Professional Documents

Culture Documents

Growth and Development of Agate Industry in Gujarat - A Case Study of Khambhat

Uploaded by

Priyal GoyalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Growth and Development of Agate Industry in Gujarat - A Case Study of Khambhat

Uploaded by

Priyal GoyalCopyright:

Available Formats

ISSN No: 2455-734X (E-Journal)

An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and Commerce

The Churning

Uma Arts & Nathiba Commerce Mahila

College, Gandhinagar, Gujarat, India

Growth and Development of Agate Industry in Gujarat –

A Case Study of Khambhat

Mahesh Patel

Department of Geography, Gujarat University

Email: mkpatel0077@gmail.com

Supervisor

Dr. J. G. Rangiya

Uma Arts & Nathiba Commerce College, Gandhinagar

Email: jaymalsavlas@gmail.com

ABSTRACT

The paper looks at the growth and development of agate industry in the Khambhat area of Gujarat,

India. The data collected for the understanding had use mix methodology which is explained in the

paper below. The paper tries to understand the current situat ion of the agate industry in context of

history, economics, environment and associated workers. The paper also explains the basic of agate and

the manufacturing process that is used in the agate industry. The paper provides an insight to the

current scenario of the agate industry in Khambhat area of Gujarat.

Keywords : Growth, Development, Agate, Industry, Khambhat

INTRODUCTION

Agates are basically hard semi-precious stones which are a different physical form of Chalcedony 1, a kind

of silicon dioxide in the form of microscopic fibrous quartz crystals. It is used as a gemstone in ornaments

and found all over the world in places including India, Asia, USA, Africa, Brazil, Germany, Mexico, Italy

and Nepal. It is found in a variety of colours and gets formed in the cavity of host rocks. This leads to the

concentric band kind of formation and appearance of these rocks (Changrani, 2016).

Agate is considered to be unique and different from other gemstones. Worldwide, agate is considered to

have metaphysical properties. It is believed that it can enhance the quality of life or even prevent and cure

psychological and mental disorders. People also believe that it can balance energies in the human body.

Due to this, agates have been extensively mined, shaped, ground and polished multiple times into beads of

all shapes and sizes. Agate’s value was quite high in antiquity, when it was used as one of the main

1

It is a fibrous microcrystalline type of silica which contains miniscule crystals of quartz. It is the family name which has many

different gemstone varieties in it.

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 13 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

gemstones. Now its value is fairly low because of global competition around the world. Some 3000-3500

years ago the ancient, Egyptians sought colourful agates and other Chalcedonies from the Aghates River

now called the Drillo River in Sicily. Consequently, many artefacts, jewellery, jewels were found in the

tombs of Kings and Queens of ancient Egypt. (Agate, 2007) Agate rates a 6.5 to 7 on the hardness scale. The

typical or more common colour of agate is a blue whitish grey. The most highly prized forms of agate are

Cornelian, Chrysoprase, Jasper, and Sard. Carnelian is yellow-orange to orange red and translucent.

Chryoscolla is an intense light blue or blue green. Chrysoprase is translucent, light to medium yellowish

green, and was once considered to be prized form of Jade bloodstone is another version of agate, opaque

and dark green with spots of dark red. Jasper can show various landscape -like patterns with the stone.

India’s gems & jewellery sector is second highest contributor to the Indian commodity exports with a share

of 13 %. The total exports of Gems and Jewellery for India in for year 2014 -15 was around $40 Billion out

of which coloured Gemstones (Agate) was $0.45 Billion. (Gujarat, 2017) However, it is to be noted that

India has been the primary exporter of agate products world over and continues to dominate the same till

date (PT, 2013).

Agate in India and the World

Agate got its name from Greek philosopher and naturalist, Theophrastus. He named it so as he discovered

it in between 3rd and 4th century, on the banks of the river Agates, which is in the city of Sicily, currently.

The stone is being used from ancient times for hard stone carving. It has been recovered at many ancient

sites including Knossos site in Crete, indicating its usage in Bronze Age. (Agate, 2007)

Currently, agate mines are prevalent all around the world. The important mines are in USA, Russia,

Canada and Europe, apart from India. In the recent times, the industry has grown in strength in the South

Dakota area of USA. It is called Fairbanks agate and is procured in the black hills. The stone has sharp

bands that run parallel to each other. Deposits of agate are scattered across Arizona and Idaho as well. In

San Luis Potosi and Aguascalientes states of Mexico, fire and multi-coloured agates are found. The apache

agate, with floating red colour is a famous clear agate in this area. Laguna and Coyamito agates are banded

agates which are less sharper found in proximity to Mexico. Agua Nueva, in the Mexican ranch is known

for its vein agate.

In Oka River, 100 Km south of Moscow, one can find agate in limestone. In Nahe river valley in Germany,

there have been traces of agate from 1497. The cutting centre here was ca lled Idar-Oberstein. On

discovery of rich agate deposits in Brazil in the 19 th century, the cutters moved there after exhaustion of

deposits in Idar-Oberstein. The second varieties of vein agates are found in Thunder Bay in Canada. Fire

agates, quartz crystals and opal eggs are found in Opal mines in California.

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 14 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

Agate Creek in far North Queensland is the recognized Australian hotspot for appealingly designed agates

that happen in and are weathered from amygdaloidal basalt of Carboniferous age. Agate Cree k agates are

famous both for the excellence and assorted variety of their alluring shading designs. It is a pity that agate

from Agate Creek in North Queensland is minimal known outside of Australia, for this agate shows about

each possible shading and example that is conceivable to see in agate.

In India, many varieties of agate are found such as the Jasper, bloodstone, chocolate stone, maimariam ,

azure, jet and Pijora varieties. These are found in parts of Bombay, Chennai and in the state of Orissa.

However, it is found predominantly in Khambhat, in the western part of Gujarat. There are four types of

agate found in this region. The first is the common agate which is of two types. The white, hal f clear stone

is called Dola, and the cloudy, streaked one is called Jamo. The second is the moss type agate, which is

from Tankara near Morvi known as Suabhaji and Phatak . The third variety is that of Kapadvanj , which is

from the river bed of Majam known as Kaiyu, Agiyu and Ratadiyu . The most valued of them all is the

veined variety of agate, called as the Doradar. India’s export for last ten years (See Table 1) has been

extremely profitable to the economy. It has made huge amount of contribution to the ec onomy in the year

2012-13 during the export of coloured gem stones.

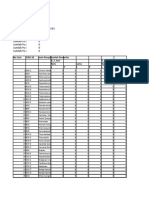

Table 1 India's Gross Exports (In Million $) of Coloured Gemstones for last ten years (Source: GJEPC)

ITEMS 2007- 2008-09 2009-10 2010-11 2011- 2012- 2013- 2014- 2015- 2016-

08 2012 2013 2014 2015 2016 2017

Coloured 295 282 306 349 420 729 647 453 433 420

Gem

Stones

The predominant occupation of people here has been manufacturing and trading of the agate stones. There

are many small industrial units in this region, which employ thousands of people and whole communities

in cutting, drying, grinding and polishing of agates (PT, 2013). These communities were traditionally

called Siddis and they had to take a lease to mine in this area from the government of India. Siddis were

originally from Africa and were one of the first communities to start mining in the Rajpipla mines. Gori Pir

was the name of the person who set up the first bead making workshop here and expand his business to

other cities. Currently few of the descendants of Gori Pir or the Sidis are involved in agate trade (Possehl,

1981).

Agate and Khambhat

In Khambhat, stone bead-making is a cottage and household industrial activity, carried out in the house

premises. They would fall under small scale industries, a self-sufficient and self-employed family unit. In

these premises rough agate stones are transformed into various other products that are beautiful and

smooth. But the fact is these industry is an oligopoly where only few individuals who own and other the

business from various households (Intercultural Resources, George PT, 2013). A large majority of the

small-scale units in the industry are not licensed and operate outside the industrial labour laws and

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 15 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

regulations. The lack of government involvement supervision of the working conditions of the units and

unavailability of proper protective gears and mechanized tools expose agate workers to a variety of

problems (Intercultural Resources, George PT, 2013). Due to this most of the workers employed in the

industry do not have the benefits of organized industries.

Figure-I

One of the abundant rocks found in this area, which is also a result of the immense siltation in the gulf

from immense catchment area such as the Narmada (Possehl, 1981). The author describes that the families

work in extracting these rocks from the ground. Men would get into small holes dug to reach the rocks,

which they brought out with their crude equipment’s, which were then carried to storage spaces by

women. They were then sorted again in the mines itself. These communities are called Siddhis and they

had to take a lease to mine in this area from the Government of India.

Though few Siddhis are still involved in agate trade, many have adapted to the changing conditions and

adapted new lifestyles, also because of the hazards related to the industry (Possehl, 1981). Before discussing

them, it is important to understand the process of manufacturing and the end products of the agate

industry.

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 16 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

Basic of Agate

Agates are formed in the holes in host rocks, which are filled up layer after layer. The arrangements,

colours and patterns vary according to conditions such as pressure, temperature and min eral contents. The

secondary deposits in the hollow cavities of igneous rocks often get transformed into agate over years.

These empty cavities are filled with fluids which are often rich in suspended quartz and mineral impurities.

When the concentration of the same gets super saturated and a gelatine like consistency is arrived at,

miniature fibrous microcrystals are formed. Following this, contrasting bands are formed with repetitive

patterns which are the agate rocks.

There are many types of agates. The common ones are:

Fortification agate – one of the most common kinds of agate, which has bands crystallized in a

concentric manner following the shape of the cavity.

Water line agate – It is formed after the extra water in the silica settling layer by laye r drains out. The

orientation is controlled by gravity.

Shadow Agate – It is an agate which has alternating translucent and opaque bans.

Tube Agate – sometimes, tube like projections form in the silica gel, which weather away or leave

hollow tubes that fill in with silica.

Eye Agates – In some cases, the silica gel predominantly drains leaving only a droplet that beads up in

the cavity, from which crystal growth further continues.

Plume agate – these are filamentous growth that resemble feathers

Geode agate – An agate with a hollow center and a crystalline outer fill.

Moss Agate – it is a cluster of mineral inclusions which resemble landscape.

Seam Agate – these form in cracks in host rock in parallel rows

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 17 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

METHODOLOGY

Figure II Methodology's Work Flow

Research utilzied primary & 7th session was utilized for

secondary data. Primary data 6th session was utilized for

conducting primary survey

collection was done through creating final questionnaire

after creating final

mix methodology route. And for primary data collection

questionnaire for the

secondary data was utilized after including secondary

workers & traders of agate

from books, articles, journals, literature and studies.

industry.

etc.

Qualitative, Quantitative,

And finally after collecting

Interview and Cartographic 5th session was utilized for

data from workers & traders

tools were utilized for conducting pilot survey on

the infromation was

primary survey. And books, 15 workers and 5 traders at

analyzed for understanding

journals, reports, articles, etc. random from agate industry

the problems & prospects of

for secondary data & of the study area.

agate industry.

information.

For collecting primary data

from workers & traders a 4th session was with regards

structured questionnaire & to how the questionnaire will

semi structured interview be conducted for the pilot

was used and it took 6 survey/test and later for final

Sessions including site visits primary survey.

for final primary survey.

Session 1 & 2 were used for 3rd session involved informal

visiting the site area for interview and conversations

general understanding of the with the people living in the

current situation of the region to understand agate

region. industry scenario.

Figure III Process of Collection of Information from Workers

Primary Survey of 10% of total

Workers (Structured Two Parameters 1) population was Random Sampling

Questionnaire & Type of Work 2) considered as was applied at time

Semi-Structured Location of Work sample size so total of the survey.

Interview) sample size 298.

Figure IV Process of Collection of Information from Traders

Primary Survey of One Parameter:

Traders (Structured Influence of the Random Sampling

Questionnaire & trader at Local, Total Sample Size 20 was applied at time

Semi-Structured State, National and of the survey.

Interview) International Scale.

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 18 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

RESULT AND DISCUSSION

1. Agate Making Process

The manufacturing process of agate includes steps such as sun drying, breaking lar ger stones into small

sizes, slicing of the stones, rounding in a ball mill, shaping on grinding wheels, polishing, drilling holes,

and assembling the final product. All of the mentioned steps are carried out by different sets of workers as

for example, fodia (chipper) or ghasiya (polisher) etc.

Primary size reduction job is done by chippers. A pointy iron rod is implanted in the ground at a certain

angle. A stone is than held against the rod by hand and is struck with a hammer made of animal horn

example cow’s horn, so that the stone is chipped into small pieces. The chipper must break the stone while

keeping in mind the final product which is to be created hence this job requires skills for work.

Rounding and process of reduction of the size is sometimes done in a drum made of wooden planks – a sort

of a barrel of ball mill, powered through an electric motor. The process is very dusty and noisy. Many

people especially the men of the working class who employees other workers, but many also work

alongside the workers to build walls around the mill to prevent silica dust from spreading everywhere in

the work environment. The walls also help to reduce the noise pollution created by the ball mill machine.

Polishing or Grinding is done by polishers or grinders. These people are the most vulnerable to exposure of

silica dust. Polishing is done in various ways depending on the final product. For creation of certain

products, a horizontal wooden bench with a vertical moving emery wheel powered by an electric motor is

commonly used. Polishing done by hand is done dry, though many workers have started to adapt wet

methods for polishing the stone. For shaping spherical beads, polishers use a rectangular wooden plank of

about 6-8 inches wide and 2 – 3 feet long. Several rounded grooves are etched into one end of the plank to

hold the stones in place, and matching set of grooves is chipped into the emery wheel. Rough agate stones

are arranged on the etchings and pressed against those grooved emery wheel. Lubricants are ut ilized at the

time of revolving process for the purpose of shaping the surface of the stone.

Giving the smooth lustful polish requires various methods for the process. The most popular of them all is

to tumble the stones in metal drums with water, aluminium oxide and emery dust. When required the

stone slicing is done by a specialized machine. Small and medium size machines are now available for

slicing of the agate stones. Stone slicing is done in an enclosed machine using kerosene as a coolant. In

other places it is done through dry process the process is noisy and dusty.

Drilling used to be done manually, creating ergonomic problems at time of creation of the final products.

Electric drilling machines are instead utilized for the purpose thereby reducin g the error in the process and

the assembly of the whole product is still done manually till date.

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 19 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

Agates are chipped into barrel shapes, long faceted beads and rectangular shape which are common (Patel

& Robbins, 2011).They are first chipped for a rough shape, then for a finer shape. They are then

smoothened and polished for primary finish. Following this, they are drilled to create holes in the centre

and sent for the final polishing. After this, the beads are again so rted for quality (Possehl, 1981).

It is to be noted that the process has been redundant without much of technological intervention except

the electric grinders. This dry grinding process releases fine dust which accumulates little by little in the

lungs of the workers, leading to the fatal disease of silicosis.

2. Growth and Development of Agate Industry

The pure handicraft and art-based industry expanded and mechanized after the induction of electricity in

the manufacturing process. Grinding the agate stones at high speed produces a large amount of dust. The

particles are 2-5 microns in size and settle in layers in the alveoli. An exposure of 5-10 years to this dust

has proven to be fatal. When continuously exposed to silica dust, the lungs gradually over the course of

time gets filled with the dust particles. Whole families have been wiped out due to this disease. In the

month of September, 2014 two people became victim of the deadly occupational disease of sili cosis, in the

Khambhat region. The number of deaths because of silicosis in the state of Gujarat reached to 19 people,

this is the highest ever in a single year.

There is also a severe social stigma associated to these workers as nobody wishes to marry t hem or their

children due to their short lifespan. Though silicosis is a compensable disease in India’s workmen’s

compensation act, agate workers never claim the same. This is more since they are declared as self -

employed and lack rights to claim compensation. The others do not have the awareness for the same. The

cost to file the claim, and the duration of the process prove to be very expensive for the workers. Doctors

hardly diagnose the same and even the workers do not care as it makes no difference to t heir lives. They

work till they die (Patel & Robbins, 2011).

Back in the 1980s itself, extensive research was done on silicosis among agate workers in Khambhat by

Industrial Toxicology Research Centre (ITRC), Lucknow. It proved that 63% of the workers suffered from

lung diseases. A public interest petition was filed in Gujarat High Court. The High Court set up an inquiry

commission. The National Institute of Occupational Health (NIOH), as a part of inquiry commission,

carried out a survey. They installed exhaust system to measure the dust level. NIOH submitted report to

the High Court but no action was taken. NIOH carried out an environmental epidemiological study during

1999-2004. It also studied the Silica dust in the environment and recommended the exhaust system with

better design. The study has conclusively shown that it is the serious major environmental problem. As the

workers are directly exposed to deadly Silica dust. Not only workers, but their family members including

children are also affected (PUCL Gujarat, 2007). Regular exposure to even 25-27 micrograms per cubic

centimetre of air can have devastating consequences on the workers’ health. Even non -workers who are

exposed to this dust are equally vulnerable to silicosis (Intercultural Resources, George PT, 2013). Another

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 20 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

study in 2007, 123 subjects were studied out of which 70% were reported to have silicosis. The study

showed an alarming fact that with every year of exposure, the probability of getting silicosis increased by

12%. Only the workers are not exposed to this, but their children, neighbours and whole villages are

affected by the dust (Patel & Robbins, 2011).

Usually, it takes some years for the symptoms of silicosis to show up. Lack of early detection, unavailability

of the treatment with added layer of malnutrition proves fatal for the workers. Most of the victims of

silicosis come to know about it only in the later stages. During the process because of lack of strength they

continuously fall ill with severe cough, fever and many other symptoms. Unable to do any physical labour,

they stay at home, chained to perennial poverty and illness, always weak, struggle to breath e. And the trap

continuous to take life out of them and they die a premature death (Intercultural Resources, George PT,

2013).

On the issue of silicosis in the Khambhat region, for a long time, in the absence of proper diagno sis, many

cases of silicosis have been recorded as cases of tuberculosis, making the morbidity figures very inaccurate

right at the outset (PUCL Gujarat, 2007). Several silicosis patients have also died either without proper

diagnosis or with treatment only for tuberculosis. Different reports show different figures. Some reports

show the total number of people affected by silicosis in Khambhat to be around 50,000, while some others

show a figure of 30,000. Government officials give a totally different picture, denying these figures and

reducing the number to around 5000. Thus, it’s a difficult task to give an accurate figure of people affected

by silicosis (Intercultural Resources, George PT, 2013).

The government of Gujarat has not acted proactively in this issue. Though the central government’s

factories act deems the exposure to more than 5% of silica as hazardous, this has not been implemented by

the state government. Rather, amendments to the state act have been carried out which have reduced the

permissible workers per factory. The government has not focused on improving the condition of work

places, providing exhausts, lowering the incidence of occupational diseases or installation of new adva nced

equipment in these factories. They have been declared as cottage industries which do not fall under the

factories act as well. In Khambhat area in 2009, 21 gemstone workers died of silicosis (The National

Labour Committee, 2010).

This is seen by many researches as a major threat to the industry as the workforce is reducing day by day

due to the health issues and new workmen are difficult to find given the hazardous exposure of the

industry. The disease can be preventable by very simple measures with occupational safeguards, which

would serve as an advantage to the growth of the industry on the whole.

3. Current Workers Scenario in the Industry

In order to understand the caste, religion and other demographic profiles of the region, various forms of

data were collected at the time of the survey.

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 21 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

The total population of family members on average was 4.97 per family. The maximum number of family

identified was 15 members in a family. The lowest is one. The mean of educated members is 2.96. Per

family the average children recorded is 2.35. The maximum children recorded in a family are 10. Among

the children how many children went to the school on average is 1.88. Out of average family of 4.97, the

members working in the family is 2.18 and out which only 1.60 members work in agate industry.

57.4% of the respondent were male and the remaining 42.6% people belong to the female. On average 1.66

males are in to agate work from the family, and similar to that female are 1.51. The a verage age of

experience of male workers in agate work is 15.68 years where as for the female it comes to 13.55 years.

Exposure to more than 5 to 10 years of experience in agate industry can lead to serious exposure to silicosis.

The (Figure 4) portrays that there are 5 caste that have highest percentage of involvement in the agate

work industry. The Thakor caste is the highest found at the time of the survey (23.8%), followed by

Chunar caste (15.1%). Baraiye caste has 11.4% people working in the agate indu stry. Malek and Shekh

caste are around 10.4% and 10.7% respectively. The other workers come from various different castes from

the society across the whole Gulf of Khambhat region.

Figure V. Caste Based Distribution among Agate Workers

The religion based demography of worker force shows majority are Hindu ( 65.1 %) followed by Muslim

(33.6%) people from the total sample survey size of 298 agate workers. People from other religious group

such as Sikh, Christians, etc. have never been found during the time of survey. Many in their research have

acknowledged that Hindus and Muslims have been part of the agate industry since couple of century.

Though there haven’t been many studies on the subject. The marital status of this worker was largel y

divided into 4 categories in Descending order of the distribution. Married workers were the highest at

77.9%, followed by 16.8% workers were unmarried. Widow and Widower turned around to be at 4.7% and

0.7% respectively among the sample size. 84.3% of the agate workers had primary education. Followed by

Secondary education at 14.7% and Higher Secondary education was merely 0.7%. 0.3% is the lowest

percentage belonged to Graduation and Post-Graduation education level in the agate workers. Education is

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 22 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

getting costlier thus the workers are struggling to provide education even for their children. Silicosis on

the other hand eats up larger share of their income; there is merely small amount of money left with the

worker to support his or her children’s education. The total monthly income is utilized largely for food and

other household expenses.

Majority of the people (82.6%) agate workers had their major family source of income from agate work.

Few worked with a combination of Agate work and Labour work (11.4%). The remaining major source of

family income was observed among agate business, farming, and labour work. See Figure (VI) for more

details.

Figure VI Major Source of Family Income

5%1%

11%

83%

Agate Business Agate and Labour Work Labour Work Agate, Farming and Labour Work, Farming

Type of business ownership was highly skewed towards personal work that the workers did. 68.1% of the

workers had their own personal work for agate. There were small amount of workers who worked

personally but also owned the business in person (17.1%). Only two percent of the workers worked in

partnerships (See Figure VII for more details).

Figure VII Type of Business Ownership

13% 2%

17%

68%

Partnership Personal Personal and Privately Owned Privately Owned

More than quarter of workers (30.9%) worked in stone breaking work at the time of the survey, followed

by 21.8% of people in stone piercing work. And polishing worked stood at 18.5%. The work distribution

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 23 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

identifies the work opportunity the workers have but on the other hand the industry is requires skill

worker with enough experience to work in particular type of agate work. For more details (See Figu re8).

On average the worker spends around 7.14 hours a day in their work. The minimum hours recorded at

time of the survey was 4 hours. Majority (69.1%) of the workers work from morning 10:00 hours to

evening 18:00 hours. Almost 8 hours a day.

Figure VIII Type of Agate Work (%)

Stone Rolling 14.8

Stone Piercing 21.8

Stone Cutting 10.1

Stone Breaking 30.9

Polish 18.5

Drum 4

0 5 10 15 20 25 30 35

More than 1/3rd (41.6%) of the workers fall under the income bracket of ₹3000 - ₹6000. Followed by

workers who have monthly income of less than ₹3000 (33.9%). There are very few workers who are paid

more than ₹12000 a month. For more details of monthly income of workers (See Figure9).

The workers are paid based on piece they create on daily basis and also on type of work they hold onto.

The workers are not allowed to work for other workers. So, it is tough for them to create a ne w source of

income apart from agate work. The agate work pays of their daily bills thus many families prefer to stay in

agate industry and also allow their children to follow the same path.

Figure IX Monthly Income of Agate Workers

Other

More than 12k

Less than 3k

9 to 12k

6 to 9k

3 to 6k

0 5 10 15 20 25 30 35 40 45

Monthly Income ('000)

For around 49% of the families of the agate worker the whole family earns between ₹5000 - ₹10000 a month.

Close to quarter, 23.5% families earn less than ₹5000 a month. Income segregation is seen because of the type of

work the workers are involved into (See Figure10).

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 24 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

Figure X Total Family Income (Per Month)

Other

More than 15k

Less than 5k

5 to 10k

10 to 15k

0 10 20 30 40 50 60

Yealy Income ('000)

CONCLUSION

Agate workers associated with this business have asymmetrical distribution and have faced prosecutive

behaviour. 54.7% are the men that engaged in this occupation. Based on caste 23.8% comes from Thakor,

15.1% comes from Chunara caste, 11.4% Baraiya Caste. Distribution based on religion 65.1% are Hindu,

33.6% are Muslim that means only people from two religions are working in this industry. 77% people are

married besides the widow 4.7%. (Whose husbands died at early age due to Silicosis). Percentage of people

involved in higher education is extremely poor it is just 1%. 82.6% of the families that are involved in this

business has agate work as their only major source of income and out of which only 68% of the people

owns those business. 30.9% of the people are involved in the stone breaking work and the lowest

percentage of work belongs to drum i.e. 4%. 41.6% people who are involved in the business have monthly

income in range of ₹3000 to ₹6000, 49% has monthly income in range of ₹5000 to ₹10000.

The ancient identity of the Khambhat region is associated with industrial landscape of agate industry.

Agate Industry even though being one of the ancient and heritage industry the growth and development of

the industry in the region is comparatively slower than other industries. This resear ch through its finding

has helped to understand the problems and obstacles face by people associated to agate business in the

Khambhat region. People who are working in Dry Polish and Drum Polish have been most affected by

Silicosis disease. The prevention of health hazards from the work environment, providing exhausts for

lowering the incidence of occupational diseases or installation of a new technologically & advanced

equipment in the factory are some of the required useful steps towards the overall deve lopment of the

Agate Industry.

REFERENCES

1. Agate, A. C. (2007, July 16). Gem. Retrieved Febraury 24, 2018, from Agate Creek Agate:

https://web.archive.org/web/20070716052933/http://www.gem.org.au/agate.htm

2. Changrani, R. (2016, March 9). Jewelinfo4u. Retrieved February 24, 2018, from Jewelinfo4u website:

https://www.jewelinfo4u.com/important-agate-mines-in-the-world

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 25 | 26

The Churning : An Inter-Disciplinary National Peer & Double Reviewed e-Journal of Languages, Social Sciences and

Commerce/ Mahesh Patel /Page 13-26

3. Department of Ocean Development, G. (2002, May). Critical Habitat Information System for Gulf of

Khambhat - Gujarat. Chennai, Tamil Nadu, India: Goverment of India (GOI), Integrated Coastal and

Marine Area Management.

4. Gujarat, V. (2017, January 10). Vibrant Gujarat. Retrieved February 24, 2018, from

http://vibrantgujarat.com: http://vibrantgujarat.com/writereaddata/images/pdf/gems-jewellery-sector.pdf

5. Intercultural Resources, George PT. (2013, June 12). The Silent Killer: Agate Workers in Khambhat Fight

against Silicosis. Retrieved March 12, 2018, from ritimo.org: https://www.ritimo.org/The-Silent-Killer-

Agate-Workers-in-Khambat-Fight-against-Silicosis

6. Patel, J., & Robbins, M. (2011). The Agate Industry and Silicosis in Khambhat, India. New Solutions:

Journal of Environmental and Occupational Health Policy, 117 - 139. Retrieved from

http://journals.sagepub.com/doi/abs/10.2190/NS.21.1.l?journalCode=newa

7. Possehl, G. L. (1981). Cambay Beadmaking - An ancient craft in modern India. Ahmedabad: Expedition.

8. PT, G. (2013, June 12). Ritimo. Retrieved February 24, 2018, from ritimo.org: http://www.ritimo.org/The-

Silent-Killer-Agate-Workers-in-Khambat-Fight-against-Silicosis

9. PUCL Gujarat. (2007, November 1). Silicosis: A Death Trap for Agate Workers in Gujarat. Retrieved March

11, 2018, from countercurrents.org: https://www.countercurrents.org/pucl021107.htm

10. The National Labour Committee. (2010). Hearts of Darkness. Ahmedabad.

11. Vincent, D., & Gupta, G. (2002). Critical Habitat Information system for Gulf of Khambhat-Gujarat.

Chennai: GoI Department of Ocean Development.

Issue 2 : 2018-2019 www.uancmahilacollege.org

Page 26 | 26

You might also like

- Gemstones, Precious and Semiprecious StonesDocument32 pagesGemstones, Precious and Semiprecious StonesHasmadi Othman100% (1)

- Daivati Bharadvaj-Natural Treatments For Chronic Fatigue SyndromeDocument217 pagesDaivati Bharadvaj-Natural Treatments For Chronic Fatigue SyndromeMihaela BrailescuNo ratings yet

- GIA's Colored Stone Essential's Reference GuideDocument140 pagesGIA's Colored Stone Essential's Reference Guideshift26097% (30)

- 7 Patellar Tracking Exercises For Subluxation & DislocationDocument9 pages7 Patellar Tracking Exercises For Subluxation & DislocationAnh Đức NguyễnNo ratings yet

- JewelleryDocument19 pagesJewelleryT Sampath Kumaran75% (4)

- AgateDocument58 pagesAgateSarika Rana100% (1)

- A Study On The Effect of Imitation Jewellery On Real Sales of Gold JewelleryDocument6 pagesA Study On The Effect of Imitation Jewellery On Real Sales of Gold JewelleryarcherselevatorsNo ratings yet

- A Guide to Birthstones - A Collection of Historical Articles on the Gemstones Linked to AstrologyFrom EverandA Guide to Birthstones - A Collection of Historical Articles on the Gemstones Linked to AstrologyNo ratings yet

- SU07Document105 pagesSU07saopauloNo ratings yet

- The Illusion of Viral Contagion - Scientific and Philosophical ReviewDocument272 pagesThe Illusion of Viral Contagion - Scientific and Philosophical ReviewFlorin The GOATNo ratings yet

- Export of MarbleDocument29 pagesExport of MarbleAnjana PatelNo ratings yet

- Gems and JewelleryDocument33 pagesGems and Jewelleryshyam soniNo ratings yet

- Agate Value, Price, and Jewelry InformationDocument7 pagesAgate Value, Price, and Jewelry Informationasset68No ratings yet

- Aspergillus 3Document8 pagesAspergillus 3metabolismeproteinNo ratings yet

- History of DiamondsDocument26 pagesHistory of DiamondsAbid KhatriNo ratings yet

- Uttar Pradesh, Meghalaya and Arunachal PradeshDocument34 pagesUttar Pradesh, Meghalaya and Arunachal PradeshRohan Mehra100% (1)

- Science4 q1 Module 2Document33 pagesScience4 q1 Module 2genevieve murilloNo ratings yet

- Gemstones, Precious and Semiprecious StonesDocument32 pagesGemstones, Precious and Semiprecious StonesmadiedianaNo ratings yet

- FA07Document94 pagesFA07saopauloNo ratings yet

- SU83Document69 pagesSU83saopauloNo ratings yet

- Project Report On Gold & Silver Jewellery Manufacturing UnitDocument9 pagesProject Report On Gold & Silver Jewellery Manufacturing UnitEIRI Board of Consultants and Publishers100% (1)

- 43 Granite: Prime Varieties of Indian GraniteDocument12 pages43 Granite: Prime Varieties of Indian GraniteAnkur BihaniNo ratings yet

- COVID-19 PandemicDocument113 pagesCOVID-19 PandemicNico Robert100% (1)

- Case Presentation Parkinson DiseaseDocument10 pagesCase Presentation Parkinson Diseasemariam aydinNo ratings yet

- INSPIRA JOURNAL OF COMMERCEECONOMICS COMPUTER SCIENCEJCECS Vol 8 No 1 January March 2022 Pages 76 To 81Document6 pagesINSPIRA JOURNAL OF COMMERCEECONOMICS COMPUTER SCIENCEJCECS Vol 8 No 1 January March 2022 Pages 76 To 81Lovish BandwalNo ratings yet

- Jewellery Industry in India: February 2018Document19 pagesJewellery Industry in India: February 2018lakshitaNo ratings yet

- JewelleryindustryinindiaDocument19 pagesJewelleryindustryinindiaSreelatha ChakravarthulaNo ratings yet

- Jewellery Industry in India: February 2018Document19 pagesJewellery Industry in India: February 2018AkchikaNo ratings yet

- GemstonepathandvaluechainDocument11 pagesGemstonepathandvaluechainsara eltonyNo ratings yet

- Ganjam Case StudyDocument15 pagesGanjam Case StudyJay GudhkaNo ratings yet

- SRADHA ASM Gem Stone Value ChainDocument17 pagesSRADHA ASM Gem Stone Value Chainsara eltonyNo ratings yet

- The Extractive Industries and Society: Arnab Roy Chowdhury, Kuntala Lahiri-DuttDocument13 pagesThe Extractive Industries and Society: Arnab Roy Chowdhury, Kuntala Lahiri-DuttDiego AlbertoNo ratings yet

- Thesis - PGDocument63 pagesThesis - PGNavin KumarNo ratings yet

- The Treasures of The EarthDocument42 pagesThe Treasures of The Earthcleopatra.hensbyNo ratings yet

- Manas - Keeladi PPT1 PDFDocument7 pagesManas - Keeladi PPT1 PDFyedhulaprakash4927No ratings yet

- Gem StoneDocument4 pagesGem StoneKamal JoshiNo ratings yet

- GI Tags (Indian Handicraft)Document5 pagesGI Tags (Indian Handicraft)prayani pohekarNo ratings yet

- The Impact of Illegal Mining On The Ghanaian Youth: Evidence From Kwaebibirem District in GhanaDocument8 pagesThe Impact of Illegal Mining On The Ghanaian Youth: Evidence From Kwaebibirem District in GhanaLUKEMAN KWAME MAAMAHNo ratings yet

- Agra ClusterDocument26 pagesAgra ClusterFaisal NumanNo ratings yet

- CHP 1Document264 pagesCHP 1Balakrishna DammatiNo ratings yet

- SU21 - Ho PDFDocument3 pagesSU21 - Ho PDFraghuvansham boutiqueNo ratings yet

- Tradition of Stones: (Hide) 1 2 o 2.1 o 2.2 o 2.3 o 2.4 o 2.5 2.5.1 o 2.6 3 4Document3 pagesTradition of Stones: (Hide) 1 2 o 2.1 o 2.2 o 2.3 o 2.4 o 2.5 2.5.1 o 2.6 3 4Tushar SharmaNo ratings yet

- Perception of Consumers Towards Branded Jewellery Products of Malabar Gold in Thiruvananthapuram CityDocument12 pagesPerception of Consumers Towards Branded Jewellery Products of Malabar Gold in Thiruvananthapuram CityOmkar VichareNo ratings yet

- Science PortfolioDocument44 pagesScience PortfoliohukaNo ratings yet

- JANUARY 2006: Form No. 5 BackDocument36 pagesJANUARY 2006: Form No. 5 BackSivakumar SelvarajNo ratings yet

- Crafts of India - Wikipedia PDFDocument5 pagesCrafts of India - Wikipedia PDFagrim aroraNo ratings yet

- Gems & Jewellery FinalDocument22 pagesGems & Jewellery FinalVarun LalwaniNo ratings yet

- "Small Scale Industry On Pottery: Dayananda Sagar College of EngineeringDocument11 pages"Small Scale Industry On Pottery: Dayananda Sagar College of EngineeringSuhan KotianNo ratings yet

- GIDocument12 pagesGINaveen SihareNo ratings yet

- Introduction To The Study: THE PLANT. in This Study The Background and Problem Formulation With Discussion For TheDocument58 pagesIntroduction To The Study: THE PLANT. in This Study The Background and Problem Formulation With Discussion For Theanon_16851326100% (1)

- Craft Documentation Gota PattiDocument28 pagesCraft Documentation Gota PattiKriti KumariNo ratings yet

- Jellewery Market ProjectDocument82 pagesJellewery Market ProjectSeema YadavNo ratings yet

- 25 Pearl CultureDocument15 pages25 Pearl CulturemvrangamNo ratings yet

- PotteryDocument14 pagesPotterymetstephNo ratings yet

- Diamond in Ancient IndiaDocument51 pagesDiamond in Ancient IndiacelverY2kNo ratings yet

- Tamta ProjectDocument98 pagesTamta ProjectPranathi ReddyNo ratings yet

- Ecotourism in Jharhkand Change Impact AnDocument5 pagesEcotourism in Jharhkand Change Impact AnthaimuNo ratings yet

- Foot Wear Cluster, Agra - DSDocument57 pagesFoot Wear Cluster, Agra - DSKritika KhannaNo ratings yet

- Crux Nicknames of Indian CitiesDocument6 pagesCrux Nicknames of Indian CitiesSuman KumarNo ratings yet

- Article On Dungaria Kondh-IJCRTDocument8 pagesArticle On Dungaria Kondh-IJCRTkrishnakumarsnairNo ratings yet

- Some Thoughts On Diamond Exploration in IndiaDocument6 pagesSome Thoughts On Diamond Exploration in IndiaharshNo ratings yet

- Ijrar19k4165 PDFDocument9 pagesIjrar19k4165 PDFMaruthi N.ENo ratings yet

- Industrial Mineral Deposits of Pakistan: Significant For Sustainable Development of PakistanDocument3 pagesIndustrial Mineral Deposits of Pakistan: Significant For Sustainable Development of PakistanEmRan LeghariNo ratings yet

- A Study On The Effect of Imitation Jewellery On Real Sales of Gold Jewellery PDFDocument6 pagesA Study On The Effect of Imitation Jewellery On Real Sales of Gold Jewellery PDFrudraksh baisNo ratings yet

- A Study On The Effect of Imitation Jewellery On Real Sales of Gold Jewellery PDFDocument6 pagesA Study On The Effect of Imitation Jewellery On Real Sales of Gold Jewellery PDFAmbrish PandeyNo ratings yet

- Ñ 3 A !" G ! !# ! ! U ! $ ! %# ! ! &'GDocument20 pagesÑ 3 A !" G ! !# ! ! U ! $ ! %# ! ! &'GAbhiyank ChaurasiaNo ratings yet

- Mood, Anxiety and PersonalityDocument109 pagesMood, Anxiety and PersonalityRahul ShitoleNo ratings yet

- Laporan SP3 LB1Document35 pagesLaporan SP3 LB1Citra AuliyaNo ratings yet

- PK PD en Critical IllnessDocument27 pagesPK PD en Critical IllnessDaniela BolivarNo ratings yet

- Assessment of Anthropometric Failure Amongst Under Five Children in An Urbanized Village of Delhi: A Cross Sectional StudyDocument7 pagesAssessment of Anthropometric Failure Amongst Under Five Children in An Urbanized Village of Delhi: A Cross Sectional StudyIJAR JOURNALNo ratings yet

- Hepatitis B VaccinationDocument3 pagesHepatitis B VaccinationCommunity Round3 G1No ratings yet

- The Endocrine System Lesson 1Document44 pagesThe Endocrine System Lesson 1Heaven Dela CruzNo ratings yet

- Xie Et Al., 2018 - High Energy ESWT Osteonecrosis Femoral HeadDocument8 pagesXie Et Al., 2018 - High Energy ESWT Osteonecrosis Femoral HeadPraganesh VarshneyNo ratings yet

- Kolaeva NotesfsdffDocument16 pagesKolaeva NotesfsdffsharenNo ratings yet

- Set 1 Checked: E. Pathological ConditionDocument60 pagesSet 1 Checked: E. Pathological ConditionKunal BhamareNo ratings yet

- Preprint Not Peer Reviewed: COVID-19 and Lockdown: A Study On The Impact On Mental HealthDocument13 pagesPreprint Not Peer Reviewed: COVID-19 and Lockdown: A Study On The Impact On Mental HealthloloasbNo ratings yet

- Drug StudyDocument2 pagesDrug Studykev mondaNo ratings yet

- Germ Theory of Diseases Von PlencizDocument2 pagesGerm Theory of Diseases Von PlencizAamni SinghNo ratings yet

- Evaluasi Atribut Kesederhanaan Ketepatan Waktu Dan PDFDocument9 pagesEvaluasi Atribut Kesederhanaan Ketepatan Waktu Dan PDFFauziahmuthmainnah FauziahuciNo ratings yet

- Vancomycin MylaninfDocument13 pagesVancomycin MylaninfAmanuel GirmayeNo ratings yet

- Philippine College of Physicians Daily Census Ward Hospital de Los Santos-Sti Medical CenterDocument22 pagesPhilippine College of Physicians Daily Census Ward Hospital de Los Santos-Sti Medical Centercruz_johnraymondNo ratings yet

- College of Nursing Allied Health Sciences: Complete Gut ObstructionDocument45 pagesCollege of Nursing Allied Health Sciences: Complete Gut ObstructionLemuel GuevarraNo ratings yet

- Neurocritical Care Review: Practice QuestionsDocument52 pagesNeurocritical Care Review: Practice QuestionsAmitShettyNo ratings yet

- INP CU 10 GlomeruloDocument5 pagesINP CU 10 GlomeruloMichelle Gliselle Guinto MallareNo ratings yet

- Dialog Medic PacientDocument4 pagesDialog Medic PacientanaNo ratings yet

- Assignment: 1: Discuss Different Problems of Adolescents and Strategies For Coping Up With These ProblemsDocument6 pagesAssignment: 1: Discuss Different Problems of Adolescents and Strategies For Coping Up With These ProblemsShabana AnjumNo ratings yet

- HypothyroidismDocument54 pagesHypothyroidismagakshat23No ratings yet

- Focus3 2E Test Unit6 GroupA 1kolDocument5 pagesFocus3 2E Test Unit6 GroupA 1kolMagdaNo ratings yet

- CPR SioDocument38 pagesCPR SioGerry OshNo ratings yet