Professional Documents

Culture Documents

Datasheet LIVEO Q7-2243

Uploaded by

felipe geymerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet LIVEO Q7-2243

Uploaded by

felipe geymerCopyright:

Available Formats

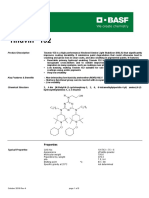

Liveo™ Q7-2243 LVA, Simethicone USP

Silicone Antifoam

Liveo™ Q7-2243 LVA, Simethicone USP is a specially formulated low volatile silicone antifoarn designed for use in

various medical and pharmaceutical applications requiring foam suppression or inhibition.

Liveo™ Q7-2243 LVA, Simethicone USP is formulated and manufactured so that the quantity of volatile, low-molecular-

weight silicone species is minimal. This low volatility (1 percent maximum) is especially advantageous in the

manufacture of antiflatulent or antiflatulent/antacid tablets and other products where processing conditions, such as

drying by high surface area exposure at elevated temperatures, will result in loss of volatile silicone species and

subsequent low assay results for silicone fluid.

Packaging :

Liveo™ Q7-2243 LVA, Simethicone USP is available in 18 and 200 kg containers, net weight.

Product information

Colour Gray -

Basis PDMS + SiO2 -

Heavy metals content ≤5 ppm

Silicon dioxide content 4-7 % PhEur 1470

Polydimethylsiloxane content 90.5 - 99 % PhEur 1470

Rheological properties

Viscosity 570 mPa.s

Specific Application Suitability

Defoaming performance, 20ppm ≤15 s PhEur 1470

Other properties

Specific Gravity 0.9751 - ASTM D 4052

Volatility, 4h at 200°C ≤1 % PhEur 1470

Refractive index 1.4041 -

1: for silicone fluid only

Storage and stability

Shelf life 24 months

Characteristics

Food contact FDA 21 CFR

Additional Information

How to use Storage:

Revised: 2020-12-14 Page: 1 of 2

Liveo™ Q7-2243 LVA, Simethicone USP

Silicone Antifoam

Some settling may occur during storage of Liveo™ Q7-2243 LVA, Simethicone

USP. Therefore, containers should be thoroughly mixed prior to use or testing.

How to Use:

Process Defoaming: In general, concentrations of 1 to 50 parts per million

(ppm) are sufficient to suppress foaming in most systems. It is suggested that a

concentration within this range be used initially. Adjustments in concentration

may be desirable to detennine the appropriate level to use for any particular

process or product.

The height to which a foam will rise can be limited by applying Liveo™ Q7-2243

LVA, Simethicone USP to processing equipment. For example, the defoamer is

often wiped on nozzles of bottle-filling machines to knock down foam as it

rises in the neck of the bottle. Similarly, if applied to the rim of a processing

container, foam overflow can be prevented.

Solvent Dispersion: In applications where solvents can be used,

Liveo™ Q7-2243 LVA, Simethiconc USP may be dispersed in a solvent and then

sprayed on the foam or the solvent dispersion may be flushed through a

system to remove remnants of foam. Dispersions may be made in an

acceptable non-polar solvent. These dispersions require constant agitation to

prevent settling of the silicon dioxide.

Tableting: In some applications, Liveo™ Q7-2243 LVA, Simethiconc USP may

be premixed with a carrier material and this mixture subsequently added

directly to the foaming system. This technique is commonly used in the

manufacture of antiflatulent and antiflatulent/antacid tablets. For this

application, the silicone antifoam compound is either dry- or wet-granulated

with common carrier materials such as sugars, starches, or cellulose

derivatives and then further processed into tablets.

Revised: 2020-12-14 Page: 2 of 2

The information set forth herein is furnished free of charge, is based on technical data that DuPont believes to be reliable, and represents typical values that fall within the normal range of

properties. This information relates only to the specific material designated and may not be valid for such material used in combination with other materials or in other processes. It is

intended for use by persons having technical skill, at their own discretion and risk. This information should not be used to establish specification limits nor used alone as the basis of design.

Handling precaution information is given with the understanding that those using it will satisfy themselves that their particular conditions of use present no health or safety hazards and

comply with applicable law. Since conditions of product use and disposal are outside our control, we make no warranties, express or implied, and assume no liability in connection with any

use of this information. As with any product, evaluation under end-use conditions prior to specification is essential. Nothing herein is to be taken as a license to operate or a recommendation

to infringe on patents.

CAUTION: Do not use DuPont materials in medical applications involving implantation in the human body or contact with internal body fluids or tissues unless the material has been provided

from DuPont under a written contract or other acknowledgement that is consistent with the DuPont policy regarding medical applications and expressly acknowledges the contemplated use.

For further information, please contact your DuPont representative.

DuPont’s sole warranty is that our products will meet our standard sales specifications in effect at the time of shipment. Your exclusive remedy for breach of such warranty is limited to

refund of purchase price or replacement of any product shown to be other than as warranted. TO THE FULLEST EXTENT PERMITTED BY APPLICABLE LAW, DUPONT SPECIFICALLY DISCLAIMS

ANY OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR NON-INFRINGEMENT. DUPONT DISCLAIMS LIABILITY FOR ANY SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

DuPont™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™, SM or ® are owned by affiliates of DuPont de Nemours, Inc. unless otherwise noted.

© 2020 DuPont. All rights reserved.

Powered by TCPDF (www.tcpdf.org)

You might also like

- Product Information DOW CORNING 1430Document2 pagesProduct Information DOW CORNING 1430Валентин СелищевNo ratings yet

- Application Guide For Water TreatmentDocument5 pagesApplication Guide For Water TreatmentNovara RahmatNo ratings yet

- Brochure Antifoams Defoamers Tego AntifoamDocument8 pagesBrochure Antifoams Defoamers Tego AntifoamJuan CubasNo ratings yet

- Mowilith LDM 2416Document2 pagesMowilith LDM 2416dtecnicoNo ratings yet

- Sag 622 Marketing BulletinDocument4 pagesSag 622 Marketing BulletinThree AuNo ratings yet

- TEGO® Foamex 810: Description Technical DataDocument1 pageTEGO® Foamex 810: Description Technical Datahai nguyenNo ratings yet

- Vitec-5100 3 PDFDocument1 pageVitec-5100 3 PDFdalton2004No ratings yet

- TEGO® Foamex 810: Description Technical DataDocument1 pageTEGO® Foamex 810: Description Technical DataEko SupriantoNo ratings yet

- UCON Fluids and Lubricants: Regulation (21 CFR) Permitted UseDocument3 pagesUCON Fluids and Lubricants: Regulation (21 CFR) Permitted UsemnasiroleslamiNo ratings yet

- FSwwNovusCE7081 ENDocument2 pagesFSwwNovusCE7081 ENamir.mohdNo ratings yet

- AFE CAV A: Product BulletinDocument2 pagesAFE CAV A: Product BulletinyfcozNo ratings yet

- DC 7-9245 EmulsionDocument2 pagesDC 7-9245 EmulsionElenaNo ratings yet

- TEGO® Airex 901 W: Description Technical DataDocument1 pageTEGO® Airex 901 W: Description Technical Datahai nguyen100% (1)

- Veraflux-PDS-2022-2 (Phosphorous-Free)Document1 pageVeraflux-PDS-2022-2 (Phosphorous-Free)Quốc Anh KhổngNo ratings yet

- 90259859 (2)Document2 pages90259859 (2)Phan-128282No ratings yet

- Afe 1430Document2 pagesAfe 1430Gabriela ZubietaNo ratings yet

- Biosolve Spill RX: Technical Data SheetDocument2 pagesBiosolve Spill RX: Technical Data SheetJackNo ratings yet

- Antifoam Solutions Brochure Indd PDFDocument12 pagesAntifoam Solutions Brochure Indd PDFRomán M Martín del CNo ratings yet

- TEGO® Airex 902 W: Description Technical DataDocument1 pageTEGO® Airex 902 W: Description Technical Datahai nguyenNo ratings yet

- Personal Care: Dow CorningDocument4 pagesPersonal Care: Dow CorningMay Wulan DewiNo ratings yet

- XIAMETER™ PMX-200 Silicone Fluid, 1000 CST, Food Grade-TDSDocument4 pagesXIAMETER™ PMX-200 Silicone Fluid, 1000 CST, Food Grade-TDSLaban KantorNo ratings yet

- TDS DC 56 PDFDocument2 pagesTDS DC 56 PDFmanox007No ratings yet

- Tinuvin 152 October 2019 R4 ICDocument3 pagesTinuvin 152 October 2019 R4 ICEmilio HipolaNo ratings yet

- TEGO® Foamex 855: Description Technical DataDocument1 pageTEGO® Foamex 855: Description Technical Datahai nguyenNo ratings yet

- TEGO® Foamex 823: Description Technical DataDocument1 pageTEGO® Foamex 823: Description Technical Datahai nguyenNo ratings yet

- Ultrasil75 CatalogSheet PDFDocument1 pageUltrasil75 CatalogSheet PDFChalut YvesNo ratings yet

- Foamex 3062Document1 pageFoamex 3062Rashid SaleemNo ratings yet

- PaintDocument4 pagesPaintpavanirajesh193No ratings yet

- TDS - Superfloc C-577 - ENDocument2 pagesTDS - Superfloc C-577 - ENArmando NavarreteNo ratings yet

- Desmotherm 2170: Characterization Form SuppliedDocument4 pagesDesmotherm 2170: Characterization Form SuppliedHardik Me1htaNo ratings yet

- Foam Measurement and Control With LasersDocument4 pagesFoam Measurement and Control With LasersGabriela CastroNo ratings yet

- Bayhydrol UV 26891 - en - 79962983 12942311 14257784Document3 pagesBayhydrol UV 26891 - en - 79962983 12942311 14257784zaryab khanNo ratings yet

- TDS 940 Carbopol SC 200Document2 pagesTDS 940 Carbopol SC 200thomas cook0% (1)

- Kleen MCT515 - PFS-SuezDocument2 pagesKleen MCT515 - PFS-SuezMuhammad SukroniNo ratings yet

- Hoja de Datos Roclean l8118 pdf1Document1 pageHoja de Datos Roclean l8118 pdf1Cesar Martin Can BriceñoNo ratings yet

- Healthcare: Dow Corning Q7-2587, 30% Simethicone Emulsion USPDocument2 pagesHealthcare: Dow Corning Q7-2587, 30% Simethicone Emulsion USPSari RofiqohNo ratings yet

- Bayhydur XP 2655 - en - 06756239 17854696 21037056Document4 pagesBayhydur XP 2655 - en - 06756239 17854696 21037056trường phạmNo ratings yet

- TDS Ucecoat 7699Document2 pagesTDS Ucecoat 7699sharemanx835No ratings yet

- Surfynol® 440 Surfactant: Description Shelf LifeDocument2 pagesSurfynol® 440 Surfactant: Description Shelf LifeWangYunNo ratings yet

- Defoam Extreme: Specialized Brine-Based System DefoamerDocument1 pageDefoam Extreme: Specialized Brine-Based System Defoamersmithyry2014No ratings yet

- Antiespumante Dow CorningDocument2 pagesAntiespumante Dow CorningJuan Carlos Vazquez RosasNo ratings yet

- XIAMETER™ AFE 0200 Antifoam Emulsion: Features & Benefits Composition ApplicationsDocument3 pagesXIAMETER™ AFE 0200 Antifoam Emulsion: Features & Benefits Composition ApplicationsZhan FangNo ratings yet

- Tinolux BMC Liquid TI enDocument4 pagesTinolux BMC Liquid TI enAbhijit PatilNo ratings yet

- Silcolapse 426R: DescriptionDocument2 pagesSilcolapse 426R: DescriptionherryNo ratings yet

- Rheovis PU 1215: Formulation AdditivesDocument3 pagesRheovis PU 1215: Formulation AdditivesAyhan CansuNo ratings yet

- Vacuum Coater EnglishDocument8 pagesVacuum Coater EnglishWilki SantanderNo ratings yet

- Data Sheet Dowcorning 111Document2 pagesData Sheet Dowcorning 111Nyoman RakaNo ratings yet

- Meggle Brochure Cellactose 20140327 en OfficeDocument8 pagesMeggle Brochure Cellactose 20140327 en OfficeErand MatiNo ratings yet

- AFE URF: Product BulletinDocument2 pagesAFE URF: Product BulletinyfcozNo ratings yet

- Deurheo 2810Document1 pageDeurheo 2810omerNo ratings yet

- Mitm11590 1Document1 pageMitm11590 1fredymademydayNo ratings yet

- Basoflux Paraffin Control For The Oil IndustryDocument6 pagesBasoflux Paraffin Control For The Oil Industryyugatha100% (1)

- Dowcorning Emulsifiers PDFDocument7 pagesDowcorning Emulsifiers PDFAbdul WasayNo ratings yet

- US UK Avista PDS Vitec 3000 FinalDocument1 pageUS UK Avista PDS Vitec 3000 FinalEmin MešićNo ratings yet

- p190035 en Versalink-Brochure NR RZ WebDocument4 pagesp190035 en Versalink-Brochure NR RZ Webyilong luoNo ratings yet

- Drilling and Completion Chemical SolutionsDocument5 pagesDrilling and Completion Chemical SolutionsSpotamya Öte AlemNo ratings yet

- Renolin Hi Temp Chain LubeDocument2 pagesRenolin Hi Temp Chain Lubempe.mohamed2010No ratings yet

- RedicoteEM 44ADocument1 pageRedicoteEM 44ARicardoNo ratings yet

- Settleability Problems and Loss of Solids in the Activated Sludge ProcessFrom EverandSettleability Problems and Loss of Solids in the Activated Sludge ProcessNo ratings yet

- Test Bank For Law and Ethics For Pharmacy Technicians 3rd Edition Jahangir MoiniDocument23 pagesTest Bank For Law and Ethics For Pharmacy Technicians 3rd Edition Jahangir Moinifrankmooreepmgoaqjkb100% (22)

- NeurontinDocument2 pagesNeurontinCortex PlussNo ratings yet

- 4 Drugs Used in GastrointestinalDocument13 pages4 Drugs Used in Gastrointestinalrajkumar871992No ratings yet

- TN Lethal Injection Protocol Investigation Report and Findings 12-13-22Document178 pagesTN Lethal Injection Protocol Investigation Report and Findings 12-13-22Gabe HauariNo ratings yet

- A Review Article On Pharmaceutical Analysis of Pharmaceutical Industry According To Pharmacopoeias - Oriental Journal of ChemistryDocument8 pagesA Review Article On Pharmaceutical Analysis of Pharmaceutical Industry According To Pharmacopoeias - Oriental Journal of ChemistryArsalanNo ratings yet

- Baker Mckenzie Telemedicine and Telehealth Legal FDocument14 pagesBaker Mckenzie Telemedicine and Telehealth Legal FVaczine SuthineeNo ratings yet

- Paracetamol 2Document6 pagesParacetamol 2akmalnaimkhairullahNo ratings yet

- General and Local AnesthesiaDocument1 pageGeneral and Local Anesthesiaahmedhelper300No ratings yet

- Apotek RS KASIH INSANI SUKATANI Laporan Penggunaan FEBRUARI 2022Document7 pagesApotek RS KASIH INSANI SUKATANI Laporan Penggunaan FEBRUARI 2022Rara LaveniaNo ratings yet

- Formulation and Evaluation of Calcium Effervescent TabletsDocument6 pagesFormulation and Evaluation of Calcium Effervescent TabletsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Drugs With Different Salt Forms: Pharmacist'S Letter / Prescriber'S LetterDocument4 pagesDrugs With Different Salt Forms: Pharmacist'S Letter / Prescriber'S LetterAnonymous VPNvLEup100% (1)

- Genentech - Capacity Planning: A Case Study OnDocument7 pagesGenentech - Capacity Planning: A Case Study OnDebaloy DeyNo ratings yet

- An Approach For Decontamination of B-Lactam Antibiotic Residues or PDFDocument4 pagesAn Approach For Decontamination of B-Lactam Antibiotic Residues or PDFdcharlies100% (1)

- Homeopathic Writing Prescription: Prateeksha Naryani B.H.M.S. 1 Year ROLL NO. 2108557581045Document9 pagesHomeopathic Writing Prescription: Prateeksha Naryani B.H.M.S. 1 Year ROLL NO. 2108557581045Wfewye DfjhersfjeNo ratings yet

- Use Pharmaceutical Calculation Techniques and TerminologiesDocument62 pagesUse Pharmaceutical Calculation Techniques and TerminologiesKena Samuel100% (3)

- Kimia Farma stock mutation reportDocument14 pagesKimia Farma stock mutation reportApotek VictoryNo ratings yet

- Primol 382 Primol 382 Primol 382 Primol 382Document3 pagesPrimol 382 Primol 382 Primol 382 Primol 382Luis OteroNo ratings yet

- Pt. Bina Mitra Jaya Bersama Daftar DealDocument14 pagesPt. Bina Mitra Jaya Bersama Daftar DealEta AmaliaNo ratings yet

- API and Intermediates of GujratDocument16 pagesAPI and Intermediates of GujratSamyak JainNo ratings yet

- Which of The Following Is Not A Characteristic of Universal PrecautionsDocument8 pagesWhich of The Following Is Not A Characteristic of Universal PrecautionsAndrei Miguel RoqueNo ratings yet

- PMLS MidtermsDocument3 pagesPMLS MidtermslhalaineiluisNo ratings yet

- Tema 2-19-20Document81 pagesTema 2-19-20Benjamín Bohigues100% (2)

- Surviving When Modern Medicine Fails A Definitive Guide To Essential Oils That Could Save Your Life During A Crisis (Johnson, Dr. Scott A.) (Z-Library)Document239 pagesSurviving When Modern Medicine Fails A Definitive Guide To Essential Oils That Could Save Your Life During A Crisis (Johnson, Dr. Scott A.) (Z-Library)amitlkoyogaNo ratings yet

- Halewood Company BrochureDocument8 pagesHalewood Company BrochurePrasoon SimsonNo ratings yet

- Pharmacology Book by N MurgeshDocument150 pagesPharmacology Book by N Murgeshabhishek08102002No ratings yet

- Feb Recalls 3Document3 pagesFeb Recalls 3reethu mammenNo ratings yet

- The Family That Built An Empire of Pain - The New Yorker PDFDocument23 pagesThe Family That Built An Empire of Pain - The New Yorker PDFryan100% (2)

- Top Drugs History, Pharmacology, Synthese (2015)Document219 pagesTop Drugs History, Pharmacology, Synthese (2015)L EPNo ratings yet

- Assessment Report Mentha X Piperita L Folium Aetheroleum Revision 1 - enDocument101 pagesAssessment Report Mentha X Piperita L Folium Aetheroleum Revision 1 - enANAHI AUQUI AROTOMANo ratings yet

- Determination of Preservative Parabens in Oral and Injection Formulations by HPLCDocument7 pagesDetermination of Preservative Parabens in Oral and Injection Formulations by HPLCLaras Dwi AyuningrumNo ratings yet