Professional Documents

Culture Documents

Nai

Nai

Uploaded by

Abir HossainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nai

Nai

Uploaded by

Abir HossainCopyright:

Available Formats

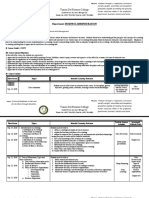

Name: Abir Hossain

Id: 1811687030

2. It was clear from the start that outside help would be required until Aisin was able to reclaim its

former skills. At the time, it was decided to ask enterprises both within and outside the Toyota group to

set up additional P-valve production facilities as soon as possible. Because new machines, drills, fixtures,

and gauges had to be procured to replace those lost in the fire, some 150 additional companies were

involved in the recovery work, including seventy machine-tool manufacturers.

The suppliers' cooperation was critical to the recovery effort's success; undoubtedly, many hoped to

increase sales to Toyota in the future. Toyota decided not to put pressure on Aisin to prioritize its own

models over those of Aisin's other customers. Manufacturing was entrusted to the division in charge of

experimental prototype production and machinery maintenance in Honsha, whose engineers and

operators had significant expertise setting up machines for new models and planning the transfer to

volume production. Toyota's production control department was tasked with managing in-house P-valve

production and providing direct support to Aisin.

There are so Many outside commentators at the time thought the Aisin event demonstrated the

vulnerability of JIT environments, claiming that any unplanned failure would bring the system down

immediately. Regardless, none of the companies we spoke with, including Toyota, were planning to quit

JIT. With approximately 30,000 elements in each car, maintaining security buffers for each component is

simply too expensive; in reality, any production system is vulnerable to unanticipated catastrophes like

as a plant fire. While the incident highlights the dangers of single-sourcing in a JIT environment, the

chances of it occurring again are slim.

Furthermore, large-scale coordinated reactions like the ones detailed here are uncommon, with the

exception of natural disasters or fires. Strikes provide unique challenges because the establishment of

alternate sites at other enterprises would be considered as interference by trade unions and would be

largely unwelcome. Despite its inherent fragility, companies value JIT for its role in building problem-

solving and continuous improvement capabilities. The Aisin incident shows that these networks are

capable of not only self-organizing, flexible crisis responses, but also ordinary issue resolution that leads

to incremental improvements in business and group performance. Although crises cannot be predicted,

the qualities needed to deal with them successfully and quickly can be built ahead of time.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Foundations of Operations Management - WK3 - Process Selection and InfluencesDocument3 pagesFoundations of Operations Management - WK3 - Process Selection and InfluencesSushobhanNo ratings yet

- Scap Assignment 2: Submitted To: Submitted byDocument12 pagesScap Assignment 2: Submitted To: Submitted bySurmayee UmatheNo ratings yet

- Trade and Technology - Gaurav SharmaDocument5 pagesTrade and Technology - Gaurav SharmaGauravNo ratings yet

- The Potentials and Challenges of Blockchain Application in FinTech in The Developing Countries - A Mauritius ExperienceDocument7 pagesThe Potentials and Challenges of Blockchain Application in FinTech in The Developing Countries - A Mauritius ExperienceThe IjbmtNo ratings yet

- Business Idea - Brainstorming TemplateDocument4 pagesBusiness Idea - Brainstorming Templatemanish20150114310No ratings yet

- Merger and AcquisitionDocument3 pagesMerger and AcquisitionRojila luitelNo ratings yet

- Ways and Means of Promoting Ethical Behavior Within The Organization in Relation To The Outside WorldDocument2 pagesWays and Means of Promoting Ethical Behavior Within The Organization in Relation To The Outside WorldArkei FortalezaNo ratings yet

- Management of Small Business and Enterpreneurship Development SYLLABEDocument9 pagesManagement of Small Business and Enterpreneurship Development SYLLABEpravin gosaviNo ratings yet

- Fintech in MENAP A Solid Foundation For GrowthDocument11 pagesFintech in MENAP A Solid Foundation For GrowthNeoNo ratings yet

- Canlas Syllabus-OBE-Format-BUSINESS-ADMINISTRATIONDocument8 pagesCanlas Syllabus-OBE-Format-BUSINESS-ADMINISTRATIONVanessa L. VinluanNo ratings yet

- CH 10Document87 pagesCH 10Chang Chan ChongNo ratings yet

- Module 6Document7 pagesModule 6Pat QuiaoitNo ratings yet

- A Full HouseDocument1 pageA Full HouseНадія МельникNo ratings yet

- IIBF Publication ListDocument17 pagesIIBF Publication ListSumit KambleNo ratings yet

- Financial Loan Application Form: Organization Name DNT PowerDocument5 pagesFinancial Loan Application Form: Organization Name DNT PowersanjayNo ratings yet

- HELE 5 Identifying Opportunities ForDocument13 pagesHELE 5 Identifying Opportunities Forn77t6tjytujNo ratings yet

- Chapter 3-Theory-ProductionDocument25 pagesChapter 3-Theory-ProductionKumar SiddharthNo ratings yet

- Bannari Amman Sugars LimitedDocument74 pagesBannari Amman Sugars LimitedSanthoshkumar ThangavelNo ratings yet

- Project Sample ReportDocument41 pagesProject Sample ReportSholeh SholehNo ratings yet

- Autotext - BackupDocument85 pagesAutotext - Backuppravita4658No ratings yet

- Economics Analysis For Business 2marksDocument7 pagesEconomics Analysis For Business 2marksNirmala PoorajaNo ratings yet

- Starbucks Segmentation, Targeting, and Positioning - PDF AgileDocument12 pagesStarbucks Segmentation, Targeting, and Positioning - PDF AgileMehdi BekriNo ratings yet

- Nipa Palm Fruit CandyDocument39 pagesNipa Palm Fruit CandyPrime RietaNo ratings yet

- Report On Company ValuationDocument37 pagesReport On Company ValuationFarzana Fariha LimaNo ratings yet

- Enager Industries, Inc.: The Crimson Press Curriculum Center The Crimson Group, IncDocument5 pagesEnager Industries, Inc.: The Crimson Press Curriculum Center The Crimson Group, IncVakul AgarwalNo ratings yet

- Coca-Cola and Pepsi Economic Analysis ReportDocument39 pagesCoca-Cola and Pepsi Economic Analysis ReportJing Xiong67% (3)

- Timesheet - 01 - 09 - 2021 To 05 - 09 - 2021Document1 pageTimesheet - 01 - 09 - 2021 To 05 - 09 - 2021dileep dudiNo ratings yet

- EntrepreureshipDocument27 pagesEntrepreureshipAyesha SiddikaNo ratings yet

- Identify The Industry Case Solution and Analysis, HBR Case Study Solution & Analysis of Harvard Case StudiesDocument2 pagesIdentify The Industry Case Solution and Analysis, HBR Case Study Solution & Analysis of Harvard Case StudiesCanvas KathaNo ratings yet

- Lecture 5 - Ss Q1 Q2 Q3Document4 pagesLecture 5 - Ss Q1 Q2 Q3Esther FanNo ratings yet