Professional Documents

Culture Documents

Leea Question and Answer 2c

Uploaded by

YAKUBU A. AROGEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leea Question and Answer 2c

Uploaded by

YAKUBU A. AROGECopyright:

Available Formats

LEEA Correspondence Courses

ASSIGNMENT 2.12

Please note: Use the up and down cursor keys to move between fields in this form.

Enter your name and student number in the spaces below.

Name: Student number:

Each question has several answers, only one of which is correct. Select your answer by typing # in the

box.

When complete, save the file using the same name. Then use the upload facility to return it for marking.

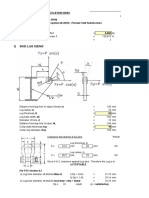

1. What type of shackle is illustrated?

Grab shackle

# D shackle

Small Bow shackle

US Federal Specification RR-C-271b

2. What type of shackle is illustrated?

US Federal Specification RR-C-271b

Grab shackle

Large D shackle

# Bow shackle

3. What type of shackle pin is illustrated?

# Screwed pin

Type B pin

Plain pin

Countersunk pin

4. What type of shackle pin is illustrated?

Plain pin

Screwed pin with cotter

# Bolt, nut and cotter pin

Plain pin with cotter

5. The advantage of a bow shackle compared to a D shackle is:

# A bow shackle can connect three or more items together

It is shaped to fit a crane hook

For a given size it has a higher WLL

There is no advantage

6. The advantage of a D shackle compared to a bow shackle is:

It is shaped to avoid snagging

# For a given size it has a higher WLL

It is shaped to connect to an eyebolt

There is no advantage

7. The advantage of the pin shown is:

© Lifting Equipment Engineers Association 2011 - training/2.12e 1

It is stronger than other types

It can be galvanised

It is more secure for long term applications

# It is quick to undo and replace

8. The advantage of the pin shown is:

It can be fitted from either side

It can easily be replaced if lost

# It is more secure for long term applications

It is tamperproof

9. What manufacturing process is used to make a shackle body to EN 13889?

# Forging

Casting

Profiling

Welding

10. As an alternative to drop forging, a shackle body to EN 13889 can be manufactured by:

Fabricating by welding

Casting

Profiling from solid

# Upsetting the ends of a bar to form eyes then bending the bar to shape

11. If there is a flash line around the shackle body, how was it made?

By casting

By upsetting and bending from a bar

# By drop forging

By profiling

12. EN 13889 requires that marking is done in a way that will not impair the mechanical properties of

the shackle. How is this done in practice?

# By using stamps on a low stress part of the shackle body

By using the largest stamps possible to make it visible without being too deep

By using the smallest stamps which are still legible and minimum force

By using an engraving technique

13. Which part of a shackle body is a low stress area?

The outside of the crown of the body

# The straight sides of the body

The inside of the crown of the body

The side of the eyes

14. What EN 13889 shackle pins should be marked with the grade, traceability code and

manufacturer’s symbol?

Nut and bolt type pins

Screwed pins

Those with a diameter less than 13mm

# Those with a diameter of 13mm and above

15. What EN 13889 shackle pins should be marked with either the grade mark or traceability code?

© Lifting Equipment Engineers Association 2011 - training/2.12e 2

# Those with a diameter of less than 13mm

Those with a diameter of 13mm and above

Screwed pins

Nut and bolt type pins

16. Why is the shackle pin larger in diameter than the shackle body?

Because it is made of a lower grade material than the shackle body

Because it is subject to more wear than the shackle body

# Because it is designed to withstand a point load in the centre

Because it provides a bearing surface to mating components

17. What is the main stress on a shackle pin is point loaded in the centre?

# Bending

Shear

Bending and shear

Bending and double shear

18. What is the main stress on a shackle pin with a uniformly distributed load?

Bending and double shear

Bending and shear

# Double shear

Bending

19. Whilst examining an in-service bow shackles with screwed pins, which of the following would cause

you to withdraw a shackle from further service?

With the pin fitted but not tightened, it can move to touch the sides of the unthreaded eye

# When the pin is screwed fully in, there is a gap between the pin collar and the eye

There are shallow bruise marks on the pin

The minimum material thickness of the crown is 6% less than the diameter of the straight side

Marking

Answers still shown in black were correct

Answers now shown in red were incorrect – the correct answers are shown in blue

Result

© Lifting Equipment Engineers Association 2011 - training/2.12e 3

You might also like

- Leea Question and Answer 2Document3 pagesLeea Question and Answer 2YAKUBU A. AROGENo ratings yet

- Unit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 FinishDocument8 pagesUnit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 Finisheetua100% (2)

- LEEA Lifting and Slinging Course OutlineDocument4 pagesLEEA Lifting and Slinging Course OutlineSankaranarayananNo ratings yet

- LEEA - Instruction For Safe Use of Flat Woven Webbing SlingsDocument2 pagesLEEA - Instruction For Safe Use of Flat Woven Webbing Slingsdonnyars1979No ratings yet

- Annual Report: Lifting Standards WorldwideDocument20 pagesAnnual Report: Lifting Standards WorldwideUlviyye ElesgerovaNo ratings yet

- LEEA Correspondence Courses: Assignment 3.11 Total MarkDocument4 pagesLEEA Correspondence Courses: Assignment 3.11 Total MarkAhmed 7mamNo ratings yet

- LEEA ACADEMY Course Study Materials - MCE - V1.0 Mar 2020-MergedDocument189 pagesLEEA ACADEMY Course Study Materials - MCE - V1.0 Mar 2020-MergedRana DanishNo ratings yet

- LEEA 059 5 Guidance To Documentation & Marking Part5Document23 pagesLEEA 059 5 Guidance To Documentation & Marking Part5GaniyuNo ratings yet

- LEEA Standards 2 2Document3 pagesLEEA Standards 2 2Steve MorrisonNo ratings yet

- LEEA-059-1 Documentation and Marking - Part 1 Manual Lifting Machines - Version 2 PDFDocument14 pagesLEEA-059-1 Documentation and Marking - Part 1 Manual Lifting Machines - Version 2 PDFopreamihNo ratings yet

- Subject: Offshore Containers: Lifting Equipment Engineers Association Examination For DiplomaDocument11 pagesSubject: Offshore Containers: Lifting Equipment Engineers Association Examination For DiplomaAhmed HamamNo ratings yet

- LEEA Audit Required DocumentsDocument1 pageLEEA Audit Required Documentsvfuntanilla100% (2)

- LOLER Lifting Equipment Inspection Duties EbookDocument19 pagesLOLER Lifting Equipment Inspection Duties EbookumnartkhNo ratings yet

- 2012 OL1 1.2 E Student 017717 Marker 42Document3 pages2012 OL1 1.2 E Student 017717 Marker 42alexedamalaNo ratings yet

- LEEA Oil & Gas Webinar Presentation - 280422Document27 pagesLEEA Oil & Gas Webinar Presentation - 280422Mohammed Ahmed NasherNo ratings yet

- LEEA-016 Correspondence Course Prospectus 2012-13docDocument7 pagesLEEA-016 Correspondence Course Prospectus 2012-13docAjith KumarNo ratings yet

- LEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFDocument72 pagesLEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFSelva GanapathiNo ratings yet

- LEEA Handbook PDFDocument1 pageLEEA Handbook PDFparamarthasom1974No ratings yet

- Foundation Course E-Learning Course Guide v1.0 Dec 16Document9 pagesFoundation Course E-Learning Course Guide v1.0 Dec 16mohammad eldeebNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Shackles and Chain Sling Inspection ChecklistDocument1 pageShackles and Chain Sling Inspection ChecklistBorislav VulićNo ratings yet

- Module 3.1Document35 pagesModule 3.1Akash VermaNo ratings yet

- LEEA-051 Guidance On Design Inspection and Use of Water Bags As Test Weights in The Offshore Industry Version 1 October 2012Document7 pagesLEEA-051 Guidance On Design Inspection and Use of Water Bags As Test Weights in The Offshore Industry Version 1 October 2012GaniyuNo ratings yet

- LEEA 059 6 Documentation&Marking-Part6Document24 pagesLEEA 059 6 Documentation&Marking-Part6GaniyuNo ratings yet

- lLEEA Academy Foundation Course Revision Test 1 - V 1.0 Jan 2019Document14 pageslLEEA Academy Foundation Course Revision Test 1 - V 1.0 Jan 2019Muaz MuhammedNo ratings yet

- LEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories, Non-Fixed Load Lifting Attachments - Version 2 PDFDocument15 pagesLEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories, Non-Fixed Load Lifting Attachments - Version 2 PDFopreamihNo ratings yet

- Wire Rope SlingsDocument5 pagesWire Rope SlingsEr Faiyaz AhmedNo ratings yet

- LEEA-3 Some DefinitionsDocument6 pagesLEEA-3 Some DefinitionsvenkateshNo ratings yet

- LEEA Correspondence Courses: Assignment 1.2Document3 pagesLEEA Correspondence Courses: Assignment 1.2Primelift Safety Resources Limited0% (1)

- LEEA Correspondence Courses: Assignment 1.3Document3 pagesLEEA Correspondence Courses: Assignment 1.3alexedamalaNo ratings yet

- LEEA Passing CriteriaDocument1 pageLEEA Passing CriteriaKhurram S. Muzammil50% (2)

- Periodic Inspection Sling GBDocument2 pagesPeriodic Inspection Sling GBjeanmichelqNo ratings yet

- Examination Procedure For Runway Beam InspectionDocument6 pagesExamination Procedure For Runway Beam InspectionTrust EmmaNo ratings yet

- Beam ClampDocument1 pageBeam ClampTrust EmmaNo ratings yet

- Instructions For The Safe Use Of: Wire Rope SlingsDocument2 pagesInstructions For The Safe Use Of: Wire Rope SlingsStuartWilliamGlennieNo ratings yet

- Aim of Procedure: Inspection of Lifting EquipmentDocument11 pagesAim of Procedure: Inspection of Lifting EquipmentEngr Arfan Ali Dhamraho100% (1)

- Jib Crane & Over Head BeamDocument5 pagesJib Crane & Over Head BeamRanjithNo ratings yet

- Inspection and Certification Procedure References For Lifting EquipmentsDocument2 pagesInspection and Certification Procedure References For Lifting EquipmentsOussama Aloulou100% (1)

- LEEA-059-5 Documentation and Marking - Part 5 Lifting Accessories, Slings PDFDocument13 pagesLEEA-059-5 Documentation and Marking - Part 5 Lifting Accessories, Slings PDFJason RobertsNo ratings yet

- LEEA-046 Guidance On The Application of Remote Controls For Lifting Machines Version 3 May 2020Document11 pagesLEEA-046 Guidance On The Application of Remote Controls For Lifting Machines Version 3 May 2020beshoyNo ratings yet

- Loler Matrix 2017 PDFDocument1 pageLoler Matrix 2017 PDFMulatua SiraitNo ratings yet

- Guidance To The Verification of Sockets and Davits.: Document Reference LEEA 061Document18 pagesGuidance To The Verification of Sockets and Davits.: Document Reference LEEA 061GaniyuNo ratings yet

- Hand Rigging and SignalsDocument75 pagesHand Rigging and SignalsReymondA.SanJuan100% (1)

- Man Rider Winch VisualDocument6 pagesMan Rider Winch VisualRanjithNo ratings yet

- Web-Sling-Recommended-Operating-and-Inspection-GuidelineDocument12 pagesWeb-Sling-Recommended-Operating-and-Inspection-GuidelineibrahimNo ratings yet

- LEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories, Non-Fixed Load Lifting AttachmentsDocument10 pagesLEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories, Non-Fixed Load Lifting Attachmentsnoormanmubarak100% (2)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- LEEA-072 Roles and Resposibilities For Ensuring The Continued Safety of Lifting Equipment Version 1 Aug 2017 PDFDocument7 pagesLEEA-072 Roles and Resposibilities For Ensuring The Continued Safety of Lifting Equipment Version 1 Aug 2017 PDFJohn DolanNo ratings yet

- 3576 Erbil MergedDocument4 pages3576 Erbil MergedAli AlahmaNo ratings yet

- SGS Lifting Work Instruction1 PDFDocument99 pagesSGS Lifting Work Instruction1 PDFashrafasdNo ratings yet

- Rigging Gear Store Management RegisterDocument6 pagesRigging Gear Store Management RegisterKhawaja Arslan Ahmed0% (1)

- User Manual Wire Rope SlingDocument4 pagesUser Manual Wire Rope SlingRashid GhaniNo ratings yet

- LEEA Correspondence Courses: Assignment 1.10Document6 pagesLEEA Correspondence Courses: Assignment 1.10ikponmwonsaNo ratings yet

- LEI - 3 Day Course-Thorough ExaminationDocument3 pagesLEI - 3 Day Course-Thorough ExaminationmossamorrisNo ratings yet

- Guidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Document6 pagesGuidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Ganiyu100% (1)

- Authorised Examiners Lifting EquipmentDocument13 pagesAuthorised Examiners Lifting EquipmentdunglxNo ratings yet

- LEEA Correspondence Courses: Assignment 1.11Document3 pagesLEEA Correspondence Courses: Assignment 1.11YAKUBU A. AROGENo ratings yet

- (Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 120 129Document10 pages(Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 120 129Khaled RaafatNo ratings yet

- Chapter 5 - Threads and FastenersDocument128 pagesChapter 5 - Threads and FastenersPradeep Kumar MehtaNo ratings yet

- 3D Photography Slide-Bars, How to Make 3D Camera Slide-Bars and Twin-Cam Mounting BarsFrom Everand3D Photography Slide-Bars, How to Make 3D Camera Slide-Bars and Twin-Cam Mounting BarsNo ratings yet

- Resistance Welding Basics: Welding Sequence Definitions Machine Set-Up Rules For Making Good WeldsDocument17 pagesResistance Welding Basics: Welding Sequence Definitions Machine Set-Up Rules For Making Good Weldskenneth lohNo ratings yet

- Unit 1.20 - Revision Assignment: See Note Below/over For Students Completing Assignments Via The Training PortalDocument3 pagesUnit 1.20 - Revision Assignment: See Note Below/over For Students Completing Assignments Via The Training PortalYAKUBU A. AROGENo ratings yet

- UNIT NO. 2.18 Lifting Beams: © Lifting Equipment Engineers Association 2011 - Training/2-18uDocument6 pagesUNIT NO. 2.18 Lifting Beams: © Lifting Equipment Engineers Association 2011 - Training/2-18uYAKUBU A. AROGENo ratings yet

- Snatch Block With Shackle Fitting, SINGLE SHEAVE, 15-60t: BlocksDocument1 pageSnatch Block With Shackle Fitting, SINGLE SHEAVE, 15-60t: BlocksYAKUBU A. AROGENo ratings yet

- Crack - Test - Products - White - Background - CTW6 (1) - 2Document7 pagesCrack - Test - Products - White - Background - CTW6 (1) - 2YAKUBU A. AROGENo ratings yet

- Chapter5 Accesories2Document45 pagesChapter5 Accesories2YAKUBU A. AROGENo ratings yet

- Chapt 4 AccessoriesDocument17 pagesChapt 4 AccessoriesYAKUBU A. AROGENo ratings yet

- GUIDE To FTDocument2 pagesGUIDE To FTAnonymous X36yT0PvZNo ratings yet

- Chapter19 REVISIONDocument1 pageChapter19 REVISIONYAKUBU A. AROGENo ratings yet

- Chapter17 Reeving and RopeguideDocument6 pagesChapter17 Reeving and RopeguideYAKUBU A. AROGENo ratings yet

- Chapter16 Hoist ConstructionDocument8 pagesChapter16 Hoist ConstructionYAKUBU A. AROGENo ratings yet

- Chapter9 LIMIT SWITCHES AND DEVICESDocument11 pagesChapter9 LIMIT SWITCHES AND DEVICESYAKUBU A. AROGENo ratings yet

- Chapter15 Pneumatic Hoist 2Document8 pagesChapter15 Pneumatic Hoist 2YAKUBU A. AROGENo ratings yet

- Chapter7 Powerfeed SystemDocument27 pagesChapter7 Powerfeed SystemYAKUBU A. AROGENo ratings yet

- Chapter8 Electric Circuit in PowerhoistDocument14 pagesChapter8 Electric Circuit in PowerhoistYAKUBU A. AROGENo ratings yet

- LEEA Correspondence Courses: Assignment 1.11Document3 pagesLEEA Correspondence Courses: Assignment 1.11YAKUBU A. AROGENo ratings yet

- UNIT NO. 5.8 Welding of Structural Steel: © Lifting Equipment Engineers Association 2012 - Training/5-8uDocument13 pagesUNIT NO. 5.8 Welding of Structural Steel: © Lifting Equipment Engineers Association 2012 - Training/5-8uYAKUBU A. AROGENo ratings yet

- UNIT NO. 5.9 Inspection and Testing of WeldsDocument15 pagesUNIT NO. 5.9 Inspection and Testing of WeldsYAKUBU A. AROGENo ratings yet

- Chapter6 Travelling TrolleysDocument14 pagesChapter6 Travelling TrolleysYAKUBU A. AROGENo ratings yet

- LEEA Correspondence Courses: Assignment 5.6 Total MarkDocument2 pagesLEEA Correspondence Courses: Assignment 5.6 Total MarkYAKUBU A. AROGENo ratings yet

- LEEA Correspondence Courses: Assignment 5.8 Total MarkDocument2 pagesLEEA Correspondence Courses: Assignment 5.8 Total MarkYAKUBU A. AROGENo ratings yet

- LEEA Correspondence Courses: Assignment 1.10Document6 pagesLEEA Correspondence Courses: Assignment 1.10ikponmwonsaNo ratings yet

- UNIT NO. 2.12 Shackles: © Lifting Equipment Engineers Association 2011 - Training/2-12uDocument7 pagesUNIT NO. 2.12 Shackles: © Lifting Equipment Engineers Association 2011 - Training/2-12uYAKUBU A. AROGENo ratings yet

- Unit 1.11 - Components: 1. ForgingDocument8 pagesUnit 1.11 - Components: 1. ForgingYAKUBU A. AROGENo ratings yet

- UNIT NO. 2.10 Components For Slings: © Lifting Equipment Engineers Association 2011Document7 pagesUNIT NO. 2.10 Components For Slings: © Lifting Equipment Engineers Association 2011YAKUBU A. AROGENo ratings yet

- UNIT NO 2.11 Eyebolts: © Lifting Equipment Engineers Association 2011 - Training/2-11uDocument7 pagesUNIT NO 2.11 Eyebolts: © Lifting Equipment Engineers Association 2011 - Training/2-11uYAKUBU A. AROGENo ratings yet

- LEEA Correspondence Courses: Assignment 5.5 Total MarkDocument3 pagesLEEA Correspondence Courses: Assignment 5.5 Total MarkYAKUBU A. AROGENo ratings yet

- LEEA Correspondence Courses: Assignment 2.18Document3 pagesLEEA Correspondence Courses: Assignment 2.18YAKUBU A. AROGENo ratings yet

- UNIT NO. 2.20 Revision Assignment: © Lifting Equipment Engineers Association 2011 - Training/2-20uDocument1 pageUNIT NO. 2.20 Revision Assignment: © Lifting Equipment Engineers Association 2011 - Training/2-20uYAKUBU A. AROGENo ratings yet

- LEEA Correspondence Courses: Assignment 5.4 Total MarkDocument2 pagesLEEA Correspondence Courses: Assignment 5.4 Total MarkYAKUBU A. AROGENo ratings yet

- 01 - Lifting Personnel Basket - ADNOCDocument4 pages01 - Lifting Personnel Basket - ADNOCEmad ZakiNo ratings yet

- PARTS MANUAL RL4 TEREX 216241 Horizontal PDFDocument104 pagesPARTS MANUAL RL4 TEREX 216241 Horizontal PDFElectromecanico 605No ratings yet

- Flat Woven Webbing SlingsDocument2 pagesFlat Woven Webbing SlingsYosses Sang NahkodaNo ratings yet

- Safe Slinging PracticeDocument78 pagesSafe Slinging Practiceanurag_4013100% (2)

- Suspended Personnel Platform Check List PDFDocument1 pageSuspended Personnel Platform Check List PDFmark lester caluzaNo ratings yet

- E-HSE-SOP-139 Retrieval of A Disabled Remote ScoopDocument3 pagesE-HSE-SOP-139 Retrieval of A Disabled Remote Scoopgildardo valdiviaNo ratings yet

- CEBECO I LINE COST (As of July 2006)Document24 pagesCEBECO I LINE COST (As of July 2006)Sugar RayNo ratings yet

- Load Chart-Sagar ChiliveriDocument8 pagesLoad Chart-Sagar ChiliveriRajanna NallaNo ratings yet

- Lifting and Rigging Procedure MA - mg.PRC.417 - Eff 1.29.2021Document88 pagesLifting and Rigging Procedure MA - mg.PRC.417 - Eff 1.29.2021Alex Sandro Borges PereiraNo ratings yet

- GuidelinesDocument27 pagesGuidelinesHunterNo ratings yet

- Detailing in Concrete StructuresDocument8 pagesDetailing in Concrete Structuresj_herndzNo ratings yet

- Torque RotariaDocument41 pagesTorque RotariaMiguel angel leon bautistaNo ratings yet

- MoSi Katalog 2013 GB Screen 02 PDFDocument260 pagesMoSi Katalog 2013 GB Screen 02 PDFGoodBikes100% (1)

- Suspended Personnel Platform Check List PDFDocument1 pageSuspended Personnel Platform Check List PDFDenease CrummieNo ratings yet

- 474 PDFDocument1 page474 PDFSam LowNo ratings yet

- Rig Up Ops Manual - D00625669 - 1Document56 pagesRig Up Ops Manual - D00625669 - 1Prakhar Sarkar100% (3)

- Architectural Fasteners & Fittings - Stainless Steel - AnzorDocument18 pagesArchitectural Fasteners & Fittings - Stainless Steel - AnzorBhaiJan59No ratings yet

- KRS-HSE-PSD-16 Lifting Equipment and Gears - Rev. 01Document20 pagesKRS-HSE-PSD-16 Lifting Equipment and Gears - Rev. 01Asensio SinagaNo ratings yet

- Crosby Shackle Load Capacity TableDocument1 pageCrosby Shackle Load Capacity TableVisas Siva100% (2)

- PLP US FIBERLIGN® HardwareDocument84 pagesPLP US FIBERLIGN® HardwareLucyana RosaNo ratings yet

- Old - KPS - Sop - MNT - 010 - Lifting Machines and Lifting Tackle V1.1Document39 pagesOld - KPS - Sop - MNT - 010 - Lifting Machines and Lifting Tackle V1.1Norman CoetzeeNo ratings yet

- Asme B30.26 (2004)Document38 pagesAsme B30.26 (2004)Omar RamirezNo ratings yet

- Mins 5100-279 (10-86) Illustrative Methods For Rigging, Shop 72, Mare Island Naval Shipyard - Submarine Parts!Document76 pagesMins 5100-279 (10-86) Illustrative Methods For Rigging, Shop 72, Mare Island Naval Shipyard - Submarine Parts!Are EssNo ratings yet

- 44.lifting Lug With Collar CalculationDocument44 pages44.lifting Lug With Collar CalculationAnonymous AyDvqg100% (1)

- Load Measuring CatalogueDocument18 pagesLoad Measuring CatalogueridzimNo ratings yet

- BRUCE MK4 Handling ProcedureDocument81 pagesBRUCE MK4 Handling ProcedureSamo SpontanostNo ratings yet

- Sa-07-09.PDF 4 Part ShackleDocument2 pagesSa-07-09.PDF 4 Part ShackleSafety VirtueNo ratings yet

- Pedestal Mounted Crane Training SampleDocument84 pagesPedestal Mounted Crane Training SampleCesar Augusto Vera JaimesNo ratings yet

- Basic RiggingDocument156 pagesBasic Riggingkampit100% (18)

- Wide Body Shackle - CrosbyDocument1 pageWide Body Shackle - CrosbyPernando SagaNo ratings yet