Professional Documents

Culture Documents

World-Beam QS18 Series Sensor: Instruction Manual

Uploaded by

swapnali patilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

World-Beam QS18 Series Sensor: Instruction Manual

Uploaded by

swapnali patilCopyright:

Available Formats

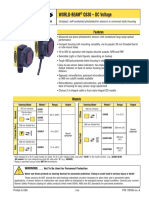

WORLD-BEAM® QS18 Series Sensor

Instruction Manual

Miniature Self-Contained Photoelectric Sensors in Universal Housing

• Easily fits (or retrofits) almost any mounting situation

• Exceptional optical performance, comparable to larger “MINI-style” or barrel sensors

• 10 V dc to 30 V dc operation, with complementary (SPDT) NPN or PNP outputs, depending

on model

• Bright LED operating status indicators are visible from 360°

• Rugged sealed housing, protected circuitry

• Models available with or without 18 mm threaded “nose”

• Less than 1 millisecond output response for excellent sensing repeatability

• Choose 2 m (6.5 ft) or 9 m (30 ft) cable or 150 mm (6 inch) Pico-style cabled QD

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to serious injury or

death. This device does not include the self-checking redundant circuitry necessary to allow its use in

personnel safety applications. A sensor failure or malfunction can cause either an energized or de-energized

sensor output condition.

Models

Model 1 Opposed Mode Range Output

QS186EV (624 nm Visible red) Effective beam: 13 mm (0.5 inch) —

QS186E (940 nm Infrared) —

QS18VN6R 20 m (66 ft) NPN

QS18VP6R OPPOSED OPPOSED PNP

QS186EB (940 nm Infrared) Effective beam: 13 mm (0.5 inch) —

QS18VN6RB NPN

3 m (10 ft)

QS18VP6RB PNP

OPPOSED

Model 1 Polarized Retroreflective Mode Range Output

QS18VN6LP 630 nm Visible red NPN

QS18VP6LP P 3.5 m (12 ft)

PNP

POLAR RETRO

1 • To order the 9 m (30 ft) PVC cable model, add the suffix "W/30" to the cabled model number. For example, QS186E W/30.

• To order the 4-pin M12/Euro-style integral quick disconnect model, add the suffix "Q8" to the model number. For example, QS186EQ8.

• To order the 4-pin M8/Pico-style integral quick disconnect model, add the suffix "Q7" to the model number. For example, QS186EQ7.

• To order the 150 mm (6 in) PVC cable model with a 4-pin M12/Euro-style quick disconnect, add the suffix "Q5" to the model number. For

example, QS186EQ5.

• To order the 150 mm (6 in) PVC cable model with a 4-pin M8/Pico-style quick disconnect, add the suffix "Q" to the model number. For example,

QS186EQ.

• Models with a quick disconnect require a mating cordset.

Original Document 29 September 2020

197052 Rev. F

197052

WORLD-BEAM® QS18 Series Sensor

Model 1 Retroreflective Mode Range Output

QS18VN6LV 628 nm Visible red NPN

6.5 m (21 ft)

QS18VP6LV PNP

RETRO

Model 1 Convergent Mode Range Output

QS18VN6CV15 630 nm Visible red NPN

16 mm (0.63 in)

QS18VP6CV15 PNP

QS18VN6CV45 NPN

43 mm (1.7 in)

QS18VP6CV45 CONVERGENT PNP

VISIBLE RED

Model 1 Diffuse Mode Range Output

QS18VN6D 940 nm Infrared NPN

450 mm (18 in)

QS18VP6D PNP

QS18VN6DL NPN

600 mm (24 in)

QS18VP6DL DIFFUSE PNP

QS18VN6DVS (Diffuse, Visible red) 630 nm Visible red NPN

250 mm (10 in)

QS18VP6DVS (Diffuse, Visible red) PNP

DIFFUSE

QS18VN6DB (Diffuse, wide) NPN

450 mm (18 in)

QS18VP6DB (Diffuse, wide) PNP

DIFFUSE

Model 1 Divergent Mode Range Output

QS18VN6W (Divergent, Infrared) 940 nm Infrared NPN

DIVERGENT

100 mm (4 in)

QS18VP6W (Divergent, Infrared) PNP

DIFFUSE

Model 1 Fixed Field Mode Range Output

QS18VN6FF50 NPN

50 mm (2 in)

QS18VP6FF50 630 nm Visible red PNP

QS18VN6FF100 NPN

100 mm (4 in)

QS18VP6FF100 PNP

QS18VP6FF125 125 mm (5 in) PNP

FIXED-FIELD

QS18VN6FF150 NPN

150 mm (6 in)

QS18VP6FF150 PNP

Model 1 Plastic Fiber Optic Mode Range Output

QS18VN6FP 660 nm Visible Red NPN

Range varies by sensing mode

QS18VP6FP and fiber optics used PNP

PLASTIC FIBER

2 www.bannerengineering.com - Tel: + 1 888 373 6767 P/N 197052 Rev. F

WORLD-BEAM® QS18 Series Sensor

Model 1 Glass Fiber Optic Mode Range Output

QS18VN6F 940 nm Infrared NPN

Range varies by sensing mode

QS18VP6F and fiber optics used PNP

GLASS FIBER

Wiring Diagrams

QS18 with NPN Outputs QS18 with PNP Outputs QS18 Emitters

bu (3) bn (1)

– +

brown

10–30 V dc 10–30 V dc

bn (1) bu (3)

–

+

+

bk (4) bk (4) 10–30 V DC

Load Load

blue

wh (2)

Load

wh (2)

Load

–

4-pin M12/Euro-style Models (Male) 4-pin M8/Pico-style Models (Male) Key

1 = Brown

1 2 4 2 = White

2 3 = Blue

4 1 3 4 = Black

3

Installing Fibers

Cutting Unterminated Plastic Fibers QS18V..6FP

Unterminated plastic fibers are designed to be cut by the user to the length required for the application.

To facilitate cutting, a Banner model PFC-1 cutting device is supplied with the fiber. Cut the fiber as follows:

Lift to Open Ports

Use small ports for fiber sizes:

Cutting Ports • 0.25 mm (0.01 inches)

• 0.5 mm (0.02 inches)

Use large ports for fiber sizes:

• 0.75 mm (0.03 inches)

• 1.0 mm (0.04 inches)

• 1.5 mm (0.06 inches)

Figure 1. PFC-1 Cutting Device

1. Locate the control end of the fiber (the unfinished end).

2. Determine the length of fiber required for the application. If using a bifurcated fiber, separate the two halves of the fiber at

least 51 mm (2 inches) beyond the fiber cutting location.

3. Lift the top (blade) of the cutter to open the cutting ports.

4. Insert one of the control ends through one of the cutting ports on the cutter so that the excess fiber protrudes from the

back of the cutter.

5. Double-check the fiber length, and close the cutter until the fiber is cut.

6. Using a different cutting port, cut the second control end to the required length.

Note: To ensure a clean cut each time, do not use a cutting port more than once.

7. Gently wipe the cut ends of the fiber with a clean, dry cloth to remove any contamination. Do not use solvents or abrasives

on any exposed optical fiber.

P/N 197052 Rev. F www.bannerengineering.com - Tel: + 1 888 373 6767 3

WORLD-BEAM® QS18 Series Sensor

Installing Plastic Fibers QS18V..6FP

Follow these steps to install the plastic fibers.

A C Fiber end

Adapter

B

Adapter Installation

Figure 2. Installing Plastic Fibers

1. Slide the fiber gripper up to unlock it (A).

2. If using 0.25 mm or 0.5 mm core fibers, slide the plastic fiber adapters onto the fibers, flush with the fiber ends.

3. Carefully insert the prepared plastic fiber ends into the ports (B) as far as possible without applying extra force.

4. Slide the fiber gripper down to lock the fibers in place (C).

Installing Glass Fibers QS18V..6F

Follow these steps to install the glass fibers.

Retaining Clip

O-rings

Figure 3. Installing Glass Fibers

1. Slide the supplied o-ring on the sensor end of the fibers, as shown.

2. Press the fiber ends firmly into the ports located on the front of the sensor.

3. Slide the supplied u-shaped retaining clip into the slot in the sensor’s barrel until the clip snaps into place.

Specifications

Supply Voltage Repeatability

10 V dc to 30 V dc (10% maximum ripple) at less than 25 mA, exclusive of Opposed Mode: 100 microseconds

load DVS, DL and FF Modes: 90 microseconds

Protected against reverse polarity and transient voltages All Other Modes: 150 microseconds

Light Source Output Configuration

Glass Fiber Optic, Opposed and Diffuse mode models: Infrared, 940 nm Solid-state complementary (SPDT): NPN or PNP (current sinking or

Plastic Fiber Optic, Retroreflective, Convergent models: Visible red, 660 nm sourcing), depending on model;

Fixed-Field and DVS models: Visible red, 630 nm Rating: 100 mA maximum each output at 25 °C

DVS, DL and FF Modes ON-state Saturation Voltage: less than 1.5 V at 10

Adjustments mA; less than 3 V at 100 mA

Glass Fiber Optic, Plastic Fiber Optic, Convergent, Diffuse, and All Other Modes: ON-state Saturation Voltage: less than 1 V at 10 mA; less

Retroreflective mode models (only): Single-turn sensitivity (Gain) adjustment than 1.5 V at 100 mA

potentiometer Protected against false pulse on power-up and continuous overload or short

Indicators circuit of outputs

2 LED indicators on sensor top Output Response

Green: Power on Opposed Mode: 750 microseconds ON; 375 microseconds OFF

Amber: Light sensed DVS, FF and DL Modes: 850 microseconds ON/OFF

Amber flashing: Marginal excess gain (1 to 1.5 times excess gain) All Other Modes: 600 microseconds ON/OFF

100 millisecond delay on power-up; outputs do not conduct during this time

4 www.bannerengineering.com - Tel: + 1 888 373 6767 P/N 197052 Rev. F

WORLD-BEAM® QS18 Series Sensor

Certifications Construction

ABS housing

3 mm mounting hardware included

Connections

2 m (6.5 ft) 4-wire PVC cable; 9 m (30 ft) 4-wire PVC cable; 4-pin M8/Pico-

style or M12/Euro-style QD; or 150 mm (6 in) cable with a 4-pin M8/Pico-

style or M12/Euro-style QD, depending on model

Required Overcurrent Protection Environmental

IEC IP67; NEMA 6

WARNING: Electrical connections must be

made by qualified personnel in accordance with Operating Conditions

local and national electrical codes and –20 °C to +70 °C (–4 °F to +158 °F)

regulations. 95% at +50 °C maximum relative humidity (non-condensing)

Overcurrent protection is required to be provided by end product Vibration and Mechanical Shock

application per the supplied table. All models meet MIL-STD-202F, Method 201A (Vibration: 10 Hz to 60 Hz

Overcurrent protection may be provided with external fusing or via Current maximum, 0.06 inch (1.52 mm) double amplitude, 10G maximum

Limiting, Class 2 Power Supply. acceleration) requirements. Also meets IEC 60947-5-2 (Shock: 30G 11 ms

Supply wiring leads < 24 AWG shall not be spliced. duration, half sine wave) requirements.

For additional product support, go to www.bannerengineering.com.

Note: For performance specifications of the

Supply Wiring (AWG) Required Overcurrent Protection (Amps)

FF50 and FF100 models built prior to date

20 5.0 code 17090, refer to document p/n 63908.

22 3.0

24 2.0

26 1.0

28 0.8

30 0.5

Dimensions

Model Suffix E, EV, R, and FF Model Suffix DB, W

Model Suffix EB, RB

31.0 mm

(1.22") 21.1 mm

21.1 mm

17.1 mm (0.82")

Yellow Green (0.82")

15.0 mm (0.67")

LED LED 3.0 mm

(0.59") 3.0 mm

3.0 mm (0.12")

(0.12")

(0.12")

24.1 mm 35.0 mm

(0.95") (1.38")

Ø3.3 mm (0.13")

Max. torque 0.6 Nm (5 in-lbs)

Model Suffix FP Model Suffix CV15, CV45, D, DL, LV, LP Model Suffix F

†

27.5 mm 31.0 mm

Single-turn 36.9 mm

15.0 mm (1.22")

(1.09") Sensitivity (1.45")

(0.59") 3.0 mm 17.1 mm 19.8 mm

17.1 mm Adjustment

(0.12") (0.67") (0.78")

(0.67") 7.5 mm

(0.30") †

CV Models:

13.4 mm 33.2 mm (1.31")

(0.53")

5.2 mm

(0.21")

7.6 mm

(0.30") M18x1 Thread

Max. torque 2.3 Nm (20 in-lbs) Slot for

Fiber Clip

P/N 197052 Rev. F www.bannerengineering.com - Tel: + 1 888 373 6767 5

WORLD-BEAM® QS18 Series Sensor

Model Suffix Q Model Suffix Q5 Model Suffix Q7 Model Suffix Q8

(e.g. QS186EQ) (e.g. QS186EQ5) (e.g. QS186EQ7) (e.g. QS186EQ8)

41.5 mm 49 mm

(1.63") (1.93")

150 mm (6")

Euro-Style

150 mm (6") QD Integral Integral

Pico-Style 4-pin 4-pin

QD Pico-Style QD Euro-Style QD

M18 x 1 Jam Nut M3 hardware packet contents: Packing list:

• 2 - M3 x 0.5 x 20 mm stainless steel screw • Sensor

• 2 - M3 x 0.5 stainless steel hex nut • M18 x 1 jam nut

• 2 - M3 stainless steel washer • M3 hardware packet

24.2 mm

(0.95") • Quick Start Guide, p/n 63687

8.0 mm

(0.32")

Performance Curves

Opposed Mode

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

1000 1000

QS186E, EV and QS18...R QS186EB and QS18...RB

QS186E, EV and 750 mm 30 in QS186EB and 450 mm 18 in

E Opposed Mode E QS18...RB Opposed Mode

QS18...R 500 mm 20 in

X X 300 mm 12 in

Opposed Mode Opposed Mode

C 250 mm 10 in C 150 mm 6 in

100 100

E 0 0 E 0 0

S 250 mm 10 in S 150 mm 6 in

S 500 mm 20 in

S

300 mm 12 in

750 mm 30 in

G 10 G 10 450 mm 18 in

A A

0 4m 8m 12 m 16 m 20 m

I 12 ft 26 ft 40 ft 52 ft 66 ft

I 0 .75 m

2.5 ft

1.5 m

5 ft

2.25 m

7.5 ft

3.0 m

10 ft

3.75 m

12.5 ft

N N

DISTANCE DISTANCE

1 1

0.1 m 1m 10 m 100 m 0.01 m 0.1 m 1m 10 m

0.3 ft 3.3 ft 33 ft 330 ft 0.03 ft 0.33 ft 3.3 ft 33 ft

DISTANCE DISTANCE

Polarized Retroreflective Retroreflective

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

1000 1000

QS18...LP QS18...LV

QS18...LP 30 mm 1.2 in QS18...LV 150 mm

Retroreflective Mode

6 in

E Retroreflective Mode E Retroreflective Mode

20 mm 0.8 in 100 mm 4 in

X Retroreflective Mode X

C 10 mm

with BRT-84 Reflector

0.4 in

C 50 mm

with BRT-84 Reflector

2 in

100 100

E 0 0 E 0 0

S 10 mm 0.4 in S 50 mm 2 in

S with BRT-84 Reflector

20 mm 0.8 in S 100 mm 4 in

30 mm 1.2 in

G 10 G 10

with BRT-84 Reflector

150 mm 6 in

A 0 .75 m 1.5 m 2.25 m 3.0 m 3.75 m A

I 0 1.5 m 3.0 m 4.5 m 6.0 m 7.5 m

2.5 ft 5 ft 7.5 ft 10 ft 12.5 ft I 5 ft 10 ft 15 ft 20 ft 25 ft

N DISTANCE N

DISTANCE

1 1

0.01 m 0.1 m 1m 10 m 0.01 m 0.1 m 1m 10 m

0.03 ft 0.33 ft 3.3 ft 33 ft 0.03 ft 0.33 ft 3.3 ft 33 ft

DISTANCE DISTANCE

6 www.bannerengineering.com - Tel: + 1 888 373 6767 P/N 197052 Rev. F

WORLD-BEAM® QS18 Series Sensor

Convergent (Performance is based on a 90% reflectance white test card.)

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

1000 1000 QS18...CV45

6 mm

QS18...CV15 .24 in 6 mm .24 in

QS18...CV15 QS18...CV45

E 4 mm

Convergent Mode

.16 in

E 4 mm

Convergent Mode

.16 in

X Convergent Mode X Convergent Mode

2 mm .08 in 2 mm .08 in

C C

100 100

E 0 0 E 0 0

S 2 mm .08 in S 2 mm .08 in

S 4 mm .16 in

S 4 mm .16 in

6 mm .24 in 6 mm .24 in

G 10 G 10

A A

0 10 mm 20 mm 30 mm 40 mm 50 mm 0 15 mm 30 mm 45 mm 60 mm 75 mm

I 0.4 in 0.8 in 1.2 in 1.6 in 2.0 in

I 0.6 in 1.2 in 1.8 in 2.4 in 3.0 in

N N

DISTANCE DISTANCE

1 1

1 mm 10 mm 100 mm 1000 mm 1 mm 10 mm 100 mm 1000 mm

0.04 in 0.4 in 4.0 in 40.0 in 0.04 in 0.4 in 4.0 in 40.0 in

DISTANCE DISTANCE

Diffuse (Performance is based on a 90% reflectance white test card.)

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

1000 1000

QS18...D

QS18...D 6 mm .24 in

10 mm

E Diffuse Mode QS18 DL

4 mm .16 in 8 mm QS18 DL

X Diffuse Mode 6 mm

C 2 mm .08 in

EXCESS GAIN

100 100 4 mm

E 0 0

2 mm

S 2 mm .08 in 0

S 2 mm

4 mm .16 in

4 mm

G 10 6 mm .24 in 10

6 mm

A 8 mm

I 0 100 mm 200 mm 300 mm 400mm 500 mm

10 mm

4.0 in 8.0 in 12.0 in 16.0 in 20.0 in

N 0 200 400 600 800

1 DISTANCE 1

1 mm 10 mm 100 mm 1000 mm 1 10 100 1000 DISTANCE (mm)

0.04 in 0.4 in 4.0 in 40.0 in

DISTANCE (mm)

DISTANCE

Diffuse (Performance is based on a 90% reflectance white test card.)

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

1000 1000 2.5 mm

QS18...DB

QS18...DB 30 mm 1.2 in QS18...DVS 2 mm

E Diffuse Mode 1.5 mm QS18...DVS

X Diffuse Mode

20 mm 0.8 in

Diffuse Mode 1 mm Diffuse Mode

C 10 mm 0.4 in

0.5 mm

100 100

E

EXCESS GAIN

0 0 0

S

10 mm 0.4 in 0.5 mm

S 1 mm

20 mm 0.8 in

1.5 mm

G 10 30 mm 1.2 in 10

2 mm

A 2.5 mm

I 0 100 mm 200 mm 300 mm 400mm 500 mm 0 50 100 150 200 250 300

N 4.0 in 8.0 in 12.0 in 16.0 in 20.0 in Distance (mm)

1 DISTANCE 1

1 mm 10 mm 100 mm 1000 mm 1 mm 10 mm 100 mm 1000 mm

0.04 in 0.4 in 4.0 in 40.0 in 0.04 in 0.4 in 4.0 in 40.0 in

DISTANCE DISTANCE

Divergent (Performance is based on a 90% reflectance white test card.)

Excess Gain Curve Beam Pattern

1000

30 mm

QS18...W 1.2 in

QS18...W

E Divergent

20 mm Diffuse Mode 0.8 in

X Divergent

C Diffuse Mode

10 mm 0.4 in

100

E 0 0

S 10 mm 0.4 in

S

20 mm 0.8 in

G 10 30 mm 1.2 in

A

I 0 20 mm 40 mm 60 mm 80 mm 100 mm

0.8 in 1.6 in 2.4 in 3.2 in 4.0 in

N

1 DISTANCE

1 mm 10 mm 100 mm 1000 mm

0.04 in 0.4 in 4.0 in 40.0 in

DISTANCE

P/N 197052 Rev. F www.bannerengineering.com - Tel: + 1 888 373 6767 7

WORLD-BEAM® QS18 Series Sensor

Fixed Field

Excess Gain Curve (50 mm) Excess Gain Curve (100 mm) Excess Gain Curve (150 mm) Spot Sizes

1000

1000

QS18..FF100

1000 50 mm Models:

QS18..FF50 QS18..FF150

At 25 mm: 8 × 5.5 mm

100 100

At 50 mm: 6 × 5 mm

100

100 mm Models

Excess Gain

Excess Gain

Excess Gain

At 50 mm: 6 × 4 mm

10 10 10

At 100 mm: 3 × 3 mm

150 mm Models

1

1

0.1 1 10 100

1

0.1 1 10 100 1000 0.1 1 10 100 1000 At 75 mm: 5 × 3.5 mm

Distance (mm)

Distance (mm) Distance (mm) At 150 mm: 6 × 6 mm

Opposed - Plastic Fiber Bifurcated - Plastic Fiber (Performance is based on a 90% reflectance white test

card.)

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

1000 QS18..FP 1000 QS18..FP

QS18..FP 60 mm QS18..FP 2.4 in QS18..FP 30 mm 1.2 in

E QS18..FP

QS18..FP E QS18..FP Diffuse Mode

40 mm PIT66U 1.6 in

X X Diffuse Mode

20 mm

Plastic Fibers

0.8 in

C PBT66U

Opposed Mode 20 mm 0.8 in C Plastic Fibers 10 mm 0.4 in

100 PIT46U 100

E Plastic Fibers 0 0 E 0 0

S 20 mm 0.8 in S PBT66U Fiber 10 mm 0.4 in

S S PBT46U

PIT66U Fiber 40 mm 1.6 in 20 mm 0.8 in

Opposed Mode

G 10 60 mm Plastic Fibers 2.4 in G 10 30 mm 1.2 in

A PIT46U Fiber

A

I 0 50 mm 100 mm 150 mm 200 mm 250 mm I 0 20 mm 40 mm 60 mm 80 mm 100 mm

2 in 4 in 6 in 8 in 10 in

N N PBT46U Fiber 0.8 in 1.6 in 2.4 in 3.2 in 4.8 in

1 DISTANCE 1 DISTANCE

1 mm 10 mm 100 mm 1000 mm .1 mm 1 mm 10 mm 100 mm

.04 in .40 in 4.0 in 40 in .004 in .04 in .4 in 4 in

DISTANCE DISTANCE

Opposed - Glass Fiber (Performance is based on a 90% reflectance white test Bifurcated - Glass Fiber (Performance is based on a 90% reflectance white test

card.) card.)

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

1000 1000

QS18F 75 mm

QS18F 3 in QS18F 1.9 mm 0.075 in

E Opposed Mode E QS18F

50 mm 2 in 1.3 mm 0.050 in

X X Diffuse Mode

Diffuse Mode

C Opposed Mode 25 mm 1 in C Glass Fibers

0.65 mm 0.025 in

100 Glass Fibers 100

E 0 IT13S IT23S 0 E 0 BT13S BT23S 0

S 25 mm 1 in S 0.65 mm 0.025 in

S IT23S Fibers S 1.3 mm 0.050 in

50 mm 2 in

w/L9 lenses BT23S Fiber 1.9 mm 0.075 in

G 10 75 mm 3 in G 10

A A 0 7.5 mm 15 mm 22.5 mm 30 mm 37.5 mm

I IT13S IT23S 0 100 mm 200 mm 300 mm 400 mm 500 mm I 0.3 in 0.6 in 0.9 in 1.2 in 1.5 in

Fibers Fibers 4 in 8 in 12 in 16 in 20 in BT13S Fiber

N N DISTANCE

DISTANCE 1

1

.01 m .1 m 1m 10 m 1 mm 10 mm 100 mm 1000 mm

.033 ft .33 ft 3.3 ft 33 ft .04 in .4 in 4 in 40 in

DISTANCE DISTANCE

Accessories

Cordsets

4-Pin Threaded M12/Euro-Style Cordsets—Single Ended

Model Length Style Dimensions Pinout (Female)

MQDC-406 2 m (6.56 ft)

MQDC-415 5 m (16.4 ft)

44 Typ. 2

1

MQDC-430 9 m (29.5 ft)

3

4

Straight

M12 x 1

MQDC-450 15 m (49.2 ft) ø 14.5 1 = Brown

2 = White

3 = Blue

4 = Black

8 www.bannerengineering.com - Tel: + 1 888 373 6767 P/N 197052 Rev. F

WORLD-BEAM® QS18 Series Sensor

4-Pin Threaded M12/Euro-Style Cordsets—Single Ended

Model Length Style Dimensions Pinout (Female)

MQDC-406RA 2 m (6.56 ft)

32 Typ.

MQDC-415RA 5 m (16.4 ft) [1.26"]

MQDC-430RA 9 m (29.5 ft)

30 Typ.

Right-Angle [1.18"]

MQDC-450RA 15 m (49.2 ft)

M12 x 1

ø 14.5 [0.57"]

4-Pin Snap-on M8/Pico-Style Cordsets—Single Ended

Model Length Style Dimensions Pinout (Female)

32 Typ.

PKG4-2 2.03 m (6.66 ft) Straight

ø 9.0

4 2

3 1

29 Typ.

1 = Brown

PKW4Z-2 2 m (6.56 ft) Right-Angle 2 = White

15 Typ. 3 = Blue

4 = Black

ø 10.9

Sensor Status Indicators

S15L Series In-Line Sensor Status Indicator

Input

Model LED Color Dimensions Female Male Wiring

Type

S15LGYPQ PNP 57.8

[2.27]

Power ON = 1 1 = Brown, 10 to 30 V DC

27.9 2

Green [1.1] 1 2 2 = White

S15LGYNQ NPN Input Active = 3 4 3 = Blue, dc common

15.0 4 3

Yellow [0.59] 4 = Black, Sensor Input

WORLD-BEAM QS18 Brackets

SMB18A SMB312S

• Right-angle mounting 30

• Stainless steel 2-axis, side- B

bracket with a curved slot mount bracket

for versatile orientation C 41 46

• 12-ga. stainless steel A B C

• 18 mm sensor mounting A

hole

46

• Clearance for M4 (#8)

hardware 32

20

Hole center spacing: A to B = 24.2

Hole size: A = ø 4.6, B = 17.0 × 4.6, C = ø 18.5 A = 4.3 × 7.5, B = diam. 3, C = 3 × 15.3

All measurements are in millimeters.

P/N 197052 Rev. F www.bannerengineering.com - Tel: + 1 888 373 6767 9

WORLD-BEAM® QS18 Series Sensor

Retroreflective Targets

Go to www.bannerengineering.com or see the Accessories section of your current Banner Engineering Corp catalog for complete

information.

Note: Polarized sensors require corner cube type retroreflective targets only.

Plastic and Glass Fiber Optics

Go to www.bannerengineering.com or see the Accessories section of your current Banner Engineering Corp catalog for a list of

plastic and glass fiber optic cables.

Banner Engineering Corp. Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner Engineering Corp. will repair or

replace, free of charge, any product of its manufacture which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty does not

cover damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO

BUYER OR ANY OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES

RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT,

STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or liabilities relating to any product previously

manufactured by Banner Engineering Corp. Any misuse, abuse, or improper application or installation of this product or use of the product for personal protection applications when the

product is identified as not intended for such purposes will void the product warranty. Any modifications to this product without prior express approval by Banner Engineering Corp will

void the product warranties. All specifications published in this document are subject to change; Banner reserves the right to modify product specifications or update documentation at

any time. Specifications and product information in English supersede that which is provided in any other language. For the most recent version of any documentation, refer to:

www.bannerengineering.com.

For patent information, see www.bannerengineering.com/patents.

FCC Part 15 and CAN ICES-3 (B)/NMB-3(B)

This device complies with part 15 of the FCC Rules and CAN ICES-3 (B)/NMB-3(B). Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules and CAN ICES-3 (B)/NMB-3(B). These limits are

designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the manufacturer.

© Banner Engineering Corp. All rights reserved

You might also like

- Semiconductor Interview Questions and Answers 2022Document6 pagesSemiconductor Interview Questions and Answers 2022Naznin Nuria AfrinNo ratings yet

- IKEA Kitchen Dreambook 2013Document35 pagesIKEA Kitchen Dreambook 2013Thomas Solis100% (3)

- Minarelli AM6 Engine Workshop Manual PDFDocument35 pagesMinarelli AM6 Engine Workshop Manual PDFAndrás SzántaiNo ratings yet

- Manual Service RICOH MP 402SPFDocument776 pagesManual Service RICOH MP 402SPFTECNOSERVICEARG100% (2)

- 4G Alarms TroubleshootingDocument22 pages4G Alarms TroubleshootingNirdosh Chhasatiya100% (2)

- MS-Installation 11Kv Switch Gear at Lusail-CP1Document6 pagesMS-Installation 11Kv Switch Gear at Lusail-CP1Tayab Ansari100% (2)

- Product Knowledge WKJ Series 2020 (Share)Document43 pagesProduct Knowledge WKJ Series 2020 (Share)ariefsusanto800% (2)

- Manual-TRACTEL-Tirak Passenger Wire Rope Hoists Elevator Installations-EN PDFDocument36 pagesManual-TRACTEL-Tirak Passenger Wire Rope Hoists Elevator Installations-EN PDFamcneelaNo ratings yet

- Sensor Datasheet PDFDocument9 pagesSensor Datasheet PDFDanish AhamadNo ratings yet

- World-Beam Qs18: DatasheetDocument10 pagesWorld-Beam Qs18: DatasheetHdufNo ratings yet

- Banner QS18 PDFDocument7 pagesBanner QS18 PDFplasticos_jfm6580No ratings yet

- Annexes Devoir 2223Document8 pagesAnnexes Devoir 2223Omar MenichiNo ratings yet

- World-Beam QS18E Series: DatasheetDocument11 pagesWorld-Beam QS18E Series: DatasheetDébora Dos SanttosNo ratings yet

- World-Beam® Qs18: ModelsDocument3 pagesWorld-Beam® Qs18: ModelssanjeckaNo ratings yet

- S18-2 Plastic 18 MM Barrel Sensors: DatasheetDocument10 pagesS18-2 Plastic 18 MM Barrel Sensors: DatasheetAlisonNo ratings yet

- World-Beam Q12 Series Sensors: DatasheetDocument8 pagesWorld-Beam Q12 Series Sensors: DatasheetRoddo RivNo ratings yet

- Banner Q12Document9 pagesBanner Q12Dian HerpadianaNo ratings yet

- Q45AD9 NAMUR Series Sensor: DatasheetDocument10 pagesQ45AD9 NAMUR Series Sensor: DatasheetEngineer ajmalNo ratings yet

- T18 Series Sensors (DC Voltage) : Installation GuideDocument4 pagesT18 Series Sensors (DC Voltage) : Installation GuideLewton CamposNo ratings yet

- QS30Document10 pagesQS30David EspiritusantoNo ratings yet

- Baliza RunbarDocument6 pagesBaliza RunbarsamuelNo ratings yet

- T18 Series Sensors (DC Voltage) : DatasheetDocument7 pagesT18 Series Sensors (DC Voltage) : DatasheetPauli TaNo ratings yet

- Mini-Beam 2 - QS12 Series Mini-Beam: FeaturesDocument8 pagesMini-Beam 2 - QS12 Series Mini-Beam: Featuresviernes06No ratings yet

- 63908Document10 pages63908mateusT850No ratings yet

- Valu-Beam 912 Series: DatasheetDocument12 pagesValu-Beam 912 Series: Datasheetgabriela grigorasNo ratings yet

- Electrical DraiwngDocument64 pagesElectrical Draiwngplasticos_jfm6580No ratings yet

- Banner Vs3rn5xlpDocument5 pagesBanner Vs3rn5xlpffNo ratings yet

- Banner Miniature Photo EyesDocument20 pagesBanner Miniature Photo EyesMemik TylnNo ratings yet

- Ficha Sensor de NivelDocument12 pagesFicha Sensor de NivelVicky GarcesNo ratings yet

- Inventario Stok de Sensores AlmacenDocument5 pagesInventario Stok de Sensores AlmacenLuis OjedaNo ratings yet

- Sensor EnfaldadorasDocument7 pagesSensor EnfaldadorasAlexander SanchezNo ratings yet

- ArchitectureDocument1 pageArchitectureMarian VladianuNo ratings yet

- Banner Download PDF K50 GBDocument8 pagesBanner Download PDF K50 GBParth GaurNo ratings yet

- Jma 650-7 650-9 660 850-7 850-9 860Document269 pagesJma 650-7 650-9 660 850-7 850-9 860toumassis_pNo ratings yet

- VS2 Series Opposed-Mode SensorsDocument4 pagesVS2 Series Opposed-Mode SensorsWilmer Yesid Granados JaimesNo ratings yet

- Ficha Tecnica Sensor Banner QS18VP6LLPQ8Document7 pagesFicha Tecnica Sensor Banner QS18VP6LLPQ8Gustavo EgasNo ratings yet

- M18 DC Photoelectric Switches With Optional Diffuse Sensitivity Adjustment SSDocument4 pagesM18 DC Photoelectric Switches With Optional Diffuse Sensitivity Adjustment SSهبال حمزةNo ratings yet

- Sistema de MedicionDocument8 pagesSistema de MedicionBlack Cat ColorNo ratings yet

- SGM2048Document17 pagesSGM2048wang seikeNo ratings yet

- Sesnsor Laser Bannner LTEPUQDocument12 pagesSesnsor Laser Bannner LTEPUQDiego VolponiNo ratings yet

- Cam Bien Quang Fotek m18 CDocument4 pagesCam Bien Quang Fotek m18 CPhát Huỳnh TấnNo ratings yet

- M18-C M18-C M18-C: SpecificationDocument4 pagesM18-C M18-C M18-C: Specificationiozsa cristianNo ratings yet

- TRC TypeDocument4 pagesTRC TypeDAPS PSNo ratings yet

- Pho M18Document4 pagesPho M18Irfan GhaniNo ratings yet

- M-18C Photo SensorDocument4 pagesM-18C Photo SensorLAUTHUSNo ratings yet

- Catálogo EZ-LightDocument4 pagesCatálogo EZ-Lightbrunonunes2010No ratings yet

- Banner MINI BEAM Photo EyesDocument37 pagesBanner MINI BEAM Photo EyesMemik TylnNo ratings yet

- RGK600 - RGK700 - RGK800 RGK900Document78 pagesRGK600 - RGK700 - RGK800 RGK900ahmed elsheikhNo ratings yet

- 6-Port Antenna: 6177488N 6177488G 6177488NGDocument4 pages6-Port Antenna: 6177488N 6177488G 6177488NGMustafa QaizarNo ratings yet

- Ultrasonic Sensors For High Precision Detection of Clear and Transparent ObjectsDocument8 pagesUltrasonic Sensors For High Precision Detection of Clear and Transparent ObjectsАлександр КачинскийNo ratings yet

- Amphenol 8 Port PDFDocument6 pagesAmphenol 8 Port PDFsevri28No ratings yet

- Manual Instalacao Sensor Ultrasonico Ua18cad04ngm1tiDocument4 pagesManual Instalacao Sensor Ultrasonico Ua18cad04ngm1tiMarcelo SilvaNo ratings yet

- ts2 Mini Joystick enDocument3 pagests2 Mini Joystick enjakalae5263No ratings yet

- 0009 - USDA 5000 Tonnage SPOB-1Document7 pages0009 - USDA 5000 Tonnage SPOB-1lutvi engineeringNo ratings yet

- Schneider SparesDocument2 pagesSchneider Sparesgovindarul4067No ratings yet

- Features: Low Cost Very High Performance SMD GPS ModuleDocument13 pagesFeatures: Low Cost Very High Performance SMD GPS ModulemauriceNo ratings yet

- VSAT-Products 2022r1Document24 pagesVSAT-Products 2022r1maolongwgNo ratings yet

- 8-Port Antenna: 6177700N 6177700G 6177700NGDocument6 pages8-Port Antenna: 6177700N 6177700G 6177700NGInsyafa NalaprajaNo ratings yet

- Q10 Series: Miniature SensorsDocument2 pagesQ10 Series: Miniature SensorsAbdalla FarisNo ratings yet

- Mini-Beam sm312cv2qdDocument14 pagesMini-Beam sm312cv2qdedgar rdzNo ratings yet

- IEC 60947-7-1, IEC 61439-2: Acti 9 Ic60, Ik60 18 MM Poles, CuttableDocument2 pagesIEC 60947-7-1, IEC 61439-2: Acti 9 Ic60, Ik60 18 MM Poles, CuttableBijay KumarNo ratings yet

- PRCM - AutonicsDocument8 pagesPRCM - AutonicsLuis Alberto Vilchez ChiroqueNo ratings yet

- UA18CLD UA30CLD DigitalDocument3 pagesUA18CLD UA30CLD DigitalDirgam DirgamNo ratings yet

- WORLD-BEAM QS18E Clear Object Detection: Quick Start GuideDocument4 pagesWORLD-BEAM QS18E Clear Object Detection: Quick Start GuideDébora Dos SanttosNo ratings yet

- Sensors SOE, Opto-ElectronicDocument62 pagesSensors SOE, Opto-ElectronicBelli DavideNo ratings yet

- Empire Vent Free SR10, SR18, SR30 BF10, BF20, BF30Document25 pagesEmpire Vent Free SR10, SR18, SR30 BF10, BF20, BF30NorthernPropaneNo ratings yet

- Matlab/Simulink Models For Typical Soft Starting Means For A DC MotorDocument6 pagesMatlab/Simulink Models For Typical Soft Starting Means For A DC MotorkensesanNo ratings yet

- Oip VS Rip-2 PDFDocument11 pagesOip VS Rip-2 PDFKarthik SriramakavachamNo ratings yet

- Symantec NetBackup 5230 Appliance and Symantec Storage Shelf Product DescriptionDocument39 pagesSymantec NetBackup 5230 Appliance and Symantec Storage Shelf Product Descriptionjarg200690No ratings yet

- 7SR11 and 7SR12 Argus Catalogue SheetDocument24 pages7SR11 and 7SR12 Argus Catalogue SheetGokul VenugopalNo ratings yet

- LPS Maintenance & TestingDocument6 pagesLPS Maintenance & TestingAri HastantoNo ratings yet

- Mosfets Prod GuideDocument63 pagesMosfets Prod GuideMuriel RembertoNo ratings yet

- Introduction To CMOS VLSI DesignDocument30 pagesIntroduction To CMOS VLSI DesignAbdelrehim SirajNo ratings yet

- Vingcard Allure: User ManualDocument54 pagesVingcard Allure: User ManualBilal El-Sayed AliNo ratings yet

- Analysis of The Indian Maintenance Center For WAG-9 Electric Locomotives and Improve For New Railways ServiceDocument45 pagesAnalysis of The Indian Maintenance Center For WAG-9 Electric Locomotives and Improve For New Railways Service2251 EE MANMAT BIRADARNo ratings yet

- Voltage Check - RDC22.20Document3 pagesVoltage Check - RDC22.20Daniel AguirreNo ratings yet

- City of Malabon Electronics Permit: Office of The Building OfficialDocument1 pageCity of Malabon Electronics Permit: Office of The Building OfficialPhel FloresNo ratings yet

- Emergency Button For 7$, Arduino, WIFI and ESP8266: Technology Workshop Craft Home Food Play Outside CostumesDocument13 pagesEmergency Button For 7$, Arduino, WIFI and ESP8266: Technology Workshop Craft Home Food Play Outside CostumesJunior CostaNo ratings yet

- ATEX Sales GuideDocument22 pagesATEX Sales GuideDanilo SampaioNo ratings yet

- Retrofit Solution For Circuit Breaker Type EDF: Desiccant Canister Helps Improving SF Gas QualityDocument2 pagesRetrofit Solution For Circuit Breaker Type EDF: Desiccant Canister Helps Improving SF Gas QualityRakesh SahaNo ratings yet

- Dimensiones de Bomba Viking L124Document1 pageDimensiones de Bomba Viking L124nerio gerardinoNo ratings yet

- Product Information: Dual Clutch Transmission Oil 8100Document1 pageProduct Information: Dual Clutch Transmission Oil 8100nazirsayyedNo ratings yet

- Coolex Concealed Ducted Split Units R407C 24-60 MBH 50HzDocument20 pagesCoolex Concealed Ducted Split Units R407C 24-60 MBH 50HzAhmed MagdyNo ratings yet

- Select Line Condenser Coil: When Our Premium Coil May Be More Than You Need - You Now Have A Quality AlternativeDocument1 pageSelect Line Condenser Coil: When Our Premium Coil May Be More Than You Need - You Now Have A Quality AlternativecarlosNo ratings yet

- Weller Model Wes51 Electronic Soldering StationDocument7 pagesWeller Model Wes51 Electronic Soldering StationlukaNo ratings yet

- 30ETH06 30ETH06S 30ETH06-1: Hyperfast RectifierDocument9 pages30ETH06 30ETH06S 30ETH06-1: Hyperfast RectifierAdrian NascimentoNo ratings yet

- Katko Switches Technical Information AllDocument10 pagesKatko Switches Technical Information AllSanishka NiroshanNo ratings yet

- NEW SUV PEUGEOT 3008 01092020 PressInfo ENDocument14 pagesNEW SUV PEUGEOT 3008 01092020 PressInfo ENGustavoNo ratings yet