamza Khan Khattak100% (1)

- 1 Syllabus For IINDUSTRY 4.0 - 20 Use CasesDocument5 pages1 Syllabus For IINDUSTRY 4.0 - 20 Use Casespavithranofficial38No ratings yet

- PLC, PLC Ladder, PLC Ebook, PLC ProgrammingDocument5 pagesPLC, PLC Ladder, PLC Ebook, PLC ProgrammingAmar ThakurNo ratings yet

- Bu34p2a00 01eDocument7 pagesBu34p2a00 01eAlex AlvesNo ratings yet

- Industrial Automation Basics, Instrumentation, Drives, HMI, SCADA & PLCDocument3 pagesIndustrial Automation Basics, Instrumentation, Drives, HMI, SCADA & PLCRahul LengadeNo ratings yet

- Introduction to Siemens STEP 7 programming softwareDocument7 pagesIntroduction to Siemens STEP 7 programming softwareKelvin Anthony OssaiNo ratings yet

- Training TIA PortalDocument2 pagesTraining TIA Portalmeghna bhootaNo ratings yet

- Siemens - s7 - 300 - 400 - PLC - & - Wincc - Flex - Hmi - Level - 1 - Equinox Training Solutions PDFDocument3 pagesSiemens - s7 - 300 - 400 - PLC - & - Wincc - Flex - Hmi - Level - 1 - Equinox Training Solutions PDFM MNo ratings yet

- Guideline To Automation EngineeringDocument3 pagesGuideline To Automation EngineeringDimuthu Nuwan AbeysingheNo ratings yet

- Integrated Control System: Prepared By: Guided By: Rajyaguru Maulik M. D.M. Patel (General Manage, Inst)Document31 pagesIntegrated Control System: Prepared By: Guided By: Rajyaguru Maulik M. D.M. Patel (General Manage, Inst)Sunil PillaiNo ratings yet

- History and Evolution of SCADA Systems for Industrial Process ControlDocument1 pageHistory and Evolution of SCADA Systems for Industrial Process Controlnomi77No ratings yet

- Ils Integrates Idec Microsmart Microsmart PLC For Batch Control of BioreactorDocument6 pagesIls Integrates Idec Microsmart Microsmart PLC For Batch Control of BioreactorEngr Nayyer Nayyab MalikNo ratings yet

- Programmable Logic ControllerDocument16 pagesProgrammable Logic ControllerMuhammad JahangirNo ratings yet

- Best PLC SCADA HMI Training Institute in India, BangaloreDocument13 pagesBest PLC SCADA HMI Training Institute in India, BangaloreCreative GroupsNo ratings yet

- PLC Interview Questions and Answers Part 1Document54 pagesPLC Interview Questions and Answers Part 1Hagos AlemNo ratings yet

- Programmable Logic Controller and ScadaDocument21 pagesProgrammable Logic Controller and ScadaNeha NiaNo ratings yet

- State Board of Technical Education and Training, Tamil Nadu Syllabus For Diploma in Electrical and Electronics Engineering L-SchemeDocument6 pagesState Board of Technical Education and Training, Tamil Nadu Syllabus For Diploma in Electrical and Electronics Engineering L-SchemeRoshindas Pudhiya PurayilNo ratings yet

- Siemens Step 7 PLC TrainingDocument3 pagesSiemens Step 7 PLC Trainingnew2trackNo ratings yet

- Automation Training & PLC Programming CoursesDocument11 pagesAutomation Training & PLC Programming CoursesGopala KrishnanNo ratings yet

- Programmable Logic Controller: From Wikipedia, The Free EncyclopediaDocument10 pagesProgrammable Logic Controller: From Wikipedia, The Free EncyclopediaAlda LopezNo ratings yet

- Programmable Logic ControllerDocument31 pagesProgrammable Logic ControllerRaj RajNo ratings yet

- Siemens Simatic S7-400 System in A Rack, Left-To-Right: Power Supply Unit (PSU), CPU, Interface Module (IM) and Communication Processor (CP)Document11 pagesSiemens Simatic S7-400 System in A Rack, Left-To-Right: Power Supply Unit (PSU), CPU, Interface Module (IM) and Communication Processor (CP)Kishore Steve AustinNo ratings yet

- In The Name of Allah The Most Benificet and The Most MercifulDocument24 pagesIn The Name of Allah The Most Benificet and The Most MercifulAsad RazaNo ratings yet

- Nmu Siemens Course Detail Guide 2021Document24 pagesNmu Siemens Course Detail Guide 2021Industrial ItNo ratings yet

- Programmable Logic Controller (PLC)Document50 pagesProgrammable Logic Controller (PLC)Ivy NingalNo ratings yet

- PLC and Industrial Automation 4-Month CourseDocument1 pagePLC and Industrial Automation 4-Month Coursekajal_ghoshNo ratings yet

- PLC Presentation NewDocument27 pagesPLC Presentation NewPrittam Kumar JenaNo ratings yet

- PLC Full BookDocument112 pagesPLC Full BookDilip Patel100% (2)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- PLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingFrom EverandPLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingRating: 4 out of 5 stars4/5 (1)

- En 3rb2283-4aa1Document6 pagesEn 3rb2283-4aa1Adetunji TaiwoNo ratings yet

- Working For The Future of Scotland: GFG AllianceDocument15 pagesWorking For The Future of Scotland: GFG AllianceAdetunji TaiwoNo ratings yet

- Installation Instructions: Door Control TS 981Document52 pagesInstallation Instructions: Door Control TS 981Adetunji TaiwoNo ratings yet

- New Salary ChatDocument1 pageNew Salary ChatAdetunji TaiwoNo ratings yet

- Immigration Skills Charge: Page 1 of 13 Published For Home Office Staff On 08 February 2023Document13 pagesImmigration Skills Charge: Page 1 of 13 Published For Home Office Staff On 08 February 2023Adetunji TaiwoNo ratings yet

- Rano RecruitmentDocument7 pagesRano RecruitmentAdetunji TaiwoNo ratings yet

- Lagos State Building Control Agency (Lasbca) : Ministry of Physical Planning and Urban DevelopmentDocument27 pagesLagos State Building Control Agency (Lasbca) : Ministry of Physical Planning and Urban DevelopmentAdetunji TaiwoNo ratings yet

- Transaction Date: Reference Number: Sender: Transaction Amount: Amount in Words: Transaction Type: Receiver: Account Number: Receiving Bank: RemarksDocument1 pageTransaction Date: Reference Number: Sender: Transaction Amount: Amount in Words: Transaction Type: Receiver: Account Number: Receiving Bank: RemarksAdetunji TaiwoNo ratings yet

- Derby to Leicester train ticket detailsDocument1 pageDerby to Leicester train ticket detailsAdetunji TaiwoNo ratings yet

- Representative Vehicles For The Driving Test: Version July 2022Document2 pagesRepresentative Vehicles For The Driving Test: Version July 2022Adetunji TaiwoNo ratings yet

- Weekly Market Review 04062021Document2 pagesWeekly Market Review 04062021Adetunji TaiwoNo ratings yet

- Nigeria KDR-1200D HMI ManualDocument27 pagesNigeria KDR-1200D HMI ManualAdetunji TaiwoNo ratings yet

- Electrical Design Engineer JD (2) (1) - 1Document2 pagesElectrical Design Engineer JD (2) (1) - 1Adetunji TaiwoNo ratings yet

- Please Note Any Latecomers Risk Being Turned AwayDocument2 pagesPlease Note Any Latecomers Risk Being Turned AwayAdetunji TaiwoNo ratings yet

- Afam Generator Output - Neutral Point CubicalDocument7 pagesAfam Generator Output - Neutral Point CubicalAdetunji TaiwoNo ratings yet

- 220089enb Generator DesignDocument58 pages220089enb Generator DesignMahmoud ElboraeNo ratings yet

- Job Description - Electrical Software Engineer Aug 2022 ST - GD Senior Software Engineer 29-9-2022 (3) - 1Document3 pagesJob Description - Electrical Software Engineer Aug 2022 ST - GD Senior Software Engineer 29-9-2022 (3) - 1Adetunji TaiwoNo ratings yet

- Water Treatment PanelDocument8 pagesWater Treatment PanelAdetunji TaiwoNo ratings yet

- Assembly Plan GeneratorDocument3 pagesAssembly Plan GeneratorAdetunji TaiwoNo ratings yet

- Generator Block ComponentsDocument1 pageGenerator Block ComponentsAdetunji TaiwoNo ratings yet

- Features: 60 Series - General Purpose Relays 6 - 10 ADocument6 pagesFeatures: 60 Series - General Purpose Relays 6 - 10 AAdetunji TaiwoNo ratings yet

- External Advert - Data Roles - 1Document3 pagesExternal Advert - Data Roles - 1Adetunji TaiwoNo ratings yet

- Relay Calibration & Testing ScheduleDocument14 pagesRelay Calibration & Testing ScheduleAdetunji TaiwoNo ratings yet

- GEA Cooler Operating InstructionsDocument26 pagesGEA Cooler Operating InstructionsAdetunji TaiwoNo ratings yet

- Circulating Water System and Station Alternative CoolingDocument6 pagesCirculating Water System and Station Alternative CoolingAdetunji TaiwoNo ratings yet

- Clocking-In TimeDocument1 pageClocking-In TimeAdetunji TaiwoNo ratings yet

- MCS100 Check Synch RelayDocument15 pagesMCS100 Check Synch RelayAdetunji TaiwoNo ratings yet

- MAS100 Auto Synch RelayDocument18 pagesMAS100 Auto Synch RelayAdetunji Taiwo100% (1)

- LearDocument151 pagesLearAdetunji TaiwoNo ratings yet

- Features: 55 Series - General Purpose Relays 7 - 10 ADocument6 pagesFeatures: 55 Series - General Purpose Relays 7 - 10 AAdetunji TaiwoNo ratings yet

- CFPA E Guideline No 32 2014 F1Document38 pagesCFPA E Guideline No 32 2014 F1akramNo ratings yet

- IAM, How Asset Management Can Enable The Circular EconomyDocument18 pagesIAM, How Asset Management Can Enable The Circular EconomyCarlos Jose Sibaja CardozoNo ratings yet

- Flipkart vs Amazon comparison studyDocument6 pagesFlipkart vs Amazon comparison studysunnyNo ratings yet

- Esaote MyLab70 Service Manual PDFDocument206 pagesEsaote MyLab70 Service Manual PDFPMJ75% (4)

- Characteristics: EXPERIMENT 08: SPICE Simulation of and Implementation For MOSFETDocument11 pagesCharacteristics: EXPERIMENT 08: SPICE Simulation of and Implementation For MOSFETJohnny NadarNo ratings yet

- Motion For New TrialDocument3 pagesMotion For New TrialKM MacNo ratings yet

- Computer MCQ NotesDocument88 pagesComputer MCQ NotesWaqas AliNo ratings yet

- Unsettling Definitions of QualDocument8 pagesUnsettling Definitions of QualJIANING ZHUNo ratings yet

- 1740 Purchasing Manager Interview Questions Answers GuideDocument11 pages1740 Purchasing Manager Interview Questions Answers GuideNaveen SharmaNo ratings yet

- Unit 13Document28 pagesUnit 13Tinh NguyenNo ratings yet

- Sgsoc Esia Oils Cameroon LimitedDocument299 pagesSgsoc Esia Oils Cameroon LimitedcameroonwebnewsNo ratings yet

- Paf-Karachi Institute of Economics & Technology Spring - 2021Document3 pagesPaf-Karachi Institute of Economics & Technology Spring - 2021Basic Knowledge Basic KnowledgeNo ratings yet

- Sindh Agriculture University Tandojam: ADMISSION / REGISTRATION FORM (For Subsequent Semester)Document2 pagesSindh Agriculture University Tandojam: ADMISSION / REGISTRATION FORM (For Subsequent Semester)Lochi GmNo ratings yet

- Tata-Aig General Insurance Company LTD: Policy No. 0238443404 / 0238443469 Claim No.Document3 pagesTata-Aig General Insurance Company LTD: Policy No. 0238443404 / 0238443469 Claim No.Mahendra SinghNo ratings yet

- Jagirdari SystemDocument10 pagesJagirdari Systemdevang guptaNo ratings yet

- Jess 303Document22 pagesJess 303Santanu Saha100% (1)

- Midas Method - Has One of The Simplest Goal Setting Processes I'Ve Ever Seen. It Just Works. I'Ve Achieved Things I Never Thought Were PossibleDocument0 pagesMidas Method - Has One of The Simplest Goal Setting Processes I'Ve Ever Seen. It Just Works. I'Ve Achieved Things I Never Thought Were PossiblePavel TisunovNo ratings yet

- History of AviationDocument80 pagesHistory of AviationAmara AbrinaNo ratings yet

- The Tamil Nadu Municipal General Service Rules, 1970Document13 pagesThe Tamil Nadu Municipal General Service Rules, 1970urbangovernance99100% (1)

- Flash 29f800Document48 pagesFlash 29f800savidhamNo ratings yet

- Brekeke Tutorial DialplanDocument22 pagesBrekeke Tutorial DialplanMiruna MocanuNo ratings yet

- DocumentDocument11 pagesDocumentKHIEZZIER GHEN LLANTADANo ratings yet

- ISO 1735 Cheese Determination of Fat Content - Gravimetric MethodDocument20 pagesISO 1735 Cheese Determination of Fat Content - Gravimetric MethodJocilene DantasNo ratings yet

- Design Model Are Included in One Part of The Graves (2000) ModelDocument8 pagesDesign Model Are Included in One Part of The Graves (2000) ModelPourya HellNo ratings yet

- P55-3 Rvge-17 PDFDocument4 pagesP55-3 Rvge-17 PDFMARCONo ratings yet

- Marc Mckinney: Current StudentDocument1 pageMarc Mckinney: Current Studentapi-534372004No ratings yet

- COST - State-Of-The-Art Review On Design, Testing, Analysis and Applications of Polymeric Composite ConnectionsDocument122 pagesCOST - State-Of-The-Art Review On Design, Testing, Analysis and Applications of Polymeric Composite ConnectionsDavid MartinsNo ratings yet

- SGLGB ImplementationDocument47 pagesSGLGB ImplementationDILG Maragondon CaviteNo ratings yet

- Waymo LetterDocument14 pagesWaymo LetterSimon AlvarezNo ratings yet