Professional Documents

Culture Documents

Concrete Pavement Specs Parking Area

Uploaded by

Anton_Young_1962Original Description:

Original Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Concrete Pavement Specs Parking Area

Uploaded by

Anton_Young_1962Copyright:

TECHNICAL SPECIFICATIONS:

CONSTRUCTION OF CONCRETE PAVEMENT FOR PARKING AREA

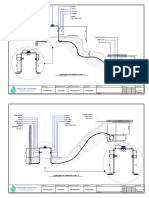

I – SITE WORKS

1.1 General

a. This includes site clearing, earthwork and site drainage, in accordance with the drawing

and specifications.

1.2 Construction Requirements

a. Clearing. All areas within which the construction has to be accomplished shall be

completely cleared from objectionable matters.

b. All excavation shall be performed to the excavation lines, grades, and slopes and profiles

shown in the drawing.

c. Fill and backfill material shall consist of suitable materials from excavation.

d. The fill shall be compacted with mechanical hand tamper.

II - REINFORCEDCONCRETEWORKS

2.1 General

a. All concrete works shall be done in accordance with the Standard Specifications

for Concrete and Reinforced Concrete as adopted by the Philippine Government.

2.2 Concrete Materials

a. PORTLAND CEMENT: Cement shall meet the requirements for the Standard

Specifications for Portland cement.

b. FINE AGGREGATES: Fine Aggregates for Concrete Mortar and Binder

shall consists clean river sand, durable and free from injurious amount of clay and

other organic matters.

c. COARSE AGGREGATES: Shall consist of river gravel, grade “G-3/4” of clean,

hard and free from Alkali, organic and other deleterious matter.

d. METAL REINFORCEMENT: Shall consist of new Billet Steel (Structural

Grade) of good quality meeting the requirements of the Standard Specifications

for Concrete Reinforcing Bars.

2.3 Proportioning of Concrete

a. CLASS “A” CONCRETE (1:2:4) shall have a minimum ultimate strength of 3,000

lbs. per square inch shall be used.

2.4 Mixing Concrete

a. Concrete shall be machined - mixed to insure uniform distribution of materials

throughout the mass.

b. Concrete that has developed initial set shall not be used. Concrete that has

practically hardened shall not be re-tempered or remixed.

2.5 Depositing Concrete

a. After concrete is mixed, it shall be immediately conveyed to the desired location

and carefully deposited in a manner as to prevent separations of ingredients or

displacement of reinforcements.

b. Concrete shall not be dropped more than 1-1/2 meters in height.

c. Concrete during pouring and immediately after, shall be thoroughly compacted. The

mixture shall be worked around the bars and into the corners of forms.

2.6 Reinforcement Bar

a. > 12 mmФ

ASTM 615 Grade 40

Deformed Bars

(fy = 275 MPa)

ASTM 615 Grade 33 ≤

12 mmФ

Deformed Bars

(fy = 230 MPa)

b. Placing of Reinforcement, Splices and Anchorages

1. Reinforcement shall be accurately placed and adequate supported by spacers or ties

and properly secured against displacement.

2. Deformed Bars, the minimum length of splices shall be 300 mm.

3. Reinforcement bars shall be adequately anchored at every joints to its

members.

2.7 Curing of Concrete:

a. Concrete should be so protected that there is no loss of moisture from a surface to a

period of seven (7) days.

b. Curing shall begin as soon as concrete has attained initial set.

2.8 Minimum Period of time in Removal of Forms:

a. Forms shall be checked for plumbness and correct alignment.

b. Forms and shoring shall be removed until the concrete is adequately set and

sufficiently strong to carry safely dead and construction live loads.

c. For Pavement/Slab On Grade (perimeter side)- - - - - One (1) day

III – MASONRY WORKS

3.1. 4” (100 mm) Concrete Hollow Block shall be used for trench side wall.

3.2 3/4” (20 mm) Thick Plastering on interior face of side wall and rough finish.

IV - MISCELLANEOUS METAL

4.1 Welding

Welding shall be in accordance with standard code of arc and gas welding of the American

Welding Society.

4.2 Angle and Round Bars

Angle and Round Bars for Steel Grating shall be assembled by welding and installed as indicated

or specified in the construction drawings.

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Technical Specifications:: Conversion of Concrete Sidewalk To RampDocument2 pagesTechnical Specifications:: Conversion of Concrete Sidewalk To RampAnton_Young_1962100% (1)

- Project: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle OrinaDocument7 pagesProject: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle Orinatyn de guzmanNo ratings yet

- Proposed Two Storey Residence Outline SpecificationsDocument10 pagesProposed Two Storey Residence Outline SpecificationsMelanie CabforoNo ratings yet

- Tech SpecsDocument13 pagesTech SpecsZidd PerezNo ratings yet

- Project Title: Construction of One Storey Residential Building Location: Brgy. Ubagan, Sto. Tomas, La Union Project Owner: Mrs. Teresita CanlasDocument14 pagesProject Title: Construction of One Storey Residential Building Location: Brgy. Ubagan, Sto. Tomas, La Union Project Owner: Mrs. Teresita CanlasArnold VercelesNo ratings yet

- BT 4Document9 pagesBT 421-03606No ratings yet

- Technical Specifications Construction of Fire StationDocument11 pagesTechnical Specifications Construction of Fire Stationp.viloriaNo ratings yet

- BT4 SpecificationsDocument8 pagesBT4 SpecificationsJet BlackNo ratings yet

- DIVISION 3: CONCRETE SPECIFICATIONSDocument12 pagesDIVISION 3: CONCRETE SPECIFICATIONSKae MoNo ratings yet

- Technical Specifications I. Demolition WorksDocument14 pagesTechnical Specifications I. Demolition WorksKiel CorpuzNo ratings yet

- Material Specifications - : LOCATION: Pristina North Residences, Bacayan, Cebu City Owner: ArchitectDocument14 pagesMaterial Specifications - : LOCATION: Pristina North Residences, Bacayan, Cebu City Owner: ArchitectRoi KimssiNo ratings yet

- Specifications (San Carlos Heights)Document10 pagesSpecifications (San Carlos Heights)Bryan Soriano PascualNo ratings yet

- SpecificationsDocument20 pagesSpecificationsJohn Dominic Delos ReyesNo ratings yet

- Structural AnalysisnewDocument6 pagesStructural AnalysisnewJunith Jay CalinawanNo ratings yet

- General SpecificationsDocument10 pagesGeneral SpecificationsChy GomezNo ratings yet

- General Specifications: Scope of WorkDocument10 pagesGeneral Specifications: Scope of WorkChy GomezNo ratings yet

- ConstructionDocument8 pagesConstructionGaspar Lig-ang TolomiaNo ratings yet

- Ii. Concrete & Reinf. ConcreteDocument1 pageIi. Concrete & Reinf. ConcreteJane Louraigne Apilado GabrilloNo ratings yet

- Camaya General SpecificationDocument11 pagesCamaya General SpecificationBenjamin Jacob Jr.No ratings yet

- Specifications Section 1 GeneralDocument4 pagesSpecifications Section 1 GeneralAgia Dela VegaNo ratings yet

- Sample Construction SpecificationsDocument14 pagesSample Construction SpecificationsFrncesca MacalindongNo ratings yet

- Labuyo SpecsDocument9 pagesLabuyo SpecsBotenes Mallorca RhonNo ratings yet

- SPECIFICATIONDocument25 pagesSPECIFICATIONkingcedsNo ratings yet

- AAB 042200 Concrete Unit MasonryDocument6 pagesAAB 042200 Concrete Unit MasonrytewodrosNo ratings yet

- PROPOSED GSD BUILDING EXCAVATION & CONCRETEDocument15 pagesPROPOSED GSD BUILDING EXCAVATION & CONCRETEJep MarianoNo ratings yet

- BIADP - Technical Specifications - Volume 2Document83 pagesBIADP - Technical Specifications - Volume 2ralpheaNo ratings yet

- SITE WORK OUTLINE SPECIFICATIONSDocument26 pagesSITE WORK OUTLINE SPECIFICATIONSMara Athena IbarraNo ratings yet

- RD Conc PavingDocument10 pagesRD Conc PavingAurelius GoraNo ratings yet

- SECTION 33 05 13 Manholes: Revised 03/2012Document52 pagesSECTION 33 05 13 Manholes: Revised 03/2012FAISAL NAZEERNo ratings yet

- Proposed Residential Building SpecsDocument6 pagesProposed Residential Building SpecsMaire Joy E. AzañaNo ratings yet

- Specification For Reinforced Soil WallDocument8 pagesSpecification For Reinforced Soil WallChin Thau WuiNo ratings yet

- Construction Specifications LongDocument7 pagesConstruction Specifications LongLimar SetatraNo ratings yet

- Section 03200-Concrete ReinforcementDocument4 pagesSection 03200-Concrete ReinforcementMØhãmmed ØwięsNo ratings yet

- Asphalt Plant Technical SpecificationsDocument5 pagesAsphalt Plant Technical SpecificationsEljoy AgsamosamNo ratings yet

- Part1 Outline SpecificationsDocument16 pagesPart1 Outline SpecificationsAdrienne Margaux DejorasNo ratings yet

- Section 03300 Cast-In-Place Concrete: Part 1 - General 1.1 ScopeDocument18 pagesSection 03300 Cast-In-Place Concrete: Part 1 - General 1.1 Scopeاحمد علي احمدNo ratings yet

- Jhlasalle 321300 Concrete PavingDocument11 pagesJhlasalle 321300 Concrete PavingPonz MadianoNo ratings yet

- Precast Reinforced Concrete BarriersDocument30 pagesPrecast Reinforced Concrete BarriersAdnan NajemNo ratings yet

- Oblepas-Residence - Specification-01 16 23Document5 pagesOblepas-Residence - Specification-01 16 23jp.fajardo777No ratings yet

- CONCRETE FORM WORK SECTION FOR CAST-IN-PLACE CONCRETEDocument7 pagesCONCRETE FORM WORK SECTION FOR CAST-IN-PLACE CONCRETEabdouNo ratings yet

- Arch 530 - BT4 Technical SpecificationsDocument13 pagesArch 530 - BT4 Technical SpecificationsAlyanna PanganibanNo ratings yet

- Specifications: PROJECT: "Perimeter Fence" OwnerDocument2 pagesSpecifications: PROJECT: "Perimeter Fence" OwnerThe One50% (2)

- Manholes - MSTDocument8 pagesManholes - MSTwafikmh4No ratings yet

- Section 03210 Epoxy Coated Concrete ReinforcementDocument7 pagesSection 03210 Epoxy Coated Concrete ReinforcementgulzamanNo ratings yet

- Proposed Residential BuildingDocument4 pagesProposed Residential BuildingZen Marl Gaor0% (1)

- SECTION 03 30 53 (Short-Form) Cast-In-Place ConcreteDocument13 pagesSECTION 03 30 53 (Short-Form) Cast-In-Place ConcreteJuanPaoloYbañezNo ratings yet

- Mr. Pioc General SpecificationsDocument11 pagesMr. Pioc General SpecificationsErick Anopol Del MonteNo ratings yet

- Short Construction-SpecificationsDocument8 pagesShort Construction-SpecificationsRany YambaoNo ratings yet

- Shiela S. Portillo Ang Specification 09112021Document9 pagesShiela S. Portillo Ang Specification 09112021JR De LeonNo ratings yet

- Proposed Three Storey Townhouse ProjectDocument4 pagesProposed Three Storey Townhouse ProjectNikolai GongoraNo ratings yet

- Method Statement Construction of Chambers-Concrete WorksDocument6 pagesMethod Statement Construction of Chambers-Concrete WorksLovemore Makora MukondomiNo ratings yet

- Project: Proposed Three Storey Three Unit Townhouse Location: Owner: Technical Specifications I. General ConditionDocument4 pagesProject: Proposed Three Storey Three Unit Townhouse Location: Owner: Technical Specifications I. General ConditionNikolai GongoraNo ratings yet

- Two Storey General SpecificationsDocument7 pagesTwo Storey General SpecificationsJoseph MalabananNo ratings yet

- Two Storey Residential Building SpecsDocument10 pagesTwo Storey Residential Building SpecsAeron AcioNo ratings yet

- Structural Specifications - OakridgeDocument13 pagesStructural Specifications - OakridgeJuliet Lobrino RozosNo ratings yet

- Section 03490-Glass-Fiber-Reinforced Precast ConcreteDocument5 pagesSection 03490-Glass-Fiber-Reinforced Precast ConcreteMØhãmmed ØwięsNo ratings yet

- PROJECTDocument66 pagesPROJECTASHLEY CAPINANo ratings yet

- General specifications-GILODocument7 pagesGeneral specifications-GILOHannah Cesaree Mae TadeoNo ratings yet

- 03 48 00clcDocument5 pages03 48 00clcAira LauzonNo ratings yet

- Bidding Documents - INFRA2021-06-009Document55 pagesBidding Documents - INFRA2021-06-009Anton_Young_1962No ratings yet

- CPM - Construction PlanningDocument13 pagesCPM - Construction PlanningAnton_Young_1962No ratings yet

- Bar Bending ScheduleDocument5 pagesBar Bending ScheduleAnton_Young_1962100% (2)

- Addl Requirements For Elevated Steel Tank - 2edDocument31 pagesAddl Requirements For Elevated Steel Tank - 2edAnton_Young_1962No ratings yet

- Revised IRR Restricts Civil Engineer Authority to Prepare Building PlansDocument80 pagesRevised IRR Restricts Civil Engineer Authority to Prepare Building PlansAnton_Young_1962No ratings yet

- Comb FootingDocument2 pagesComb FootingAnton_Young_1962100% (1)

- CPM - IntroductionDocument13 pagesCPM - IntroductionAnton_Young_1962No ratings yet

- World Water Day - 2022Document1 pageWorld Water Day - 2022Anton_Young_1962No ratings yet

- DrawingsDocument5 pagesDrawingsAnton_Young_1962No ratings yet

- Water Service ConnectionDocument3 pagesWater Service ConnectionAnton_Young_1962No ratings yet

- Construction Contract AdministrationDocument8 pagesConstruction Contract AdministrationAnton_Young_1962No ratings yet

- BSCE Validation Survey FormDocument4 pagesBSCE Validation Survey FormAnton_Young_1962No ratings yet

- Iso FootingDocument2 pagesIso FootingAnton_Young_19620% (1)

- Workbookand Study GuideDocument50 pagesWorkbookand Study GuideAnton_Young_1962No ratings yet

- Design Summary - Nalook PDFDocument3 pagesDesign Summary - Nalook PDFAnton_Young_1962No ratings yet

- Contract DocumentsDocument12 pagesContract DocumentsAnton_Young_1962No ratings yet

- CIVL 1101 What is GIS? - An Introduction to Geographic Information SystemsDocument9 pagesCIVL 1101 What is GIS? - An Introduction to Geographic Information SystemsAnton_Young_1962No ratings yet

- Bidding ProceduresDocument15 pagesBidding ProceduresAnton_Young_1962No ratings yet

- 3) Steel Sections Selection CriteriaDocument1 page3) Steel Sections Selection CriteriaAnton_Young_1962No ratings yet

- SpecificationsDocument10 pagesSpecificationsAnton_Young_1962No ratings yet

- 4rules PCE PDFDocument6 pages4rules PCE PDFAnton_Young_1962No ratings yet

- Designing Struts: R-Index of Safety and EconomyDocument1 pageDesigning Struts: R-Index of Safety and EconomyAnton_Young_1962No ratings yet

- 1) Steel Struct DesignerDocument3 pages1) Steel Struct DesignerAnton_Young_1962No ratings yet

- Construction Drawing Types ExplainedDocument25 pagesConstruction Drawing Types ExplainedAnton_Young_1962No ratings yet

- CSI MasterFormat Construction Spec IndexDocument2 pagesCSI MasterFormat Construction Spec IndexAnton_Young_1962100% (1)

- Introduction To Procurement Management PDFDocument43 pagesIntroduction To Procurement Management PDFSiampol Feepakphor100% (1)

- R Index: Safety & Economy Design GuideDocument1 pageR Index: Safety & Economy Design GuideAnton_Young_1962No ratings yet

- BAC Observer Tools - PPT (Compatibility Mode)Document16 pagesBAC Observer Tools - PPT (Compatibility Mode)Anton_Young_1962No ratings yet

- Implementing Rules and Regulations of RA 11058 on OSH StandardsDocument78 pagesImplementing Rules and Regulations of RA 11058 on OSH Standardspaolo mosicoNo ratings yet

- Managing Construction Contracts Liquidated Damages (LDS) & Extension of Time (EOT) Claims in PracticeDocument27 pagesManaging Construction Contracts Liquidated Damages (LDS) & Extension of Time (EOT) Claims in PracticeAnton_Young_1962No ratings yet

- 3d-Pic-04 When Jesus Was BaptizedDocument8 pages3d-Pic-04 When Jesus Was BaptizedVictor TancaraNo ratings yet

- Avenged Sevenfold - Seize The DayDocument2 pagesAvenged Sevenfold - Seize The Dayb1gbrotherNo ratings yet

- 17-2 Material Types & FinishesDocument9 pages17-2 Material Types & FinishesZuberYousufNo ratings yet

- Tactical Manual Small Unit Tactics PDFDocument3 pagesTactical Manual Small Unit Tactics PDFDbeis100% (1)

- Tate Modern London, Pay Congestion ChargeDocument6 pagesTate Modern London, Pay Congestion ChargeCongestionChargeNo ratings yet

- Bach PDFDocument624 pagesBach PDFChopin970% (1)

- Oracle of The Mermaids Magical Messages of Healing Love RomanceDocument3 pagesOracle of The Mermaids Magical Messages of Healing Love RomanceGunter Pilarte14% (7)

- Rare 18th C French Sand Automaton by LandrasDocument20 pagesRare 18th C French Sand Automaton by LandrasAle Saez0% (1)

- St. Johns County Road ProjectsDocument4 pagesSt. Johns County Road ProjectsThe Florida Times-UnionNo ratings yet

- Gutindex 2009Document170 pagesGutindex 2009Lankesh ZadeNo ratings yet

- Tbilisi Marriott Magazine 2008 - Issue #8Document60 pagesTbilisi Marriott Magazine 2008 - Issue #8tbilisimarriottNo ratings yet

- Interference Michelson InterferometerDocument6 pagesInterference Michelson InterferometerAsa mathewNo ratings yet

- Nocturne (Live in Los Angeles) Scott Colley and Julian LageDocument7 pagesNocturne (Live in Los Angeles) Scott Colley and Julian LageSaurabh ShivakumarNo ratings yet

- 1 Back in The DayDocument508 pages1 Back in The DayGaby Murillo100% (3)

- TEN 2 FIVE - I WILL FLYDocument55 pagesTEN 2 FIVE - I WILL FLYAinun Hanafi AdnanNo ratings yet

- Martha Stewart Weddings Summer 2017 FreeMags CC PDFDocument245 pagesMartha Stewart Weddings Summer 2017 FreeMags CC PDFgiovana_mtzNo ratings yet

- Holo Lens: Seminar ReportDocument24 pagesHolo Lens: Seminar ReportBharat Chaudhary83% (30)

- My New Years ResolutionsDocument3 pagesMy New Years ResolutionsDr. Liza ManaloNo ratings yet

- Easter's End PDFDocument6 pagesEaster's End PDFJess DevanNo ratings yet

- An American Marriage: Readers GuideDocument2 pagesAn American Marriage: Readers GuideCBS This MorningNo ratings yet

- Alegeri 2019-10-26 - 122610-PV-afisare-judet-BDocument211 pagesAlegeri 2019-10-26 - 122610-PV-afisare-judet-BDaniel DanNo ratings yet

- Natural Cooling Systems of Jaisalmer: Vinod GuptaDocument7 pagesNatural Cooling Systems of Jaisalmer: Vinod GuptaMALLIMPATTINo ratings yet

- Procedimiento para el desarrollo curricular de formación profesional en el Centro Nacional de Hotelería Turismo y AlimentosDocument5 pagesProcedimiento para el desarrollo curricular de formación profesional en el Centro Nacional de Hotelería Turismo y AlimentosAndres ReyesNo ratings yet

- One Two Buckle My ShoeDocument5 pagesOne Two Buckle My ShoeDonnette DavisNo ratings yet

- Strindberg InfernoDocument18 pagesStrindberg InfernoRogerio CathalaNo ratings yet

- Missa No. 2 in G Mass No. 2 in G Major (D 167) : Franz Schubert (1797 - 1828)Document35 pagesMissa No. 2 in G Mass No. 2 in G Major (D 167) : Franz Schubert (1797 - 1828)Sergio Enrique Rosales CruzNo ratings yet

- CatalogDocument5 pagesCataloglangtu2011No ratings yet

- Letters of A TravellerNotes of Things Seen in Europe and America by Bryant, William Cullen, 1794-1878Document155 pagesLetters of A TravellerNotes of Things Seen in Europe and America by Bryant, William Cullen, 1794-1878Gutenberg.org100% (1)

- Three Wrathful OnesDocument4 pagesThree Wrathful OnesThomas Skelly100% (6)

- Clemen Carl de Guzman: About The ArtistDocument3 pagesClemen Carl de Guzman: About The ArtistLOVELYGIRLNo ratings yet