Professional Documents

Culture Documents

Supply Chain Social Responsibility

Uploaded by

ThuThuy Bui0 ratings0% found this document useful (0 votes)

10 views10 pagesThe document discusses Canon's supply chain management and social responsibility initiatives. It describes Canon's global manufacturing operations and partnerships with thousands of suppliers. It outlines policies and standards to promote ethical, environmental, and socially responsible practices throughout the supply chain. Key initiatives include supplier evaluations and audits, providing guidance for improvement, and working with suppliers to fulfill commitments to international standards for labor, health, safety, and the environment.

Original Description:

Original Title

Supply Chain Management

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses Canon's supply chain management and social responsibility initiatives. It describes Canon's global manufacturing operations and partnerships with thousands of suppliers. It outlines policies and standards to promote ethical, environmental, and socially responsible practices throughout the supply chain. Key initiatives include supplier evaluations and audits, providing guidance for improvement, and working with suppliers to fulfill commitments to international standards for labor, health, safety, and the environment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views10 pagesSupply Chain Social Responsibility

Uploaded by

ThuThuy BuiThe document discusses Canon's supply chain management and social responsibility initiatives. It describes Canon's global manufacturing operations and partnerships with thousands of suppliers. It outlines policies and standards to promote ethical, environmental, and socially responsible practices throughout the supply chain. Key initiatives include supplier evaluations and audits, providing guidance for improvement, and working with suppliers to fulfill commitments to international standards for labor, health, safety, and the environment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 10

Supply Chain Management

Supply Chain and the Fulfillment of its Social Responsibility

Cooperation with Suppliers

Fair and Transparent Dealings

Addressing the Issue of Responsible Minerals Sourcing

Compliance with UK Modern Slavery Act

Supply Chain and the Fulfillment of its Social

Responsibility

Canon’s Supply Chain

In recent years, the environment, human rights and labor issues have

been topics of increasing attention, giving rise to questions from

various stakeholders about Canon’s social responsibility initiatives

throughout its supply chain. Manufactures are expected to exercise

social responsibility especially in the areas of raw material

procurement and product manufacture.

Many manufacturers have outsourced assembly operations or other

production processes to outside contractors; however, Canon places

great importance on manufacturing, and besides product assembly,

Canon manufactures certain components, parts and materials in house,

at Canon Inc. production facilities or at Group manufacturing

companies (collectively, “Canon production sites”). Manufacturing

subsidiaries and affiliates within the Canon Group are spread across

Japan, China, Taiwan, Malaysia, Thailand, the Philippines, Vietnam,

the United States and Europe. They supply Canon products to Canon

Inc. as well as Group marketing subsidiaries and affiliates. As the head

of the Canon Group, Canon Inc. supervises Group manufacturing

companies that directly employ large numbers of people.

Canon production sites have partnerships with thousands of suppliers

unaffiliated with the Canon Group, from whom they purchase

considerable numbers of components, such as electronic parts,

mechanical parts, units and materials.

Canon’s Supply Chain

Supply Chain-related Policies

All Canon production sites are required to adhere to various Canon

Group policies covering matters such as human rights, labor, the

environment, legal compliance, procurement and security. These

policies include the Canon Group Code of Conduct, the Canon Group

CSR Basic Statement and the Canon Group Environmental Charter. In

addition, in December 2019, Canon joined the Responsible Business

Alliance (RBA), a coalition of companies that promotes socially

responsible global supply chains and works to ensure compliance with

the RBA Code of Conduct.

In alignment with the UN Guiding Principles on Business and Human

Rights, the provisions in the RBA Code of Conduct are derived from

and respect internationally recognized standards including the ILO

Declaration on Fundamental Principles and Rights at Work and the

UN Universal Declaration of Human Rights. The Code is currently

available in 27 languages, including English, Chinese, Japanese, Thai,

Vietnamese and Malay.

Canon established the Procurement Policy as its basic stance toward

procurement, and seeks the understanding and cooperation of our

suppliers. Moreover, we have formulated the Canon Supplier Code of

Conduct, which is based on the RBA Code of Conduct, as the basis for

ensuring socially responsible procurement activities. We are working

with suppliers to develop a socially responsible global Canon supply

chain on issues such as labor, occupational health and safety, the

environment, business ethics and management systems. We also

request our second-tier suppliers for the understanding and

implementing the Canon Supplier Code of Conduct through first-tier

suppliers. We publish the code on our corporate website to make it

widely known to stakeholders while making it known to suppliers

globally through an annual survey.

Canon Group CSR Basic Statement (275KB)

Procurement Policy

Canon Supplier Code of Conduct (313KB)

Supply Chain Initiatives

Canon Group initiatives

As the headquarters of the Canon Group, the headquarters divisions,

product operations and auditing divisions at Canon Inc. verify the

situation at Group companies around the world from the standpoints of

internal controls and risk management. In addition, Canon production

sites conduct selfassessments on CSR (labor, health and safety,

environment, ethics, management systems, etc.) using the RBA Self-

Assessment Questionnaire (SAQ). In 2020, we conducted SAQ at 37

production sites in our main business, and there were no major CSR

risks. However, we recognized issues to be improved such as

development of policies, which is required by the RBA,

documentation of management procedures, requests to labor agencies

and service providers for compliance with the RBA Code of Conduct

and monitoring of their compliance. We also conducted independent

third-party audits at two Group companies in Asia, and found no major

issues.

Organizational Structure for Promoting CSR within Supply Chain

Initiatives with Suppliers

Before starting a business with a new supplier, Canon conducts an

assessment based on the Canon Supplier Code of Conduct and other

reference standards, whether the company fulfills all requisite

standards in terms of corporate ethics (legal compliance, product

safety, management of confidential information, human rights, labor,

health and safety, intellectual property rights protection, etc.),

environmental conservation (chemical substance management,

prevention of air pollution and water pollution, proper disposal of

waste, initiatives aimed at conserving energy and resources, reduction

of GHG, and biodiversity conservation) , finance, and production

structure (quality, cost, delivery, manufacturing capacity, and

management).

In the environmental area, Canon has established Canon Green

Procurement Standards, which outline its environment-related requests

to suppliers. Suppliers must comply with these standards to do

business with Canon. Specifically, we view a supplier’s environmental

management as consisting of two interrelated elements: Management

of business activities and Management of parts and materials. We

require that the supplier must operate effective environmental

management in each of the four frameworks labeled A – D in the

diagram below. If a supplier is found to have a negative impact on the

environment, we immediately demand corrective action be taken and

check the status of improvements made.

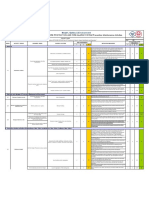

Requirements of the Canon Green Procurement Standards

Only those suppliers who meet these criteria will be registered in the

Supplier List. Canon conducts an annual survey on these suppliers to

comprehensively evaluate them based on the results of the survey and

the transaction performance. The results are then reflected in the

supplier list, enabling us to preferentially deal with suppliers with high

evaluations. We also conduct on-site audits of suppliers with low

evaluations, and provide guidance and education for improvement. In

particular, Canon may choose to terminate business with suppliers if

they are not complying with laws and social agreements covering areas

such as human rights, labor, and the environment.

Supplier Evaluation System

With the aim of improving CSR in the supply chain, Canon requests

suppliers of our main business (“major suppliers”) to sign a letter of

agreement of the RBA Code of Conduct. In 2020, we sent out requests

to 271 major suppliers and received agreements from 257 firms (a

95% response rate). At the same time, we are working to identify CSR

risks using the RBA Self-Assessment Questionnaire (SAQ). In 2020,

we conducted a survey of 271 major suppliers using the SAQ and

received responses from 249 suppliers (392 sites). No ‘High Risk’

businesses were identified among these suppliers, however, we are

planning to provide relevant guidance to those suppliers who need

improvement in future. In 2020, we provided feedback on the results

of labor, health and safety, the environment and ethics to our major

suppliers and requested them to recognize their weaknesses and use

them for future improvement.

It was already Canon practice to check suppliers regarding the

organization and environmental performance of their business

activities and any corrective measures taken. Now, it has further

strengthened its risk management to help prevent pollution in its

supply chain. For example, in order to ensure compliance with

strengthened regulation of operating sites, we are taking measures to

boost information gathering and analysis activities regarding laws and

regulations on wastewater and emissions in emerging countries. We

are also reinforcing risk management in plating processes, where there

is a relatively high risk of environmental pollution associated with

wastewater treatment as a certain volume of heavy metals is used. As

some of our plating contractors, who constitute tier-two suppliers, lack

an in-house wastewater treatment facility and subcontract services to a

wastewater treatment provider, Canon now also verifies the

compliance status of these subcontractors. Expanding the scope of risk

management in this way helps ensure that pollution is prevented in

advance.

Hazardous Chemical Substances Management System

You might also like

- Supply Chain ManagementDocument11 pagesSupply Chain ManagementToufiq AmanNo ratings yet

- Responsible Supply Chain OverviewDocument6 pagesResponsible Supply Chain Overviewhameed hanifNo ratings yet

- Nokia Supplier 06 WWWDocument12 pagesNokia Supplier 06 WWWanais_lee2010No ratings yet

- Supply Chain ManagementDocument11 pagesSupply Chain Managementkamal1342No ratings yet

- NIKE Inc Statement Forced Labor Human Trafficking Modern Slavery FY22 11.30.2022Document1 pageNIKE Inc Statement Forced Labor Human Trafficking Modern Slavery FY22 11.30.2022NymdavaaNo ratings yet

- Ms Statement-2022 (1)Document8 pagesMs Statement-2022 (1)omm berNo ratings yet

- Canon Inc. Corporate Social ResponsibilityDocument8 pagesCanon Inc. Corporate Social ResponsibilityMa. Monica De Los TrinosNo ratings yet

- Sony Global - Supply Chain ManagementDocument7 pagesSony Global - Supply Chain ManagementSamir SuljkanovicNo ratings yet

- ICC Guide To Responsible SourcingDocument16 pagesICC Guide To Responsible SourcingLoai100% (1)

- Concept of Sustainable Supply Chain2Document8 pagesConcept of Sustainable Supply Chain2sanzitNo ratings yet

- Current ConcernsDocument6 pagesCurrent ConcernswandiganamunyakNo ratings yet

- Acer Supplier Code of Conduct AuditsDocument6 pagesAcer Supplier Code of Conduct AuditsshaherikhkhanNo ratings yet

- Value Chain: P. 70 Working With Our Suppliers P. 72 Working With Our DealersDocument5 pagesValue Chain: P. 70 Working With Our Suppliers P. 72 Working With Our DealersTaVoVelaNo ratings yet

- Understanding Supply Chain Due Diligence - TauliaDocument3 pagesUnderstanding Supply Chain Due Diligence - TauliaNajaraNo ratings yet

- Practices of Good Governance ofDocument6 pagesPractices of Good Governance ofRosemarie Ű RodolfoNo ratings yet

- Sustainable Supply Chain ManagementDocument12 pagesSustainable Supply Chain ManagementGlobal Supply Chain Council100% (3)

- Corporate Social and Environmental Responsibility A Short Report On IKEA B.VDocument8 pagesCorporate Social and Environmental Responsibility A Short Report On IKEA B.VbrazzrNo ratings yet

- History and Impact of Business EthicsDocument7 pagesHistory and Impact of Business Ethicsdaisy mfumbaikaNo ratings yet

- Apple SR 2016 Progress ReportDocument33 pagesApple SR 2016 Progress Reportโยอันนา ยุนอา แคทเธอรีน เอี่ยมสุวรรณNo ratings yet

- Cem Ödev EKSTRADocument8 pagesCem Ödev EKSTRAiremNo ratings yet

- Risk Review Committee Recommendation Letter On Serving Clients in Controversial Industries (10) - Bia-FileDocument2 pagesRisk Review Committee Recommendation Letter On Serving Clients in Controversial Industries (10) - Bia-FiledalasvidmanNo ratings yet

- Nike's Strategy To Improve Conditions in Its Global Supply Chain A Mini-CaseDocument7 pagesNike's Strategy To Improve Conditions in Its Global Supply Chain A Mini-CaseHoai Thuong Le100% (1)

- 2nd January, 2021Document23 pages2nd January, 2021Anjum OnyNo ratings yet

- Apple Supplier Responsibility 2016 Progress ReportDocument33 pagesApple Supplier Responsibility 2016 Progress ReportappleinsiderNo ratings yet

- Supply Chain RisksDocument18 pagesSupply Chain RisksMakhjanul IslamNo ratings yet

- ISO 14001 Step by Step - A practical guide: Second editionFrom EverandISO 14001 Step by Step - A practical guide: Second editionRating: 5 out of 5 stars5/5 (1)

- Yamaha Supply Chain Breakdown by RegionDocument7 pagesYamaha Supply Chain Breakdown by RegionkagneyNo ratings yet

- 2 BSR Case StudyDocument10 pages2 BSR Case StudyAamir WaseemNo ratings yet

- What Is Nike's Responsibility For Harms in Its Supply Chain?Document2 pagesWhat Is Nike's Responsibility For Harms in Its Supply Chain?mona fathyNo ratings yet

- Our ReportingDocument51 pagesOur ReportingPatrick Ferguson AssuahNo ratings yet

- Responsible Suppliers DeclarationDocument3 pagesResponsible Suppliers DeclarationFlexatherm HONo ratings yet

- Corporate Governace (TY BBA 5th Practical Studies 2)Document16 pagesCorporate Governace (TY BBA 5th Practical Studies 2)Payal BhattNo ratings yet

- Executive SummaryDocument5 pagesExecutive SummaryRahul Singh DeoNo ratings yet

- Dyson ATADocument2 pagesDyson ATADisha GoelNo ratings yet

- Hakan Tozan+Alper Erturk - Book - Applications of Contemporary Management Approaches in Supply Chains PDFDocument166 pagesHakan Tozan+Alper Erturk - Book - Applications of Contemporary Management Approaches in Supply Chains PDFJose LaraNo ratings yet

- Managing Quality: An Essential Guide and Resource GatewayFrom EverandManaging Quality: An Essential Guide and Resource GatewayRating: 5 out of 5 stars5/5 (3)

- The Sony Group Code of ConductDocument4 pagesThe Sony Group Code of ConductShane CabinganNo ratings yet

- A Sample Questionnaire OutlineDocument10 pagesA Sample Questionnaire OutlineNaznina MehzabinNo ratings yet

- Business Continuity Management Systems: Implementation and certification to ISO 22301From EverandBusiness Continuity Management Systems: Implementation and certification to ISO 22301No ratings yet

- EthicsDocument6 pagesEthicsGungun JainNo ratings yet

- Health Safety & Environment: Management SystemDocument48 pagesHealth Safety & Environment: Management SystemElias Moussa100% (1)

- Coca ColaDocument18 pagesCoca ColaMehwish AwanNo ratings yet

- Document 1Document4 pagesDocument 1Kavin PillayNo ratings yet

- Corporate Social ResponsibilityDocument28 pagesCorporate Social ResponsibilityMarium HSNo ratings yet

- Buisiness Ethics - Nike Case StudyDocument2 pagesBuisiness Ethics - Nike Case Studydilip_992002100% (1)

- Global Sourcing PrinciplesDocument12 pagesGlobal Sourcing PrinciplessejalsehgalNo ratings yet

- ArcelorMittal Responsible Sourcing GuideDocument24 pagesArcelorMittal Responsible Sourcing GuideadNo ratings yet

- CSRDocument8 pagesCSRShadeen RajaNo ratings yet

- Case 24 AssignmentDocument5 pagesCase 24 Assignmentaishwarya swaroopNo ratings yet

- Establishing and Implementing The Sony Group Policy For Responsible Supply Chain of MineralsDocument5 pagesEstablishing and Implementing The Sony Group Policy For Responsible Supply Chain of MineralsSitio BayabasanNo ratings yet

- Sustainable Supply ChainDocument12 pagesSustainable Supply Chainpratik9967No ratings yet

- Adidas - Supply Chain ApproachDocument13 pagesAdidas - Supply Chain ApproachAlvaro Casas CobaledaNo ratings yet

- Supply Chain Mini Project PDFDocument14 pagesSupply Chain Mini Project PDFarun kumarNo ratings yet

- GGSR - Chapter 6Document18 pagesGGSR - Chapter 6Steffanie OlivarNo ratings yet

- Electronic Industry Code of Conduct Guideline SummaryDocument5 pagesElectronic Industry Code of Conduct Guideline Summarypseudo_klNo ratings yet

- Case Study SCM - HP PDFDocument21 pagesCase Study SCM - HP PDFAna BashtoNo ratings yet

- CCS 4204 Lecture 2Document27 pagesCCS 4204 Lecture 2AnthonyNo ratings yet

- Project Report: Name: Haseeb Ur RehmanDocument5 pagesProject Report: Name: Haseeb Ur RehmanMehdi AdileeNo ratings yet

- Types of Hazard in The WorkplaceDocument29 pagesTypes of Hazard in The Workplacemonaliza gumbayNo ratings yet

- Official EIA 625 Southern BypassDocument105 pagesOfficial EIA 625 Southern BypassPaula Kahumbu100% (1)

- HSE ViolationDocument1 pageHSE ViolationVIKASNo ratings yet

- Health, Safety & Environment: Risk Assessment For FIRE PROTECTION AND FIRE ALARM SYSTEM Preventive Maintenance ActivitiesDocument2 pagesHealth, Safety & Environment: Risk Assessment For FIRE PROTECTION AND FIRE ALARM SYSTEM Preventive Maintenance Activitiesbelhareth seifeddineNo ratings yet

- Major Hazard Control Standards: Management StandardDocument23 pagesMajor Hazard Control Standards: Management StandardTimNo ratings yet

- PROJ MNGRS - SACPCMP - Tariff of Fees - Eff - Sep2019 PDFDocument16 pagesPROJ MNGRS - SACPCMP - Tariff of Fees - Eff - Sep2019 PDFStranger J. MonarengNo ratings yet

- Eosin Y Safety Data SheetDocument6 pagesEosin Y Safety Data SheetFISR FAPSRNo ratings yet

- TR Emergency Medical Services NC II 2013Document92 pagesTR Emergency Medical Services NC II 2013Eustace TrifalgarNo ratings yet

- Standard 13Document22 pagesStandard 13Bridget Gumbo100% (1)

- Incident Reporting Policy General Policy Gp8Document28 pagesIncident Reporting Policy General Policy Gp8Marvin CamalNo ratings yet

- Yanbu Ii Power & Water Project: Method Statement For U/G Piping Installation & Lamination of GRPDocument47 pagesYanbu Ii Power & Water Project: Method Statement For U/G Piping Installation & Lamination of GRPric leonisoNo ratings yet

- Gas Pressure Regulator RS 250 / RS 251: Operating and Maintenance InstructionsDocument52 pagesGas Pressure Regulator RS 250 / RS 251: Operating and Maintenance InstructionsAdilson Melo de MouraNo ratings yet

- Science TechnicianDocument5 pagesScience TechnicianChrist's SchoolNo ratings yet

- ISO 45001 MigrationDocument3 pagesISO 45001 MigrationCONFAB SafetyNo ratings yet

- New Blue-SDSDocument6 pagesNew Blue-SDSHVFS SalesNo ratings yet

- NEBOSH Ncc1 Exam RPT Dec 09Document5 pagesNEBOSH Ncc1 Exam RPT Dec 09Yan MusevNo ratings yet

- DLL - Tle Ict CSS 10 - Q1 - D2Document5 pagesDLL - Tle Ict CSS 10 - Q1 - D2Aubz Almelia NavarroNo ratings yet

- Bauer Compressor OilDocument6 pagesBauer Compressor OilSergei KurpishNo ratings yet

- Nebosh Batam Jul 09Document7 pagesNebosh Batam Jul 09supermujiNo ratings yet

- Safe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFDocument36 pagesSafe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFFarid RezaeianNo ratings yet

- Printofix Blue FB RT HPDocument9 pagesPrintofix Blue FB RT HPMayank DhawanNo ratings yet

- CWA 16335 2011 Biosafety Professional Competence (54p)Document54 pagesCWA 16335 2011 Biosafety Professional Competence (54p)Mark Kwan100% (1)

- 3 PDFDocument131 pages3 PDFjoenediath9345No ratings yet

- NIOSH SHO 07-Risk AssessmentDocument58 pagesNIOSH SHO 07-Risk AssessmentIkhmal Ismayatim100% (1)

- Msds Unioleo ChemicalDocument8 pagesMsds Unioleo ChemicalB4nt3nNo ratings yet

- Mediclean MsdsDocument5 pagesMediclean MsdsfischaNo ratings yet

- Flood Testing Methodology for Waterproofing ProjectsDocument6 pagesFlood Testing Methodology for Waterproofing ProjectsBryan BcalNo ratings yet

- Emergency Response Team Updates 2023Document13 pagesEmergency Response Team Updates 2023johnaronecarmeloNo ratings yet

- Lesson 2. Safety in The WorkplaceDocument40 pagesLesson 2. Safety in The WorkplaceTchr Angelle Bliss67% (3)

- BAFE SP101 2017 Scheme Document Draft Consultation Version 1 - January 2017Document24 pagesBAFE SP101 2017 Scheme Document Draft Consultation Version 1 - January 2017orkhan manuchehriNo ratings yet