Professional Documents

Culture Documents

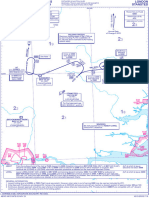

Gripen Park Jet (Assembly Drawing Tiled)

Gripen Park Jet (Assembly Drawing Tiled)

Uploaded by

Alfredo Arnéz Paz SoldánCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gripen Park Jet (Assembly Drawing Tiled)

Gripen Park Jet (Assembly Drawing Tiled)

Uploaded by

Alfredo Arnéz Paz SoldánCopyright:

Available Formats

Notes:

* All parts are made from 6mm Depron or BlueCore foam unless

otherwise indicated

* If using BlueCore, peel the plastic covering off both sides

of all fuselage parts (leave the skin on all wing and Sand fuselage corners

empennage parts) round as shown below

(not to scale)

* Sand all wing and empennage leading edges round and Sand turtledeck corners

apply a piece of 3M Satin tape around the leading edge to round as shown below

add smoothness and durability (not to scale)

* Elevon and canard mixing is recommended for pitch control.

Set it up so that full aft stick provides 3/4" trailing edge down

on the canard and 3/8" trailing edge up on the elevons.

* Rudder control is optional but provides much better control

during low-speed high alpha flight.

* Recommended control deflections (all dimensions Canard servo

measured at root trailing edge):

Canard: +/- 3/4"

Elevons: +/- 3/4" (ailerons), +/-3/8" (elevators)

Rudder: +/- 1.5"

* Use -60% exponential rate on all flight controls

* Make first flights at the forward CG location shown, which

provides more stability. Pre-set several clicks of up elevator

trim before launching at this CG location (prototype required

3/16" trailing edge down canard deflection to trim).

* For best results choose a power system that provides

Rudder servo (optional)

15-20 oz static thrust and 45-50 mph pitch speed.

* Recommended brushed power system: GWS EPS-350C

with C gearing (5.33), 8x6 GWS SF prop, 11.1V 1200 mAh .157" x 8.25" carbon tube pivoting inside

Lipo battery three short pieces of 3/16" aluminum tubing

* Recommended brushless power system: Himax 2015-4100,

4.4 gearing, 9x6 APC SF prop, 11.1V 1200 mAh Lipo battery

* Use a heat gun to gently bend the foam in the fuselage

to pre-form it to the shapes shown

Remov

4 with two

forward

Scale in inches

2

Nosecone and canopy made

from laminated foam sheets

or foam block carved to shape

0 2 4 6 8

Span: 23.9"

Wing area: 258 sq in Battery mounted to fuselage Use servo arm for

Weight: 16.0 - 18.0 oz RTF floor with a strip of Velcro control horn (drilled

Wing loading: 9.5 oz/sq ft (to allow CG adjustment) out to fit carbon tube)

Designed and drawn by Steve Shumate

Copyright © 2004 All Rights Reserved

.21" dia x 19.5" carbon tube spar

Elevons

4.62"

4.12"

Cut 45 deg bevel in elevon leading

edge and hinge with 3M Satin tape

Flaperon servos (with 1/32"

music wire pushrods)

Cover wing leading edge with

a strip of 3M Satin tape for

smoothness and durability

Balsa missle rails

3/8" sq x 4.5"

Removable canopy mounted hardwood

with two bamboo skewers motor mount

forward and two Velcro strips aft

Cut hatch for access

to receiver

GWS EPS-350

Receiver Dashed green lines indicate doublers motor shown

arm for at corners (see parts templates for details) (no right or

3/4" square 1/64" ply down thrust)

(drilled bearing supports

on tube)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Mitsubishi MU-2B-60 Marquise Pilot's Operating ManualDocument675 pagesMitsubishi MU-2B-60 Marquise Pilot's Operating Manuallegoulu2193% (14)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aeromodelo f15 - Planos para DepronDocument1 pageAeromodelo f15 - Planos para Depronmam73100% (1)

- 552-15Y2E005v4 Student Handout PDFDocument92 pages552-15Y2E005v4 Student Handout PDFHezkyel TradeNo ratings yet

- Airbus FLT Control LawsDocument4 pagesAirbus FLT Control LawsJehan IchhaporiaNo ratings yet

- Me 262Document3 pagesMe 262mam73100% (2)

- Warbirds Series: Scale 1/48 Design by NOBIDocument1 pageWarbirds Series: Scale 1/48 Design by NOBImam73No ratings yet

- Manual Futaba 6exapDocument24 pagesManual Futaba 6exapmam73No ratings yet

- Ing Swin Gar M 1/8" Lite-PlyDocument1 pageIng Swin Gar M 1/8" Lite-Plymam73100% (1)

- Happy New Year 2005 Happy New Year 2005: Free IssueDocument5 pagesHappy New Year 2005 Happy New Year 2005: Free Issuemam73100% (1)

- X-15 300 DpiDocument5 pagesX-15 300 Dpimam73100% (1)

- Fokker DR1 Plans (Parts Templates Non-Tiled)Document1 pageFokker DR1 Plans (Parts Templates Non-Tiled)mam73No ratings yet

- CA15Document5 pagesCA15mam73No ratings yet

- Me 262Document3 pagesMe 262mam73100% (2)

- Me 262Document3 pagesMe 262mam73100% (2)

- Fokker DR1 Plans (Parts Templates Tiled)Document25 pagesFokker DR1 Plans (Parts Templates Tiled)mam73No ratings yet

- Howard CarpenterDocument1 pageHoward Carpentermam73No ratings yet

- Diablo 3 D TiledDocument25 pagesDiablo 3 D Tiledmam73No ratings yet

- F-14 Park Jet Construction GuideDocument23 pagesF-14 Park Jet Construction Guidemam73100% (1)

- JAS 39 Park Jet Construction ManualDocument17 pagesJAS 39 Park Jet Construction Manualmam73No ratings yet

- F-107 Instructions FullDocument20 pagesF-107 Instructions Fullmam73No ratings yet

- Tucano T1Document6 pagesTucano T1mam73No ratings yet

- BirdDogbig Tiled FoamDocument10 pagesBirdDogbig Tiled Foammam73No ratings yet

- Avionics Upgrade (Final Copy)Document3 pagesAvionics Upgrade (Final Copy)David PfefferNo ratings yet

- A109S Grand Tech SpecDocument9 pagesA109S Grand Tech SpecAlphard DarmawanNo ratings yet

- Learjet A&E 35A-339Document54 pagesLearjet A&E 35A-339Lucas AlvesNo ratings yet

- Turbojets Vs Turbofans DocumentDocument9 pagesTurbojets Vs Turbofans DocumentMuhammadAl-AtekNo ratings yet

- RFN14IFG Red Flag Nellis 2014Document79 pagesRFN14IFG Red Flag Nellis 2014Ok FrogNo ratings yet

- Egss Ils22Document1 pageEgss Ils22piwowarczykptNo ratings yet

- Technical Presentation 737-A320 May 2012Document45 pagesTechnical Presentation 737-A320 May 2012Interogator586% (7)

- PDF N Fcom Sva TF N Eu 20130101 DSC 22 10Document58 pagesPDF N Fcom Sva TF N Eu 20130101 DSC 22 10JP ZemogNo ratings yet

- CAR-66 Aircraft Maintenance Licensing Requirements - FinalDocument2 pagesCAR-66 Aircraft Maintenance Licensing Requirements - FinalmidunNo ratings yet

- Fuselage and Tail Sizing - 3 Topics: Airplane Design (Aerodynamic) Prof. E.G. Tulapurkara Chapter-6Document16 pagesFuselage and Tail Sizing - 3 Topics: Airplane Design (Aerodynamic) Prof. E.G. Tulapurkara Chapter-6Ajay YadavNo ratings yet

- Custer Channel Wing InvestigationDocument19 pagesCuster Channel Wing InvestigationWayne ManchesterNo ratings yet

- Mi-8 Flight Controls PDFDocument64 pagesMi-8 Flight Controls PDFYosif Thiab100% (2)

- 05 Brochure Dassault Falcon 7x PDFDocument7 pages05 Brochure Dassault Falcon 7x PDFJefferson Vieitas FragosoNo ratings yet

- Pilot's Operating HandbookDocument2 pagesPilot's Operating HandbooktotalityNo ratings yet

- A Systems Engineering Approach To Unmanned Aerial Vehicle DesignDocument23 pagesA Systems Engineering Approach To Unmanned Aerial Vehicle Designpravin_06065364100% (1)

- Instructors Briefing MaterialDocument117 pagesInstructors Briefing MaterialadityaNo ratings yet

- Analysis of Stability and Control of The AircraftDocument48 pagesAnalysis of Stability and Control of The AircraftBalaji AeroNo ratings yet

- Adp Fighter AircraftDocument66 pagesAdp Fighter AircraftHarsha HarNo ratings yet

- Airport Chart HKT - VTSPDocument34 pagesAirport Chart HKT - VTSPaoonjaiNo ratings yet

- Cyeg (Edmonton Intl) - R (20aug15) PDFDocument28 pagesCyeg (Edmonton Intl) - R (20aug15) PDFnabatmanNo ratings yet

- Tcas SystemDocument30 pagesTcas Systemaidil kashul100% (1)

- Airfoil NomenclatureDocument25 pagesAirfoil Nomenclatureqasim zaheer100% (1)

- Third Country Organisation Approvals: Easa Cert NR Company Name CountryDocument6 pagesThird Country Organisation Approvals: Easa Cert NR Company Name CountryCTQMNo ratings yet

- P3D PMDG 747 400 GuideDocument164 pagesP3D PMDG 747 400 Guidecatchman8675% (4)

- ASH 26 SpecificationsDocument2 pagesASH 26 Specificationslegoulu21No ratings yet

- LTFG/GZP Gazipasa, Turkey: Batnu 1C Elrop 1C Utuso 1CDocument10 pagesLTFG/GZP Gazipasa, Turkey: Batnu 1C Elrop 1C Utuso 1CTweed3ANo ratings yet