Professional Documents

Culture Documents

Soya Based Food Products

Uploaded by

vodounnou0 ratings0% found this document useful (0 votes)

12 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views5 pagesSoya Based Food Products

Uploaded by

vodounnouCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

22

S OYA BASED FOOD PRODUCTS

PRODUCT CODE : New Products

QUALITY AND STANDARDS : PFA (Prevention of Food

Adulteration Act, 1955

PRODUCTION CAPACITY : Item Qt

Qtyy.( Kg .)

Kg.) Valu

Valu

aluee (Rs .)

(Rs.)

(PER ANNUM) Flavoured 60,000 6,60,000

Soya Milk

Tofu (Soya 6,000 2,40,000

Paneer)

Soya Curd 12,000 1,44,000

MONTH AND YEAR : February, 2003

OF PREPARATION

PREPARED BY : Small Industries Service Institute

Industrial Area-B,

Ludhiana-141003

Punjab.

Phone Nos. : 531733-34-35

Fax: 91-161-533225

E-mail: sisildh@sisildh.com

INTRODUCTION diabetes and lactose-intolerance. It can

be said that Soyabean is a valuable gift

Soyabean is the most cheapest and of mother nature to human beings.

best health food. Soya milk and related

food products are becoming popular MARKET POTENTIAL

throughout the world due to their good

nutritional values and medicinal With the increasing health

qualities. Soya milk is high in protein, consciousness among the general

low in fat and carbohydrate and contains people, the use of Soyabean is getting

no cholesterol. It is an excellent food acceptance in the form of textured

for babies, children, elderly people and vegetable protein (popularly known as

pregnant and lactating women since it Soya bodi or Soya nuggets), Soya

contains vegetable protein which is very fortified wheat flour, Soya milk, Tofu and

nutritious and easy to digest. Besides Soya curd etc. Being mainly the country

possessing high nutritional values, Soya of vegetarians, India has indeed a very

milk is best for people suffering from great potential for Soya products.

128 S OYA BASED FOOD PRODUCTS

Experts predict that the Soya food and preparation

industry will grow 20% annually over the of Project Report

next few years. Soya milk sales alone 2. Sanction of loan 2-3 Months

rose by 50% in 2001 and is expected to

grow by atleast another 300% by the 3. Selection of machinery 1 Month

year 2005.

4. Commissioning 4-5 Months

B ASIS AND PRESUMPTIONS and trial run, etc.

Due to overlapping of some activities,

I. It is presumed that the unit will normally 4 to 5 months are required to

run single shift per day and 300 implement the Project.

days in a year.

II. The rate of interest has been

taken 15% on an average both

TECHNICAL ASPECTS

for fixed investment and working Process of Manufacture

capital.

The initial stage involves the cleaning,

III. It is presumed that 1 kg. of

sorting of the Soyabean followed by

Soyabean may yield 7.5 litres of

dehulling and soaking at room

Soyamilk. 1 litre Soyamilk can be

temperature in 0.5-1% sodium

converted into two litres of

flavoured Soya milk or 1 kg of bicarbonate solution in 1: 3 ratio (soya:

Soya curd or 200 gms of Soya solution). After soaking, the weight of

Paneer (Tofu). original soyabean becomes double, the

split (dehulled beans) are ground in hot

IV. The rates of machinery and

water in 1:7 ratio and filtered to get milk.

equipments and raw materials are

those prevailing at the time The residue is known as okra. The milk

of preparation of Project Profile. is then cooled to 70ºC and 0.1 molar

They are likely to vary from calcium sulphate/magnesium chloride

place to place and supplier to or 2% citric acid solution is added with

supplier and necessary changes slow stirring. These chemicals

are to be made as and when precipitate/coagulate the proteins of

required. soya milk. The muslin cloth containing

Soya protein is pressed in paneer

IMPLEMENTATION SCHEDULE making boxes for 30 to 45 mts. and then

cut into pieces of approx. desired size

The approximate time required for and put in cold water for another 30

various activities is given below. minutes. Vacuum packed tofu should

However, it may vary from place to place always be kept in the fridge and, after

depending upon the local circumstances

unpacking, immersed in water. The

and enthusiasm of the entrepreneur:

various products which can be

1. Selection of site, 1 Month manufactured are mentioned in the

provisional registration Chart below:

S OYA BASED FOOD PRODUCTS 129

Clean and Soak Soyabeans

1 kg. Beans 3.3 Lit. Water

Airless grind and cook

5.2 Litre Water

13 kg. steam

Extract

Soya milk Base 7.5 Litre

Soya milk 1.4 kg Okara

Add water Add coagulant or Add Sweetner, Okra

sweetener flavour citric salt and yoghurt Add salts, spices,

salt, etc. culture Flour Veggies

Homogenize or Extract Curd and press Incubate Yoghurt Bake or Fry or add

mix well Soya milk in a forming Box Tofu (Paneer) optionally add fruits to foods and Cook

Quality Control and Standards Land and Building Amount

(In Rs.)

Product should conform to the PFA place, finished @ Rs 20 per

(Prevention of Food Adulteration) store and office etc. sq. mtr.

Act, 1955.

ii) Machinery and Equipments

Production Capacity (per annum) Sl. Description No. Amount

No. (In Rs.)

Flavoured Soya milk : 60,000 kg.

a. Soya Machine for soya 1 No. 1,00,000

Soya paneer : 6,000 kg. milk and paneer (Tofu)

Soya curd : 12,000 kg. consisting of grinder

cooker, Manual Boiler,

Motive Power 20 H.P. Filter Press, Tofu Box &

Tofu Press.

Pollution Control b. Deodorizer 1 No. 43,000

Though no industrial effluent is c. Vacuum Packaging Machine 1 No. 75,000

released in the manufacturing process d. Freezer 2 Nos. 30,000

even then a NOC from State Pollution e. Pouch Sealing Machine 1 No. 10,000

Control Board is to be obtained before

commercial production. f. Tables with AL Top 3 Nos. 10,500

g. Plastic Trays/Tubes and L.S. 15,000

FINANCIAL ASPECTS other misc. items

h. Packaging -2%, Excise 79,380

A. Fixed Capital 16% Sales tax-10%

i) Land and Building Amount Total 3,62,880

(In Rs.) Electrification and Installation @ 10% 28,350

Built up area 100 sq. mtr. Rs 2,000 Office Furniture and Equipments 10,000

including mfg. (rented) per month

Total 4,01,230

130 S OYA BASED FOOD PRODUCTS

iii. Pre-operative Expenses 5000 v) Total Recurring Expenses Amount

(per month) (In Rs.)

Total Fixed Cost (ii+iii) = Rs. 4,06,230

i. Raw materials 24,000

B. Working Capital (per month) ii. Personnel 15,525

iii. Utilities 8,000

i) Personnel Salary

(In Rs.) iv. Other expenses 7,000

1. Manager 1 No. @ Rs. 5000 5000 Total 54,525

2. Skilled 2 Nos. @ Rs. 2000 4000

vi) Working Capital (for 2 months) Rs.1,09,050

workers

3. Sales 1 No. @ Rs. 3000 3000

Supervisor C. Total Capital Investment

4. Peon 1 No. @ Rs. 1500 1500 Amount

Total 13,500 (In Rs.)

Perquisites @ 15% 2,025 i. Fixed Capital. 4,06,230

Total 15,525 ii. Working Capital (for 2 months) 1,09,050

Total 5,15,280

ii) Raw Materials including Amount

Packaging (In Rs.)

FINANCIAL ANALYSIS

i. Soyabean- 800 kg. 12,000

@ Rs15per kg. 1. Cost of Production (per annum) Amount

(In Rs.)

ii. Chemicals and other misc. L.S. 8,000

expenses 1. Total recurring cost 6,54,300

iii. Packaging material for milk L.S. 4,000 2. Depreciation on machinery 56,700

and paneer @ 20%

Total 24,000 3. Depreciation on furniture 2,000

@ 20%

iii) Utilities Amount

4. Interest on total investment 77,300

(In Rs.)

@ 15%

1. Power 2,000

Total 7,90,300

2. Fuel/LPG 5,000

Say 7,90,000

3. Water 1,000

2. Turn-over (per annum) Total

Total 8,000

(In Rs.)

iv) Other Contingent Expenses Amount i. Flavoured Soya milk 60,000 kgs. 6,60,000

(In Rs.) @ Rs 11per kg.

i. Rent 2,000 ii. Tofu (paneer) 6000 kgs. 2,40,000

@ Rs 40 per kg.

ii. Postage and stationery 300

iii. Soya Curd- 12000 kgs. 1,44,000

iii. Consumable store 500 @ Rs 12 per kg.

iv. Repairs and maintenance 300 Total 10,44,000

v. Advertisement and publicity 1,000

3. Net Profit (per annum) Rs. 2,54,000

vi. Sales Expenses 1,000

4. Net Profit Ratio

vii. Telephone 500

= 254000 × 100

viii. Miscellaneous Expenses 1,400 1044000

Total 7,000 = 24%

S OYA BASED FOOD PRODUCTS 131

5. Rate of Return B.E.P.

= 2,68,120 × 100

= 254000 × 100

515280 2,68,120 + 2,54,000

= 49% = 2,68,120 × 100

5,22,120

6. Break-even Point = 51%

Fixed Cost (per annum) Amount

(In Rs.)

Addresses of Machinery Suppliers

i. Depreciation on machinery 56,700 1. M/s. SSP Limited

ii. Depreciation on furniture 2,000 19, DLF Industrial Area-IV,

iii. Rent 24,000

13/4, Mathura Road,

Faridabad- 121003 (Haryana)

iv. 40% of other expenses 33,600

Phone: 0129 (527544), 5277730,

v. 40% of salary and wages 74,520

Fax: 91-129-527744)

vi. Interest on total investment

@ 15% per annum 77,300 Raw Material Suppliers

Total 2,68,120 Locally Available.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 09 SprayerDocument8 pages09 Sprayerasephidayat042No ratings yet

- Skull RadiographyDocument12 pagesSkull RadiographyMohamed AufNo ratings yet

- Hlimkhawpui - 18.04.2021Document2 pagesHlimkhawpui - 18.04.2021JC LalthanfalaNo ratings yet

- 8 Useful Behavior Modification Techniques For Adults - Operation Meditation - Operation Meditation PDFDocument3 pages8 Useful Behavior Modification Techniques For Adults - Operation Meditation - Operation Meditation PDFAdam AzlanNo ratings yet

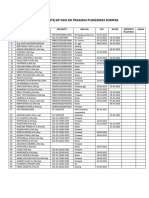

- Daftar Ceklis STR, Sip Dan Sik Pegawai Puskesmas SompakDocument1 pageDaftar Ceklis STR, Sip Dan Sik Pegawai Puskesmas SompakAkwila PaudyaNo ratings yet

- Dysarthria Assessment and TreatmentDocument6 pagesDysarthria Assessment and Treatmentapi-3705274100% (4)

- The Flaw of Averages in Flattening The CurveDocument7 pagesThe Flaw of Averages in Flattening The CurveFahad IzharNo ratings yet

- Full Syllabus Test 03: Result (Dropper NEET) : Name Candidate ID Physics Chemistry Botany Zoology Total AIR Center RankDocument50 pagesFull Syllabus Test 03: Result (Dropper NEET) : Name Candidate ID Physics Chemistry Botany Zoology Total AIR Center RankKeshav PargeeNo ratings yet

- Soccer Field Turf - FINAL - Dec - 1Document45 pagesSoccer Field Turf - FINAL - Dec - 1Yudhy NoviantoNo ratings yet

- Physiotherapy For Primary Frozen Shoulder in Secondary Care Hanchard 2019Document11 pagesPhysiotherapy For Primary Frozen Shoulder in Secondary Care Hanchard 2019patinoomar67No ratings yet

- Dr. Mohammad Shaikhani. Sulaimani University, College of Medicine. Sulaimanya-Iraqi KurdistanDocument51 pagesDr. Mohammad Shaikhani. Sulaimani University, College of Medicine. Sulaimanya-Iraqi KurdistanHNINNo ratings yet

- Alcohol Cetoestearilico MsdsDocument6 pagesAlcohol Cetoestearilico MsdsJoha Darwin ChNo ratings yet

- Guidance Note For Implementation of RMNCH+A Interventions in High Priority DistrictsDocument26 pagesGuidance Note For Implementation of RMNCH+A Interventions in High Priority DistrictsJennifer Pearson-ParedesNo ratings yet

- Sistem Pelaporan Dan Pembelajaran Keselamatan Pasien RS Arjaty 2022Document13 pagesSistem Pelaporan Dan Pembelajaran Keselamatan Pasien RS Arjaty 2022vera kusunyadewiNo ratings yet

- Gad Plan 2022-2023Document6 pagesGad Plan 2022-2023Melvin AlmeriaNo ratings yet

- Analytical ReasoningDocument4 pagesAnalytical ReasoningBilalAzamNo ratings yet

- DR Daniel Pompa Smoothies To Heal Your Gut Ed 1115r3Document20 pagesDR Daniel Pompa Smoothies To Heal Your Gut Ed 1115r3Rares Dinu100% (2)

- Fecal ImpactionDocument5 pagesFecal Impactioncharie2No ratings yet

- sugarfilmSTS SalonDocument1 pagesugarfilmSTS SalonAlyana Mae SalonNo ratings yet

- Zeher Insan Ka AssignmentDocument7 pagesZeher Insan Ka AssignmentHuzaifa KhanNo ratings yet

- Technical Report of Lab 1 Tablet LatestDocument5 pagesTechnical Report of Lab 1 Tablet LatestHasni Abdul RahimNo ratings yet

- Philippine Kidney Dialysis FoundationDocument1 pagePhilippine Kidney Dialysis FoundationHarbyNo ratings yet

- Kualitas Hidup Pasien GoutDocument10 pagesKualitas Hidup Pasien GoutShared LifeNo ratings yet

- Cimicifuga RacemosaDocument16 pagesCimicifuga RacemosaKamalNo ratings yet

- Managing Insomnia Lesson 1Document22 pagesManaging Insomnia Lesson 1taurus_europe100% (2)

- WHO Uppsala ReportDocument24 pagesWHO Uppsala ReportAslam HossainNo ratings yet

- Drug AdiictionDocument17 pagesDrug AdiictionRahul PatelNo ratings yet

- Noorani 2014Document3 pagesNoorani 2014MD Luthfy LubisNo ratings yet

- Emergency Rescue and TransferDocument35 pagesEmergency Rescue and TransferGavinKarl MianabanataoNo ratings yet

- 151 Beauty SecretsDocument24 pages151 Beauty SecretsAlesha Rose97% (35)