Professional Documents

Culture Documents

Precast Reinforced Concrete Barriers

Uploaded by

Adnan NajemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Precast Reinforced Concrete Barriers

Uploaded by

Adnan NajemCopyright:

Available Formats

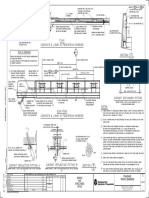

SECTION 941

PRECAST REINFORCED CONCRETE BARRIERS

941.01 Scope - This Section covers the quality and reinforcement may be installed to assist handling during the

manufacture of precast reinforced concrete roadside and precasting operations but shall be subject to prior approval

median barriers for highway and other off-highway traffic by the Ministry Representative.

confinement use.

b.) Fibrillated Fibres (polyolefin or polypropylene or a blend

The concrete traffic barrier units shall be supplied in the of these fibres) are an acceptable substitute of welded wire

sizes and types as required by the Purchase Order, Work mesh. Fibrillated fibres shall meet requirements of ASTM C

Order or Drawing in strict conformity with this Section and 1116 Type 3 Synthetic Fibre Reinforced Concrete or

pertinent Standard Drawings of the SP941 Series. shotcrete.

941.02 Concrete Quality Fibres shall have a minimum length of 50 mm, added at a

dosage rate of 1 kg/m3 (min of 0.1% by volume) and shall be

a) Concrete quality shall conform to CSA Standard CAN3-

thoroughly mixed with concrete before placement into the

A23.1-M except where amended hereafter.

forms.

b) A compressive strength test result is defined as the

Fibres shall have a minimum tensile strength of 350 MPa and

average of the strengths of three 28 day compressive test

a minimum modulus of elasticity of 4.2 GPa.

cylinder breaks with a standard cylinder size of 150 mm

diameter and height of 300 mm. Fibres are to be added early in the mixing process following

manufacture’s recommendations to ensure evenly distributed

c) The strength level of the concrete represented by the test

fibres.

shall be considered satisfactory if the test result equals or

exceeds 30 MPa and no individual cylinder strength is less The Supplier/Manufacturer of the fibre must furnish test data

than 27 MPa. If this condition is not met, the concrete will in accordance with ASTM C 1018 and/or ASTM C 1399 to

be considered to have failed the strength requirements. No the Precast Supplier to show the fibre complies with the

other form of testing to prove the relative strength at a later specification requirements as part of the Precast Supplier’s

date will be allowed without the approval of the Ministry Quality Control.

Representative. When the fibre option is used, a single length of 15 mm rebar

d) Concrete testing cylinders shall be cast by the Precast shall be wire tied to the horizontal sections of the hook or

Supplier or his authorized representative at the time of eye assemblies as shown on the Standard Drawings.

placing concrete. Frequency of testing will be one cylinder Steel fibres shall not be used in the concrete mix for concrete

collected at the start of the first pour; mid way and at the barriers.

final pour of the concrete used for the making of the barrier

with that batch run. , Concrete cylinder samples may be c) Reinforcing steel for bent and hooked connections shall

collected by the Ministry Representative at any time and conform to CSA CAN3-G40.21-M Grade 260W and shall be

tested to ensure the concrete is meeting specification carefully bent to the radii detailed and installed as shown on

requirements. the Standard Drawings.

e) Calcium chloride or admixtures containing calcium Bending shall be done by methods that will not produce

chloride shall not be used in the concrete. fracture or other injury. The metal heating shall not be to a

higher temperature than that producing a "dark cherry red"

f) Concrete shall meet the following additional colour. After heating, the metal shall be cooled as slowly as

requirements: possible. Following the bending, the surface of the metal

i) Minimum cement content of 320 kg per cubic metre. shall be carefully inspected for evidence of fracture, and any

fractured pieces shall be replaced.

ii) Maximum water/cement ratio of 0.45.

Prior to delivery, exposed surfaces of connections shall be

iii) Course aggregate of a nominal maximum size not

prepared for and given a heavy application of zinc rich

exceeding 28 mm.

coating to CGSB Standard 1-GP-181M.

iv) Slump of 50 mm ± 20 mm.

d) Pick-up points for handling units shall be formed with

v) Entrained air of 5 to 8%. accurately placed rigid P.V.C. pipe recessed 15 mm from

both finished surfaces as detailed.

941.03 Reinforcing Steel, Fibrillated Fibres, Attachment

Hardware & Miscellaneous Items 941.04 Optional Features - Where barrier is ordered with

a) Welded steel wire mesh reinforcement shall be supplied drainage slots or grouting holes or both, they shall be

and installed in each section as shown on the Standard accurately cast-in as detailed. Facilities for the installation

Drawings, and in accordance with SS 412. Additional of anti-glare screens will be detailed as and when required.

BC MoT 2016 941 (1 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

cement paste and filled with mortar. The mortar, properly

proportioned of the same sand and cement as the original

941.05 Placing and Finishing of Concrete

concrete and reasonably colour matched to the cured dry unit

a) Concrete shall be placed in the forms and carefully with the addition of white cement where necessary, shall be

consolidated in strict accordance with CSA CAN3-A23.4-M, pre-shrunk for about one hour before retempering and use.

Clause 19. The patching mortar shall be well tooled in, finished flush

b) Curing and protection shall be carried out strictly and smooth and the area covered to cure adequately.

according to CSA CAN3-A23.4-M Clause 21. f) End connection surfaces shall be cleared out.

i) Curing shall be considered complete when test g) All concrete surfaces prior to shipment shall be accurate

cylinders reach the specified 28 day compressive strength to detail and, in particular at the end connections, true to

provided such strength is reached not later than 28 days dimension tolerances.

after the barriers are cast.

941.06 Tolerances – Allowable Tolerances for the concrete

ii) Steam curing is permissible for either the entire dimensions of the barriers shall be ± 3 mm except as

curing period or portion thereof and shall be carried out otherwise indicated on the detail drawings.

in accordance with CSA CAN3-A23.4-M Clause 21.4.

941.07 Procedure of Manufacture - The Supplier shall

iii) At no time during or at completion of the curing notify the Ministry in advance concerning the date when the

period shall the temperature differential between the order is to be manufactured, so that detailed inspection can

concrete surface and the ambient temperature be greater be carried out. All processes shall be open for inspection

than 20°C. and approval by the Ministry Representative. No material

iv) If steam is used for a portion of the curing period, shall be shipped prior to the inspection or written release for

additional normal curing shall be carried out after the shipment by the Ministry Representative.

steam curing, according to CSA CAN3-A23.4-M Clause The manufacturer's name or trade mark, year of manufacture

21.3 until such time as strength tests of concrete test and form number shall be embedded on the end of each unit

cylinders that have been both steam and normally cured in a manner, size and depth that are permanently legible.

with the barriers reach the specified concrete strength.

Authorized patching or making good may be inspected

c) Exposed surfaces shall be uniform in texture and colour before shipment or upon delivery and the rejected unit(s)

as produced from well maintained steel form surfaces and shall be replaced at no cost to the Ministry.

proper vibration methods without excessive surface fines or

941.08 Handling - In handling the finished product, the

laitance.

concrete and connecting devices shall not be damaged or

d) Defects of the exposed surface will normally be cause for distorted.

the rejection of any unit except where such are within the

941.09 Payment - Payment shall be at unit price bid per unit

permissible limits or are subject to making good as follows:

(section). The price bid shall be full compensation for

i) Unobtrusive defects of any kind where their total area everything furnished and done including supply of forms and

is not in excess of 2% of the exposed surface area of the all materials, placing, vibrating and curing air entrained

unit. concrete, concrete testing, stripping, finishing, general clean-

ii) Air holes not greater than 3 mm in diameter and not up and delivery.

more than 20 holes in any isolated 300 mm X 300 mm

area.

iii) Sharp protrusions at the edges of the exposed

surfaces where necessary shall be softened by careful

rubbing or grinding.

iv) Patching of isolated small holes, cavities and similar

self-confining defects may be permitted when authorized

in writing by the Ministry Representative.

e) Patching, only when authorized, shall have the defective

area well saturated with water and the defect prepared with

941 (2 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (3 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (4 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (5 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (6 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (7 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (8 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (9 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (10 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (11 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (12 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (13 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (14 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (15 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (16 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (17 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (18 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (19 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (20 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (21 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (22 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (23 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (24 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (25 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (26 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (27 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

941 (28 of 30) 2016 BC MoT

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

BC MoT 2016 941 (29 of 30)

SECTION 941 PRECAST REINFORCED CONCRETE BARRIERS

THIS PAGE IS LEFT INTENTIONALLY BLANK

941 (30 of 30) 2016 BC MoT

You might also like

- Diaphragm/slurry Wall SpecificationDocument27 pagesDiaphragm/slurry Wall SpecificationRoy PersonalNo ratings yet

- Abs 0678Document11 pagesAbs 0678Jorge OrtegaNo ratings yet

- Project Title: Construction of One Storey Residential Building Location: Brgy. Ubagan, Sto. Tomas, La Union Project Owner: Mrs. Teresita CanlasDocument14 pagesProject Title: Construction of One Storey Residential Building Location: Brgy. Ubagan, Sto. Tomas, La Union Project Owner: Mrs. Teresita CanlasArnold VercelesNo ratings yet

- Building A Learning Culture That Drives Business ForwardDocument11 pagesBuilding A Learning Culture That Drives Business ForwardPedroNo ratings yet

- Item 311Document85 pagesItem 311MewnEProwt100% (2)

- HPCL Cement Lined Spec PDFDocument167 pagesHPCL Cement Lined Spec PDFvenkateshwaranNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- General Notes and Specifications For Structural Works (Issued As A Supplement To The Structural Plans)Document12 pagesGeneral Notes and Specifications For Structural Works (Issued As A Supplement To The Structural Plans)Brian SantosNo ratings yet

- 3010 - II - Concrete Work PDFDocument35 pages3010 - II - Concrete Work PDFWayne Chong100% (1)

- Specifications Segment Inserts & GasketsDocument6 pagesSpecifications Segment Inserts & Gasketssatan007No ratings yet

- Technical Specs of PoleDocument22 pagesTechnical Specs of Poleanon_237992751No ratings yet

- Foundations of StructuresDocument14 pagesFoundations of StructuresAdnan NajemNo ratings yet

- Positioning Ceramic Foam Filters in Gating System For Casting Alloy FiltrationDocument8 pagesPositioning Ceramic Foam Filters in Gating System For Casting Alloy FiltrationSiddharth GuptaNo ratings yet

- Specs Pre-Cast Segment LiningsDocument8 pagesSpecs Pre-Cast Segment Liningssatan007No ratings yet

- Technical Specification - PSC PoleDocument8 pagesTechnical Specification - PSC PoleJogendra Nath NeogNo ratings yet

- Action Plan ESP 2023 24Document2 pagesAction Plan ESP 2023 24Je-Ann EstriborNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Lecture Notes On Climatology: Integrated Meteorological Training CourseDocument90 pagesLecture Notes On Climatology: Integrated Meteorological Training CourseDasSonam100% (1)

- System Learning Plan Preparation: Krislizz International AcademyDocument11 pagesSystem Learning Plan Preparation: Krislizz International AcademyQhutie Little CatNo ratings yet

- AAB 042200 Concrete Unit MasonryDocument6 pagesAAB 042200 Concrete Unit MasonrytewodrosNo ratings yet

- ML-15 - Concrete Coating PDFDocument13 pagesML-15 - Concrete Coating PDFDeepakNo ratings yet

- PBG SpesifikasiDocument19 pagesPBG SpesifikasikaryantoherlambangNo ratings yet

- Technical Specifications:: Construction of Concrete Pavement For Parking AreaDocument2 pagesTechnical Specifications:: Construction of Concrete Pavement For Parking AreaAnton_Young_1962No ratings yet

- UG-IV-1-Concrete WorkDocument8 pagesUG-IV-1-Concrete WorkshreejeshNo ratings yet

- 900 - Rigid PavementsDocument22 pages900 - Rigid Pavementsruwan.smb1No ratings yet

- Nonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe (Metric)Document5 pagesNonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe (Metric)VictorAndresMillaSalazarNo ratings yet

- C14M.1265935-1-Nonreinforce Concrete Storm Drain PDFDocument5 pagesC14M.1265935-1-Nonreinforce Concrete Storm Drain PDFphett sopanhchaknaNo ratings yet

- Concrete Facing Brick: Standard Specification ForDocument3 pagesConcrete Facing Brick: Standard Specification ForAbdelrahman AshmawyNo ratings yet

- ShotcreteDocument10 pagesShotcreteHemaNo ratings yet

- IS218.02B - Suggested Specification For Concrete Parking AreasDocument2 pagesIS218.02B - Suggested Specification For Concrete Parking AreasfarhanNo ratings yet

- Annex A - Technical SpecificationsDocument50 pagesAnnex A - Technical SpecificationsGAhr CeredonNo ratings yet

- Specs Thgghgfhfghgfhjftbuilding From Blue BookDocument97 pagesSpecs Thgghgfhfghgfhjftbuilding From Blue BookhirohinataNo ratings yet

- Bored Cast in Place PilesDocument10 pagesBored Cast in Place Pilesmarufpwd442No ratings yet

- Nonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe (Metric)Document5 pagesNonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe (Metric)Ahmad Zubair RasulyNo ratings yet

- ROCK Fill Specifiation & StandardsDocument17 pagesROCK Fill Specifiation & StandardsibrahimNo ratings yet

- Specification For Pre Stressed Cement Concrete PolesDocument10 pagesSpecification For Pre Stressed Cement Concrete PolesNagabhushanam PayapalleNo ratings yet

- Division 3&4 Concrete&MasonryDocument9 pagesDivision 3&4 Concrete&MasonryAceron Torres MalicdanNo ratings yet

- Guideline Suggestions For Specification of Concrete Slab-On-Grade Substrates To Receive Epoxy TerrazzoDocument2 pagesGuideline Suggestions For Specification of Concrete Slab-On-Grade Substrates To Receive Epoxy TerrazzowalidNo ratings yet

- Construction Methods and ManagementDocument8 pagesConstruction Methods and ManagementAsh BlueNo ratings yet

- Item 900 - Reinforced Concrete 900.1 DescriptionDocument9 pagesItem 900 - Reinforced Concrete 900.1 DescriptionEster MarianNo ratings yet

- 04200Document9 pages04200uddinnadeemNo ratings yet

- C 14M - 03 - Qze0tqDocument4 pagesC 14M - 03 - Qze0tqEmre DalgicNo ratings yet

- Bldg. Spec and Volume 3 Completed (Autosaved) (Autosaved) (Autosaved) (Autosaved) (Autosaved) (Autosaved) 1Document120 pagesBldg. Spec and Volume 3 Completed (Autosaved) (Autosaved) (Autosaved) (Autosaved) (Autosaved) (Autosaved) 1francita bergoniaNo ratings yet

- C14MDocument5 pagesC14Msharon blushteinNo ratings yet

- MS TW3Document5 pagesMS TW3Aleksandar StanojevicNo ratings yet

- C 14 PDFDocument4 pagesC 14 PDFAnwar MohiuddinNo ratings yet

- Prosedur PipaDocument16 pagesProsedur PipaDaengkulle Firmansyah PuteraNo ratings yet

- Concrete Lined CanalsDocument8 pagesConcrete Lined CanalsahmedNo ratings yet

- Astm C14Document4 pagesAstm C14Julio Demer100% (1)

- RD Conc PavingDocument10 pagesRD Conc PavingAurelius GoraNo ratings yet

- PCC Poles For Distribution Engg.Document9 pagesPCC Poles For Distribution Engg.Prakash RoutNo ratings yet

- Technical Specifications I. Demolition WorksDocument14 pagesTechnical Specifications I. Demolition WorksKiel CorpuzNo ratings yet

- 26.sec.2600 (Expansion Joints)Document13 pages26.sec.2600 (Expansion Joints)aalignup arc & const. pvt ltdNo ratings yet

- Specifications (San Carlos Heights)Document10 pagesSpecifications (San Carlos Heights)Bryan Soriano PascualNo ratings yet

- Pavement and Overlay in Principle Approval MCWDocument5 pagesPavement and Overlay in Principle Approval MCWPurshottam SharmaNo ratings yet

- Specification For Permanent Soil Nailed Slope: 1.0 DescriptionDocument12 pagesSpecification For Permanent Soil Nailed Slope: 1.0 DescriptionSiva ViharNo ratings yet

- E-Cld-3002 - Astm C-14Document5 pagesE-Cld-3002 - Astm C-14Andre FarfanNo ratings yet

- InterviewDocument18 pagesInterviewVIJAY BHILWADENo ratings yet

- Section 03370-ShotcreteDocument7 pagesSection 03370-ShotcreteMØhãmmed ØwięsNo ratings yet

- Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDocument10 pagesReinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationKumar AtrayNo ratings yet

- C014M PDFDocument4 pagesC014M PDFleo_pio_ochoaNo ratings yet

- Jhlasalle 321300 Concrete PavingDocument11 pagesJhlasalle 321300 Concrete PavingPonz MadianoNo ratings yet

- Thinset Terrazzo FinishDocument4 pagesThinset Terrazzo Finishmuhammad iqbalNo ratings yet

- ASTM C1433M 07aDocument10 pagesASTM C1433M 07aEyas hamadNo ratings yet

- Solution Manual Prestressed Concrete A Fundamental Approach 5th Edition Edward G. NawyDocument64 pagesSolution Manual Prestressed Concrete A Fundamental Approach 5th Edition Edward G. Nawykrakatua100% (1)

- Grouted RiprapDocument8 pagesGrouted RiprapEdison G. CaluzaNo ratings yet

- A Review On Major Structure On ElevatedDocument2 pagesA Review On Major Structure On ElevatedAdnan NajemNo ratings yet

- Reply To The Discussion by Bakht Et Al. On "Fibre-Reinforced Polymer Composite Bars For The Concrete Deck Slab of Wotton Bridge"Document2 pagesReply To The Discussion by Bakht Et Al. On "Fibre-Reinforced Polymer Composite Bars For The Concrete Deck Slab of Wotton Bridge"Adnan NajemNo ratings yet

- Slap DesignDocument9 pagesSlap DesignAdnan NajemNo ratings yet

- Technical Report - STEEL - FRAMED BUILDING - Seismic - AnalysisDocument6 pagesTechnical Report - STEEL - FRAMED BUILDING - Seismic - AnalysisAdnan NajemNo ratings yet

- Gmail: Battlefield Successes and Challenges: Recent Efforts To Win The War Against ISISDocument124 pagesGmail: Battlefield Successes and Challenges: Recent Efforts To Win The War Against ISISAdnan NajemNo ratings yet

- Norwegian Refugee Council - Itb-Shelter-Upgrades-AnbarDocument50 pagesNorwegian Refugee Council - Itb-Shelter-Upgrades-AnbarAdnan NajemNo ratings yet

- Bridge Engineeing Drawings 10.2 - A4 - 3Document1 pageBridge Engineeing Drawings 10.2 - A4 - 3Adnan NajemNo ratings yet

- Vehicle Restraint Systems-Temporary-systems-Hennie-KotzeDocument35 pagesVehicle Restraint Systems-Temporary-systems-Hennie-KotzeAdnan NajemNo ratings yet

- Conex Compression Technical BrochureDocument48 pagesConex Compression Technical BrochureAdnan NajemNo ratings yet

- Li2011 2Document5 pagesLi2011 2Adnan NajemNo ratings yet

- Parameter Calculation and Verification of Concrete Plastic Damage Model of AbaqusDocument9 pagesParameter Calculation and Verification of Concrete Plastic Damage Model of AbaqusAdnan NajemNo ratings yet

- Bridge Engineeing Drawings 10.2 - A6 - 3Document1 pageBridge Engineeing Drawings 10.2 - A6 - 3Adnan NajemNo ratings yet

- 6M Concrete Security T-Walls U.S. Embassy Baghdad, Iraq: Contract DocumentsDocument13 pages6M Concrete Security T-Walls U.S. Embassy Baghdad, Iraq: Contract DocumentsAdnan NajemNo ratings yet

- Bridge Engineeing Drawings 10.2 - A5 - 3Document1 pageBridge Engineeing Drawings 10.2 - A5 - 3Adnan NajemNo ratings yet

- Bridge Engineering Drawings 10.2 - A3 - 3Document1 pageBridge Engineering Drawings 10.2 - A3 - 3Adnan NajemNo ratings yet

- Equations of Order One: Differential Equations Module 2ADocument5 pagesEquations of Order One: Differential Equations Module 2AJuvilee RicoNo ratings yet

- Choice TheoryDocument2 pagesChoice Theoryginabonieve100% (1)

- Partial Blockage Detection in Underground Pipe Based On Guided Wave&semi-Supervised LearningDocument3 pagesPartial Blockage Detection in Underground Pipe Based On Guided Wave&semi-Supervised Learningrakesh cNo ratings yet

- Evrc Grade One-Math Dll-5thweek2ndquarterDocument8 pagesEvrc Grade One-Math Dll-5thweek2ndquarterAngelica Pastrana Dela CruzNo ratings yet

- Wire Rope LubricantsDocument12 pagesWire Rope LubricantsAlbert Aromin100% (1)

- م م م م م م م م Kkkk אلد אلد אلد אلد א א א א Llll دאوאدא دאوאدא دאوאدא دאوאدאDocument47 pagesم م م م م م م م Kkkk אلد אلد אلد אلد א א א א Llll دאوאدא دאوאدא دאوאدא دאوאدאYoucef kahlrsNo ratings yet

- Decimal Million & Fraction MillionDocument21 pagesDecimal Million & Fraction MillionSuganthi SupaiahNo ratings yet

- Chemical KineticsDocument8 pagesChemical KineticsHosam Hasan Abd ElhadyNo ratings yet

- IEOR 6711: Stochastic Models I Fall 2003, Professor Whitt Class Lecture Notes: Tuesday, November 18. Solutions To Problems For DiscussionDocument2 pagesIEOR 6711: Stochastic Models I Fall 2003, Professor Whitt Class Lecture Notes: Tuesday, November 18. Solutions To Problems For Discussionscanny16No ratings yet

- Theory Summarized R1 To R5Document10 pagesTheory Summarized R1 To R5ALINDOGAN, KimleeNo ratings yet

- Some Books For Stat 602XDocument1 pageSome Books For Stat 602XAmit SharmaNo ratings yet

- Brainware University: Practice Set ofDocument4 pagesBrainware University: Practice Set ofDeep TarafdarNo ratings yet

- Risk Analysis Tools NIOSH Lifting EquationDocument14 pagesRisk Analysis Tools NIOSH Lifting EquationMarian RaduNo ratings yet

- Resume and AppDocument3 pagesResume and AppLORNA GUIWANNo ratings yet

- Revision - The 1 Term Test Grade 12: A.Exercises I. PronunciationDocument16 pagesRevision - The 1 Term Test Grade 12: A.Exercises I. PronunciationBách LêNo ratings yet

- Delegation of Authority Lecture Principles of ManagementDocument34 pagesDelegation of Authority Lecture Principles of Management2021-SC040 PRANAYSAKHARAMDHANDENo ratings yet

- Standard Padeye SheetDocument1 pageStandard Padeye SheetSethGraceNo ratings yet

- Amperometric Titrations: Principle, Instrumentation and ApplicationsDocument6 pagesAmperometric Titrations: Principle, Instrumentation and ApplicationsNandhanNo ratings yet

- Zero Gravity ManufacturingDocument17 pagesZero Gravity Manufacturingsunny sunnyNo ratings yet

- Unit 1: Page ! - The Art of Storytelling: Your Hero's Journey 1 Sunyi - CoDocument35 pagesUnit 1: Page ! - The Art of Storytelling: Your Hero's Journey 1 Sunyi - CoKevin SmithNo ratings yet

- Design and Fluid Structural Interface Analysis of Marine PropellerDocument67 pagesDesign and Fluid Structural Interface Analysis of Marine PropellerPavaniNo ratings yet

- Uplift ModelingDocument4 pagesUplift ModelingMatthew ChengNo ratings yet

- Chem Ch4 NIE Premium NOtesDocument19 pagesChem Ch4 NIE Premium NOtesAadil ShaikhNo ratings yet

- SCR Control System, DIA - NE XT4: Technical InstructionDocument48 pagesSCR Control System, DIA - NE XT4: Technical InstructionAli QaziNo ratings yet