Professional Documents

Culture Documents

Recon-Structing America's First Super Highway With Asphalt

Uploaded by

Sri RamyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Recon-Structing America's First Super Highway With Asphalt

Uploaded by

Sri RamyaCopyright:

Available Formats

Recon-

he Pennsylvania Turnpike, America’s grated. Also, freeze-thaw conditions in

T first Superhighway, turned 60 years old

on October 1, 2000.

the Pennsylvania mountains caused

severe scaling of the PCC. Maintenance

When the first stretch opened to costs were high and increasing traffic

traffic in 1940, it ran from Middlesex loads cracked the pavement in

near Harrisburg to Irwin near many places.

structing

Pittsburgh. It was America’s first limit- At first, maintenance crews used

ed access, four-lane, divided highway— hot mix asphalt (HMA) to reduce the

no stoplights, stop signs or cross traffic. forces of expansion and contraction

It cut three hours off the trip from on the original PCC. Crews cut out

Harrisburg to Pittsburgh. 10-foot widths of concrete every

1,500 feet and replaced them with

America’s

The $70 million,160-mile Turnpike

offered long straight-aways, relatively 14-inch-thick sections of HMA. The

gentle curves and easy grades. Its maintenance cuts eased the pressure

original Portland cement concrete on the original 47-foot-long PCC slabs.

(PCC) pavement consisted of two

12-foot traffic lanes in each direction.

First

It is this stretch of 9-inch-thick PCC— First HMA Overlay

all of it overlaid with asphalt—that is

being totally reconstructed by the The first HMA overlay occurred in

Pennsylvania Turnpike Commission. July 1954, a little less than 14 years

after the Turnpike opened. This 22-

mile-long stretch was the first of a

Super Early Pavement Problems

After WWII, the Turnpike’s original

roadway was extended east to connect

with the New Jersey Turnpike and

series of resurfacings on the then 327-

mile Turnpike system. On this overlay,

the paving contractor maintained two-

way traffic on one side of the median

strip while resurfacing the other side.

Highway

west to the Ohio state line. A 110-mile Two pavers working in tandem

northeastern extension was added in placed the 2-inch leveling course and

the 1-inch surface course, which

consisted of fine slag and

aggregate. Maintenance

Photo by Pennsylvania Turnpike Commission

crews also undersealed

with many of the 47-foot-long

PCC slabs with liquid

asphalt. By 1966, most of

the original pavement

was undersealed.

Asphalt 1957, bringing the total

to 470 miles. Another

42 miles were added

Photo by Pennsylvania Turnpike Commission

over the years in small

expansion projects,

bringing the Turnpike’s

current mileage total

to 512.

Because the original

160 miles of PCC pave-

ment was constructed

on relatively poor sub-

soil, much of it disinte- Widening the Turnpike

Sixty Years Later

Now, after 60 years of heavy use,

the Pennsylvania Turnpike Commission

has decided to rebuild America’s

Superhighway. It has thus far estab-

lished eleven locations on the original

stretch for total reconstruction. All

eleven project locations will involve

removing the existing pavement and

replacing it with new pavement.

Currently, one of the eleven proj-

ects is complete. Two others will be

complete by the fall of 2002. Eight

others are in one of three stages—

feasibility, preliminary design or

final design.

Total turnpike reconstruction

includes:

▲ Widening the median (up to 40 feet)

where feasible

Rebuilding America’s First Superhighway

▲ Straightening curves, making slopes

more gentle and adjusting roadway

original 160 miles are often unstable.

geometrics where feasible

Some of these soil conditions have

Smooth Ride?

▲ Widening the roadway using appro- caused significant problems on current

priate cuts and fills for the subgrade projects where temporary roads were This project specified a 36-inch-

necessary. per-mile rideability index using a zero

▲ Installation of an all-new roadway blanking band. Lane Construction

plus drainage used a K.J.Law lightweight profilometer

▲ Construction of all new overhead First Project to measure smoothness. The ride num-

ber for the eastbound pavement aver-

and mainline bridges and other Begun in 1998, the first total recon- aged 23 inches of roughness per mile.

structures struction project of the original Turnpike engineers and Lane

Turnpike was completed in August targeted several aspects of the project

Subgrade cuts and fills are impor- 2000. It went from Milepost 94 to where they could lower the 23 inches

tant because soil conditions on the Milepost 99. This five-mile stretch of of roughness per mile. Lane began

totally reconstructed roadway is paving the westbound lanes in June

the benchmark for subsequent

Currently, more than 160 total reconstruction projects.

2000. They decided that continuous

paving with equipment and delivery

The project cost $28 million, trucks accessing the work area ahead

million vehicles are approximately 40 percent of

the total estimated cost of the

of the paving train would limit the

amount of travel on the prepared

original Turnpike in 1938.

using the Pennsylvania Lane Construction

surface.

Lane decided to pave one lane of

Corporation of Meridian, asphalt-treated permeable base (ATPB)

Turnpike per year. Of Connecticut, completed the

staged construction project in

in one day, usually one mile in length.

They paved the adjacent lane the fol-

two years. Stages two and lowing day. Then Lane placed the first

that 160 million-plus three were the complete recon- 3-inch lift of HMA base course over

struction of the three eastbound both lanes. This operation continued

vehicles, 21.3 million or travel lanes and the shoulder.

Stage four was reconstruction

until all five miles of ATPB and the first

3-inch lift of HMA base course was in

of the westbound travel lanes place. Subsequent lifts of the HMA

13 percent are trucks. and shoulder.

base course were then placed in

lengths of 2.5 miles per day on the Second

travel lane and shoulder.

Reconstruction

Project

Super Smooth Superpave Major features

Lane also used a sonic leveling ski of the second

attached to the paving machine during reconstruction

the placement of the HMA base project—from

course. With each layer of base course, Milepost 185 to

Lane measured the profile index. Lane Milepost 197—

noted a marked improvement over the included the total

previous lift index although they didn’t reconstruction of

use a materials transfer buggy. ten miles of road-

Lane then paved the Superpave way and the

intermediate course non-stop with no milling and resur-

transverse joints using a transfer buggy. facing of three

The profile index on the intermediate dual tunnels. This

course of the westbound lanes aver- phase of the proj-

aged 19 inches of roughness per mile. ect will be com-

The final smoothness analysis on the plete in the sum-

westbound Superpave surface course mer of 2002. The

measured a low 13.3 inches of rough- original pave-

Photo by Pennsylvania Turnpike Commission

ness per mile. ment on this

Materials used in this first project project was rein-

included approximately 44,000 tons of forced concrete

ATPB, approximately 151,000 tons of with asphalt over-

HMA base course, approximately lays. The new

36,000 tons of Superpave intermediate pavement struc-

course, and approximately 35,000 tons ture is totally

of Superpave surface course. Approx- asphalt. The new

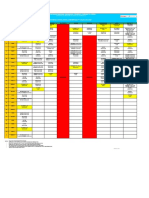

imately 41,000 tons of RAP and 77,000 pavement design Staged Construction for Turnpike Widening

tons of recycled concrete pavement includes 6 inches

were used in the reconstruction of of subbase, 4 inches of ATPB, 11 inches

the roadway. of HMA base course, 2 inches of Tight Window, High Tonnage

Superpave binder and 2 inches of

Superpave wearing surface. Because of the large tonnage

Contract specifications gave Lane required on the project, Lane set up

Construction the option of bidding a HMA plant adjacent to the New

Now, after 60 years asphalt or reinforced concrete. Lane Enterprise Dry Run Quarry, four miles

chose asphalt because they believed from the project. With traffic in single-

of heavy use, the they could complete the project

quicker and at less cost and inconven-

lane patterns and a work force nearing

180 workers, Lane rebuilt the project’s

ience to the motorist. Lane also believed eastern six miles of the westbound

Pennsylvania that the asphalt pavement would be roadway between the Labor Day and

easier to maintain. Thanksgiving Day holidays.

Turnpike Commission Lane began work in May 1999 on

the project. The Turnpike Commission 17

During the October 8 to November

timeframe, Lane placed a total of

developed the construction phasing of 153,388 tons of HMA on the roadway.

has decided to the project so that inconvenience to This included 18,482 tons of ATBP,

the summer Turnpike motorist was 89,239 tons of HMA base course,

rebuild America’s minimized. Consequently, the spring 24,656 tons of Superpave intermediate

course, and 18,013 tons of Superpave

and fall months became the heavy

surface course. The project paving

Superhighway. construction periods for this two-and-

one-half-year project. team set company records by placing

49,710 tons in a week and 10,051

“We are a

tons in 24 hours. Transfer vehicles

were used for placing the Superpave New Approach

mixes on the travel lanes and the

outside shoulder. DeFebo says that late last year

Lane recycled all existing roadway

materials on the project. The concrete

pavement was crushed and used as a

Turnpike engineers came up with a

new design approach. It is based on

widening the medians so the contrac-

customer-

subbase for the new pavement base tor does not have to build temporary

and the existing asphalt surface was

being used as RAP in the HMA base

course and Superpave mixes.

roadways.

The new approach is a two-stage

process geared to providing the driv-

driven

ing public with maximum service.

Durable Overlays

“We keep four lanes open at all times,”

says DeFebo. “We use the shoulder

and median as part of the new passing

facility,”

Over the years, the typical thickness

for Turnpike HMA overlays has been

4 inches—a 1-inch leveling course, a

lane. Then we switch traffic to this

newly reconstructed lane. Next we

construct the median—up to 40 feet

says

2-inch intermediate course, and a wide. Finally, when we add the third

1-inch surface course.The Commission

has had good success with these HMA

overlays. In 1991 they were getting

lane, the median lane is used to

carry traffic.

“We are a customer-driven facility,”

DeFebo.

between 8 and 15 years out of them. says DeFebo. “They pay to use our

Turnpike rehabilitation typically

includes redecking bridges, reconstruc-

tion of shoulders, and milling and

road and our first priority is to accom-

modate them.” “Motorists

resurfacing with HMA.

For widenings, the Turnpike uses a

Deep-Strength® design, composed of

10 inches compacted subbase material

Increasing Traffic pay to use

Currently, more than 160 million

plus up to 15 inches of HMA. When

adding new lanes in sections where

soils are weak, design engineers specify

vehicles are using the Pennsylvania

Turnpike per year. Of that 160 million-

plus vehicles,21.3 million or 13 percent

our road

Full-Depth asphalt. Shoulders are are trucks. In 1999, more than

normally reconstructed with 8.5 or

9.5 inches of HMA.

156 million vehicles used the Turnpike,

19.8 million were trucks. In 1998,

more than 151 million used the road

and our

and 18.6 million were trucks. Traffic is

Traffic Control

During rehabilitation projects, the

increasing by about 3 percent per year.

Despite increasing traffic and tight

reconstruction deadlines, the

first priority

is to

Turnpike Traffic Control Department Pennsylvania Turnpike Commission is

uses staging and phasing because committed to making its road the

Turnpike policy encourages the main- number one east-west artery in the

tenance of four traffic lanes at all times. state for the next 40 years.▲

Turnpike engineers like HMA because

it gives them the speed and flexibility

to keep high volume traffic moving.

Information and photos for this article

were provided by the Pennsylvania

accommo-

“Our goal is to keep four lanes Turnpike Commission’s Public

open at all times,” says Carl DeFebo,

technical spokesman for the Turnpike’s

Public Relations Department. “We

Relations Department and the

Pennsylvania Asphalt Pavement

Association.

date

don’t allow single lanes at all in the

summer—especially in August, which

is our busiest month. Any lane

closures we do in the summer have

Deep-Strength® is a registered trademark of the

Asphalt Institute. them.”

to be off-peak.”

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- W32 Engine-Manual PDFDocument346 pagesW32 Engine-Manual PDFctsak87% (30)

- National Building Code 2005Document1,161 pagesNational Building Code 2005api-2617216889% (47)

- This Study Resource Was: Assignment: Changing TiresDocument1 pageThis Study Resource Was: Assignment: Changing TiresCourse heroNo ratings yet

- CTRG2015 Submission 455Document10 pagesCTRG2015 Submission 455Sri RamyaNo ratings yet

- Preparation of Viscosity Blends For Hot Recycled Bituminous MaterialsDocument3 pagesPreparation of Viscosity Blends For Hot Recycled Bituminous MaterialsSri RamyaNo ratings yet

- Asphalt Hot Mix Training ManualDocument91 pagesAsphalt Hot Mix Training Manualyazqa50% (2)

- D2172 7764-1 PDFDocument12 pagesD2172 7764-1 PDFDivya DeenuNo ratings yet

- BIS - Modified Binder - 15462 PDFDocument14 pagesBIS - Modified Binder - 15462 PDFAravind KumarNo ratings yet

- CTRG2015 Submission 460Document12 pagesCTRG2015 Submission 460Sri RamyaNo ratings yet

- CTRG2015 Submission 453Document13 pagesCTRG2015 Submission 453Sri RamyaNo ratings yet

- 2005 09 MSCRDocument5 pages2005 09 MSCRSri RamyaNo ratings yet

- CTRG2015 Submission 464Document12 pagesCTRG2015 Submission 464Sri RamyaNo ratings yet

- CTRG2015 Submission 463Document12 pagesCTRG2015 Submission 463Sri RamyaNo ratings yet

- CTRG2015 Submission 462Document14 pagesCTRG2015 Submission 462Sri RamyaNo ratings yet

- CTRG2015 Submission 454Document13 pagesCTRG2015 Submission 454Sri RamyaNo ratings yet

- CTRG2015 Submission 451Document12 pagesCTRG2015 Submission 451Sri RamyaNo ratings yet

- NBC - Fire SafetyDocument200 pagesNBC - Fire Safetyvenkin84507486% (7)

- CTRG2015 Submission 452Document10 pagesCTRG2015 Submission 452Sri RamyaNo ratings yet

- Guidelines For Classification of Hotels JAN2011Document41 pagesGuidelines For Classification of Hotels JAN2011Dharmesh PatelNo ratings yet

- Guidelines for Conventional, Thin, and Ultra-Thin WhitetoppingDocument31 pagesGuidelines for Conventional, Thin, and Ultra-Thin WhitetoppingSri Ramya100% (1)

- Project Report On Multi Storied Building Design and AnalysisDocument122 pagesProject Report On Multi Storied Building Design and AnalysisSri RamyaNo ratings yet

- Irc-Sp-100-2014 Use of Cold Mix Technology in Consturction & Maintainance of Roads Using Bitumen EmulsionDocument94 pagesIrc-Sp-100-2014 Use of Cold Mix Technology in Consturction & Maintainance of Roads Using Bitumen EmulsionAkash Yadav100% (2)

- Project Report-12Document89 pagesProject Report-12Sri RamyaNo ratings yet

- Design and Analysis of Multi-Storied Building Project ReportDocument122 pagesDesign and Analysis of Multi-Storied Building Project ReportSri RamyaNo ratings yet

- Guidelines for Using Waste Plastic in Road ConstructionDocument24 pagesGuidelines for Using Waste Plastic in Road ConstructionAkash YadavNo ratings yet

- IRC SP 16 2019 Guidelines On Measuring Road RoughnessDocument27 pagesIRC SP 16 2019 Guidelines On Measuring Road RoughnessSri RamyaNo ratings yet

- Draft IRC SP 98 Waste Plastic Specs 1st December 2019Document21 pagesDraft IRC SP 98 Waste Plastic Specs 1st December 2019Sri RamyaNo ratings yet

- Irc SP 101-2014Document24 pagesIrc SP 101-2014Sri RamyaNo ratings yet

- Glossary of Transportation Construction Quality Assurance TermsDocument48 pagesGlossary of Transportation Construction Quality Assurance TermsSri RamyaNo ratings yet

- Excel For Civil Engineers-1Document36 pagesExcel For Civil Engineers-1mp SinghNo ratings yet

- Airport Pavement ManagmentDocument26 pagesAirport Pavement ManagmentJamik_888No ratings yet

- Arif Corporation SDN BHDDocument2 pagesArif Corporation SDN BHDMOHD NAIM MOKSIN HUSSINNo ratings yet

- On Latest JPO On Stabling Loads DT 18.06.21Document10 pagesOn Latest JPO On Stabling Loads DT 18.06.21Naveen Kushwaha100% (3)

- Sma Final Code - IRC SP 79 2023 First Revision-03.12.2023Document23 pagesSma Final Code - IRC SP 79 2023 First Revision-03.12.2023SRINIVASNo ratings yet

- Ideas Forecast Speaking Quý 3 - 2023Document71 pagesIdeas Forecast Speaking Quý 3 - 2023Ngocha1003No ratings yet

- 1-10 IbDocument13 pages1-10 IbqwertyuiopabcdNo ratings yet

- Drive Cycle SimulationDocument20 pagesDrive Cycle SimulationVc CvNo ratings yet

- AFIKLMEM Schedule Technical Training 2023 v15NOV22Document4 pagesAFIKLMEM Schedule Technical Training 2023 v15NOV22Dylan GalpeNo ratings yet

- Introduction To Loads - IsAE SUPAERODocument231 pagesIntroduction To Loads - IsAE SUPAEROGuilherme De SouzaNo ratings yet

- Birla Institute of Technology and Science, Pilani Pilani Campus Instruction DivisionDocument3 pagesBirla Institute of Technology and Science, Pilani Pilani Campus Instruction DivisionNavik BhandariNo ratings yet

- Emplooi Priok 2022 Update 20-06-2022Document1 pageEmplooi Priok 2022 Update 20-06-2022Heriyanto PmlNo ratings yet

- Sustainable TransportDocument15 pagesSustainable TransportHardik ChhabraNo ratings yet

- Traffic Management PlanDocument42 pagesTraffic Management PlanAbdul Malik YacobNo ratings yet

- Sl. No. RC Name RC Code Address Operational AreaDocument14 pagesSl. No. RC Name RC Code Address Operational AreaRavinder SinghNo ratings yet

- 8294 Pneu Triumph SchvalDocument19 pages8294 Pneu Triumph SchvalErik ŠtréglNo ratings yet

- FM1 300 (1998)Document210 pagesFM1 300 (1998)Chris WhiteheadNo ratings yet

- Heavy vehicles accident causation & preventionDocument39 pagesHeavy vehicles accident causation & preventionNoemi Itzel Agrazal LaraNo ratings yet

- BKPRDocument22 pagesBKPRGFNo ratings yet

- Ankleshwar Stock Audit Report PDFDocument30 pagesAnkleshwar Stock Audit Report PDFjayesh jarwaniNo ratings yet

- 166.873.03Document5 pages166.873.03Hilal HazaaNo ratings yet

- Latihan Bab 3Document12 pagesLatihan Bab 3Hasnah GhaniNo ratings yet

- Aircraft DeicingDocument2 pagesAircraft DeicingIduni HiranyaNo ratings yet

- Shaban Booklet 19-11-2016 - 162 Pages NewDocument162 pagesShaban Booklet 19-11-2016 - 162 Pages NewMahmood DlzarNo ratings yet

- CTI Technical Paper TP10-19Document28 pagesCTI Technical Paper TP10-19Mehul BansalNo ratings yet

- 1478509168446223172Document9 pages1478509168446223172علی چیواییNo ratings yet

- NOAH Plan BDocument39 pagesNOAH Plan BAlvin KonoNo ratings yet

- Acrow Bridge Table Form (Press)Document32 pagesAcrow Bridge Table Form (Press)alaaNo ratings yet

- CAMC Trucks Service Manual PDFDocument535 pagesCAMC Trucks Service Manual PDFchuck absulio100% (1)

- SCE 2022 Exhibitor ListingDocument57 pagesSCE 2022 Exhibitor ListingTony MwangiNo ratings yet