Professional Documents

Culture Documents

Crosby® Alloy Easy-Loc® Shackles83

Uploaded by

elias aouadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crosby® Alloy Easy-Loc® Shackles83

Uploaded by

elias aouadCopyright:

Available Formats

Crosby® Alloy Easy-Loc® Shackles

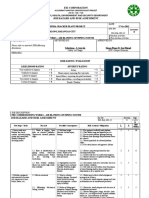

• Quenched and Tempered. G

• Alloy bows, Alloy bolts. L K

• Forged Alloy Steel 200 thru 300 metric tons. Meets performance C

requirements of Grade 8 shackles.

Shackles

• Working Load Limit is permanently shown on every shackle. E

J

• 200, 250, and 300 metric ton shackle bows are Dimetcoted®; pins are

Dimetcoted and painted red.

D

• All sizes are larger than 1-1/2 IN, RFID EQUIPPED.

• Approved for use at -40° C (-40° F) to 204° C (400° F). B

A

F

• Shackles are Quenched and Tempered and can meet DNV impact G H

requirements of 42 Joules (31 ft•lbf) at -20° C (-4° F). L K

G-2140E • All sizes are individually proof tested to 2.0 times the Working Load Limit. C

G-2140E meets the performance

requirements of Federal Specificatio • Refer to page 87 for Crosby COLD TUFF® shackles that meet the additional

RR-C-271G, Type IVA, Grade B, requirements of DNV rules for certification of lifting applications - Loose Gea . E

Class 3, except for those provisions J

required of the contractor. For • Shackles are provided as follows: N

additional information, see page 452.

• Serialized bolt and bow D M

• Material certification (chemical

• Magnetic particle inspected. B

A

• Certification must be requested at time of orde . F

H

• Meets or exceeds all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly,

these shackles meet other critical performance requirements including impact

properties and material traceability, not addressed by ASME B30.26.

• Type Approval certification in accordance with ABS 2016 Steel Vessel Rules

and 2016 ABS Guide for Certification of Lifting Appliances. Certificates

available when requested at time of order and may include additional charges.

• Look for the Red Pin® . . . the mark of genuine Crosby quality.

SEE APPLICATION INFORMATION

On Page 92 of the General Catalog

Para Español: www.thecrosbygroup.com

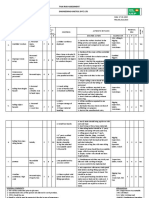

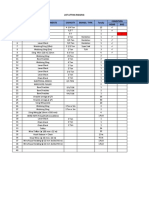

G-2140E Crosby® Alloy Easy-Loc Shackles

Nominal Working Dimensions Tolerance

Shackle Load Stock No. Weight (in) +/-

Size Limit Each D

(in) (t)* G-2140E (lb) A B C +/- .02 E F G H J K L M N A E

4-3/4 † 200 1021475 458 7.25 10.50 5.00 4.75 15.19 4.58 20.84 23.01 27.81 11.00 4.75 4.00 1.80 0.25 0.25

5 † 250 1021484 597 8.50 12.00 5.63 5.00 18.50 4.48 23.63 23.84 32.63 13.00 5.00 4.00 1.80 0.25 0.25

6 † 300 1021493 791 8.38 13.00 6.06 6.00 18.72 4.89 24.76 25.01 34.28 13.00 5.88 4.00 1.80 0.25 0.25

* Note: Maximum Proof Load is 2 times the Working Load Limit. For 200 thru 400 metric tons, Minimum Ultimate Load is 4 times the Working Load Limit. † Furnished with Round Head

Bolts with a handle for handling. For Working Load Limit reduction due to side loading applications, see page 94.

Copyright © 2019 The Crosby Group LLC All Rights Reserved 83

You might also like

- Crosby® Wide Body Shackles85Document1 pageCrosby® Wide Body Shackles85elias aouadNo ratings yet

- Manilhas Crosby G2130Document1 pageManilhas Crosby G2130Álamo NatividadeNo ratings yet

- Crosby G-2150Document1 pageCrosby G-2150jdpardoNo ratings yet

- 1 - Rectangular Duct (Single & Double Wall)Document40 pages1 - Rectangular Duct (Single & Double Wall)Tariq AsgharNo ratings yet

- Crosby G-2140 Alloy Shackle Product SheetDocument1 pageCrosby G-2140 Alloy Shackle Product Sheetmihai_serban13No ratings yet

- Sling Saver Web Sling Shackles: Bolt Type Sling Shackle Screw Pin Sling ShackleDocument1 pageSling Saver Web Sling Shackles: Bolt Type Sling Shackle Screw Pin Sling ShackleKonstantinos SynodinosNo ratings yet

- PacifiCorp Spec TD041Document16 pagesPacifiCorp Spec TD041alexayala5151No ratings yet

- Crosby Shackles G-2130 PDFDocument2 pagesCrosby Shackles G-2130 PDFBolarinwaNo ratings yet

- Crosby ShackleDocument1 pageCrosby Shacklecaner_kurtoglu-1No ratings yet

- Grilletes G-2140, S-2140 CrosbyDocument1 pageGrilletes G-2140, S-2140 CrosbyLuis Manuel Montoya RiveraNo ratings yet

- Wide ShackleDocument1 pageWide ShacklerahulNo ratings yet

- Purlin Data Sheet MEIDocument1 pagePurlin Data Sheet MEIKamal FayazNo ratings yet

- Sta-Kon Rings, Forks and Locking Forks: Ring TerminalsDocument2 pagesSta-Kon Rings, Forks and Locking Forks: Ring TerminalssoayNo ratings yet

- G-2140 / S-2140 Crosby Alloy Bolt Type Anchor ShacklesDocument1 pageG-2140 / S-2140 Crosby Alloy Bolt Type Anchor ShacklessaurabhsubhuNo ratings yet

- G2130, G2140, G2150 Crosby Bolt Anchor Safety Shackles PDFDocument2 pagesG2130, G2140, G2150 Crosby Bolt Anchor Safety Shackles PDFSonhaji11No ratings yet

- Flanđe OsovineDocument4 pagesFlanđe OsovineIvo MaštrapaNo ratings yet

- Reliable Electrical Solutions To Keep Cargo MovingDocument4 pagesReliable Electrical Solutions To Keep Cargo MovingYohanes Dimas PriambodhoNo ratings yet

- Atos hydraulic cylinder specificationsDocument4 pagesAtos hydraulic cylinder specificationsStéphane ArnaudNo ratings yet

- Crosby ShacklesDocument18 pagesCrosby ShacklesAnjar DarundriyaNo ratings yet

- Bolt Type Anchor Shackles Bolt Type Chain ShacklesDocument1 pageBolt Type Anchor Shackles Bolt Type Chain ShacklesdanamuanNo ratings yet

- Pro 110 Fire ExtinguisherDocument1 pagePro 110 Fire ExtinguisherSergio Imaña GuzmanNo ratings yet

- For Lifting and Transferring Concrete Pipe Sections and WellsDocument1 pageFor Lifting and Transferring Concrete Pipe Sections and Wellsjunyang liNo ratings yet

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDocument1 pageScrew Pin Anchor Shackles Screw Pin Chain Shacklesfcesar1986No ratings yet

- Spreadsheets To BS 8110: VK 14-Jan-2022 1 - 3271Document24 pagesSpreadsheets To BS 8110: VK 14-Jan-2022 1 - 3271christi SNo ratings yet

- Crosby G2140 ShackleDocument1 pageCrosby G2140 Shacklepgarrett775814233No ratings yet

- RLCDocument3 pagesRLCAptan DonNo ratings yet

- Crosby Eye Hooks: On Pages 122 - 123Document1 pageCrosby Eye Hooks: On Pages 122 - 123Yudha J MalmsteenNo ratings yet

- Fab - Y-Strainers - 2nd EditionDocument15 pagesFab - Y-Strainers - 2nd EditionRichard V. Quispe CastillonNo ratings yet

- HoneywellDocument2 pagesHoneywellzenerdiodeNo ratings yet

- CrosbyDocument1 pageCrosbybdispoNo ratings yet

- The Original Dome ValveDocument4 pagesThe Original Dome ValveTan Nguyen Huu100% (2)

- Crosby ShacklesDocument1 pageCrosby Shacklesroy sihalohoNo ratings yet

- HVA Capsule Adhesive Anchor Product Data 814698Document20 pagesHVA Capsule Adhesive Anchor Product Data 814698Teodoro MendezNo ratings yet

- Torsiflex-I Disc Couplings: For General Purpose ApplicationsDocument8 pagesTorsiflex-I Disc Couplings: For General Purpose Applicationsmarcelo castilloNo ratings yet

- BRC Series: High Temperature Metal Bellows SealsDocument2 pagesBRC Series: High Temperature Metal Bellows SealsDhananjay B KNo ratings yet

- Crosby Value Added: All Rights Reserved 75Document1 pageCrosby Value Added: All Rights Reserved 75tarun1976No ratings yet

- 36 - Construction Standard 2 2013-Steel Reinforcement Test Standard-PowerPoint - 17dec12Document21 pages36 - Construction Standard 2 2013-Steel Reinforcement Test Standard-PowerPoint - 17dec12Helen NgNo ratings yet

- Dextra Metro-Rail PresentationDocument84 pagesDextra Metro-Rail PresentationMarcosNo ratings yet

- STB Insulated ConnectorsDocument3 pagesSTB Insulated ConnectorsPablo Jeremias Campos VenegasNo ratings yet

- Hydraulic cylinders ISO 6020-3 standard big boreDocument4 pagesHydraulic cylinders ISO 6020-3 standard big boreStéphane ArnaudNo ratings yet

- AADSS1230110Document4 pagesAADSS1230110RennieNo ratings yet

- 38Document1 page38BoraNo ratings yet

- Honeywell BK G1.6 G4Document2 pagesHoneywell BK G1.6 G4Mugywara luNo ratings yet

- JZ-500 flexible meter marking cableDocument2 pagesJZ-500 flexible meter marking cableJosé LopesNo ratings yet

- Spherical Roller Bearings Exq Series NachiDocument8 pagesSpherical Roller Bearings Exq Series Nachijuan gordonNo ratings yet

- ZSD 1000490622 2 enDocument4 pagesZSD 1000490622 2 engoofflineNo ratings yet

- Cold Tuff Master LinkDocument1 pageCold Tuff Master LinkSelamet MirantoNo ratings yet

- st50APLTONE01235 275 276Document2 pagesst50APLTONE01235 275 276soayNo ratings yet

- Self-priming side channel pump PN 40 technical descriptionDocument8 pagesSelf-priming side channel pump PN 40 technical descriptionsdafas dfNo ratings yet

- Sl No QuestionDocument6 pagesSl No QuestionYogeshPalanisamyNo ratings yet

- Flry BDocument1 pageFlry BseenudesignNo ratings yet

- Eaton Hydroline TS CylinderDocument8 pagesEaton Hydroline TS CylinderHanzil HakeemNo ratings yet

- Grapa Tipo Pistola - MACLEAN AR-A0930Document1 pageGrapa Tipo Pistola - MACLEAN AR-A0930RogerNo ratings yet

- FLRY-B (Norma Cabo Automotivo)Document1 pageFLRY-B (Norma Cabo Automotivo)Djair LopesNo ratings yet

- Spreadsheets To BS 8110: Advisory Group ECBP Typical Floor To BS8110 RMW 11-Jun-2020 123 CHG - R68Document23 pagesSpreadsheets To BS 8110: Advisory Group ECBP Typical Floor To BS8110 RMW 11-Jun-2020 123 CHG - R68Hossen LeopoldNo ratings yet

- Turnbuckles, Swivels, & Hoist RingsDocument5 pagesTurnbuckles, Swivels, & Hoist RingscelonevesNo ratings yet

- DTS Ac8 0607 EngDocument2 pagesDTS Ac8 0607 EngFabianoNo ratings yet

- Catalog Insulated Grounding Bushing For Threadless Threaded RMC Imc o Z Gedney en 588910Document8 pagesCatalog Insulated Grounding Bushing For Threadless Threaded RMC Imc o Z Gedney en 588910NaveedMalikNo ratings yet

- Shackle CrosbyDocument1 pageShackle Crosbyabdulloh_99No ratings yet

- Grilletes G-2140e, 1021475, 1021484, 1021493 CrosbyDocument1 pageGrilletes G-2140e, 1021475, 1021484, 1021493 CrosbyLuis Manuel Montoya RiveraNo ratings yet

- 2020 Jeep Performance Parts CatalogDocument35 pages2020 Jeep Performance Parts CatalogLuis Segundo Chuello ChirinosNo ratings yet

- Grilletes G-2140e, 1021475, 1021484, 1021493 CrosbyDocument1 pageGrilletes G-2140e, 1021475, 1021484, 1021493 CrosbyLuis Manuel Montoya RiveraNo ratings yet

- Standard For Blasting ISO 8501 1Document2 pagesStandard For Blasting ISO 8501 1Roberto Silva100% (3)

- Solvent-Free Epoxy Coating for PipesDocument4 pagesSolvent-Free Epoxy Coating for PipesElie AouadNo ratings yet

- CCB BrochureDocument50 pagesCCB Brochureelias aouadNo ratings yet

- MaxilucDocument2 pagesMaxilucelias aouadNo ratings yet

- Pipes Angles BM 22 36 en - 2Document1 pagePipes Angles BM 22 36 en - 2elias aouadNo ratings yet

- 12 585 Rov Latches Brochure v3 Web 1 PDFDocument8 pages12 585 Rov Latches Brochure v3 Web 1 PDFIZayvenkoNo ratings yet

- RIGGING SAFETY TrainingDocument43 pagesRIGGING SAFETY TrainingBG REDDYNo ratings yet

- Crosby Shackles Price List - Project Sales Corp - June 19, 2010Document1 pageCrosby Shackles Price List - Project Sales Corp - June 19, 2010Project Sales CorpNo ratings yet

- Inspection Procedure-Cargo Carrying UnitsDocument27 pagesInspection Procedure-Cargo Carrying UnitsTrust Emma100% (2)

- Guidance for Securing OOG CargoDocument30 pagesGuidance for Securing OOG CargoSergiy KovernikNo ratings yet

- Crosby Bolt Type Shackles: Testing The LimitsDocument1 pageCrosby Bolt Type Shackles: Testing The LimitsStephen KokoNo ratings yet

- Stok Gudang 30 November 18Document31 pagesStok Gudang 30 November 18Rizal BlingsatanNo ratings yet

- Crane Suspended Personnel Platform (Manbasket) Permit: Page 1 of 3Document3 pagesCrane Suspended Personnel Platform (Manbasket) Permit: Page 1 of 3Satyadip TeraiyaNo ratings yet

- Airtek Front Air Suspension With STEERTEK NXT Axle For Freightliner - Western StarDocument16 pagesAirtek Front Air Suspension With STEERTEK NXT Axle For Freightliner - Western StarJonathan Smith Vargas torresNo ratings yet

- G-209 / S-209 Screw Pin Anchor ShacklesDocument1 pageG-209 / S-209 Screw Pin Anchor ShacklesdannyNo ratings yet

- General Instruction Manual: Crane Suspended Personnel Platform (Manbasket) OperationsDocument9 pagesGeneral Instruction Manual: Crane Suspended Personnel Platform (Manbasket) OperationsJoseph Magbanua100% (2)

- D Shackle Inspection ChecklistDocument16 pagesD Shackle Inspection ChecklistAbhilash PattanaikNo ratings yet

- LIFTCALC 30aDocument105 pagesLIFTCALC 30aJaycee Pagador0% (1)

- JHA On Erection of Temporary ShedDocument15 pagesJHA On Erection of Temporary ShedM8Rskn6wcNo ratings yet

- Lifting Equipment Inspection ChecklistsDocument59 pagesLifting Equipment Inspection ChecklistsMahmud ShalehudinNo ratings yet

- 1.2 - Catalog of Oil Fence (En)Document7 pages1.2 - Catalog of Oil Fence (En)jeorgeNo ratings yet

- Guidance on Industry Standard for Overhead Underhung Trolley Type HoistsDocument15 pagesGuidance on Industry Standard for Overhead Underhung Trolley Type HoistsArash SotoudehNo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformASIF MUZAFFARNo ratings yet

- Leea Question and Answer 2cDocument3 pagesLeea Question and Answer 2cYAKUBU A. AROGENo ratings yet

- Guide Notes For MODU Towing ArrangementsDocument12 pagesGuide Notes For MODU Towing ArrangementsAnonymous UCveMQ100% (1)

- NullDocument67 pagesNullMichael OkwuwaNo ratings yet

- Lifting Gear Inspection & MaintenanceDocument11 pagesLifting Gear Inspection & MaintenanceNhien ManNo ratings yet

- Dogging Guide 2003 - WorkCover NSWDocument76 pagesDogging Guide 2003 - WorkCover NSWtadeumatas100% (1)

- Is 5242-1979Document8 pagesIs 5242-1979Dhatchana moorthy.SNo ratings yet

- Jgs-Ra-102-12 Pre-Commissioning Works - Air Blowing of Piping SystemsDocument6 pagesJgs-Ra-102-12 Pre-Commissioning Works - Air Blowing of Piping Systemsarnel sungkip100% (2)

- BS 6994. Grade M ShacklesDocument20 pagesBS 6994. Grade M ShacklesPmohamedFazilNo ratings yet

- Jergens Lifting Solutions CatalogDocument33 pagesJergens Lifting Solutions CatalogMeyn GarciaNo ratings yet

- Lifitng GuideDocument56 pagesLifitng GuideinrsafetyNo ratings yet

- List Lifting RiggingDocument2 pagesList Lifting RiggingrezaNo ratings yet

- TAUT Mooring System PDFDocument17 pagesTAUT Mooring System PDFAmenNo ratings yet