Professional Documents

Culture Documents

Self Healing Material

Uploaded by

RISHIK GUPTAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Self Healing Material

Uploaded by

RISHIK GUPTACopyright:

Available Formats

In extrinsic self-healing systems,a healing agent is pre-embedded in the polymer matrix

in

microcapsules or vascular networks which, after material damage/cracking, release their content

into the crack plane, reacting and allowing the restoration of material functionalities. Extrinsic self-

healing materials can achieve healing efficiencies over 100% even when the damage is large.

These systems can be further subdivided in several categories.

• Microcapsule healing

microcapsules have a healing agent embedded into the bulk polymer matrix. When

cracks develop in the polymer matrix, the curing agent is released from the

microcapsules to cross-link and repair the cracks. In order for this process to happen

at room temperature, and for the reactants to remain in a monomeric state within the

capsule, a catalyst is also imbedded into the thermoset. The catalyst lowers

the energy barrier of the reaction and allows the monomer to polymerize without the

addition of heat.

• Hollow tube approach

For the first method, fragile glass capillaries or fibers are imbedded within a composite

material.The resulting porous network is filled with monomer. When damage occurs in the

material from regular use, the tubes also crack and the monomer is released into the cracks.

Other tubes containing a hardening agent also crack and mix with the monomer, causing the

crack to be healed

• Discrete channels

• Vascular approaches

• Interconnected networks

• Carbon nanotube networks

Nowadays an artificial

bone replacement can last up to 10-15

years. Good biocompatible self-healing

polymer composites may extend this

time. In dentistry, it can be used for

making artificial teeth and tooth filling

materials.

Fibre-reinforced polymer composites, metal alloy composites and fibre-reinforced ceramic

composites have been manufactured by adapting self-healing techniques for the past few

decades. Several of these materials find application in aerospace structures and components,

including fuselage, engines and coatings.

Body armor and other protection equipment made from materials that can

heal themselves will be helpful in battles or any other violent engagements. Even the jets

and ships of Airforce and Navy respectively could be made out of these materials.

Currently, innovative self-healing nanosystems are being developed with the help of computer

simulations for repairing damages.

Potential future uses for self-healing plastics include longer lasting cell-phones, cars and laptops,

whilst larger scale structures will also benefit, from aeroplanes to spacecraft. The future

possibilities for these smart materials look to be almost limitless.

two companies are attempting to bring the newer applications of self-healing materials to the

market. Arkema, a leading chemicals company, announced in 2009 the beginning of industrial

production of self-healing elastomers. [149] As of 2012, Autonomic Materials Inc., had raised over

three million US dollars.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Calorific Value of Liquid FuelDocument1 pageCalorific Value of Liquid FuelRISHIK GUPTANo ratings yet

- Available and Unavailable Energy: S T Q T T Q Q WDocument12 pagesAvailable and Unavailable Energy: S T Q T T Q Q WRISHIK GUPTANo ratings yet

- Available and Unavailable Energy: S T Q T T Q Q WDocument12 pagesAvailable and Unavailable Energy: S T Q T T Q Q WRISHIK GUPTANo ratings yet

- System of ForcesDocument23 pagesSystem of ForcesRISHIK GUPTANo ratings yet

- Pythagoras Theorem Statement-: Hypotenuse Perpendicular + BaseDocument2 pagesPythagoras Theorem Statement-: Hypotenuse Perpendicular + BaseRISHIK GUPTANo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- P44x Manual PDFDocument598 pagesP44x Manual PDFRK K100% (1)

- Aircraft Piston Engine Emissions: Appendix 4: Nanoparticle Measurements and Research For Cleaner AVGASDocument32 pagesAircraft Piston Engine Emissions: Appendix 4: Nanoparticle Measurements and Research For Cleaner AVGASYADWINDER SINGHNo ratings yet

- Esquema Electrico 320E - 300EDocument2 pagesEsquema Electrico 320E - 300EJuan Pablo Barron Marin100% (1)

- 1297 Manual PDFDocument118 pages1297 Manual PDFEWERTONNo ratings yet

- Class Notes - Digital Design - ch03 - Frank VahidDocument68 pagesClass Notes - Digital Design - ch03 - Frank VahidElder SantosNo ratings yet

- Rolling FrictionDocument4 pagesRolling FrictionBruno GarcíaNo ratings yet

- Highway Engineering EssayDocument4 pagesHighway Engineering EssayKevin Miscala MelendresNo ratings yet

- Work WearDocument10 pagesWork WearRahul KumarNo ratings yet

- Reportero IndustrialDocument19 pagesReportero IndustrialdayyanetNo ratings yet

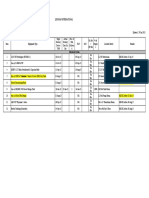

- (Electrical) M & E Major Equipment Delivery ScheduleDocument1 page(Electrical) M & E Major Equipment Delivery SchedulePaul KwongNo ratings yet

- Trailer Mounted Concrete Pump Catalog - Taian Sinotep Machinery Co.,Ltd - Concrete Pump Manufacturer in ChinaDocument25 pagesTrailer Mounted Concrete Pump Catalog - Taian Sinotep Machinery Co.,Ltd - Concrete Pump Manufacturer in ChinasinotepconcretepumpNo ratings yet

- Wind EnergyDocument16 pagesWind EnergygarysNo ratings yet

- Rapid PrototypingDocument17 pagesRapid PrototypingAkshAy ShAhNo ratings yet

- Geotechnical Investigations For Design and Construction of Airfield PavementsDocument63 pagesGeotechnical Investigations For Design and Construction of Airfield PavementsBajocarNo ratings yet

- Indian Coins Lots 1489-1631Document38 pagesIndian Coins Lots 1489-1631Mayank MevchaNo ratings yet

- 16-Concrete Pavements (Part 2) - Jointing in PCC ConstructionDocument89 pages16-Concrete Pavements (Part 2) - Jointing in PCC ConstructionHimanshu SainiNo ratings yet

- Isoreactive Red He3bDocument3 pagesIsoreactive Red He3bscribd_user2010No ratings yet

- 904L Round BarDocument4 pages904L Round BarSP METALNo ratings yet

- Tds Aqualoc Tp350Document1 pageTds Aqualoc Tp350Vikram ManeNo ratings yet

- Prestressed BeamDocument15 pagesPrestressed BeamMohamed Abbassy100% (1)

- Cycle Atlanta - Corridor ADocument28 pagesCycle Atlanta - Corridor AjmidtownNo ratings yet

- 1.0 Purpose: Standard Operating Procedure - EMS-0100.005 Name: Training Procedure City of GastoniaDocument129 pages1.0 Purpose: Standard Operating Procedure - EMS-0100.005 Name: Training Procedure City of GastoniaSanjay Kumar DubeyNo ratings yet

- HDK® H30: Product DescriptionDocument2 pagesHDK® H30: Product DescriptionjaviomoteroNo ratings yet

- Energies 11 01677 PDFDocument17 pagesEnergies 11 01677 PDFSantosa Edy WibowoNo ratings yet

- CROSS To Mann 2016Document94 pagesCROSS To Mann 2016Sebastian Ganci0% (1)

- Toshiba PCB Design Manual For Colour TV DesignDocument149 pagesToshiba PCB Design Manual For Colour TV DesignJames Head100% (1)

- Classic ManualDocument79 pagesClassic ManualHurricane Wind PowerNo ratings yet

- Gas Turbine Gas Fuel Composition Performance CorrectionDocument7 pagesGas Turbine Gas Fuel Composition Performance CorrectionDurga PrasadNo ratings yet

- Unit Weight or Density of Different Construction MaterialsDocument2 pagesUnit Weight or Density of Different Construction MaterialsHari RNo ratings yet

- Essar White Goods AnalysisDocument85 pagesEssar White Goods AnalysisRomil JainNo ratings yet