Professional Documents

Culture Documents

LEEA Correspondence Courses: Assignment 3.11 Total Mark

Uploaded by

Ahmed 7mamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LEEA Correspondence Courses: Assignment 3.11 Total Mark

Uploaded by

Ahmed 7mamCopyright:

Available Formats

LEEA Correspondence Courses

ASSIGNMENT 3.11

TOTAL MARK %

Please note: Use the up and down cursor keys to move between fields in this form.

Enter your name and student number in the spaces below.

Name: OGEH EMEDOH Student number: 9043

Answer the following questions by typing into the grey fields. The fields will expand to accommodate

your answer but keep your answers as brief as possible. The marks allocated to each question are

shown and are in proportion to the amount of work we expect will be required to answer the question.

When complete, save the file using the same name. Then use the upload facility to return it for marking.

1. The maximum period between the through examinations of hand chain blocks

allowed by LOLER is:

6 months

9 months

# 12 months

14 months

2. To show that the manufacturer has complied with the essential safety requirements

lifting equipment must be CE marked. This is a requirement of:

The Factories Act 1961

The Health and Safety at Work Act 1974

The Management of Health and Safety at Work Regulations 1992

# The Supply of Machinery (Safety) Regulations 1992

3. When a user makes an item of lifting equipment for his own use, eg a spreader beam

and has it tested by a lifting equipment company:

The test company is responsible for issuing an EC Declaration of Conformity

# The user is responsible for issuing an EC Declaration of Conformity

The HSE must issue an EC Declaration of Conformity

No need for an EC Declaration of Conformity as it is for the users own use

4. The legal duty of an employer to keep work equipment properly maintained is a

requirement of:

The Supply of Machinery (Safety) Regulations

The Maintenance of Work Equipment (Safety) Regulations

# The Provision and use of Work Equipment Regulations

The Manual Handling Regulations

© Lifting Equipment Engineers Association 2011 - training\311e 1

5. When introducing a new piece of lifting equipment into the work place it must

comply with the relevant Directives. This is a requirement of:

# The Supply of Machinery (Safety) Regulations1992

The Lifting Plant and Equipment Regulations 1992

The Provision and Use of Work Equipment Regulations 1998

The Lifting Operations and Lifting Equipment Regulations 1998

Maximum mark 5 Your mark

Answer the following questions by typing into the grey fields. The fields will expand to

accommodate your answer but keep your answers as brief as possible. The marks allocated to

each question are shown and are in proportion to the amount of work we expect will be

required to answer the question.

6. Explain briefly what is meant by velocity ratio.

Velocity ratio is the distance moved by the effort to the distance moved by the load.

Maximum mark 3 Your mark

For tutor’s purposes only

7. A lifting machine has a velocity ratio of 10 and a mechanical advantage of 8. calculate

the Efficiency of the machine.

Efficiency = M.A/VR X 100

8/10 X 100 = 800/10 = 80% Ans.

Maximum mark 2 Your mark

For tutor’s purposes only

8. A 2t SWL snatch block which complied to BS 4018 has been repaired and a new

swivel eye head fitting has been fitted. State the proof load that should be applied and

the reason for this load.

Proof load = 4 times the WLL.As the head fitting carries both the load and the effort,as full

capacity it will be subject to a force of twice the marked WLL.In order to proof load test the

head fitting it is therefore necessary to apply a load of 4 times the marked WLL.

Maximum mark 3 Your mark

For tutor’s purposes only

© Lifting Equipment Engineers Association 2011 - training\311e 2

9. Describe how you would test the safe operation of a hand chain block brake and

explain why this particular test is necessary.

By carrying out a thorough visual examination,Function testing, A light load test of 2% and

5% of the SWL,The reason is to check for the efficiency and integrity of the brake of the

chain block.

Maximum mark 4 Your mark

For tutor’s purposes only

10. State a) the maximum permissible wear in a short link load chain fitted to a hand

chain block, b) the maximum elongation of a short link load chain fitted to a lever

hoist and c) the maximum elongation to a roller load chain fitted to a lever hoist.

a) 8% reduction in diameter.

b) 3% maximum elongation.

c) 2% maximum elongation.

Maximum mark 3 Your mark

For tutor’s purposes only

11. What component of a hand chain block must be checked if the load chain is replaced?

The load wheel,The chain guide roller,the chain stripper and the brake.

Maximum mark 2 Your mark

For tutor’s purposes only

12 What would be the effect of fitting a trolley with tapered wheels for RSJ onto a UB

runway?

Because the wheel would only make a point contact with the edge of the flange.This would

cause rapid wear to both the track and the wheel.It would also increase the transverse stress in

the flange producing a bending effect so overloading the flange and causing it to turn down.

Maximum mark 3 Your mark

For tutor’s purposes only

© Lifting Equipment Engineers Association 2011 - training\311e 3

13 Some modern trolleys utilise left and right hand threaded load bars to connect the side

plate. When examining such trolleys what checks should be made regarding the side

plates?

Caution is needed to ensure that one side plate has not been turned on the screw more than the

other.

Maximum mark 2 Your mark

For tutor’s purposes only

14 When examining a hand geared trolley you find one of the links in the hand chain has

not been welded. What is the reason for this and what action would you take?

The unwelded link on the hand chain is used to passed on the wheel and i will take no action

because it is not a defect.

Maximum mark 3 Your mark

For tutor’s purposes only

© Lifting Equipment Engineers Association 2011 - training\311e 4

You might also like

- Drilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final RevisionDocument2 pagesDrilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final Revisionengmuhmud100% (1)

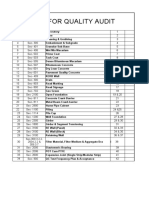

- LEEA Audit Required DocumentsDocument1 pageLEEA Audit Required Documentsvfuntanilla100% (2)

- Mewps Operator Practical Only Assessment Sheets 2021 MercuryDocument4 pagesMewps Operator Practical Only Assessment Sheets 2021 MercuryWILLIAM KEAGUE100% (1)

- LOLER Lifting Equipment Inspection Duties EbookDocument19 pagesLOLER Lifting Equipment Inspection Duties EbookumnartkhNo ratings yet

- New Crane Safety LawsDocument31 pagesNew Crane Safety LawsFabian LandauNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Appointed Person: Planning and Regulatory RequirementsDocument6 pagesAppointed Person: Planning and Regulatory RequirementssamNo ratings yet

- LEEADocument12 pagesLEEAAmeerUlHaqNo ratings yet

- Hoist Equipment Inspection ProcedureDocument5 pagesHoist Equipment Inspection ProcedureAhmed Imtiaz Rao100% (1)

- Periodic Inspection Sling GBDocument2 pagesPeriodic Inspection Sling GBjeanmichelqNo ratings yet

- Guidance Notes Inspection and Examination - Lifting EquipmentDocument48 pagesGuidance Notes Inspection and Examination - Lifting Equipmentbiopro1100% (1)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Rigger Crane Operator Banksman CVDocument2 pagesRigger Crane Operator Banksman CVMike Kelley100% (1)

- LEEA Correspondence Courses: Assignment 2.4Document3 pagesLEEA Correspondence Courses: Assignment 2.4ikponmwonsaNo ratings yet

- LEEA - Instruction For Safe Use of Flat Woven Webbing SlingsDocument2 pagesLEEA - Instruction For Safe Use of Flat Woven Webbing Slingsdonnyars1979No ratings yet

- LEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesDocument6 pagesLEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesnoormanmubarakNo ratings yet

- User Manual Wire Rope SlingDocument4 pagesUser Manual Wire Rope SlingRashid GhaniNo ratings yet

- LEEA Handbook PDFDocument1 pageLEEA Handbook PDFparamarthasom1974No ratings yet

- Aramco Rigger 3 Lifting PlanDocument1 pageAramco Rigger 3 Lifting PlanMahdi AlbinalshaikhNo ratings yet

- LEEA-036 (A) - Academy Practical Training Courses Jan - June 2020 Version 1 October 2019Document18 pagesLEEA-036 (A) - Academy Practical Training Courses Jan - June 2020 Version 1 October 2019kaito kurabaNo ratings yet

- Hand Rigging and SignalsDocument75 pagesHand Rigging and SignalsReymondA.SanJuan100% (1)

- Usdhs / Uscbp / Basc "Best Practice" 8-Point Ocean Container Security Inspection GuideDocument2 pagesUsdhs / Uscbp / Basc "Best Practice" 8-Point Ocean Container Security Inspection GuideMohd Shahrul Irwan Mohd ZinNo ratings yet

- LEEA-3 Some DefinitionsDocument6 pagesLEEA-3 Some DefinitionsvenkateshNo ratings yet

- Riggers Quiz: Name: - DateDocument1 pageRiggers Quiz: Name: - Dategunnery02No ratings yet

- LEEA ACADEMY Course Study Materials - MCE - V1.0 Mar 2020-MergedDocument189 pagesLEEA ACADEMY Course Study Materials - MCE - V1.0 Mar 2020-MergedRana DanishNo ratings yet

- A61 Appointed Persons Theory Test Questions For Candidates PDFDocument6 pagesA61 Appointed Persons Theory Test Questions For Candidates PDFChandra Kumar100% (1)

- LEEA Academy P1E Revision Test 2 - July 2015 ANSWERSDocument17 pagesLEEA Academy P1E Revision Test 2 - July 2015 ANSWERSMohmed AllamNo ratings yet

- Leea Question and Answer 2cDocument3 pagesLeea Question and Answer 2cYAKUBU A. AROGENo ratings yet

- LEEA 039a Accreditation Scheme Appendix 1Document25 pagesLEEA 039a Accreditation Scheme Appendix 1Irshad Akhter100% (1)

- Backgroud of Malaysia AirlinesDocument38 pagesBackgroud of Malaysia Airlinesmalvin_ong50% (8)

- Axle Partsbook enDocument36 pagesAxle Partsbook enALPEL ALBISNo ratings yet

- LEI - 3 Day Course-Thorough ExaminationDocument3 pagesLEI - 3 Day Course-Thorough ExaminationmossamorrisNo ratings yet

- Foundation Course (FOU) : DescriptionDocument15 pagesFoundation Course (FOU) : DescriptionVinu VincentNo ratings yet

- HoistingRiggingPlan PDFDocument5 pagesHoistingRiggingPlan PDFHadiwinata DjakariaNo ratings yet

- Banksman SlingerDocument9 pagesBanksman SlingerPirlo PoloNo ratings yet

- Leea Question and Answer 2Document3 pagesLeea Question and Answer 2YAKUBU A. AROGENo ratings yet

- lLEEA Academy Foundation Course Revision Test 1 - V 1.0 Jan 2019Document14 pageslLEEA Academy Foundation Course Revision Test 1 - V 1.0 Jan 2019Muaz MuhammedNo ratings yet

- TCL l40f10f - Power InveterDocument3 pagesTCL l40f10f - Power InveterĐặngĐạt100% (1)

- Rigging Question2 PDFDocument2 pagesRigging Question2 PDFMuhammad Azhar AliNo ratings yet

- LLEEA Academy Foundation Course Revision Test 2 - V 1.0 Jan 2019Document15 pagesLLEEA Academy Foundation Course Revision Test 2 - V 1.0 Jan 2019Muaz Muhammed100% (2)

- Process Analysis WSDDocument28 pagesProcess Analysis WSDAkhilesh ChaudharyNo ratings yet

- Fire Safety Guidelines For Road TunnelsDocument45 pagesFire Safety Guidelines For Road TunnelsAhmed SherifNo ratings yet

- API5b Changes in 16th EditionDocument4 pagesAPI5b Changes in 16th EditionMostafa FikryNo ratings yet

- Module 3.1Document35 pagesModule 3.1Akash VermaNo ratings yet

- Wire Rope SlingsDocument5 pagesWire Rope SlingsEr Faiyaz AhmedNo ratings yet

- LEEA Academy MCE Module Quiz Paper - ANSWERS Mar20Document39 pagesLEEA Academy MCE Module Quiz Paper - ANSWERS Mar20Rana Danish100% (1)

- ICAO Aerodrome Best PracticeDocument16 pagesICAO Aerodrome Best Practicenimsv1980100% (2)

- Rigging Gear Store Management RegisterDocument6 pagesRigging Gear Store Management RegisterKhawaja Arslan Ahmed0% (1)

- Draft Offshore ChecklistDocument2 pagesDraft Offshore Checklistmohamad nur saufiNo ratings yet

- Subject: Offshore Containers: Lifting Equipment Engineers Association Examination For DiplomaDocument11 pagesSubject: Offshore Containers: Lifting Equipment Engineers Association Examination For DiplomaAhmed HamamNo ratings yet

- Annual Report: Lifting Standards WorldwideDocument20 pagesAnnual Report: Lifting Standards WorldwideUlviyye ElesgerovaNo ratings yet

- 2012 OL1 1.2 E Student 017717 Marker 42Document3 pages2012 OL1 1.2 E Student 017717 Marker 42alexedamalaNo ratings yet

- LEEA Correspondence Courses: Assignment 1.9Document3 pagesLEEA Correspondence Courses: Assignment 1.9Primelift Safety Resources LimitedNo ratings yet

- LEEA Correspondence Courses: Assignment 1.2Document3 pagesLEEA Correspondence Courses: Assignment 1.2Primelift Safety Resources Limited0% (1)

- Lifting Equipment Controller Course GuidelinesDocument5 pagesLifting Equipment Controller Course GuidelinesHitesh GuptaNo ratings yet

- A Basic Introduction To IELTS v2Document3 pagesA Basic Introduction To IELTS v2Crisline PilapilNo ratings yet

- LEEA Correspondence Courses: Assignment 1.3Document3 pagesLEEA Correspondence Courses: Assignment 1.3alexedamalaNo ratings yet

- LEEA Correspondence Courses: Assignment 1.10Document6 pagesLEEA Correspondence Courses: Assignment 1.10ikponmwonsaNo ratings yet

- 2012 Ol1 1.7 UDocument14 pages2012 Ol1 1.7 UalexedamalaNo ratings yet

- LEEA Correspondence Courses: Assignment 1.1Document3 pagesLEEA Correspondence Courses: Assignment 1.1alexedamalaNo ratings yet

- LEEA Oil & Gas Webinar Presentation - 280422Document27 pagesLEEA Oil & Gas Webinar Presentation - 280422Mohammed Ahmed NasherNo ratings yet

- LOLER Competent PersonDocument1 pageLOLER Competent PersonMulatua SiraitNo ratings yet

- F4a 2018 LEEA Assessments - Information For Members & Students Version 2 December 2017Document4 pagesF4a 2018 LEEA Assessments - Information For Members & Students Version 2 December 2017VishnuNo ratings yet

- Slinging Tubulars, Scaffold, BeamsDocument3 pagesSlinging Tubulars, Scaffold, BeamsAngel AngeleyeNo ratings yet

- EIAC Requirements TrainingDocument52 pagesEIAC Requirements TrainingFarrukh AhmedNo ratings yet

- Tech & Rigger Tools & PPEDocument2 pagesTech & Rigger Tools & PPESathiyaseelan VelayuthamNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- General Terms and Conditions of Online Application FormDocument1 pageGeneral Terms and Conditions of Online Application FormAhmed 7mamNo ratings yet

- The Squirrel-Cage Induction Motor Model and Its Parameter Identification Via Steady and Dynamic TestsDocument27 pagesThe Squirrel-Cage Induction Motor Model and Its Parameter Identification Via Steady and Dynamic TestsAhmed 7mamNo ratings yet

- Leea Book 3Document30 pagesLeea Book 3Ahmed 7mam100% (2)

- Check List (Quality Auditors) - Converted1Document65 pagesCheck List (Quality Auditors) - Converted1DeepakNo ratings yet

- MIS HersheysDocument31 pagesMIS HersheysKaustubh Kirti100% (1)

- Airman Products: More Options, Better SolutionsDocument10 pagesAirman Products: More Options, Better SolutionsAHMADNo ratings yet

- Revision Grade 3Document36 pagesRevision Grade 3AhmadNo ratings yet

- Supply Chain Tutorial4Document3 pagesSupply Chain Tutorial4高玉山67% (9)

- Amended Sop - Inspection For RTPDocument21 pagesAmended Sop - Inspection For RTPMarieo ParillaNo ratings yet

- Minda Corporation (Through Its Subsidiary) Announces A 50:50 Joint Venture With SBHAP, China (A BAIC Group Subsidiary) (Company Update)Document3 pagesMinda Corporation (Through Its Subsidiary) Announces A 50:50 Joint Venture With SBHAP, China (A BAIC Group Subsidiary) (Company Update)Shyam SunderNo ratings yet

- SIST EN 15328 2020 Opra1 2022Document10 pagesSIST EN 15328 2020 Opra1 2022pourya masoumiNo ratings yet

- File 1028201405303507 PDFDocument59 pagesFile 1028201405303507 PDFAr Abhinav SrivastavNo ratings yet

- Human Factors and The Accident Involving Aircraft VH-ZCRDocument7 pagesHuman Factors and The Accident Involving Aircraft VH-ZCRHao SuNo ratings yet

- Advice PDFDocument2 pagesAdvice PDFgeoff thomasNo ratings yet

- 2011 Nissan Towing GuideDocument27 pages2011 Nissan Towing Guidebuckley121No ratings yet

- Taguig City - Penalties & Violations: Code Type of Offence/Violation PenaltiesDocument3 pagesTaguig City - Penalties & Violations: Code Type of Offence/Violation PenaltiesZoe SanchezNo ratings yet

- Chery LP Setiembre 2023Document1 pageChery LP Setiembre 2023johaira.cmNo ratings yet

- BT Reprot Version 1Document11 pagesBT Reprot Version 1W GangenathNo ratings yet

- Thesis (RDL)Document4 pagesThesis (RDL)Romela Solero100% (1)

- Terex Peiner SK315 PDFDocument6 pagesTerex Peiner SK315 PDFJhony Espinoza Perez0% (1)

- JammuDocument3 pagesJammusonu sharmaNo ratings yet

- POSH Radiant 05052016Document2 pagesPOSH Radiant 05052016Andi IrfanNo ratings yet

- Управление маслостанцией PDFDocument12 pagesУправление маслостанцией PDFIvan MaltsevNo ratings yet

- Indian Standard: Design, Erection and Testing (Structural Portion) of Cranes and Hoists - Code of PracticeDocument76 pagesIndian Standard: Design, Erection and Testing (Structural Portion) of Cranes and Hoists - Code of PracticeKishalaya KunduNo ratings yet

- 100124119Document175 pages100124119mkeiwuaNo ratings yet

- Equasis - Ship Folder Nawata BhumDocument6 pagesEquasis - Ship Folder Nawata BhumKub Hasta Karya JombangNo ratings yet