Professional Documents

Culture Documents

QMS-ENG-D-002 General Quality Plan

Uploaded by

shalukaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QMS-ENG-D-002 General Quality Plan

Uploaded by

shalukaCopyright:

Available Formats

GENERAL QUALITY PLAN Doc No.

QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

Check list for

1.Contract Document PM / Eng / SE/ site take over &

requirements TO mobilization

(CL 01)

2. Past performance of

Suppliers

Suppliers and Sub Supervisor

evaluation,

Contractors Within the

Awarding

time period 1.Supply 2.Check with

Site take over and latter,BOQ, During site

1 3. Brand, Gauge, mention in the incorrect the approved

Mobilization drawings & Client mobilization Suppliers

Material size, Quantity, awarding Material materials

specification performance

Price, Punctuality and as letter.

sheet,

per specifications

Material test

4.Sample test of material

reports,

5.Consultant approval of Sub contractor’s

material agreements.

Should be

Awarding clean enough

1.Check with Check list for

latter,BOQ, 1.Get the consultant’s During & After to carry out 1.Clering PM / Eng / SE /

2 Site Clearing the client land site clearing (CL

drawings & Client approvals the site clearing setting out other land TO

area 02)

specification without any

obstruction.

2.Used the proper 2.Not clearing

2.Reclering Soil test report

equipment & machines properly

Issue 01, dated 2017 - 01 - 02 Page 1 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

3.Removal of structures

4.Removal of trees which

could obstruct the work

5.Removal of top soil

layer with the

vegetations (150mm)

6.Soil test(If required)

7.Barricate exiting power

cable / water supply line

& drainage line in use

1.Get the consultant’s

At start work

approvals

BOQ, drawings & 2, Parallel /Perpendicular During work Dimensions of 1.error of Measuring Check list for

to existing building PM / Eng /

3 Setting out-General Client setting out measuring equipment setting out-

survey / TO

specification drawing. equipment Calibration General (CL 03)

3, Checking diagonals At end work

4, Cross checking

dimensions from two or

more directions

1.Get the consultant’s During & After Check list for

Setting out-Anchor

4 approvals for anchor bolt the Anchor Bolt setting out-

bolt placing Placing

material General (CL 03)

Issue 01, dated 2017 - 01 - 02 Page 2 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

Strength repot of

2. Quality of material

material

3. diameter & heights of

anchor bolts

4. checking template

measurement &

Thickness

5. Suitability of welding

equipment

6. Skill of welder

7. Thickness of welding

8. Checking diagonals

9. Protection of threaded

area

10. Check with the

existing floor level

Check list for

BOQ, drawings &

Excavation and Earth 1.Get the consultant’s SCA /4 Building 1.Using proper PM / Eng / SE / Excavation &

5 consultants During work 1.Earth claps

work. approvals works. shoring method TO Earth work (CL

specification,

05)

After each

2.Dimension excavation, Supervisor Level sheet

After backfilling.

Compaction test

3.Height

report

4.Levels

Issue 01, dated 2017 - 01 - 02 Page 3 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

5.Disposal of excavated

materials

6.Dewatering & Shoring

7.Method of shoring

8.Used the proper

equipment & machines

9.Quality of shoring

material

10.Quality of soil

11.Back filling layer

thickness

12.Sand binding layer

13.Watering & vibrating

14.Back filling &

Compactions method

15.Compaction test

BOQ, drawings & Check list for

1.Get the consultant’s SCA /4 Building PM / Eng / SE /

6 Screed Concreting consultants At start screed concrete

approval works. TO

specification (CL 06)

2.Thickness of screed During work Supervisor Slum test

Material test

.3Grade of Concrete

reports,

Issue 01, dated 2017 - 01 - 02 Page 4 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

Sub contractor’s

4.Aggregates

agreements.

5.Polythene is

required/not

6.Leveling

7.Dimension

8.Water cement ratio

9.Mixing method &

mixing equipment

condition

10.Slum test

11.Curing

1.Making

BOQ, drawings & Check list for

Random Rubble 1.Get the consultant’s SCA /4 Building drawings PM / Eng / SE /

7 consultant At start work 1.Wall crack Random Rubble

masonry approvals works. marking TO

specification Masonary (CL 07)

expansion joint

2.Using proper Sub contractor’s

2.Dimensions, During work Supervisor

mortar ratio agreements.

3.Alignment, At end work

4.Levels

5.Type of bond curing,

6.Type of wall

7.Size of rubble

8.Mortar ratio

Issue 01, dated 2017 - 01 - 02 Page 5 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

9.Expression joints,

10.Mortar quality

11.Weep holes

12.Finishing of wall

surface

BOQ, drawings & 1.Mistakes of Check list for

1.Get the consultant’s SCA /4 Building 1.check with PM / Eng / Qs /

8 Gabion wall consultant At start work wall level and gabion wall (CL

approvals. works. level and wide SE

specification wide 08)

2.Dimensions, During work Supervisor

3.Alignment, At end work

4.Levels

5.thickness of geo textile

6.gauge of gabion net

7.Used the proper

equipment & machines

8.Dewatering & Shoring

9.Shoring method

10.Size of rubble

11.Finishing of surface

2.Evertime

BOQ, drawings & 1.wrong bar check with the Check list for

1.Get the consultant’s SCA /4 Building PM / Eng / Qs /

9 Reinforcement work consultant At start work spacing and drawings bar reinforcement

approvals works. TO

specification lap length spacing and lap work(CL 09)

length

2.Quality of bar (SLS

Bar schedule During work Supervisor bar schedule

certified)

Issue 01, dated 2017 - 01 - 02 Page 6 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

3.Stability of the

At end work

reinforcement

4.Check with bar

schedule

5.Bar diameter

6.Clear cover

7.Cleanliness

8.Bar spacing

9.Stools & Cover blocks

10.Check with the

consultant approved lap

length

11.Check with the bar

type & marking

12.lap joints

BOQ, drawings & 2.Using proper Check list for

1.Get the consultant’s SCA /4 Building 1.Wrong PM / Eng / Qs /

10 Form work consultant At start work vertical Form work (CL

approvals works. alignment TO

specification supports 10)

2.Dimension During work Supervisor

3.Alignments

4.Accuracy of levels

5.Vertical and lateral

support

6.Quality of materials

7.Type of form work

method

Issue 01, dated 2017 - 01 - 02 Page 7 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

8.Clear cover with the

reinforcement

9.Type of form work

material (steel or timber)

10.Quality of work

Check list for

Concreting Work concrete work

BOQ, drawings &

(Footing, Columns, 1. Get the consultant’s SCA /4 Building 1. Concrete 1.properly PM / Eng / Qs / (Footing,

11 consultant At start work

Beams, Walls & approvals works. floor cracking. curing TO Columns, Beams,

specification

Others) Walls & Others)

(CL 11)

2.Using proper

2.Levels & Dimension During work 2.Hony comb vibrating Supervisor Test report

method

3.Condition of

At end work Slum test

equipment

4. Aggregates Level sheet

5.Grade of concrete

6. Slum

7.Setting time,

8.Final cleaning &

Checking

9.Test Cube

10. Compaction method

Issue 01, dated 2017 - 01 - 02 Page 8 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

11. Finishes(Honeycomb)

12. Curing & Protection

13. Vertical alignment

14. Protection of anchor

bolt

15. Bonding method &

chemicals

16. Used the proper

equipment & machines

Check list for

Concrete Works 1.Get the consultant’s SCA /4 Building 1. Concrete 1.properly PM / Eng / Qs / concrete work

12 At start work

(floor & slab) approvals works. floor cracking. curing TO (Floor & Slab)

(CL12)

2.Using proper

2.Levels & Dimension During work 2.Hony comb vibrating Supervisor Test report

method

3.Condition of

At end work Slum test

equipment

4.Aggregates Level sheet

5.Grade of concrete

6.Slum

7.setting time,

8.Final cleaning &

Checking

9.Test Cube

10.compaction method

Issue 01, dated 2017 - 01 - 02 Page 9 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

11.Curing & Protection

12.Protection of anchor

bolt

13 Protection of anchor

bolt

14. Bonding method &

chemicals

15. Type of finishing

16. Expansion or

construction joint

17. curing method

18. Used the proper

equipment & machines

19. Anti- termite method

20. Gauge of polythene

After removing form

work

21.Beam or wall

alignment

22.Finishes

(Honeycomb)

BOQ, drawings & Check list for

Brick/Block masonry 1.Get the consultant’s

13 consultant brick/block

work approvals

specification masonry (CL13)

Issue 01, dated 2017 - 01 - 02 Page 10 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

SCA /4 Building 1.making PM / Eng / Qs /

2.Dimension At start work 1.Wall crack Test report

works. expansion joint TO

2.Insert of

3.Verticality During work Supervisor

Bonding mesh

4.Right angles

5.Alignment

6.Type of bond,

7. Curing.

8. Stiffener columns.

9. Mortar thickness

10.Openings to be

provided

11.Type of wall

12. Quality of material

13. Test report

14. Size of Brick/block

15. Mortar ratio

16. Size of wall

17. Quality of wall

1.idetify the

BOQ, drawings & Check list for

1.Get the consultant’s SCA /4 Building 1.Water leakage point PM / Eng / Qs /

14 Water proofing work consultant At start work water proofing

approvals works. leakage and re-water TO

specification work (CL13)

proofing

2.Compliance with Grantee

During work Supervisor

specification certificate

3.quality of materials At end of work

4.Quality of equipment

Issue 01, dated 2017 - 01 - 02 Page 11 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

5.Surface preparation

6.Remove dust ,oil and

water on the floor

7.1st coat of

waterproofing

8.2nd coat of

waterproofing

9. Setting time

10. Protective screed.

11. Skill of worker

12, Thickness of layers

13. Thickness of water

proofing members

14. Angle & height of

fillet

15. Setting time

16. Mixing method &

ratio

17. Fixing joints

Check list for

BOQ, drawings & 1. Suitability of

Loading of steel PM / Eng / Qs / Loading of steel

15 Consultant machinery weight At start work

structure TO structure

specification capacity & length

(CL 15)

Packing list 2. Surface of unloading During work Supervisor

2. Method of unloading At end work

3. Damages

Issue 01, dated 2017 - 01 - 02 Page 12 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

BOQ, drawings & Check list for

1. Suitability of

Unloading of steel Consultant Unloading of

16 machinery weight

structure specification steel structure

capacity & length

Packing list (CL 16)

2. Method of packing Packing list

3. Quality of packing

4. Check with the packing

list

4. Check with the packing

list

Check list for

BOQ, drawings & 1.Get the consultant’s 1.Marking it

Fabrication of steel SCA /4 Building 1.change the PM / Eng / Qs / Fabrication of

17 Consultant approvals materials & At start work properly after

structure works. marking TO steel structure

specification fabrication drawings fabrication

(CL 17)

2.Close the

2.Punching the Welding check

2.Quality of materials, During work marking after Supervisor

marking list

painting

3.Sutability of welding & 3. Cracking of 3. Grinding and

At end work

drilling equipment welding joints re welding

4.Dimensions & 4.Damage of 4.safely loading

Thickness of materials painting and unloading

5.Cutting joints & edges,

6. Suitability of Cutting

equipment

Issue 01, dated 2017 - 01 - 02 Page 13 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

7. Suitability of surface to

be welded

8. Correctness of

drawings

9. Skill of welder &

fabricator

10. Correctness of

marking line & point

11. Thickness of welding

12. Surface cleaning

13. Levels

14. Alignment

15. Correctness of holes

punching

16. Welding check list

BOQ, drawings

1.Get the consultant’s Check list for

Painting of steel client & PM / Eng / Qs /

18 approvals materials & At start work Painting of steel

structure Consultant TO

fabrication drawings structure (CL18)

specification

painting check

2. Surface cleaning During work Supervisor

list

3. Sand blasting or soft

At end work

blasting.

4. Application of primer

(Anticorrosive)

Issue 01, dated 2017 - 01 - 02 Page 14 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

5. Layer of painting coats

6. Thickness of painting

coats

7. Colour

8. Skill of painter

9. Covering area for paint

yard

10. painting check list

BOQ, drawings & 1.Get the consultant’s Check list for

Erecting of steel PM / Eng / Qs /

19 Consultant approvals for errection At start work Erecting steel

structure TO

specification method structure (CL19)

2. Correctness of anchor

Erecting manual During work Supervisor

bolts

3. Suitability of

machinery weight At end work

capacity & length

4. Skill of erector

5. Safety rule &

regulation

6. Leveling of base plate

7. Starting of first bracing

bay & alignment

8. Gauge of nut & bolt

Issue 01, dated 2017 - 01 - 02 Page 15 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

9. Tightness of joints

BOQ, drawings & 1.Change the 1.Check with

Check list for

Fixing Doors & Client & 1.Get the consultant’s SCA /4 Building door or the door PM / Eng / Qs /

20 At start work fixing door &

Windows consultant approvals works. window window TO

window (CL20)

specification materials schedule

2.Quality of materials During work Supervisor

3.Colour At end work

4.Cutting

5.Sizes & Type

5.Thickness or Gauge

6.Dimensions,

7.fixing joints

8.Alignment

9.Fixing ironmongery

10.Fixing glasses

11.Fixing accessories

12.Levels

14.Protection

BOQ, drawings & SCA /8-

1.Properly Check list for

Client & 1.Get the consultant’s Electrical and 1.Current PM / Eng / Qs /

21 Electrical Work At start work insulation of electrical work

consultant approvals Mechanical leakage TO

joints (CL21)

specification works.

2. Preparation of the

During work Supervisor As built drawings

shop drawing

Electrical

3.Quality of materials At end work

certificate

4. Laying of conduits

Issue 01, dated 2017 - 01 - 02 Page 16 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

5. Breaking and drilling

the walls for piping

6. wiring the electrical

lines

7. Temporary fixing of

the sunk boxes

8. Permanent fixing of

sun boxes and dist

boards after completion

of plastering

9. Fixing of switches and

socket outlets

10. Fixing of earth

electrode

11. Insulation testing,

Earth resistance testing

12. Fixing of electrical

fittings & Accessories

13. Quality of accessories

14. Protection marking of

underground cable (

laying sand & tile)

Issue 01, dated 2017 - 01 - 02 Page 17 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

15. Size of cable

16. Weight capacity of

cable tray

17. Load capacity of

MCB,Baker & Fittings

18. Load capacity of

cable

19. Skill of electrician

20. Power testing

(whether working or

not?)

21. Existing area as built

drawings

22. Fixing level

Check list for

BOQ, drawings & 1.Change the

Plumbing & Drainage 1.Get the consultant’s SCA /4 Building 1.Over flow of PM / Eng / Qs / plumbing &

22 consultant At start work level or making

Work approvals works. man hole TO drainage work

specification extra line

(CL 22)

As built drawings

2.Quality of materials During work Supervisor

3. Type & Size of the

At end work

pipes and fittings

4. Dimensions of pipes

5. Positions and levels of

the pipes

Issue 01, dated 2017 - 01 - 02 Page 18 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

6. Groves and holes in

floor and walls

7. Fittings and joints

8. Fixing accessories

9. Standard of

accessories & fitting

10. Fixing level of fitting

& accessories

11. Spacing of man holes

12. Capacity of septic &

soakage pit

13. Levels

14. Slopes

15. pressure testing

16.Complete with all

connections to gully &

manholes

.17. Existing area as built

drawings

BOQ, drawings &

Client ,

Check list for

consultant 1.Get the consultant’s SCA /4 Building 1.Wrong fixing PM / Eng / Qs /

23 Sanitary ware At start work 1.Refixing sanitary ware

specification approvals works. height TO

(CL 23)

Fixing

specification

2. Quality of material During work Supervisor

Issue 01, dated 2017 - 01 - 02 Page 19 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

3. Surface preparations At end work

4. Plumbing work.

5. Fixing height

6. Colour

7. Type of standard

8. Dimension

BOQ, drawings &

1.Get the consultant’s SCA /4 Building 1.Ceiling sheet 1.Change bar PM / Eng / Qs / ceiling

24 Ceiling Work consultant At start work

approvals works. sagging spacing TO work(CL24)

specification

2.Type During work Supervisor

3. Quality of materials At end work

4. Thickness

5. Dimensions

6. Ceiling Level

7. Painting

8. Neatness

9. Opening for service

line

10.Color

BOQ, drawings

Client & 1.Get the consultant’s SCA /4 Building 1.Roof sheet PM / Eng / Qs / Check list for

25 Roof Work At start work 1.Roof leakage

consultant approvals works. replace TO roof work (CL25)

specification

2.Apply water

2.Type of roof During work Supervisor

proof chemical

3. Quality of materials At end work

Issue 01, dated 2017 - 01 - 02 Page 20 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

4. Thickness of roof

sheet/tile

5. Dimensions of roof

sheet / tile

6. Color of roof sheet /

tile

6. Roof angle/curvature

7. Wall plate level.

8. Painting

9 .Neatness

10.Color of inside the

roof

11.Spacing of roof nail

point / hooks

12. Roof ventilation

system required or not

13. Type of insulation

14.Thickness of

insulation

15. Spacing of purling

16. Sky light area

17. Gauge & length of

nail / hook

18. Quality of nail & hook

Issue 01, dated 2017 - 01 - 02 Page 21 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

BOQ, drawings

1.Over flow of 1.Change the Check list for

consultant & 1.Get the consultant’s SCA /4 Building PM / Eng / Qs /

26 Roof plumbing. At start work gutter ,down down pipe roof plumbing

Client approvals works. TO

pipe &gutter size (CL 26)

specification

2.Gutter

2.Rectification

2. Quality of material During work ,down pipe Supervisor

of leakage point

leakage

3. Dimensions At end work

4.Cutting joints

5.Levels of gutter &

down pipe

6.Alignment of gutter &

down pipe

7.Fixing accessories

8. Type & Size of the

pipes and fittings

9. Positions and levels of

the pipes

10. Fittings and fixtures

11. joints

12. Dimensions of pipes

13.Slopes

16. Alignment of pipe &

Valance board

15.Including paint &

primer

Issue 01, dated 2017 - 01 - 02 Page 22 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

16. Thickness of pipe &

gutter

1.Dimolished

BOQ, drawings & Check list for

1.Get the consultant’s SCA /4 Building 1.Plaster cracking line PM / Eng / Qs /

27 Plastering work Client At start work Plastering Work

approvals works. cracking and insert mesh TO

specification (CL 27)

, re-plastering

2. Whether the surface is

clean any free from all During work Supervisor

dust

3.Leveling At end work

4. Mortar quality

5. Plastering thickness

6. Vertical & horizontal

alignment with other

wall finishes

7. Corners & edges

8. Size of openings

9. surface condition

10.Quality of sand

11. Mortar ratio

12. Bonding mesh

13. Neatness

14. Right angles

15. Curing

Issue 01, dated 2017 - 01 - 02 Page 23 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

16. Protection of

electrical item , door &

window frame , pipe line

17. Molding

Check list for

BOQ, drawings &

Cement rendering 1.Get the consultant’s SCA /4 Building 1.Surface 1.Properly PM / Eng / Qs / cement

28 Client At start work

work approvals works. cracking curing TO rendering work

specification

(CL 28)

2.macking

2.wrong

correct opening

2. Surface preparations During work opening for Supervisor

& -re-rendering

service line

wrong opening

3. Levels of bed At end work

4. Mortar quality

5. Thickness of mortar

6. Color of cement grout

7. Cement grouting

8. finishing of surface

9. Surface curing

10.Motar ratio

11. Slop

12. Opening for service

line/fitting

13. Neatness

Issue 01, dated 2017 - 01 - 02 Page 24 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

BOQ, drawings

1.Changing of Check list for

consultant & 1.Get the consultant’s SCA /4 Building 1.Purching with PM / Eng / Qs /

29 Tiling work. At start work colour or tiling work (CL

Client approvals works. the sample TO

design 29)

specification

2. Quality of material During work Supervisor

3. Surface preparations At end work

4. Levels of tile bed

5. Colour & size of tile

6. Type of tile

7. Thickness of tile

8. Wetting of tiles for at

least one hour period

before fixing

9. Mortar quality &

thickness

10. Apply even mortar

thickness

11. Maintaining Tile

surface level

12. Maintaining even

grove size

13.Preventing air voids

between tile bed &

corners

14. Neatness of edges &

corners

Issue 01, dated 2017 - 01 - 02 Page 25 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

15.Alignment of grove

16. Surface Cleaning

before grouting

17. Colour of Tile grout

18. Tile grouting

19. Maintaining Slop if

required

20. Protection cover for

tile floor

BOQ, drawings

1.match with Check list for

consultant & 1.Get the consultant’s 1.Colour PM / Eng / Qs /

30 Painting work At start work SCA /4 Building existing colour painting work

Client approvals changing TO

sample (CL 30)

specification

2.Apply sample

Mixing

2. Quality of materials, During work works. one get the Supervisor

specification

approvel

3. Surface dust & oil

At end work

cleaning

4. Surface preparation

5. Colour

6. Anti-fungus paint for

external

7. Method of painting

8. Mixing ratio

9. Apply two coats of

wall putty

Issue 01, dated 2017 - 01 - 02 Page 26 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

10. Protection of other

areas.

11. Edges & corners

preparation

12. Apply filler coats

(Primer)

13. First coat of

approved type paint

14. Touchup works

15. Second coat of

approved type paint

16. Thickness of paint

17. Final Inspection

Check list for

MD

BOQ, drawings & After Completion of

Completion of work 1. Complete balance Contract 1.Rectification /CONSULTANT

31 Client completion of 1.Defects work & Final

& Final Inspections work Document work CLIENT / PM /

specification constructions Inspections (CL

ENG

31)

Customer

2.Cleaning all area Section 3 satisfaction

report & letter

Condition of

3.Identified defects

Contract,

4.Get the consultants

Clause 55.1

approvals

5.Get the client

satisfaction

Issue 01, dated 2017 - 01 - 02 Page 27 of 28

Review By........................................MR Approved By....................................MD

GENERAL QUALITY PLAN Doc No. QMS/ENG/D/002

Related Record to prove

Frequency of Requirement / Possible Action Responsibility

document Applicable verification / Possible Non that verification

SL No Activity verification / standard to be for Non of verification /

involved in the Monitoring Conformities / monitoring

monitoring met Conformities monitoring

activity done

Project

Agreement, BOQ,

drawings &

consultant, Client

Handing over the After

specification, as Contract MD/PM/ENG/ Handing over

32 project & 1.Delivery date rectification of

built drawings, Document T O letter

Maintenance period list of defects.

guarantee

certificates,

warrantee cards

list of key

2.Delayed period Section 3 SUPERVISOR

Condition of

3.Retention date

Contract,

Clause 56.1

Issue 01, dated 2017 - 01 - 02 Page 28 of 28

Review By........................................MR Approved By....................................MD

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 4 - AOA NetworksDocument45 pages4 - AOA NetworksshalukaNo ratings yet

- A Review of Piano Key Weir As A SuperiorDocument12 pagesA Review of Piano Key Weir As A SuperiorshalukaNo ratings yet

- 303ENG20006 - S. WijesiriDocument9 pages303ENG20006 - S. WijesirishalukaNo ratings yet

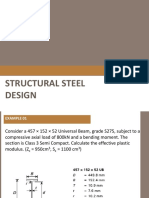

- Structural Steel DesignDocument32 pagesStructural Steel Designshaluka100% (1)

- Lecture 01Document49 pagesLecture 01shalukaNo ratings yet

- Structural Steel DesignDocument32 pagesStructural Steel DesignshalukaNo ratings yet

- The Beatles CUTTING - UP - A - GLASS - ONION - READING - THE - BEADocument18 pagesThe Beatles CUTTING - UP - A - GLASS - ONION - READING - THE - BEAshalukaNo ratings yet

- CE9053 - Assignment 1Document4 pagesCE9053 - Assignment 1shalukaNo ratings yet

- Training Report 2Document51 pagesTraining Report 2shalukaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Drambo ManualDocument38 pagesDrambo ManualMatthew HartmanNo ratings yet

- PHP Coding Sample QuestionDocument63 pagesPHP Coding Sample QuestionAbhinav Raj EJAqXCJLYLNo ratings yet

- How To Activate SMART GPRS - 3G Settings - Access Point Names (APN) - HowToQuickDocument5 pagesHow To Activate SMART GPRS - 3G Settings - Access Point Names (APN) - HowToQuickBryan MagnayeNo ratings yet

- Weebb 1Document3 pagesWeebb 1api-581438961No ratings yet

- Standa Modules 2022Document39 pagesStanda Modules 2022vlado_314No ratings yet

- تقريرات بدء الأمالي للشيخ ميمون زبير السارانيDocument41 pagesتقريرات بدء الأمالي للشيخ ميمون زبير السارانيRidwan FuadNo ratings yet

- DOL StartersDocument2 pagesDOL StartersAbhi TiwariNo ratings yet

- Saif Powertec Limited Project "Standard Operating Process" As-Is DocumentDocument6 pagesSaif Powertec Limited Project "Standard Operating Process" As-Is DocumentAbhishekChowdhuryNo ratings yet

- DS Tic Tac Toe DocumentationDocument20 pagesDS Tic Tac Toe DocumentationB. S BabuNo ratings yet

- Bale Opening and Carding MachineDocument4 pagesBale Opening and Carding MachineMaruf Uddin Ahmed100% (4)

- Vande Bharat Ex Chair Car (CC)Document3 pagesVande Bharat Ex Chair Car (CC)M SHANVINo ratings yet

- Assignment No. 4 Harsh TaydeDocument11 pagesAssignment No. 4 Harsh TaydeFridyNo ratings yet

- EN Komplett Set Active Sound Mit Sound Booster Audi A6 A7 4GDocument18 pagesEN Komplett Set Active Sound Mit Sound Booster Audi A6 A7 4GIstván PatakiNo ratings yet

- STAT 714 Linear Statistical Models: Lecture NotesDocument150 pagesSTAT 714 Linear Statistical Models: Lecture NotesFucKerWengieNo ratings yet

- BMBS For Freight Stock-SKDocument25 pagesBMBS For Freight Stock-SKSoumen BhattaNo ratings yet

- Mathematische Annalen: Extreme Values of The Riemann Zeta Function and Its ArgumentDocument17 pagesMathematische Annalen: Extreme Values of The Riemann Zeta Function and Its ArgumentSam TaylorNo ratings yet

- FRM - Model Risk - TP059572Document16 pagesFRM - Model Risk - TP059572Sidrah RakhangeNo ratings yet

- What S New in CSS3 - PDF Books PDFDocument38 pagesWhat S New in CSS3 - PDF Books PDFismarovskiNo ratings yet

- YET402PC-WIFI 2-Circuit Smart Receiving Controller Manual: V1.0 ContentDocument8 pagesYET402PC-WIFI 2-Circuit Smart Receiving Controller Manual: V1.0 ContentLuisCarlosLiraPulgarNo ratings yet

- Design of SlabDocument26 pagesDesign of SlabSumanth SangemNo ratings yet

- Graphs Breadth First Search & Depth First Search: by Shailendra UpadhyeDocument21 pagesGraphs Breadth First Search & Depth First Search: by Shailendra Upadhyeجعفر عباسNo ratings yet

- Manual KV Studio V9 PDFDocument542 pagesManual KV Studio V9 PDFMiguel Hitos100% (1)

- The Tale of Johnny Town-MouseDocument10 pagesThe Tale of Johnny Town-Mousesunn0No ratings yet

- GRS 900Document60 pagesGRS 900Luis Manuel Saavedra75% (4)

- IndicSpeech Text-To-Speech Corpus For Indian LanguagesDocument6 pagesIndicSpeech Text-To-Speech Corpus For Indian LanguagesVR IndaNo ratings yet

- T500 - Parts Book - 12261-228 - 09-01-2002Document206 pagesT500 - Parts Book - 12261-228 - 09-01-2002gustavo enriquez67% (3)

- M XszzwyDocument8 pagesM XszzwyRADON electronicsNo ratings yet

- WedgeARP AMB v2.1 Training - Module G - OperationsDocument59 pagesWedgeARP AMB v2.1 Training - Module G - Operationsahmed gaafarNo ratings yet

- An Integrated Approach To Vehicle and Subsystem Sizing and Analysis For Novel Subsystem ArchitecturesDocument19 pagesAn Integrated Approach To Vehicle and Subsystem Sizing and Analysis For Novel Subsystem ArchitecturesO GoogleNo ratings yet

- Class 10 Science Notes in Hindi-Genetics-And-Biological-Evolution PDFDocument15 pagesClass 10 Science Notes in Hindi-Genetics-And-Biological-Evolution PDFVinothKumarVinothNo ratings yet