Professional Documents

Culture Documents

API Standard 661/ISO 13706:2001: American Petroleum Institute

Uploaded by

Hamza HashimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API Standard 661/ISO 13706:2001: American Petroleum Institute

Uploaded by

Hamza HashimCopyright:

Available Formats

API Standard 661/ISO 13706:2001 American Petroleum Institute

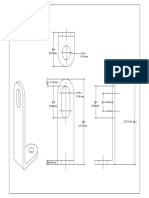

a)ÊÊÊStud construction, b)ÊÊÊFlanged construction, c)ÊÊÊFlanged construction,

confined gasket confined gasket full-faced gasket

FigureÊ4ÊÑ Typical confined and full-faced gasket joint details

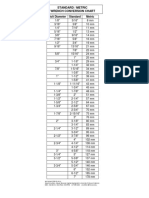

TableÊ2ÊÑ Minimum flange bolt spacing

Nominal bolt diameter Minimum bolt spacing

5 1

16 mm ( /8 inch) 38 mm (1 /2 inch)

3 3

19 mm ( /4 inch) 44 mm (1 /4 inch)

7 1

22 mm ( /8 inch) 52 mm (2 /16 inch)

1

25 mm (1 inch) 57 mm (2 /4 inch)

1 1

29 mm (1 /8 inch) 64 mm (2 /2 inch)

1 13

32 mm (1 /4 inch) 71 mm (2 /16 inch)

3 1

35 mm (1 /8 inch) 76 mm (3 /16 inch)

1 1

38 mm (1 /2 inch) 83 mm (3 /4 inch)

5 1

41 mm (1 /8 inch) 89 mm (3 /2 inch)

3 3

44 mm (1 /4 inch) 95 mm (3 /4 inch)

7

48 mm (1 /8 inch) 102 mm (4 inch)

1

51 mm (2 inch) 108 mm (4 /4 inch)

7.1.6.2.11 Spacing between bolts straddling corners shall be such that the diagonal distance between bolts

adjacent to the corner does not exceed the lesser of the spacing on the sides or the ends.

7.1.6.3 Plug headers

7.1.6.3.1 Threaded plug holes shall be provided opposite the ends of each tube for access. Holes shall be

threaded to the full depth of the plug sheet or 50Êmm (2Êinch), whichever is less. FigureÊ5 shows typical construction

of a tube bundle with plug headers.

7.1.6.3.2 The diameter of the plug holes shall be equal to the nominal outside diameter of the tube plus at least

1

0,8Êmm ( /32Êinch).

7.1.6.3.3 Gasket contact surfaces of plug holes shall be spot-faced. The edges of the facing shall be free of

burrs.

12

You might also like

- 6WG1 e 01 (2 - 2)Document266 pages6WG1 e 01 (2 - 2)mohan100% (8)

- Radiographic Method API 650Document4 pagesRadiographic Method API 650Riza Ahmad Sofikul Irfan0% (1)

- Expansion Loop CalculationDocument2 pagesExpansion Loop Calculationsk130986100% (1)

- Dremel Bit PosterDocument1 pageDremel Bit PosterPhil BooeNo ratings yet

- Leak GisDocument14 pagesLeak GisTravis WoodNo ratings yet

- Design Philosophy - StaticDocument61 pagesDesign Philosophy - StaticDarshan PanchalNo ratings yet

- Questions Related To CodesDocument10 pagesQuestions Related To CodesMayur Mandrekar100% (1)

- BS 1881-5 - 1970Document27 pagesBS 1881-5 - 1970عمر عمرNo ratings yet

- Pip Vessm001 Specification For Small Pressure Vessels and Heat Exchangers With Limited Design ConditionsDocument12 pagesPip Vessm001 Specification For Small Pressure Vessels and Heat Exchangers With Limited Design ConditionsAmit SharmaNo ratings yet

- DSI Underground Systems Mechanical Rock Bolts Extension Bolts Stelpipe Bolts US 01Document16 pagesDSI Underground Systems Mechanical Rock Bolts Extension Bolts Stelpipe Bolts US 01Tato Del AguilaNo ratings yet

- Floating Head Heat Exchanger HydrotestDocument15 pagesFloating Head Heat Exchanger Hydrotestjohn0% (1)

- PB 4BG1 Engine PDFDocument64 pagesPB 4BG1 Engine PDFhanafi yusufNo ratings yet

- Trunnion Calculation SheetDocument3 pagesTrunnion Calculation Sheetsudhisnair67% (3)

- Holley 1-Barrel Parts IndexDocument38 pagesHolley 1-Barrel Parts IndexBillyNo ratings yet

- WellIntegrity MFC+Combined-+NewDocument6 pagesWellIntegrity MFC+Combined-+NewOuaingar ngueadoumNo ratings yet

- Cummins M11 engine Spare parts catalogDocument15 pagesCummins M11 engine Spare parts catalogChen Caroline100% (1)

- Solvent Jointing of CPVC PipesDocument20 pagesSolvent Jointing of CPVC PipesHamza Hashim100% (1)

- Sprinkler Cabinets 3, 6, & 12 Sprinklers, 1/2 or 3/4 Inch NPT 6 ESFR Sprinklers, 3/4 or 1 Inch NPT General Description Technical DataDocument4 pagesSprinkler Cabinets 3, 6, & 12 Sprinklers, 1/2 or 3/4 Inch NPT 6 ESFR Sprinklers, 3/4 or 1 Inch NPT General Description Technical Datacarlos vegaNo ratings yet

- Square Style Railing Clamps With Radius Base: For 2" (51 MM) Diameter Round TubingDocument1 pageSquare Style Railing Clamps With Radius Base: For 2" (51 MM) Diameter Round TubingcrlaurenceNo ratings yet

- Round Style Railing Clamps With Radius Base: For 2" (51 MM) Diameter Round TubingDocument1 pageRound Style Railing Clamps With Radius Base: For 2" (51 MM) Diameter Round TubingcrlaurenceNo ratings yet

- Plastic Pipe Sizes Chart - Epco PlasticsDocument1 pagePlastic Pipe Sizes Chart - Epco Plasticsdattu33No ratings yet

- Slic Aerial Closure With Spiral End Seals and Bond Assembly: InstructionsDocument9 pagesSlic Aerial Closure With Spiral End Seals and Bond Assembly: InstructionsKen NethNo ratings yet

- Datasheet of DS 1276ZJ SUS - 20171201Document1 pageDatasheet of DS 1276ZJ SUS - 20171201Ngọc Lan Lê ThịNo ratings yet

- Plastic Pipes Inch To Metric Sizing GuidelinesDocument1 pagePlastic Pipes Inch To Metric Sizing GuidelinesFawaaz KhurwolahNo ratings yet

- Soporte PDFDocument1 pageSoporte PDFFran Cruz JNo ratings yet

- Soporte PDFDocument1 pageSoporte PDFFran Cruz JNo ratings yet

- BQ Daftar Upah Bahan 2 GbtrakorDocument2 pagesBQ Daftar Upah Bahan 2 GbtrakorFarid AhmadNo ratings yet

- Honeywell 8712009 8712109 8712309 8712309L 8712409 8712509Document20 pagesHoneywell 8712009 8712109 8712309 8712309L 8712409 8712509Adi WalangsnNo ratings yet

- Catálogo GoldenDocument7 pagesCatálogo GoldenhelenosnetoNo ratings yet

- Model Model: Belt Alignment Control Belt Alignment ControlDocument2 pagesModel Model: Belt Alignment Control Belt Alignment ControlJaime Valenzuela MarchantNo ratings yet

- Workbench - Paul SellersDocument6 pagesWorkbench - Paul SellersChris SpragueNo ratings yet

- Dibujo Industrial II Ing. Elkin PaduaDocument6 pagesDibujo Industrial II Ing. Elkin PaduaElkinNo ratings yet

- Core Identi Fication Guide: Automatic Roll FiltersDocument2 pagesCore Identi Fication Guide: Automatic Roll Filterssakura_jNo ratings yet

- 16. DS-1275ZJ-SUS Bracket poleDocument1 page16. DS-1275ZJ-SUS Bracket poleDILMER JAVIERNo ratings yet

- Heavy-Duty Door Hanger for 200lb LoadsDocument1 pageHeavy-Duty Door Hanger for 200lb LoadsKelvin DavilaNo ratings yet

- E Translicer Bias Cutter: Batch Processing For Niche MarketsDocument2 pagesE Translicer Bias Cutter: Batch Processing For Niche MarketsLorenzo YapNo ratings yet

- SS-00181 Aby904nDocument2 pagesSS-00181 Aby904nvanymendozaNo ratings yet

- 32-79 T32ge01-M Cylnd Metal EngDocument1 page32-79 T32ge01-M Cylnd Metal EngRahul KumarNo ratings yet

- Report Sheet Pengukuran Kelompok: No Item Yang Diukur Hasil Ukur StandarDocument1 pageReport Sheet Pengukuran Kelompok: No Item Yang Diukur Hasil Ukur StandarDedy SutriyonoNo ratings yet

- Datasheet of DS 1276ZJ SUS Black 20190108Document1 pageDatasheet of DS 1276ZJ SUS Black 20190108Klayton PiresNo ratings yet

- Standard: Metric Wrench Conversion ChartDocument1 pageStandard: Metric Wrench Conversion ChartLeslie SeerattanNo ratings yet

- Ensemble: 60" X 32" End Drain Shower Stall With Aging in Place BackerboardsDocument2 pagesEnsemble: 60" X 32" End Drain Shower Stall With Aging in Place Backerboardsny10013No ratings yet

- 15-A02 01 Arix Foot System 2.3 2.8 Ca 191206 SDocument28 pages15-A02 01 Arix Foot System 2.3 2.8 Ca 191206 SDaniel VideaNo ratings yet

- Power Master 800 SeriesDocument2 pagesPower Master 800 SeriesGeorge MadisonNo ratings yet

- 2Document1 page2Jasa Bumi ProstheticNo ratings yet

- C0636A×1000 Bench LatheDocument2 pagesC0636A×1000 Bench LatheAlireza KazemiNo ratings yet

- Screws Thread Styles GuideDocument3 pagesScrews Thread Styles GuideAris OlimpoNo ratings yet

- Inch To MMDocument1 pageInch To MMAutospark GreeceNo ratings yet

- Furon® SCM2 Valve: Manually Actuated, 2-Way Molded Stopcock ValveDocument3 pagesFuron® SCM2 Valve: Manually Actuated, 2-Way Molded Stopcock ValveXavierNo ratings yet

- BSP (British Standard Pipe) Whitworth Thread Data, BSP and BSPT TapsDocument1 pageBSP (British Standard Pipe) Whitworth Thread Data, BSP and BSPT TapsKundan RokadeNo ratings yet

- Tyco # 567059010Document4 pagesTyco # 567059010bhupalkoiralaNo ratings yet

- 1 1.6 1.Choosing-Installing RadarDocument2 pages1 1.6 1.Choosing-Installing RadarmeeNo ratings yet

- Standard MetricWrenchChart PDFDocument1 pageStandard MetricWrenchChart PDFCita del RosarioNo ratings yet

- Bolt-Standart Metrik PDFDocument1 pageBolt-Standart Metrik PDFAndi Yusuf MasseseNo ratings yet

- Standard Metricwrenchchart PDFDocument1 pageStandard Metricwrenchchart PDFchandu666creatorNo ratings yet

- Standard Metricwrenchchart PDFDocument1 pageStandard Metricwrenchchart PDFGabriel Ivan AviñaNo ratings yet

- Standard MetricWrenchChart PDFDocument1 pageStandard MetricWrenchChart PDFphuyangNo ratings yet

- Standard MetricWrenchChart PDFDocument1 pageStandard MetricWrenchChart PDFandi yusufNo ratings yet

- Standard / Metric Wrench Conversion ChartDocument1 pageStandard / Metric Wrench Conversion ChartAeron MercadoNo ratings yet

- Size and Gauge ChartDocument1 pageSize and Gauge ChartsageousNo ratings yet

- EVOS Wrist Surgical Technique Smith and NephewDocument32 pagesEVOS Wrist Surgical Technique Smith and NephewWillem SmitNo ratings yet

- Yesid Ferney Torres Q. Motor Detroit Pincher 8.2Document64 pagesYesid Ferney Torres Q. Motor Detroit Pincher 8.2Yesid Ferney Torres QuirogaNo ratings yet

- Es 16Document7 pagesEs 16Nuttaphon100% (1)

- Expanding, Extracting & Flaring ToolsDocument25 pagesExpanding, Extracting & Flaring ToolsMusic NetNo ratings yet

- Webster County: Standard-Metric Wrench ChartDocument2 pagesWebster County: Standard-Metric Wrench ChartLuke WrightNo ratings yet

- Comparison Table of Standard Sieve SeriesDocument3 pagesComparison Table of Standard Sieve SeriesAlexander HillNo ratings yet

- Handline Nozzles and Shutoffs GuideDocument1 pageHandline Nozzles and Shutoffs GuideAdmisión Bomberos HualpenNo ratings yet

- Standard / Metric Wrench Conversion ChartDocument1 pageStandard / Metric Wrench Conversion ChartNaresh HarbuckhanNo ratings yet

- STC Rating Chart PDFDocument1 pageSTC Rating Chart PDFtroyel99No ratings yet

- DS 1275ZJ S SUS - DatasheetDocument1 pageDS 1275ZJ S SUS - DatasheetDocument controlNo ratings yet

- Baumfolder D5DrillDocument2 pagesBaumfolder D5DrillKBR Graphics CanadaNo ratings yet

- Master Bedroom LavDocument2 pagesMaster Bedroom Lavhucyg63No ratings yet

- Field Travel InfoDocument1 pageField Travel InfoHamza HashimNo ratings yet

- Evaluation of Pipeline Flanges Subject To Internal Pressure and Imposed External LoadsDocument7 pagesEvaluation of Pipeline Flanges Subject To Internal Pressure and Imposed External LoadsHamza HashimNo ratings yet

- Calculation Sheet: 002-000-PDF-566 (015311) EPF-0027 Rev 2 (5-Mar-07) Corporate Base Page 1 of 2Document2 pagesCalculation Sheet: 002-000-PDF-566 (015311) EPF-0027 Rev 2 (5-Mar-07) Corporate Base Page 1 of 2Hamza HashimNo ratings yet

- PSV Force Calculation SheetDocument4 pagesPSV Force Calculation SheetHamza HashimNo ratings yet

- Sigma 500Document1 pageSigma 500Homer SilvaNo ratings yet

- Bidding Documents: Procurement OF Stationary & Janitorial ItemsDocument22 pagesBidding Documents: Procurement OF Stationary & Janitorial ItemsHamza HashimNo ratings yet

- Data SF3300Document2 pagesData SF3300Ingrid Johhana BalbinNo ratings yet

- What Is Stainless Steel enDocument6 pagesWhat Is Stainless Steel enPetar RadonjićNo ratings yet

- Solvent Jointing of CPVC PipesDocument20 pagesSolvent Jointing of CPVC PipesHamza HashimNo ratings yet

- RWTH Aachen Deadlines GuideDocument1 pageRWTH Aachen Deadlines GuideHajar AbunaeemNo ratings yet

- 3 - Pen Chart RecorderDocument1 page3 - Pen Chart RecorderHamza HashimNo ratings yet

- "Standard"Separate Vacuum Hopper Loader - SAL G PDFDocument34 pages"Standard"Separate Vacuum Hopper Loader - SAL G PDFJD126No ratings yet

- Hopper DryersDocument6 pagesHopper DryersHamza HashimNo ratings yet

- Compressed Sheet With Carbon Fibers, NBR Binder: ApplicationDocument2 pagesCompressed Sheet With Carbon Fibers, NBR Binder: ApplicationEmmanuelNo ratings yet

- M870 Operator Manual PDFDocument62 pagesM870 Operator Manual PDFAngel Danubio Medina PerezNo ratings yet

- PCC Technova Series CPL Cylindrical ValvesDocument5 pagesPCC Technova Series CPL Cylindrical ValvesAnju VijayanNo ratings yet

- Equipment Data Requisition Sheet C4 Intermediate Vessel 5210-V-101Document8 pagesEquipment Data Requisition Sheet C4 Intermediate Vessel 5210-V-101AzriNo ratings yet

- 8000 In-Manual r10Document8 pages8000 In-Manual r10Guatemalan1979No ratings yet

- Fire Pump Spare ListDocument6 pagesFire Pump Spare ListtskumarNo ratings yet

- KTA50 ESN 25329037 Parts ListDocument8 pagesKTA50 ESN 25329037 Parts ListNikkikumarNo ratings yet

- Auma Actuator-DBBV 1 PDFDocument20 pagesAuma Actuator-DBBV 1 PDFambrishNo ratings yet

- Afloat Lube Oil and Mogas Systems and Operations: LEARNING OBJECTIVES: Describe A TypicalDocument26 pagesAfloat Lube Oil and Mogas Systems and Operations: LEARNING OBJECTIVES: Describe A TypicalYerixon Daniel Aguilar SequerasNo ratings yet

- Splendor NXG ES PDFDocument89 pagesSplendor NXG ES PDFAlexander OlivosNo ratings yet

- KF FlangeDocument76 pagesKF Flangehisaj4uNo ratings yet

- Project: Mansourah-Massarah Ma’aden Gold Project (GRE Option) Method StatementDocument10 pagesProject: Mansourah-Massarah Ma’aden Gold Project (GRE Option) Method StatementSaravananNandhuNo ratings yet

- RLNG Pipeline Piping Material SpecificationDocument28 pagesRLNG Pipeline Piping Material SpecificationUmer KhanNo ratings yet

- Mechanic SystemDocument24 pagesMechanic SystemCristian.E.BNo ratings yet

- File39014 0 MK15BWDocument2 pagesFile39014 0 MK15BWMarielena ChunabNo ratings yet

- Atg Za290 ManualDocument31 pagesAtg Za290 ManualCamilo AlvaradoNo ratings yet

- FisherDocument20 pagesFishermanmohansingh1999No ratings yet

- Pages From ANNEXURE-I (Duct Construction Schedule & References) - 2 PDFDocument7 pagesPages From ANNEXURE-I (Duct Construction Schedule & References) - 2 PDFEslam ElsayedNo ratings yet

- WWW - Imp-Ta - Si WWW - Imp-Ta - Si: Control The Stream Control The StreamDocument16 pagesWWW - Imp-Ta - Si WWW - Imp-Ta - Si: Control The Stream Control The StreamCedoNo ratings yet