Professional Documents

Culture Documents

MED 111 Principles of Design and

MED 111 Principles of Design and

Uploaded by

Abanoub Hany Abd Elmalak SalehOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MED 111 Principles of Design and

MED 111 Principles of Design and

Uploaded by

Abanoub Hany Abd Elmalak SalehCopyright:

Available Formats

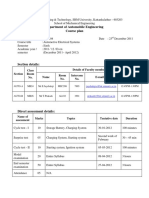

المعهد الكندي العالي لتكنولوجيا

الهندسة و اإلدارة

Engineering Department Course Name: Principles of Design &

Manufacturing Engineering

Academic Year : 2018/2019 Course Code: MED 111

Spring Semester Exam Period: 1.5 hrs

Mid Exam Total Marks: 40 marks

Instructor Name: Dr. Mohamed Abdel Azeem No. of Pages: 2 pages

ILOs Mark Time

K4,I9,G8 8 15

Question # 1

Explain in sequence the general steps for design a product?

Question # 2 ILOs Mark Time

K4,I4,P2 4 10

Explain & Draw the concept of safety factor during the design of mechanical

parts using ductile material and brittle material. What are the factors affecting the

selection of safety factor? ILOs Mark Time

K17,I3,P6 6 15

Question # 3

A metal bar with five meters long and five cm in diameter is heated to 125 Co, if

the free expansion is prevented find the magnitude and nature of bar induced

stress if the bar material modulus of elasticity is 3x105 N/mm2 with thermal

coefficient of expansion 0.000008/C0 .

ILOs Mark Time

Question # 4 K4,I4,P2 4 10

Compare between mechanical stress and thermal stress. What is the relation

between mechanical stress and thermal stress?

Question # 5

ILOs Mark Time

K4,I4,P2 4 10

Calculate the thermal expansion coefficient and the final length of a circular

metal rod with a circumference of 40 mm and original length 40 cm , if

0.0001 plastic thermal strain is generated due to 80 Co temperature raise .

المعهد الكندي العالي لتكنولوجيا الهندسة و اإلدارة Page 2

المعهد الكندي العالي لتكنولوجيا

الهندسة و اإلدارة

Question # 6 ILOs Mark Time

K4,I4,P2 2 5

Describe with Drawing the different types of power screw?

Question # 7 ILOs Mark Time

K4,I4,P2 2 5

Describe with Draw the different types of keys that connect shaft with hub?

Question # 8

Correct the wrong statement of the following : ILOs Mark Time

1- Bending stress developed due to shear stress. K4,I4,P2 10 20

2- Tensile stress developed due to compressive force..

3- The technical support of the new product (non-existing product) is different

than the existing product.

4- During design the working stress must equal the yield stress.

5- The key between shaft and hub is subjected to shearing and twisting load.

6- The higher safety factor result into higher product cost.

7- The rod length is equal to the original length during plastic zone.

8- Spring is plastic member to withstand load.

9- The difference between spring free length and spring solid length is the

spring working space.

10- Power screws must have adequate bearing area to withstand force.

Examination Committee

Name Signature

Dr. Mohamed Abd El-Azeem Mohamed Abd El-Azeem

Dr. Tarek Anwer Madboly Tarek Anwer Madboly

المعهد الكندي العالي لتكنولوجيا الهندسة و اإلدارة Page 2

You might also like

- OP Malhotra-Law of Industrial DisputesDocument1,264 pagesOP Malhotra-Law of Industrial DisputesAnkita Shah Jain83% (6)

- Cummins v555 Series Parts CatalogDocument4 pagesCummins v555 Series Parts Catalogdeborah100% (57)

- The Jeepney PhaseDocument12 pagesThe Jeepney PhaseShaiAbretilNieloMalinao100% (1)

- 0 - 3D Printing MT-2 Questions PaperDocument2 pages0 - 3D Printing MT-2 Questions PaperMaradugu Krishna Sai VigneshNo ratings yet

- ISO27k Gap Analysis - Executive SummaryDocument9 pagesISO27k Gap Analysis - Executive Summaryjtabeling100% (2)

- Lab Manual IpeDocument700 pagesLab Manual IpeMominul Islam OpuNo ratings yet

- Exercise No. 5 Welding: Mtec 121: Workshop Theory and Practice 116Document14 pagesExercise No. 5 Welding: Mtec 121: Workshop Theory and Practice 116Mark Anthony Salazar ArcayanNo ratings yet

- MME 1061 Workshop PracticeDocument111 pagesMME 1061 Workshop Practicekaleem zargarNo ratings yet

- 5 6280779123619004524 PDFDocument143 pages5 6280779123619004524 PDFÀràvìñd CháñNo ratings yet

- C-14-Deee-V&vi SemsDocument87 pagesC-14-Deee-V&vi Semsd ramNo ratings yet

- 686 Electromedical Technology 2nd SemDocument24 pages686 Electromedical Technology 2nd Semmaymonamou 2001No ratings yet

- DKN10022 Practical Task 3Document11 pagesDKN10022 Practical Task 3Nisha PanneerNo ratings yet

- Effect of Recast Layer Thickness On The Mechanical Characteristics of INCONEL 718 Machined by Spark EDM ProcessDocument7 pagesEffect of Recast Layer Thickness On The Mechanical Characteristics of INCONEL 718 Machined by Spark EDM Processhasib_07No ratings yet

- Piping Interview Questions and Answers - Part 01Document5 pagesPiping Interview Questions and Answers - Part 01Jose LuisNo ratings yet

- EWS Manual 21-22Document29 pagesEWS Manual 21-22Vivek ReddyNo ratings yet

- Creep - Iwshibli PDFDocument32 pagesCreep - Iwshibli PDFIvanUribeNo ratings yet

- Basic ElectricalDocument133 pagesBasic ElectricalBk BhaiNo ratings yet

- 1st Year Lab Manual For Students Rev 2021Document142 pages1st Year Lab Manual For Students Rev 2021Shyam 4No ratings yet

- EE428 Course Outline - IPC Spring 2022Document4 pagesEE428 Course Outline - IPC Spring 2022Skiwordy MediaNo ratings yet

- Engineering and Innovation: Practical TaskDocument4 pagesEngineering and Innovation: Practical TaskMuthu Rajan0% (1)

- Laboratory Manual: Department of Mechanical EngineeringDocument7 pagesLaboratory Manual: Department of Mechanical Engineeringrajamanickam s0% (1)

- MT 1 Lab Manual PDFDocument40 pagesMT 1 Lab Manual PDFrajamanickam sNo ratings yet

- Workshop Lab Manual 2019-20Document61 pagesWorkshop Lab Manual 2019-20Vivek ReddyNo ratings yet

- Final ProjectDocument50 pagesFinal ProjectIsmail BiradarNo ratings yet

- Thermal EngineeringDocument11 pagesThermal EngineeringParasNo ratings yet

- Larsen and Toubro Limited: Electrical Standard Products Electrical and Automation Powai WorksDocument22 pagesLarsen and Toubro Limited: Electrical Standard Products Electrical and Automation Powai WorksramsankarNo ratings yet

- SOM Lab ManualDocument41 pagesSOM Lab ManualThiru KannanNo ratings yet

- Laboratory Manual: Department of Mechanical EngineeringDocument9 pagesLaboratory Manual: Department of Mechanical Engineeringrajamanickam sNo ratings yet

- 2019 ECITB Technical Test Catalogue V10Document16 pages2019 ECITB Technical Test Catalogue V10SaikrishnaNo ratings yet

- Engineering Workshop PracticeDocument3 pagesEngineering Workshop Practicemyatminmdy1516No ratings yet

- Welding Technologies in Shipbuilding IndustryDocument8 pagesWelding Technologies in Shipbuilding Industrypetar.svirecovNo ratings yet

- An Industrial Training Report On-1Document35 pagesAn Industrial Training Report On-1rigeldewNo ratings yet

- Mechanical Technology Nov 2019 (Fitting & Machining) EngDocument18 pagesMechanical Technology Nov 2019 (Fitting & Machining) EngKhathutshelo KharivheNo ratings yet

- 1 Manufacturing TechnologyDocument2 pages1 Manufacturing TechnologyNarasimha Murthy InampudiNo ratings yet

- SMTHybrid2012 05Document80 pagesSMTHybrid2012 05gengi.skan1927No ratings yet

- Inconel 718 ThesisDocument6 pagesInconel 718 Thesisafjrydnwp100% (2)

- L TH T P Full Marks. External Exam Marks Internal Exam Marks External Pas Marks Total Pass Marks Duration of External Exams 4 50 30 20 - 25Document4 pagesL TH T P Full Marks. External Exam Marks Internal Exam Marks External Pas Marks Total Pass Marks Duration of External Exams 4 50 30 20 - 25Pʀʌĸʌsʜ Kʋɱʌʀ AʛʌʀwʌɭNo ratings yet

- 6th Sem Milling MachineDocument41 pages6th Sem Milling MachineIshan VermaNo ratings yet

- Department of Automobile Engineering Course PlanDocument4 pagesDepartment of Automobile Engineering Course Plansanthi saranyaNo ratings yet

- Estimation of Tool Life by Industrial Method and TDocument8 pagesEstimation of Tool Life by Industrial Method and TKamesh JaiNo ratings yet

- Gujarat Technological University Bachelor of Engineering: Subject Code: 3110012Document5 pagesGujarat Technological University Bachelor of Engineering: Subject Code: 3110012Devaliya pradipNo ratings yet

- Assignment No 1Document1 pageAssignment No 1Thakur Kali DassNo ratings yet

- Epl Lab Manual Sxcce PDFDocument110 pagesEpl Lab Manual Sxcce PDFBijumonNo ratings yet

- Shielded Metal Arc Welding: Mild Steel I (E7018)Document41 pagesShielded Metal Arc Welding: Mild Steel I (E7018)greatsteelNo ratings yet

- 7SEE - EID - Assignment 02Document1 page7SEE - EID - Assignment 02ptarwatkar123No ratings yet

- U19GE111 - EPL Syllabus Ver 6.0Document2 pagesU19GE111 - EPL Syllabus Ver 6.0jubairrubyNo ratings yet

- Final CoTm Curriculum Draft@2nd HarmonizationDocument113 pagesFinal CoTm Curriculum Draft@2nd Harmonizationamare ayeleNo ratings yet

- MP 24july PDFDocument130 pagesMP 24july PDFMaloth PrakashNo ratings yet

- Influence of PMEDM On MRR and TWRDocument11 pagesInfluence of PMEDM On MRR and TWRdanikichlerNo ratings yet

- Studying The Effect of Ignition Voltage (Ue) and Amperage (Ie) When Processing Hardened SKD 11 Materials On Wire Cut Electric Discharge Machining (WEDM)Document6 pagesStudying The Effect of Ignition Voltage (Ue) and Amperage (Ie) When Processing Hardened SKD 11 Materials On Wire Cut Electric Discharge Machining (WEDM)International Journal of Innovative Science and Research TechnologyNo ratings yet

- WS Manual (Updated)Document82 pagesWS Manual (Updated)Ashish MishraNo ratings yet

- Workshop Lab ManualDocument38 pagesWorkshop Lab ManualNISHANT GARGNo ratings yet

- Acknowledgement: Gawade S.R. Class Coordinator Prof. Shirke Sir, Principal Dr. Narve N.G. and All The StaffDocument16 pagesAcknowledgement: Gawade S.R. Class Coordinator Prof. Shirke Sir, Principal Dr. Narve N.G. and All The StaffShubham PhadtareNo ratings yet

- Ge3271-Engineering Practices LaboratoryDocument80 pagesGe3271-Engineering Practices LaboratoryvaitheemechNo ratings yet

- J Surfcoat 2017 05 098Document40 pagesJ Surfcoat 2017 05 098Nadia ArrousseNo ratings yet

- EME LAB SyllabusDocument1 pageEME LAB SyllabusSHAIK ISMAIL BASHANo ratings yet

- Important Instructions To Examiners:: (Autonomous)Document22 pagesImportant Instructions To Examiners:: (Autonomous)Pramod DhaigudeNo ratings yet

- 2018 Ques 5th SemDocument15 pages2018 Ques 5th SemVishal kumarNo ratings yet

- "Pas de Deux" of High-Temperature Alloy and 3D Reactor Technology For Steam Cracking Coils: Impact On Product Yields and Coke FormationDocument2 pages"Pas de Deux" of High-Temperature Alloy and 3D Reactor Technology For Steam Cracking Coils: Impact On Product Yields and Coke FormationChonkarn ChieblamNo ratings yet

- Ods FS Sic-WDocument26 pagesOds FS Sic-WSamiran MukherjeeNo ratings yet

- Be (Prod) MP II Ese - Dec.2009Document1 pageBe (Prod) MP II Ese - Dec.2009rahul72No ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM561/KJP516/470Document4 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM561/KJP516/470Nasri JamaludinNo ratings yet

- Gujarat Technological University: 1 Year, Subject Code: 3110012Document6 pagesGujarat Technological University: 1 Year, Subject Code: 3110012dhairyaapandyaNo ratings yet

- 30 Theories of RetailDocument30 pages30 Theories of RetailDrparul Khanna0% (1)

- Well:,H W: Technolocjl... JDocument90 pagesWell:,H W: Technolocjl... Jمحمد المحمديNo ratings yet

- Macro Sessions 2-5 GDP PDFDocument129 pagesMacro Sessions 2-5 GDP PDFTarun Sai KrishnaNo ratings yet

- InvoiceDocument1 pageInvoiceTejinder Singh Lakhwani (P20MS008)No ratings yet

- Russia Guidance December 2023Document24 pagesRussia Guidance December 2023stephencweeksNo ratings yet

- Battery Operated LawnmowerDocument51 pagesBattery Operated LawnmowerMohammad ShoebNo ratings yet

- Dyeing MachineDocument17 pagesDyeing MachineRipon SayanNo ratings yet

- Component Based Software EngineeringDocument21 pagesComponent Based Software Engineeringkarishma10No ratings yet

- Day 3 Recapitulation Exercises R1 - Rico D.JDocument2 pagesDay 3 Recapitulation Exercises R1 - Rico D.JRico Danu JatmikoNo ratings yet

- 1 PBDocument9 pages1 PBcucu sitimaryamNo ratings yet

- Antibiotics TMJDocument6 pagesAntibiotics TMJRaphaela TravassosNo ratings yet

- Name ID Course Section Term Paper: Arshman Shahbaz F2019376001 DLD Y1 ArduinoDocument11 pagesName ID Course Section Term Paper: Arshman Shahbaz F2019376001 DLD Y1 ArduinoArshman ShahbazNo ratings yet

- Inquiries, Investigation, and Immersion: Understanding Data and Ways To Collect Data (Population and Sampling Method)Document20 pagesInquiries, Investigation, and Immersion: Understanding Data and Ways To Collect Data (Population and Sampling Method)Rhiza Marie Monares67% (3)

- d4753 15 Standard Guide For Evaluating Selecting and Specifying Balances and Standard Masses For Use in Soil Rock and Construction Materials TestingDocument6 pagesd4753 15 Standard Guide For Evaluating Selecting and Specifying Balances and Standard Masses For Use in Soil Rock and Construction Materials TestingAfra AliNo ratings yet

- SAFI SS1 L3 4 Analysis of Tension Members Yielding Rupture Shear Lag 16 and 23-11-2020Document137 pagesSAFI SS1 L3 4 Analysis of Tension Members Yielding Rupture Shear Lag 16 and 23-11-2020esamalnhari77No ratings yet

- Connecting Loop Units: Interactive Fire Detection SystemsDocument64 pagesConnecting Loop Units: Interactive Fire Detection SystemsProduktif TetapNo ratings yet

- Design and Optimization of A Drivetrain With Two-Speed Transmission For Electric Delivery Step VanDocument21 pagesDesign and Optimization of A Drivetrain With Two-Speed Transmission For Electric Delivery Step VanAlexei MorozovNo ratings yet

- CCN Part 4Document15 pagesCCN Part 4116TanzeelNo ratings yet

- Cavite Mutiny Written ReportDocument6 pagesCavite Mutiny Written ReportDaisy KetchNo ratings yet

- Sentinel Event Notification and Management Policy Final20227484Document19 pagesSentinel Event Notification and Management Policy Final20227484ahamedsahibNo ratings yet

- IB Phys6 1 Planning TiDocument3 pagesIB Phys6 1 Planning TiAlper KarayelNo ratings yet

- Ryan Rodriguez Et Al v. West Publishing Corporation Et Al - Document No. 432Document37 pagesRyan Rodriguez Et Al v. West Publishing Corporation Et Al - Document No. 432Justia.comNo ratings yet

- Definition of EncumbranceDocument3 pagesDefinition of EncumbranceamvronaNo ratings yet

- Industech Exhibitor List 2020Document5 pagesIndustech Exhibitor List 2020kuldeepNo ratings yet

- Data Structures Through C++: Chapter - 1 1.1. C++ Class Overview-Basic Oop ConceptsDocument31 pagesData Structures Through C++: Chapter - 1 1.1. C++ Class Overview-Basic Oop ConceptsajNo ratings yet