Professional Documents

Culture Documents

Serial No. Sds-Ch10-E07 KH Grease 6459 (BNST Free) Revision Date - 1 September 2014 Safety Data Sheet

Serial No. Sds-Ch10-E07 KH Grease 6459 (BNST Free) Revision Date - 1 September 2014 Safety Data Sheet

Uploaded by

Nam ĐặngOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Serial No. Sds-Ch10-E07 KH Grease 6459 (BNST Free) Revision Date - 1 September 2014 Safety Data Sheet

Serial No. Sds-Ch10-E07 KH Grease 6459 (BNST Free) Revision Date - 1 September 2014 Safety Data Sheet

Uploaded by

Nam ĐặngCopyright:

Available Formats

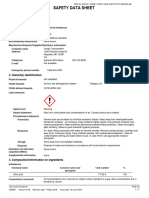

Serial No.

SDS-CH10-E07 KH GREASE 6459 (BNST FREE) Revision Date: 1 September 2014

SAFETY DATA SHEET

Revision Date : 1 September 2014

1. IDENTIFICATION OF THE SUBSTANCE/PREPARATION AND COMPANY/UNDERTAKING

Product Name : KH GREASE 6459 (BNST FREE)

Recommended Use : Lubricating Grease

Serial No. : SDS-CH10-E07

Manufacturer : Sodick Co., Ltd.

Department : Supply Products Division

Address : 3-12-1 Nakamachidai, Tsuzuki-ku, Yokohama, Kanagawa 224-8522, Japan

Tel : +81-45-944-3050

Emergency Tel : +81-45-944-3050

2. HAZARDS IDENTIFICATION

GHS Classification

Long-Term Hazards to the : Category 3

Aquatic Environment

GHS Label Elements

Symbol(s) : No symbol

Signal Words : No signal word

Hazard Statement : H412: Harmful to aquatic life with long lasting effects

GHS Precautionary Statements

Prevention : P273: Avoid release to the environment.

Response : No precautionary phrases.

Storage : No precautionary phrases.

Disposal : P501: Dispose of contents/container to appropriate waste site or

reclaimer in accordance with local and national regulations.

Not Result in Classification : Please see Chapter 4 - 8 before use for Prevention / Response / Storage

/ Disposal. Used oil may contain harmful impurities.

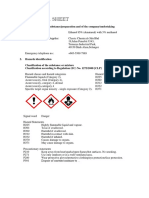

3. COMPOSITION, INFORMATION ON INGREDIENTS

Substance or Mixture : Mixture

Chemical Description : Lubricating grease.

Component Information : Lubricant base oil 85-90%

Grease thickener (Poly urea) 10-15%

Additives ≤5%

Chemical Formula : Not possible to define.

CAS Registry Number : Trade secret

Additional Information : The highly refined mineral oil contains <3% DMSO-extract, according to

IP346.

Pollutant Release and Transfer : Not applicable

Register (PRTR) Law

Industrial Safety and Health : Article 57-2 (Delivery of Documents) / No.168 Mineral oil 80-90%

Law

Poisonous and Deleterious : Not applicable

Substance Control Law

Classification of Components : [Chemical Identity / Hazard Class (category) / Hazard Statement / Conc.]

According to GHS Zinc naphthenate / Skin Irrit. 2, Eye Irrit. 2, Aquatic Chronic 1 /

H315,H319,H410 / 0.1-0.9%

Ethoxylated diamine / Acute Tox. 4, Skin Corr. 1B, Aquatic Chronic 1 /

H302,H314,H410 / 0.1-0.9%

Sodick Co., Ltd. 1/7

Serial No. SDS-CH10-E07 KH GREASE 6459 (BNST FREE) Revision Date: 1 September 2014

4. FIRST AID MEASURES

General Information : Not expected to be a health hazard when used under normal

conditions.

Inhalation : Remove casualty to fresh air and keep at rest in a position comfortable

for breathing. Cover with blanket to keep warm and rest in a quiet

surrounding. Seek immediate medical advice and attention.

Skin Contact : Wash skin with large amount of water using soap.

Eye Contact : Rinse cautiously with clean water for several minutes. Remove contact

lenses, if present and easy to do, and continue rinsing. After rinsing for

a minimum of 15 minutes, seek medical advice and attention.

Ingestion : Without inducing vomiting, call a doctor for treatment. If mouth has

been dirtied, clean with water.

Most Important Symptoms/Effects, : If swallowed, may irritate mucous membrane of stomach and induce

Acute & Delayed vomiting. Inhalation if mist may cause feeling ill. Skin contact and eye

contact may cause irritation.

Immediate Medical Attention, : Treat symptomatically. Call a doctor or poison control center for

Special Treatment guidance.

5. FIRE FIGHTING MEASURES

Clear fire area of all non-emergency personnel.

Suitable Extinguishing Media : Concentrated strong liquid in mist and powder forms, carbon dioxide

and foam. Use powder and carbon dioxide may be used small fires only.

Effective to use foam to shutdown the air in a large fires.

Unsuitable Extinguishing Media : Do not use water in a jet.

Specific Hazards Arising from : Hazardous combustion products may include: A complex mixture of

Chemicals airborne solid and liquid particulates and gases (smoke). Carbon

monoxide. Unidentified organic and inorganic compounds.

Fire Fighting Instructions : Water the surrounding equipment to cool them down. Cordon off the

affected place and its vicinity to all, except the concerned parties.

Protective Equipment & Precautions : Ensure to wear protective equipment and approach from windward.

for Fighters

6. ACCIDENTAL RELEASE MEASURES

Avoid contact with spilled or released material. For guidance on selection of personal protective equipment see

Chapter 8 of this Material Safety Data Sheet. See Chapter 13 for information on disposal. Observe the relevant

local and international regulations.

Personal Precautions, Protective : Avoid contact with skin and eyes. Prepare suitable equipment and

Equipment and Emergency materials.

Procedures

Environmental Precautions : Use appropriate containment to avoid environmental contamination.

Prevent from spreading or entering drains, ditches or rivers by using

sand, earth, or other appropriate barriers. In event of entering in the

sea, extend oil fences to prevent from spreading, and sop up with

absorbent materials. Use chemicals and/or detergents, they must

satisfy technical standards as set by the Ministry of Land,

Infrastructure and Transport / Ministry of the Environment.

Methods and Material for : Promptly remove all ignition sources and stop leakages. In a small

Containment and Clean Up leakage, absorb and recover by use of soil, sand, sawdust and waste

clothes. In a large leakage, cordon off the danger zone, prevent from

entering and enclose it with sand bank and stop outflow. Cover liquid

surface with foam, and recover liquid into containers.

Additional Advice : Local authorities should be advised if significant spillages cannot be

contained.

Sodick Co., Ltd. 2/7

Serial No. SDS-CH10-E07 KH GREASE 6459 (BNST FREE) Revision Date: 1 September 2014

7. HANDLING AND STORAGE

Handling

Technical Measures : In handling this material over the allocated volume, ensure approval to

meet requires of the laws. Keep away from heat, sparks, open flames,

hot objects. No smoking. Take measures against static discharge.

Ensure to wear clothing and shoes made of conductive materials. When

fixing or processing machine, it carries out after removing dangerous

objects completely. NEVER suck up (siphoning) this material by

mouth. Wear suitable protect equipment if skin or eye contact may

cause. Seal containers hermetically without handling in violent such as

falling, dropping, or jolting.

Ventilation Precautions : See Chapter 8.

Precautions for Safe Handling : Use under normal temperature. Prevent from mixing water and

impurity. Avoid contact with halogens, strong acids, alkali and

oxidizing materials.

Storage

Conditions for Safe Storage : Keep containers tightly closed and in a cool, well-ventilated place away

from direct sunlight. It is recommended to lock up storage area. Use

properly labelled and closeable containers. Avoid heat, sparks, open

flame and static accumulation.

Technical Measures : All electrical appliances shall be explosion-proof types, and they all

must be earthed.

Precautions for Safe Storage : Avoid contact and storage in same place with halogens, strong acids,

alkali and oxidizing materials.

Recommended Materials : Storage in original containers. Do not pressurize empty containers.

May cause rupture. Do not weld, heat up, drill or cut containers. May

ignite the residue and cause explosion.

8. EXPOSURE CONTROLS, PERSONAL PROTECTION

If the American Conference of Governmental Industrial Hygienists (ACGIH) value is provided on this document,

it is provided for information only.

Equipment : Seal or install ventilations for mist occurs. Install eye shower and body shower

near working site.

Standard Concentration : Not specified

Control

Occupational Exposure : Japan Society for Occupational Health(2012)(1) 3mg/m3 (Oil mist, mineral)

Limits ACGIH(2012) TWA[Inhalable fraction.](2) 5mg/m3 (Oil mist, mineral)

Protective Equipment : Skin protection not ordinarily required beyond standard issue work clothes.

Respiratory Protection : No respiratory protection is ordinarily required under normal conditions of

use. Use appropriate equipment in response to the circumstances.

Hand Protection : Use oil-proof protective hand gloves under prolonged or repeated skin contact.

Eye Protection : Wear safety glasses or full face shield if splashes are likely to occur.

Skin and Body Protection : Use oil-proof/long sleeved clothing under prolonged usage.

Appropriate Sanitary : Remove immediately all contaminated clothing. Contaminated clothing must

Measures be laundered before reuse.

9. PHYSICAL AND CHEMICAL PROPERTIES

Physical State : Semi-solid.

Colour : Light yellow.

Odour : Characteristic mineral oil

pH : Not applicable.

Initial Boiling Point : Expected >250°C

Pour Point : < Data not available °C

Flash Point : ≥ 200°C (SETA)

Sodick Co., Ltd. 3/7

Serial No. SDS-CH10-E07 KH GREASE 6459 (BNST FREE) Revision Date: 1 September 2014

Upper / Lower Flammability or Explosion : Typical 1 - 7 %(V) (based on mineral oil)

Limits

Auto-Ignition Temperature : Data not available. Expected >320°C

Density : Approx. 0.9 g/cm3 (15°C)

Solubility : Water: Negligible. Other solvents: Data not available

Decomposition Temperature : Data not available

Vapour Pressure : Data not available

Vapour Density : Data not available. Expected >1

n-Octanol/Water Partition Coefficient (log Pow) : Data not available

Evaporation Rate : Data not available

10. STABILITY AND REACTIVITY

Chemical Stability : Stable under normal condition.

Hazardous Reactivity : Avoid contact with strong oxidising agent.

Conditions to Avoid : Avoid contact with halogens, strong acids, alkalis, and oxidizing materials.

Incompatible Materials : Data not available.

Hazardous : Hazardous decomposition products are not expected to form during normal storage.

Decomposition Products Generates smoke, carbon monoxide, sulfurous acid gas etc. during combustion.

11. TOXICOLOGICAL INFORMATION

Basis for Assessment : Information given is based on data on the toxicology of lubricant base oil.

Toxicological information on product is not available. Components contained above

cut-off value is described on Chapter 3.

Acute Toxicity : 1. Oral Expected to be of low toxicity: LD50 > 5000 mg/kg, Rat(3)

2. Dermal Expected to be of low toxicity: LD50 > 5000 mg/kg, Rabbit(3)

3. Inhalation(Vapour) Data not available

4. Inhalation(Mist) Low toxicity: LC50 > 5 mg/l, 4h, Rat(3)

Skin Corrosion / : Not classified as a skin irritation (rabbit test).(3) Prolonged/repeated contact may

Irritation cause defatting of the skin which can lead to dermatitis.

Serious Eye Damage / : Not classified as an eye irritation (rabbit test).(3)

Irritation

Respiratory or Skin : No data available concerning respiratory sensitisation.

Sensitisation Not classified as a skin sensitisation (Buehler test; guinea pig).(3)

Germ Cell Mutagenicity : The mutagenic potential of the product category ‘other lubricant base oils’ has been

extensively studied in a range of "in vivo" and "in vitro" assays. The majority of the

studies showed no evidence of mutagenic activity.(3)

Carcinogenicity : Product contains mineral oils of types shown to be noncarcinogenic in animal

skin-painting studies.(3)

Highly refined mineral oils are not classified as carcinogenic by the International

Agency for Research on Cancer (IARC monographs: Group 3)(4), ACGIH(5) and EU

Directives.(6)

Reproductive and : Results of developmental and reproductive toxicity studies showed no evidence of

Developmental Toxicity developmental or reproductive toxicity in rats.(3)

Specific Target Organ : Acute studies do not indicate any specific organ toxicity following single exposure.(3)

Toxicity - Single

Exposure

Specific Target Organ : The repeat dose toxicity has been investigated by dermal and inhalation routes for

Toxicity - Repeated periods between 4 weeks and up to 2 years. No systemic effects showed. (3)

Exposure

Aspiration Hazard : Not classified as a hydrocarbon with kinetic viscosity ≤ 20.5mm 2/s measured at

40°C. Not considered an aspiration hazard.

Sodick Co., Ltd. 4/7

Serial No. SDS-CH10-E07 KH GREASE 6459 (BNST FREE) Revision Date: 1 September 2014

12. ECOLOGICAL INFORMATION

Basis for Assessment : Ecotoxicological data have not been determined specifically for this product.

Information given is based on a knowledge of the components and the

ecotoxicology of similar products. Components contained above cut-off value is

described on Chapter 3.

Caution : Poorly soluble mixture. May cause physical fouling of aquatic organisms. The

Water Accommodated Fraction (WAF) is applied following tests.

Toxicity : Fish(Fathead minnow, 96h) LL50 >100mg/L(3)

Fish(Fathead minnow, 14d) NOEL >100mg/L(3)

Crustacea (Daphnia magna, 48h) EL50 /NOEL >10,000mg/L(3)

Crustacea (Daphnia magna, 21d) NOEL >10mg/L(3)

Algae(Pseudokirchneriella subcapitata) NOEL >100mg/L(3)

In a static 4-day microorganism luminescence inhibition study, no significant

luminescence inhibition was observed.(3)

Acute Aquatic Toxicity : Not expected to be a hazard.

Chronic Aquatic Toxicity : Not expected to be a hazard.

Mobility : Generally floats on water.

Lubricating oil components have estimated log Koc >3, indicating these

components are likely to be adsorbed onto soil and sediment and are not likely

to leach to ground water.

Persistence/Degradability : Another lubricant base oil was determined to be inherently biodegradable but

not readily biodegradable, with a mean degradation of 31% by day 28.

Bioaccumulative Potential : Not available as highly refined base oil.

Hazardous to Ozone Layer : Not classified because this product not contained substances listed on

Montreal Protocol and Ozone Layer Protection Law.

13. DISPOSAL CONSIDERATIONS

Material Disposal : 1. Waste disposal yourself or entrust the industrial waste treatment

company who obtained the prefectural governor's permission or municipal

corporation. Disposal should be in accordance with applicable regional,

national, and local laws and regulations.

2. Do not dispose into the environment, in drains or in water courses.

3. For landfill disposal, destroy by fire and confirm cinders agreed to Waste

Disposal Law.

4. In event of burning this material, ensure to carryout work in safe place

with guards in position, and select a method that would not cause any

harm or damage to others during combustion or explosion.

Container Disposal : Purify and recycle or performs suitable disposal in accordance with the

standard of related laws and regulations. Disposal with remove content

completely.

14. TRANSPORT INFORMATION

International Restriction

UN Class : Not applicable.

UN Number : Not applicable.

Other Information : This material is not classified as dangerous under IMDG/IATA regulations.

Domestic Restriction : Since domestic laws and regulations shown below are applicable, containers

and transportation methods shall be required to follow each and every

regulation.

Land

Fire Service Law : Not considered as dangerous goods.

Container : If product classified as dangerous goods, use containers (other than tanker,

tank car and tank truck) for transportation usage, shall meet the Clause 2,

Notice Attachment 3, concerning dangerous materials.

Sodick Co., Ltd. 5/7

Serial No. SDS-CH10-E07 KH GREASE 6459 (BNST FREE) Revision Date: 1 September 2014

Sea : Ship Safety Law: Not Dangerous Goods.

Air : Civil Aeronautics Act: Not Dangerous Goods.

Specific Safety Measures : 1. Caution: Flammable.

and Conditions for 2. Transport remarkably with containers may not cause friction or agitation.

Transportation

3. Display signage on vehicle and provide with fire fighting equipment, if and

when required to transport more than the specified quantity. Total piled

height of vehicle shall be less than 3 meters.

4. Consolidation of this material with dangerous goods belonging to the 1st

and 6th Classification is prohibited.

5. Abide by other laws and regulations that are applicable.

15. REGULATORY INFORMATION

International Information

EINECS/ELINCS (EC) : All components listed or polymer exempt.

TSCA (USA) : All components listed or in compliance.

METI (JAPAN) : All components listed or in compliance.

Domestic Information

Fire Service Law : Not considered as dangerous goods.

Pollutant Release and Transfer : Not applicable

Register (PRTR) Law

Industrial Safety and Health Law : Article 57-2(Delivery of Documents) / No.168 Mineral oil 80-90%

Poisonous and Deleterious : Not applicable

Substance Control Law

Marine Pollution Protection Law : Waste Oil Regulation.

Sewage Control Law : Mineral Oil Disposal Regulation. (5mg/L)

Water Pollution Prevention Law : Oil Disposal Regulation. (5mg/L)

Waste Disposal and Public : Industrial Waste Regulation.

Cleaning Law

16. OTHER INFORMATION

- Subscribe "%" in this document means weight percentage.

[Quotation]

1. Recommendation of Occupational Exposure Limits (2012), Japanese Society of Occupational Health

2. Thresholds limit values for chemical substances and physical agents and biological exposure indices,

ACGIH (2012)

3. ECHA (European Chemicals Agency), website "ECHA CHEM", Information on Registered Substances

(2011). SDS of EU suppliers (2011)

4. IARC Monographs Programme on the Evaluation of Carcinogenic Risk to Humans (2006)

5. ACGIH documentation (2006)

6. EC Directive 67/548/EEC Annex I, EU CLP Regulation(EC) No.1272/2008 Annex VI Table 3.1, Table 3.2

[Reference]

- Globally Harmonized System of Classification and Labelling of Chemicals (GHS) 4th revised edition,

UNITED NATIONS(2011)

- Japanese Standards Association (JSA), JIS Z 7253:2012, JIS Z 7252:2014

- National Institute of Technology and Evaluation (nite), "GHS Information"

- Ministry of Economy, Trade and Industry, Chemical Management site.

- Ministry of Health, Labour and Welfare, "Label and MSDS information for GHS model"

Safety Data Sheet (SDS) about hazardous chemical is provided for a entrepreneur as reference information for

safety handling. Refer to this document and perform suitable handling. Nothing in this document shall reduce the

Sodick Co., Ltd. 6/7

Serial No. SDS-CH10-E07 KH GREASE 6459 (BNST FREE) Revision Date: 1 September 2014

user's responsibility to satisfy itself as to the suitability, accuracy, reliability, and completeness of such information

for its particular use. There is no warranty against intellectual property infringement. The information contained in

this document is based upon data believed to be reliable through our supply chain at the time. So, we could not

guarantee all about the contents. This document is based on JIS Z7253:2012, and is not a guarantee of safety.

Contents of SDS updated periodically. SDS compliance is required as a rule to all business enterprises engaged in

transaction of chemicals (including products containing them) with other businesses. Retailer/Wholesaler must

provide newest SDS to customers.

Sodick Co., Ltd. 7/7

You might also like

- Anest Iwata Spray GunDocument30 pagesAnest Iwata Spray GunFerry SandraNo ratings yet

- Artep7 90Document381 pagesArtep7 90Sean Pringle100% (1)

- Philippine History and Constitution: Eastern Samar State UniversityDocument18 pagesPhilippine History and Constitution: Eastern Samar State UniversityDelsie May Alipio100% (1)

- Environmental Management Plan: M/s. Covalent Laboratories Pvt. LTD., Unit-IDocument138 pagesEnvironmental Management Plan: M/s. Covalent Laboratories Pvt. LTD., Unit-IjyothiNo ratings yet

- Cullex Resin MSDSDocument6 pagesCullex Resin MSDSJuan ArcosNo ratings yet

- Notes On CSE Review - BARMMDocument19 pagesNotes On CSE Review - BARMMsakura100% (1)

- Irr of Ra - 9003Document66 pagesIrr of Ra - 9003albertNo ratings yet

- ED1 2010 Exam-Report-Dec PDFDocument11 pagesED1 2010 Exam-Report-Dec PDFfrancis100% (1)

- REVANCHA-10-EC-BIFENTHRIN SafetyData SheetDocument8 pagesREVANCHA-10-EC-BIFENTHRIN SafetyData SheetBong Casir100% (1)

- Indore CityDocument17 pagesIndore CityParul VyasNo ratings yet

- Chockfast Orange Resin GhsDocument8 pagesChockfast Orange Resin GhsRizky RamadhanNo ratings yet

- MSDS - Xylar - 2 - 2022Document14 pagesMSDS - Xylar - 2 - 2022SYED MAZHAR100% (2)

- Valorisation of Chicken FeathersDocument17 pagesValorisation of Chicken Feathersrr345No ratings yet

- Career AdbDocument28 pagesCareer AdbL461ONNo ratings yet

- Safety Data Sheet (SDS) : SHELL ALVANIA EP GREASE R000, R00, R0,1,2 Code:613131 Date:June 1, 2016 Page.1/5Document5 pagesSafety Data Sheet (SDS) : SHELL ALVANIA EP GREASE R000, R00, R0,1,2 Code:613131 Date:June 1, 2016 Page.1/5Nam ĐặngNo ratings yet

- Alvania EP GreaseDocument5 pagesAlvania EP Greasemingyu parkNo ratings yet

- Safety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Document5 pagesSafety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Chanchai PrugpadeeNo ratings yet

- MSDS TELLUS S2 M68aDocument5 pagesMSDS TELLUS S2 M68amflorian69No ratings yet

- Shell Tellus S22 M22Document5 pagesShell Tellus S22 M22Hafifi IsmailNo ratings yet

- Safety Data Sheet (SDS) : TOUGHNESS FINE B Shosekikako Co.,Ltd. 0075 Revised: March 1, 2021 Page.1/4Document4 pagesSafety Data Sheet (SDS) : TOUGHNESS FINE B Shosekikako Co.,Ltd. 0075 Revised: March 1, 2021 Page.1/4Bong CasirNo ratings yet

- Corena Oil PDocument5 pagesCorena Oil Pmingyu parkNo ratings yet

- 6.1. MSDS Fine BondDocument4 pages6.1. MSDS Fine BondBong CasirNo ratings yet

- 6.2. MSDS Toughness Fine ADocument4 pages6.2. MSDS Toughness Fine ABong CasirNo ratings yet

- LATAPOXY 300 Adhesive Part B SDS - US EnglishDocument7 pagesLATAPOXY 300 Adhesive Part B SDS - US Englishpetersom 93No ratings yet

- Safety Data Sheet: ARDROX 907PB AerosolDocument11 pagesSafety Data Sheet: ARDROX 907PB Aerosolabdulbaset alselwi100% (1)

- Mercury 4t Oil MSDSDocument5 pagesMercury 4t Oil MSDSCelesNo ratings yet

- Air Tool Lubricant - 2016 - 0Document8 pagesAir Tool Lubricant - 2016 - 0Cristhina LabraNo ratings yet

- Hydraulic Mineral oil-202008-ENG-GHSDocument9 pagesHydraulic Mineral oil-202008-ENG-GHSGiromotoNo ratings yet

- Hoja de Seguridad - Aceite DielectricoDocument8 pagesHoja de Seguridad - Aceite DielectricoBELTCO CONVEYOR SYSTEM SOLUTIONSNo ratings yet

- HS Bobcat 15W40 InglesDocument5 pagesHS Bobcat 15W40 InglesLuisa Fernanda Villalobos MirandaNo ratings yet

- Rimula r4 150w 40Document7 pagesRimula r4 150w 40Hermando RizkiNo ratings yet

- Enxofre Lukoil - MSDSDocument7 pagesEnxofre Lukoil - MSDSbrunaspinola82No ratings yet

- Castrol CRB TurbomaxDocument10 pagesCastrol CRB Turbomaxzeta10151015No ratings yet

- Polyferric Sulphate Liquid SdsDocument7 pagesPolyferric Sulphate Liquid SdsAddisonjuttie6345No ratings yet

- SDS US - Crystal Clean 142 Mineral Spirits (915876) Revision Date 2-11-15Document7 pagesSDS US - Crystal Clean 142 Mineral Spirits (915876) Revision Date 2-11-15ashadeofdarknessNo ratings yet

- FISPQ Citric Acid AnhydrousDocument7 pagesFISPQ Citric Acid AnhydrousJade LimaNo ratings yet

- LD 4 MSDSDocument19 pagesLD 4 MSDSKevin John P. PangilinanNo ratings yet

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet: 1. Product and Company IdentificationHazem HassonNo ratings yet

- Aceite Refrigerante Mineral 4GS C-4S 1 Galón 3,79L Nu-Calgon.Document10 pagesAceite Refrigerante Mineral 4GS C-4S 1 Galón 3,79L Nu-Calgon.danielbarbosagoncalvNo ratings yet

- SDS Roto-Xtend Duty Fluid 010314 in enDocument6 pagesSDS Roto-Xtend Duty Fluid 010314 in enfarmanNo ratings yet

- SGP26903Document28 pagesSGP26903ezgiNo ratings yet

- SDS-Copper Zinc Catalyst - WOLF TRAX - Copper - KOCH Agronomic Services US-CAN 2021-0602Document9 pagesSDS-Copper Zinc Catalyst - WOLF TRAX - Copper - KOCH Agronomic Services US-CAN 2021-0602AlNo ratings yet

- SW 945Document10 pagesSW 945sintaNo ratings yet

- Brake & Clutch Fluid Dot 3 PDFDocument6 pagesBrake & Clutch Fluid Dot 3 PDFBryan GonzalesNo ratings yet

- Roto Xtend MsdsDocument6 pagesRoto Xtend MsdsService DeskNo ratings yet

- Material Safety Data Sheet: Effective Date 11.03.2010Document6 pagesMaterial Safety Data Sheet: Effective Date 11.03.2010Connie Elanie KimNo ratings yet

- SDS-Flake Phthalic Anhydride of Contitnental Petrochemicals (Thailand) Co.,Ltd.Document6 pagesSDS-Flake Phthalic Anhydride of Contitnental Petrochemicals (Thailand) Co.,Ltd.Muslim NasirNo ratings yet

- HP R GreaseDocument8 pagesHP R GreaseDavidNo ratings yet

- 201 Rubber Cement SolutionDocument7 pages201 Rubber Cement Solutionapi-265234726No ratings yet

- Staroxy Grout LV Msds PDFDocument15 pagesStaroxy Grout LV Msds PDFShivam NagarkarNo ratings yet

- Material Safety Data Sheet: Product and Company Identification 1Document7 pagesMaterial Safety Data Sheet: Product and Company Identification 1faisiiNo ratings yet

- ABB Cable Pulling Lube MSDSDocument7 pagesABB Cable Pulling Lube MSDSRichard SyNo ratings yet

- MSDS Clove Leaf Oil RectifiedDocument4 pagesMSDS Clove Leaf Oil RectifiedKushDaiwikNo ratings yet

- Therminol 66 Sds EastmanDocument14 pagesTherminol 66 Sds Eastmansclad91No ratings yet

- Sulfuric AcidDocument5 pagesSulfuric Acidqaisarabbas90020% (1)

- Makino Spindle Oil SDSDocument7 pagesMakino Spindle Oil SDSViệt NguyễnNo ratings yet

- DOALL-MSDS US English - BRIGHT EDGE 240 - US - DOALLDocument7 pagesDOALL-MSDS US English - BRIGHT EDGE 240 - US - DOALLJAY CORTEZ MAMABICHONo ratings yet

- Carbopol 676Document9 pagesCarbopol 676QUIMFAC BARCELONA SLNo ratings yet

- LPS LSTDocument7 pagesLPS LSTNikolayNo ratings yet

- 20. Dầu Bôi Trơn 47005 Me Vbc Hydro Bsh-68vDocument4 pages20. Dầu Bôi Trơn 47005 Me Vbc Hydro Bsh-68vhuong.nguonsongxanhNo ratings yet

- MSDS Shell Spirax S2 A90 - 080811Document7 pagesMSDS Shell Spirax S2 A90 - 080811Eko Dodi SetiawanNo ratings yet

- SDS Petron Rev X HD 40 and HD 50 Rev 10Document5 pagesSDS Petron Rev X HD 40 and HD 50 Rev 10Florence Matthew T BesaresNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Preparation and CompanyDocument8 pagesSafety Data Sheet: 1. Identification of The Substance/Preparation and CompanyEdin Krdžalić EdoNo ratings yet

- MSDS REFINED OIL - InternationalDocument4 pagesMSDS REFINED OIL - Internationalrizal bestNo ratings yet

- MSDS PC Duron e Synthetic 10W-40 PDFDocument6 pagesMSDS PC Duron e Synthetic 10W-40 PDFaliosk8799No ratings yet

- SDS DC Fair Repair 1610Document11 pagesSDS DC Fair Repair 16104919404No ratings yet

- Safety Data Sheet: 1. IdentificationDocument12 pagesSafety Data Sheet: 1. IdentificationeadriesNo ratings yet

- LECTURE NOTES Solid and Hazardous WasteDocument120 pagesLECTURE NOTES Solid and Hazardous WasteOng KaiBoonNo ratings yet

- Bayle RA9003 EssayDocument3 pagesBayle RA9003 EssayLuciano Cromwell NavalNo ratings yet

- License Requirments of Waste Treatment Technologies & Recycling FacilitiesDocument5 pagesLicense Requirments of Waste Treatment Technologies & Recycling Facilitiespiyush_palNo ratings yet

- Recycling of Waste PVC Leather and PVC Urethane in The Automobile IndustryDocument8 pagesRecycling of Waste PVC Leather and PVC Urethane in The Automobile IndustrySenthil KumarNo ratings yet

- Gujarat Industrial Policy-2003Document23 pagesGujarat Industrial Policy-2003Nitin SharmaNo ratings yet

- SK Catininingan As RevisedDocument12 pagesSK Catininingan As RevisedRonnie ManaoNo ratings yet

- G2 CDX Kapai Lanao Del Sur 1.studentsDocument26 pagesG2 CDX Kapai Lanao Del Sur 1.studentsTintin LevidaNo ratings yet

- Bedbug Battle PlanDocument39 pagesBedbug Battle PlanCity RoomNo ratings yet

- Directional Power Sensor: ManualDocument109 pagesDirectional Power Sensor: ManualJuan Manuel RojasNo ratings yet

- E710 Manual 05-0461 Rev15.1 EN LoresDocument160 pagesE710 Manual 05-0461 Rev15.1 EN LoresGary MosesNo ratings yet

- Bonderite M-ZN 300X - KNOWN AS BONDERITE 300XDocument9 pagesBonderite M-ZN 300X - KNOWN AS BONDERITE 300XPetchi MuthuNo ratings yet

- An Introduction To Regional Economics HooverDocument164 pagesAn Introduction To Regional Economics Hooversfdkhkfjsfnsk njfsnksfnNo ratings yet

- Adane and MuletaDocument15 pagesAdane and MuletaDeepak Rao RaoNo ratings yet

- Sunlite GigE2 User ManualDocument106 pagesSunlite GigE2 User ManualjdjimenezNo ratings yet

- Community Led Total Sanitation Training ManualDocument104 pagesCommunity Led Total Sanitation Training ManualMohammad Ali ArianNo ratings yet

- Ethanol 95% DenaturedDocument10 pagesEthanol 95% Denaturedlailahalim1994No ratings yet

- Sly Automatic Rotary Pre-FiltersDocument5 pagesSly Automatic Rotary Pre-FiltersLinus RidgeNo ratings yet

- FWMC Business LWDocument4 pagesFWMC Business LWUsman TariqNo ratings yet

- AGPT04E-09 Guide To Pavement Technology Part 4E PDFDocument32 pagesAGPT04E-09 Guide To Pavement Technology Part 4E PDFWawan FadelNo ratings yet

- Aqueous Alkaline Cleaners: An Alternative To Organic SolventsDocument89 pagesAqueous Alkaline Cleaners: An Alternative To Organic Solventsdareen santosNo ratings yet

- G20 SolutionDocument11 pagesG20 SolutionAbidemi Benjamen AttehNo ratings yet

- EC SDS IN2 Epoxy Infusion Resin and HardenerDocument20 pagesEC SDS IN2 Epoxy Infusion Resin and HardenerDiego JimenezNo ratings yet

- Survey On Environmental Impact of Waste Disposal in Brgy Sta Cruz Group 2Document20 pagesSurvey On Environmental Impact of Waste Disposal in Brgy Sta Cruz Group 2Genivy SalidoNo ratings yet