Professional Documents

Culture Documents

Product Data

Uploaded by

nestroyersOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Data

Uploaded by

nestroyersCopyright:

Available Formats

Product Data

HEMPADUR®MULTI-STRENGTH®GF 35870

BASE 35879 with CURING AGENT 98870

Description: HEMPADUR MULTI-STRENGTH GF 35870 is an amine-adduct cured epoxy coating - the

product is reinforced with Glassflakes. It is a hard, impact and abrasion resistant

coating with good resistance to sea water, mineral oils, aliphatic hydrocarbons and

splashes from petrol and related products.

Recommended use: As a self-primed, high build coating primarily for areas subject to abrasion and/or to a

highly corrosive environment. E.g. splash zones, jetty pilings and working decks.

Can be used as interior lining for crude oil and fuel oil storage tanks.

Service temperatures: Dry exposure only: In water (no temperature gradient):

Maximum: 140°C/284°F 60°C/140°F (See REMARKS overleaf)

Availability: Part of Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Colours/Shade nos: Black/19990

Finish: Glossy

Volume solids, %: 87 ± 1

Theoretical spreading rate: 2.5 m²/litre - 350 microns

100 sq.ft./US gallon - 14 mils

Flash point: 32°C/90°F

Specific gravity: 1.3 kg/litre

10.8 lbs/US gallon

Surface dry: 4 (approx.) hours at 20°C/68°F

Dry to touch: 6 (approx.) hours at 20°C/68°F

Fully cured: 7 days at 20°C/68°F

V.O.C.: 180 g/litre - 1.5 lbs/US gallon

The physical constants stated are nominal data according to the HEMPEL Group's approved formulas. They are

subject to normal manufacturing tolerances and where stated, being standard deviation according to ISO 3534-1.

APPLICATION DETAILS:

Mixing ratio for 35870: Base 35879 : Curing agent 98870

3 : 1 by volume

Application method: Airless spray

Thinner (max.vol.): 08450 (5%)

Pot life: 1 hour (20°C/68°F)

Nozzle orifice: .023"-.027" (Reversible)

Nozzle pressure: 250 bar/3600 psi

(Airless spray data are indicative and subject to adjustment)

Cleaning of tools: HEMPEL’S TOOL CLEANER 99610

Indicated film thickness, dry: 350 micron/14 mils

Indicated film thickness, wet: 400 micron/16 mils

Recoat interval, min: See REMARKS overleaf

Recoat interval, max: See REMARKS overleaf

Safety: Handle with care. Before and during use, observe all safety labels on packaging and

paint containers, consult HEMPEL Material Safety Data Sheets and follow all local or

national safety regulations. Avoid inhalation, avoid contact with skin and eyes, and do

not swallow. Take precautions against possible risks of fire or explosions as well as

protection of the environment. Apply only in well ventilated areas.

Issued: March 2007 Page 1 of 2

HEMPEL

Product Data Sheet

HEMPADUR MULTI-STRENGTH GF 35870

SURFACE New steel (dry conditions): Abrasive blasting to Sa 2½, (ISO 8501-1:1988) with a surface profile

PREPARATION: equivalent to Rugotest No. 3 BN 10, Keane-Tator Comparator 3.0 G/S or ISO Comparator, ROUGH

MEDIUM (G).

Remove any oil, grease and other contaminants by detergent and salts by high fresh water hosing

prior to abrasive blasting.

Maintenance: Remove oil and grease etc. with suitable detergent. Remove salt and other

contaminants by (high pressure) fresh water cleaning. Remove all rust and loose material by wet or

dry abrasive blasting or for minor areas power tool cleaning. Feather edges to sound and intact

areas. After wet abrasive blasting hose down the surface by hot water rinsing ("steam cleaning").

Touch up bare spots to full film thickness when the surface has become visually dry.

APPLICATION HEMPADUR MULTI-STRENGTH GF 35870 may be applied and will cure at temperatures down to

CONDITIONS: 5°C/41°F.

The temperature of the paint itself should be above 15°C/59°F. The best result is obtained at 20-

30°C/68-86°F.

In confined spaces provide adequate ventilation.

PRECEDING COAT: None. If a blast primer is required use HEMPADUR 15590.

SUBSEQUENT COAT: None or according to specification.

REMARKS:

Weathering/ The natural tendency of epoxy coatings to chalk in outdoor exposure and to become more

service sensitive to mechanical damage and chemical exposure at elevated temperatures is also

temperatures: reflected in this product.

Colour: Light shades will have a tendency to yellow when exposed to sunshine and darken when exposed

to heat.

Service Maximum peak temperature in water is 80°C/176°F.

temperatures:

Film thicknesses: May be specified in another film thickness than indicated depending on purpose and area of use.

This will alter spreading rate and may influence drying time and recoating interval. Normal range

dry is 350-500 micron/14-20 mils.

Application Standard airless heavy-duty spray equipment:

equipment: Pump ratio: min 45:1 (see Note below)

Pump output: min 12 litres/minute (theoretical)

Spray hoses: max 15 metres/50 feet, 3/8" internal diameter

max 3 metres/10 feet, 1/4" internal diameter

Note: If longer spray hoses are necessary, up to 50 metres/150 feet hose (½" internal diameter)

can be added. The pump ratio must be raised to 60:1 or more, however, the high output capacity

of the pump must be maintained. Bigger spray nozzles will also call for increased pump size.

A reversible nozzle is recommended.

Filter: Surge tank filter and tip filter should be removed.

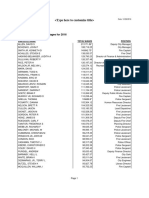

Recoating: Recoating intervals related to later conditions of exposure at 20°C/68°F :

(350 micron/14 mils dry film thickness of HEMPADUR MULTI-STRENGHT GF 35870).

Recoated with Minimum Maximum

Atmospheric Atmospheric

Medium Severe Immersion Medium Severe Immersion

HEMPATHANE 4 hours 6 hours NR 10 Days 3 Days NR

HEMPADUR 6 hours 8 hours 16 hours 60 Days 30 Days 30 Days

If the maximum recoat interval is exceeded, roughening of the surface is necessary to

ensure adhesion.

Note: HEMPADUR MULTI-STRENGTH GF 35870 is for professional use only.

ISSUED BY: HEMPEL A/S - 3587019990CR002

supersedes those

This Product Data Sheet supersedes those previously

previouslyissued.

issued.

explanations, definitions

For explanations, definitionsand

andscope,

scope,seesee“Explanatory

“ExplanatoryNotes”

Notes”ininthetheHEMPEL

HEMPELBook.Book.

specifications, directions

Data, specifications, directionsand

andrecommendations

recommendationsgiven givenininthis

thisdata

datasheet

sheet represent

representonly

onlytest results

test or or

results

experience obtained

experience obtainedunder

undercontrolled

controlledororspecially

speciallydefined

definedcircumstances.

circumstances. Their

Theiraccuracy,

accuracy, completeness

completeness or or

appropriateness under

appropriateness underthe

theactual

actualconditions

conditionsofofany

anyintended

intendeduse use ofofthe

theProducts

Products herein must

herein mustbebedetermined

determined

exclusively by the Buyer and/or

and/or User.

User.

Products are supplied

The Products supplied and

and all

alltechnical

technicalassistance

assistanceisisgiven

givensubject

subject totoHEMPEL's

HEMPEL'sGENERAL

GENERALCONDITIONS

CONDITIONS OF OF

SALES, DELIVERY

SALES, DELIVERYAND ANDSERVICE,

SERVICE, unless

unless otherwise

otherwise expresslyagreed

expressly agreedininwriting.

writing.TheThe Manufacturerand

Manufacturer andSeller

Seller

disclaim,

disclaim, and

and Buyer

Buyer and/or

and/orUser

Userwaive

waive all

allclaims

claimsinvolving,

involving,anyanyliability,

liability,including

includingbutbutnot

notlimited

limitedtotonegligence,

negligence,

except as expressed

expressed inin said

saidGENERAL

GENERAL CONDITIONS

CONDITIONS for forall

all results,

results, injury

injury or

or direct

direct or consequential

consequential losses

lossesoror

damages arising

damages arisingfrom

fromthe

theuse

useofofthe

theProducts

Productsasasrecommended

recommendedabove, above,on onthe

theoverleaf

overleafororotherwise.

otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Issued: March 2007 Page 2 of 2 Product Data Sheet

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- CIS 13 Public Comment 10.11.2021Document53 pagesCIS 13 Public Comment 10.11.2021nestroyersNo ratings yet

- CS S 15PipeLoadingUnloadingDuringConstruction Rev1Document15 pagesCS S 15PipeLoadingUnloadingDuringConstruction Rev1nestroyersNo ratings yet

- Propeller Thermo-Anemometer: Key PointsDocument2 pagesPropeller Thermo-Anemometer: Key PointsnestroyersNo ratings yet

- Article Transport of Pipeline Optimisation 149 3Document4 pagesArticle Transport of Pipeline Optimisation 149 3nestroyersNo ratings yet

- MSDS-Hardtop AX Comp ADocument13 pagesMSDS-Hardtop AX Comp AnestroyersNo ratings yet

- Safety Data Sheet: Hardtop AX Comp BDocument16 pagesSafety Data Sheet: Hardtop AX Comp BnestroyersNo ratings yet

- MSDS-jotomastıc 87 Comp-ADocument14 pagesMSDS-jotomastıc 87 Comp-AnestroyersNo ratings yet

- Jotun Thinner No17-PDSDocument2 pagesJotun Thinner No17-PDSnestroyersNo ratings yet

- MSDS-jotomastıc 87 Comp-BDocument11 pagesMSDS-jotomastıc 87 Comp-BnestroyersNo ratings yet

- Jotun Thinner No10-PDSDocument2 pagesJotun Thinner No10-PDSnestroyersNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Understanding PTS Security PDFDocument37 pagesUnderstanding PTS Security PDFNeon LogicNo ratings yet

- Walking in Space - Lyrics and Chord PatternDocument2 pagesWalking in Space - Lyrics and Chord Patternjohn smithNo ratings yet

- Cam 18 Test 3 ListeningDocument6 pagesCam 18 Test 3 ListeningKhắc Trung NguyễnNo ratings yet

- 2016 IT - Sheilding Guide PDFDocument40 pages2016 IT - Sheilding Guide PDFlazarosNo ratings yet

- NIQS BESMM 4 BillDocument85 pagesNIQS BESMM 4 BillAliNo ratings yet

- Genomic Tools For Crop ImprovementDocument41 pagesGenomic Tools For Crop ImprovementNeeru RedhuNo ratings yet

- Manual For Tacho Universal Edition 2006: Legal DisclaimerDocument9 pagesManual For Tacho Universal Edition 2006: Legal DisclaimerboirxNo ratings yet

- Knee JointDocument28 pagesKnee JointRaj Shekhar Singh100% (1)

- Prospekt Puk U5 en Mail 1185Document8 pagesProspekt Puk U5 en Mail 1185sakthivelNo ratings yet

- Arduino Uno CNC ShieldDocument11 pagesArduino Uno CNC ShieldMărian IoanNo ratings yet

- Organization Culture Impacts On Employee Motivation: A Case Study On An Apparel Company in Sri LankaDocument4 pagesOrganization Culture Impacts On Employee Motivation: A Case Study On An Apparel Company in Sri LankaSupreet PurohitNo ratings yet

- HRMDocument118 pagesHRMKarthic KasiliaNo ratings yet

- Sankranthi PDFDocument39 pagesSankranthi PDFMaruthiNo ratings yet

- DFo 2 1Document15 pagesDFo 2 1Donna HernandezNo ratings yet

- Haier in India Building Presence in A Mass Market Beyond ChinaDocument14 pagesHaier in India Building Presence in A Mass Market Beyond ChinaGaurav Sharma100% (1)

- Open Source NetworkingDocument226 pagesOpen Source NetworkingyemenlinuxNo ratings yet

- Amendments To The PPDA Law: Execution of Works by Force AccountDocument2 pagesAmendments To The PPDA Law: Execution of Works by Force AccountIsmail A Ismail100% (1)

- 10 Killer Tips For Transcribing Jazz Solos - Jazz AdviceDocument21 pages10 Killer Tips For Transcribing Jazz Solos - Jazz Advicecdmb100% (2)

- Project Management TY BSC ITDocument57 pagesProject Management TY BSC ITdarshan130275% (12)

- Artificial Intelligence Techniques For Encrypt Images Based On The Chaotic System Implemented On Field-Programmable Gate ArrayDocument10 pagesArtificial Intelligence Techniques For Encrypt Images Based On The Chaotic System Implemented On Field-Programmable Gate ArrayIAES IJAINo ratings yet

- Expression of Interest (Consultancy) (BDC)Document4 pagesExpression of Interest (Consultancy) (BDC)Brave zizNo ratings yet

- SreenuDocument2 pagesSreenuSubbareddy NvNo ratings yet

- 2016 W-2 Gross Wages CityDocument16 pages2016 W-2 Gross Wages CityportsmouthheraldNo ratings yet

- Notes On Antibodies PropertiesDocument3 pagesNotes On Antibodies PropertiesBidur Acharya100% (1)

- Pipe Cleaner Lesson PlanDocument2 pagesPipe Cleaner Lesson PlanTaylor FranklinNo ratings yet

- Gomez-Acevedo 2010 Neotropical Mutualism Between Acacia and Pseudomyrmex Phylogeny and Divergence TimesDocument16 pagesGomez-Acevedo 2010 Neotropical Mutualism Between Acacia and Pseudomyrmex Phylogeny and Divergence TimesTheChaoticFlameNo ratings yet

- ResumeDocument3 pagesResumeapi-280300136No ratings yet

- Colorfastness of Zippers To Light: Standard Test Method ForDocument2 pagesColorfastness of Zippers To Light: Standard Test Method ForShaker QaidiNo ratings yet

- Lab Report SBK Sem 3 (Priscilla Tuyang)Document6 pagesLab Report SBK Sem 3 (Priscilla Tuyang)Priscilla Tuyang100% (1)

- Advertising II Marathi VersionDocument91 pagesAdvertising II Marathi VersionHarsh Sangani100% (1)