Professional Documents

Culture Documents

Oracle Iot Intelligent Applications

Uploaded by

Bhushan PawarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oracle Iot Intelligent Applications

Uploaded by

Bhushan PawarCopyright:

Available Formats

Oracle IoT

Intelligent Applications

Oracle IoT Intelligent Applications uses sensor data from connected devices to provide you with more

visibility, insights and efficiencies for smart manufacturing, predictive maintenance, connected

logistics, workplace safety monitoring and a connected customer service. Our applications have built-

in predictive analytics and integrations with SCM, ERP and HCM to help you drive better business

outcomes across your organization.

Real-time, end-to-end visibility with IoT

Improve profitability and drive real-time operational efficiencies through automated monitoring of assets, logistics,

production, and workers. Digital supply chains will enable businesses to detect, analyze, and respond to IoT signals,

then incorporate those insights into rapidly evolving market capabilities.

Empower your line-of-business users with ready-to-use IoT applications to achieve business outcomes that were

previously hampered due to interoperability gaps between operations technology and information technology. Built

with highly scalable, robust proven IoT technology running on Oracle Cloud Infrastructure, Oracle IoT Intelligent

Applications provides the tools and technologies to integrate, analyze, build, and deploy IoT solutions that deliver

analytical insights from real-time IoT data into your existing business applications. All backed by Oracle’s value-added

ecosystem of partners and experts that help you rapidly scale and realize business value.

Ready-to-deploy IoT business use cases for fast time-to-value

Oracle IoT Intelligent Applications makes IoT easy by enabling a wide range of use cases with identified business

outcomes and returns on investment, applicable across multiple industry segments such as:

Oracle IoT Intelligent Applications | Smart Manufacturing

Use sensor data from connected devices to manage work-in-progress, prevent unplanned downtime and

maximize product quality for manufacturing. To achieve smart manufacturing, Oracle brings together IoT

production monitoring, cloud maintenance and cloud manufacturing products.

Smart Manufacturing — Work In-Progress Monitoring: Gain real-time visibility of work-in-progress for

just- in-time production operation to maximize production line utilization and avoid shipment delays.

Continuously tracked, built-in business metrics include; percentage behind plan for work orders and

production quantity, overall equipment efficiency (OEE), production completions at each operation including

good units, scraps and rejects, and number of operations pending for each work order or batch.

Smart Manufacturing — Maximizing Product Quality: Benefit from real-time visibility of production

completions by monitoring product item specific scrap and rejects by operation, by machine and by factory

to minimize operations cost and achieve on-time customer deliveries.

1 Data Sheet / Oracle IoT Intelligent Applications / Version 2.0

Copyright © 2020, Oracle and/or its affiliates / Public

Smart Manufacturing — Preventing Unplanned Downtime: Avoid unplanned downtime with real-time

monitoring of machine current and predicted health. Using standard and user-defined machine and factory

health metrics, the automated detection of anomalies and trends, machine-learning based failure predictions

and performance deterioration forecasts, machine maintenance schedules can be optimized to maximize

factory’s production.

Oracle IoT Intelligent Applications | Predictive Maintenance

With sensor data from connected devices, monitor and ensure uptime, reduce loss and understand usage of

equipment. IoT Predictive maintenance consists of two primary products, Oracle IoT Asset Monitoring and

Oracle Cloud Maintenance.

Connected Assets — Predictive Maintenance: Unplanned asset downtime can have a significantly

detrimental impact on business goals and outcomes, optimize asset availability and utilization through the

continuous remote tracking and visualization of usage, condition, performance and operating environments

to optimize maintenance and increase asset value. Increase the capabilities, reach and productivity of the

maintenance and field service teams through auto-generation of alerts and maintenance work orders,

remote diagnostics and maintenance, adjustment of scheduled maintenance to reflect actual and predicted

asset condition.

Connected Products— Product-as-a-Service: In business models where the product is an expression of a

service, revenue and return is directly linked to asset availability, usage and customer value. Key metrics to

be measured focus on product and service team returns. These will include product performance, efficiency,

usage, availability, condition along with the costs of service such as number of service trips per incident,

incident duration, and overall efficiency of the service operation such as first-time fix, The use of custom

metrics can further extend the value for the service provider and their customers providing insights into

areas such as product usage (e.g., % of asset capacity utilization, asset performance and efficiency), asset

lifetime – actual and predicted, and rental revenue– actual and predicted.

Oracle IoT Intelligent Applications | Connected Logistics

Connect devices to monitor products with sensors across transportation and warehouse systems. IoT Connected

Logistics consists of Oracle IoT Fleet and Shipment Monitoring, Oracle Transportation Management and

Oracle Warehouse Management systems.

Connected Logistics — Shipment Monitoring: Monitor shipments on your private fleet and/or 3rd party

carriers for unforeseen situations and circumstances leading to delayed deliveries. Gain real-time visibility of

shipment location and conditions from pick-up to delivery. Benefit from pre-built dashboards with exception

widgets providing real-time insights on transportation assets, in-transit movements and above threshold

deviations. Streamline receiving operations at warehouse for real-time tracking of incoming shipments and

likely delays.

Connected Logistics — Warehouse Automation: Monitor warehouse facilities for yard and dock operations

to effectively handle any unforeseen situations and circumstances leading to excessive dwell time or turn-

around time for deliveries. Gain real-time visibility of incoming vehicles and in-transit delays. Benefit from

pre-built dashboards with exception widgets (KPIs) providing real-time insights on warehouse facilities

operations, utilization of assets, in-transit movements and above threshold dwell times.

2 Data Sheet / Oracle IoT Intelligent Applications / Version 2.0

Copyright © 2020, Oracle and/or its affiliates / Public

Oracle IoT Intelligent Applications | Worker Safety

Apply sensor data from employee wearables to track worker locations in real-time and ensure regulatory

compliancy. IoT Worker Safety consists of Oracle IoT Connected Worker, Oracle HCM and other SCM systems.

Gain a better understanding of environmental conditions and reduce safety violations.

Connected Worker – Safety Monitoring: Increase workplace safety by minimizing near misses and

unsafe acts before they escalate into major incidents. Key capabilities: deliver real-time monitoring of

worker movement to prevent unsafe acts such as entering hazardous or unauthorized areas, reducing time-

to- respond in case of accidents and monitoring compliance by automated rules-driven enforcement of

safety policies.

The prebuilt Oracle IoT Intelligent Applications named below support the defined business use cases listed above.

1. IoT Production Monitoring: Continuous tracking and prediction of production performance across factories,

products, lines and machines

2. IoT Asset Monitoring: Real-time visibility of asset health, location and utilization, and predict maintenance needs

3. IoT Fleet & Shipment Monitoring: Optimize end-to-end logistics operations with proactive detection of

anomalies and deviations

4. IoT Connected Worker: Ensure worker health and safety, improve compliance, and automate time and labor

tracking to improve productivity.

Proven, robust IoT technology foundation

Oracle IoT Intelligent Applications simplifies IoT so you can rapidly assimilate the concepts and technologies into your

digital strategy and create innovative services with less risk.

Managing and analyzing the enormous amount of real-time data generated by all the IoT-connected devices

demands a multi-faceted, yet robust IoT solution that incorporates latest innovations such as Digital Twins, Machine-

Learning/AI and Edge Computing.

Oracle IoT Intelligent Applications includes a full featured IoT technology stack that incorporates:

Digital Twin modeling and wide range of device connectivity and edge processing capabilities.

Analytics capabilities customized for time series data, spatial-temporal analysis and real time data processing

with built in domain specific dashboards and metrics. A highly scalable industry-standard big data analytics stack

based on for operationalizing AI & Machine Learning based algorithms for anomaly detection, predictive analytics

& recommendations is included as part of the standard subscription.

Pre-built Digital Threads with enterprise applications such as manufacturing, maintenance, transportation,

warehouse management, and human capital management make it easy to quickly deploy pre- configured

business workflows that automate exception management. Integrations with 3rd party applications can be easily

established using REST API or Oracle Integration Cloud.

Secure and reliable edge computing components enabling bidirectional communication between IoT devices and

the cloud, and advanced edge analytics to conserve bandwidth and reduce latency for actions. IoT devices may

connect to the cloud directly, or indirectly through a certified partner gateway over a variety of supported IoT

protocols.

3 Data Sheet / Oracle IoT Intelligent Applications / Version 2.0

Copyright © 2020, Oracle and/or its affiliates / Public

Digital Twins for Industrial Assets

Oracle IoT Intelligent Applications Cloud Service includes Digital Twin capabilities as standard functionality, that

consists of three different areas:

Virtual Twin: Allows creation of a software representation of a physical asset, including things like the set of

attributes and controls that the physical device supports, software-synthesizable simulators that allow creation of

simulated assets to test out the entire IoT value-proposition before connecting physical devices.

Predictive Twin: This describes the behavioral of the asset. Examples include a predictive model that can be

evaluated to forecast a future state of the asset or its environment.

Twin Projections: Digital twins are integrated in manufacturing, maintenance, field-service, supply chain-planning,

transportation, utilities, and warehousing products

In addition, the digital twin supports integrated what-if analysis capabilities. The what-if analysis tool creates

synthetic conditions to validate end-to-end business processes for safety, compliance or audits.

3D Visualization with IoT context

The digital twin enables users to get a complete, contextualized view of their asset in a single place, including the

hierarchy of asset components and the relevant functional aspects or “state” of the asset as represented by real-time

values of key variables.

Exploded views of the asset and its component hierarchy are available, along with the ability to rotate the asset and

examine it from different angles. Contextual data relevant for each subsystem is displayed.

This capability requires a subscription to Oracle IoT, 3D Digital Twin, which is an optional SKU for Oracle IoT Intelligent

Applications.

Upload Industry standard 3d file formats

Subscriptions of Oracle IoT that include the optional 3D Digital Twin SKU provides users the ability to upload 3D CAD

models in a variety of file formats which are standard in the CAD industry. These are then converted to web-viewable

forms. Supported 3D CAD file formats include commonly used file formats such as STEP, 3DS, AutoCAD DWG,

AutoCAD DXF, CATIA, OBJ, STL, among others.

Key business benefits

Pre-built interoperability with a number of enterprise applications including Manufacturing, Maintenance,

Transportation, Warehouse Management and Worker Health & Safety Management

Purpose-built, ready- to-use applications to achieve clear business outcomes

Built on a proven, robust and scalable IoT technology foundation running on Oracle Cloud Infrastructure

Incorporates latest innovations in the IoT space, including Digital Twins, Machine Learning and AI for streaming

time-series machine data, and edge computing

Extensive global partner ecosystem of IoT device and implementation vendors

Technical details

Device to cloud connectivity protocols

MQTT over SSL

4 Data Sheet / Oracle IoT Intelligent Applications / Version 2.0

Copyright © 2020, Oracle and/or its affiliates / Public

HTTPS

Built-in industrial IOT connectivity

OPC UA

Historians

OBD II

SAE J1939

Supported IOT message data formats

JSON

Binary

Certified partners based IOT device connectivity

MODBUS

Bacnet

Ethernet/IP

Many others

Supported platforms for Oracle IOT client software

Java SE 5 and above

C/C++ (POSIX, Linux)

iOS

Android

Python

JavaScript

More information available at https://www.oracle.com/internet-of-things/

Connect with us

Call +1.800.ORACLE1 or visit oracle.com. Outside North America, find your local office at: oracle.com/contact.

blogs.oracle.com facebook.com/oracle twitter.com/oracle

Copyright © 2020, Oracle and/or its affiliates. All rights reserved. This document is Oracle and Java are registered trademarks of Oracle and/or its affiliates. Other names may be

provided for information purposes only, and the contents hereof are subject to change trademarks of their respective owners.

without notice. This document is not warranted to be error-free, nor subject to any other

Intel and Intel Xeon are trademarks or registered trademarks of Intel Corporation. All SPARC

warranties or conditions, whether expressed orally or implied in law, including implied

trademarks are used under license and are trademarks or registered trademarks of SPARC

warranties and conditions of merchantability or fitness for a particular purpose. We

International, Inc. AMD, Opteron, the AMD logo, and the AMD Opteron logo are trademarks or

specifically disclaim any liability with respect to this document, and no contractual

registered trademarks of Advanced Micro Devices. UNIX is a registered trademark of The Open

obligations are formed either directly or indirectly by this document. This document may

Group. 0120

not be reproduced or transmitted in any form or by any means, electronic or mechanical,

for any purpose, without our prior written permission. Disclaimer: This document is for informational purposes. It is not a commitment to deliver any

material, code, or functionality, and should not be relied upon in making purchasing decisions.

This device has not been authorized as required by the rules of the Federal

The development, release, timing, and pricing of any features or functionality described in this

Communications Commission. This device is not, and may not be, offered for sale or

document may change and remains at the sole discretion of Oracle Corporation.

lease, or sold or leased, until authorization is obtained.

5 Data Sheet / Oracle IoT Intelligent Applications / Version 2.0

Copyright © 2020, Oracle and/or its affiliates / Public

You might also like

- Development of Technology in Inventory ManagementDocument12 pagesDevelopment of Technology in Inventory ManagementBhushan PawarNo ratings yet

- Group 2.1 - Industry 4.0 - Development - in - ContainerizationDocument12 pagesGroup 2.1 - Industry 4.0 - Development - in - ContainerizationBhushan PawarNo ratings yet

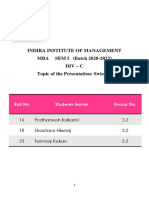

- Indira Institute of Management MBA SEM I (Batch 2020-2022) Div - C Topic of The Presentation: SwisslogDocument5 pagesIndira Institute of Management MBA SEM I (Batch 2020-2022) Div - C Topic of The Presentation: SwisslogBhushan PawarNo ratings yet

- Oracle: Putting The Business Process First in Iot: Vendor ProfileDocument6 pagesOracle: Putting The Business Process First in Iot: Vendor ProfileBhushan PawarNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Growatt Export Limitation Guide Growatt 3 15K TL3 SDocument6 pagesGrowatt Export Limitation Guide Growatt 3 15K TL3 SDragana SpasojevicNo ratings yet

- Data Science PDF 3Document90 pagesData Science PDF 3Hardik vengurlekarNo ratings yet

- UNIT 3 RS & Gis NotesDocument58 pagesUNIT 3 RS & Gis NotesShyam NaniNo ratings yet

- Pg080 Axi Fifo MM SDocument54 pagesPg080 Axi Fifo MM SYagna BharathiNo ratings yet

- Ict SkillsDocument6 pagesIct SkillsdfsfdsNo ratings yet

- Codingal Python CurriculumDocument14 pagesCodingal Python CurriculumDion princeNo ratings yet

- Chapter 2 Microfinance BankDocument12 pagesChapter 2 Microfinance BankMohamed Ahmed AbdiNo ratings yet

- ChangesDocument5 pagesChangesVietcongsoilderNo ratings yet

- 04 - Logical Design in Data WarehouseDocument39 pages04 - Logical Design in Data WarehouseMuhamad Lukman NurhakimNo ratings yet

- 22.1.2 Lab Troubleshoot Ios AaaDocument4 pages22.1.2 Lab Troubleshoot Ios Aaahassa nestor theraNo ratings yet

- (Gandhi) (Malayalam Drama) (PDFDrive)Document235 pages(Gandhi) (Malayalam Drama) (PDFDrive)Rajesh NanooNo ratings yet

- R.O.P CJ2019Document9 pagesR.O.P CJ2019Muh. Fani AkbarNo ratings yet

- Nursery Plant Management SystemDocument30 pagesNursery Plant Management SystemKapil SidhpuriaNo ratings yet

- ToolKit v6.3Document36 pagesToolKit v6.3Zhero CB barcafeNo ratings yet

- PV Intake - Training PPT 4.5 - UpdatedDocument124 pagesPV Intake - Training PPT 4.5 - Updatedisha jainNo ratings yet

- Ora 00979 Not A Group by Expression Case Statement IssueDocument2 pagesOra 00979 Not A Group by Expression Case Statement IssuekarthikmasNo ratings yet

- LAB1Document6 pagesLAB1Yenna CayasaNo ratings yet

- A Starter Set of ITSM Guiding PrinciplesDocument96 pagesA Starter Set of ITSM Guiding PrinciplesalawawdsNo ratings yet

- PMDG 747-400X: Aircraft Operating Manual & Flight Management Computer HandbookDocument44 pagesPMDG 747-400X: Aircraft Operating Manual & Flight Management Computer HandbookErick AvendañoNo ratings yet

- Datacolor QTX File Specification PDFDocument8 pagesDatacolor QTX File Specification PDFandrewtdNo ratings yet

- Responding To The Growing Threat of Human-Operated Ransomware AttacksDocument13 pagesResponding To The Growing Threat of Human-Operated Ransomware AttacksAmita Singh RajputNo ratings yet

- Kecerdasan Artifisial Dan Masyarakat - M5Document8 pagesKecerdasan Artifisial Dan Masyarakat - M5Citra LarasatiNo ratings yet

- Intiail Download GuideDocument32 pagesIntiail Download GuidejimtramsayNo ratings yet

- Citra LogDocument20 pagesCitra LogbaixclimaNo ratings yet

- Python Tutorial: Guido Van Rossum and The Python Development TeamDocument149 pagesPython Tutorial: Guido Van Rossum and The Python Development TeamAbility JoshuaNo ratings yet

- The Role of The Product Owner in Scrum-ComparisonDocument12 pagesThe Role of The Product Owner in Scrum-Comparisonhimanshudhol25No ratings yet

- Supplement Programming OpenfoamDocument78 pagesSupplement Programming OpenfoamVăn Đức AnhNo ratings yet

- Olivia Wilson: IT Project ManagerDocument1 pageOlivia Wilson: IT Project ManagerMuhammad Qamar SharifNo ratings yet

- HXGN EamDocument10 pagesHXGN EamgwisaksanaNo ratings yet

- CH 1 INTRODUCTION TO WEB DESIGN - MCQ - EngDocument6 pagesCH 1 INTRODUCTION TO WEB DESIGN - MCQ - EngSports Gaming by nitilNo ratings yet