Professional Documents

Culture Documents

MUPW+611.4: Material .4) 83 Itwh or Ksa Be The Flange, Lap

Uploaded by

TAHIR MAHMOODOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MUPW+611.4: Material .4) 83 Itwh or Ksa Be The Flange, Lap

Uploaded by

TAHIR MAHMOODCopyright:

Available Formats

.

MUPW+611.4

C.E. = C+ Mn+Mo+Cr+Ni+Cui I’ 34.1 Geaerd. Welds of material .4)83 itwh

T Tr 1s 5 thkk or ksa may be of the flange, but~ lap,

:L3.L2 Corrosion and heat-resistant stickel- or tMet joinu aa ●pplicabk Welds of mate-

chromium steels shall not be welded unless rial thicker lhan .083 inch shall be of the

butt or fillet type 8s ●pplwabk Lap joints

they are of ● composition which is stabilised

against sensitization to intergranular oorrtP may be d in material thicker than tLINt:

sion, tubs * maximum Urbon content is inch aubjed to the approvtd of the inspectw

0.03% or * or unless they an mh-t- Or, in the sase of rriti8td jointa. to the alb

proval of the procuring sgency.

lrded in acwrdance with Military Specifi-

catioi~ MIL-1 1-6, Table L 3.4.2 Joird lkuipt~. Joint design alwuid, m

generai, be in accordance with 1he latest

3&2 Fifkr Jfettd. Welding rods, we!dinsr

prndices recommended by lhc Amwieall

wire, and ekctrodea used in the welding of

Welding Society.

steels and corrosion and heahesistant alloys

shall be capable of producing satisfactory MS Acces@i/ity. Aii purtious d a weld .

welds when used by a certified welding oper- Shanbe ~ble to proper removal of flux

ator with satisfactory welding ●pparatus, residm

and shall have a compositionsuitable for pm

ducing welds conforming to the swquire-

ments specified herein. Coated ekdrodes

used for welding mild and low alloy steel 35.1 Procedure Certijkuhon. Prior to M.

shall confom~ to Military Spedkation bflL- tm8ixM!in prdutiim welding, the contractor

E-6843 or MIL-E-S697 as applicabk Coat- shall demonstrate to the authorised govern-

ed electrodes used for welding corrosion or ment inspector the satisfactory quaiity of

heat-resistant alloys shall conform to bfili- rep~tive welds by means of tile -L<

+-

tary Specifkntion MIM34844. R&is used 8PWifkd in Section 4. Procedure Cerlificatiw

for the weiding of mild and alloy steel shall is intended to cover a technique of o~r*-

conform to Military S~fication MILR- tiorta rather than a specific application nml

5632. Rods used for welding corrosion or accordingly shall not im repeated for differ-

heat-wsistant alloys ahaIl conform to Mili- ent weld aasernbiies, uniess recertifkalioll is

tary SEificntion MILJU031. The filler warranted by a break in the continuity {If

met mI med ill the weiding of dissimilar production, by a sttbsbmtial increase in Lhr

mc(.ak shall etmfovrn to the requirements of complexity of the work being perffwrrwfl,

the prncuring agency. The class of filler or by substantial changes in prordu re. it)

metil emplm-ed shrdl be comwtible with the case of rifJuiL the l]*eSSlty fw I“ccerliflca -

Iume metal in maintaining the mechaniad tion shall be cleterminwl hy t iw aut hnrlmrl

properties nnd corrosion-resiatttnce of tttc government inspector.

&se metal.

35-2 Preparation 0/ Swrjucts. Surfaces 10

3.3.3 FIMx. Flux for gas welding of corr~ be welded shall be free from grease or othw

sion or heat-resistant alloys shall conform to foreign matter ●nd shail be as free as pcNs-

the requirements of Military Specification sible from rust and protective coatings.

M II=F-7516. Fluxes shall not increase the Cleaning with a wile brush orabrasive paper

cnrbon content of the weld metal ttignifi- may be used for rernotiing’ rust and protec-

cnntiy. tive coatings. Where a wire brush is used it

is recommended that its composition, insofar

3.3.4 Guses. Gases shall be of a grade des- as practicabk, be similar to the composition

ignated for weiding. of the materiai being welded.

3.4 Weld Design. 3&3 Srrtoothneuu md wdd coni our. Where

L-

You might also like

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingFrom EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNo ratings yet

- MIl W 8611.PDF Rev ADocument10 pagesMIl W 8611.PDF Rev ABryan MartinezNo ratings yet

- Mil B 7883Document16 pagesMil B 7883Bryan MartinezNo ratings yet

- Dilw-Sma: That Atmngth Ievel. (Document1 pageDilw-Sma: That Atmngth Ievel. (TAHIR MAHMOODNo ratings yet

- Mil B 7883BDocument14 pagesMil B 7883BAnonymous 5pURWfNo ratings yet

- Mil B 7883BDocument14 pagesMil B 7883BMichael SkrableNo ratings yet

- MIL-K-8662E - Knife, Hunting, Sheathed, Survival, PilotsDocument24 pagesMIL-K-8662E - Knife, Hunting, Sheathed, Survival, Pilotscjnjr1No ratings yet

- Section 5. Welding and BrazingDocument27 pagesSection 5. Welding and BrazingrobinyNo ratings yet

- Soldering: / JoiningDocument5 pagesSoldering: / JoiningKasia MazurNo ratings yet

- Recommended Practice FOR Welded Fabrication in Wagons: Government of India Ministry of RailwaysDocument75 pagesRecommended Practice FOR Welded Fabrication in Wagons: Government of India Ministry of RailwaysAMIT KUMAR100% (1)

- Marth 1800 PrestressingDocument17 pagesMarth 1800 PrestressingRamesh100% (4)

- Fabrication Procedure of StructureDocument8 pagesFabrication Procedure of StructureAyub KhanNo ratings yet

- Annexure D Spec PDFDocument19 pagesAnnexure D Spec PDFTanmay GorNo ratings yet

- Mil T 10727BDocument12 pagesMil T 10727BnightmanmxNo ratings yet

- Clad Metal WeldingDocument6 pagesClad Metal WeldinggoguluNo ratings yet

- 1325Document2 pages1325balaengg1No ratings yet

- Weld TechnicsDocument208 pagesWeld TechnicsSiraj Ahamed ShaikNo ratings yet

- Building codes related to cable, fabric & stonesDocument15 pagesBuilding codes related to cable, fabric & stonesPikuNo ratings yet

- Is 210-1993 Grey Cast IronDocument12 pagesIs 210-1993 Grey Cast IronnavikiranNo ratings yet

- Recom. de Soldadura XARDocument4 pagesRecom. de Soldadura XARelias667No ratings yet

- Class Result: of DefenseDocument12 pagesClass Result: of DefenseJay MillerNo ratings yet

- Orbital Tube WeldingDocument5 pagesOrbital Tube WeldingGray Fox GarcíaNo ratings yet

- Specification For: AlloyDocument9 pagesSpecification For: AlloyTarkeshwar SharmaNo ratings yet

- Abstract of ASTM B633 1998Document6 pagesAbstract of ASTM B633 1998Jesse ChenNo ratings yet

- Astm A 153M-05Document5 pagesAstm A 153M-05MritunjayNo ratings yet

- Weapons Wall Thickness StandardsDocument21 pagesWeapons Wall Thickness Standardsangelines123100% (2)

- Guía 2 - Referencias y DiagramasDocument8 pagesGuía 2 - Referencias y DiagramasSantiago UrrutiaNo ratings yet

- Heat Treatment PDFDocument10 pagesHeat Treatment PDFSatwant SinghNo ratings yet

- IACS Wear of Chains - Guide For Anchoring Equipment in ServiceDocument10 pagesIACS Wear of Chains - Guide For Anchoring Equipment in ServicegabelendaNo ratings yet

- Zinc-Coated Steel Wire Rope and Fittings For Highway GuardrailDocument2 pagesZinc-Coated Steel Wire Rope and Fittings For Highway GuardrailmjgutierrezperaltaNo ratings yet

- Rec79-Guidelines For Securing by Welding of Chain Cable Studs in ServiceDocument2 pagesRec79-Guidelines For Securing by Welding of Chain Cable Studs in ServiceThe MatrixNo ratings yet

- Irsm 46 2012Document28 pagesIrsm 46 2012Rakesh Srivastava100% (3)

- Complete Guide to SKV WeldingDocument132 pagesComplete Guide to SKV WeldingradhakrishnangNo ratings yet

- Manual For Fusion Welding of Rails by The Alumino-Thermic ProcessDocument49 pagesManual For Fusion Welding of Rails by The Alumino-Thermic ProcesskrischaeverNo ratings yet

- Riopipeline2019 1237 1237 19 RPL Revisao Enviada 11Document9 pagesRiopipeline2019 1237 1237 19 RPL Revisao Enviada 11barraocos emailsNo ratings yet

- SAE J434 1986 Automotive Ductile Iron Castings Nodular Iron CastingsDocument10 pagesSAE J434 1986 Automotive Ductile Iron Castings Nodular Iron Castingsvinicius_bacellarNo ratings yet

- Is 1367 - 13 PDFDocument4 pagesIs 1367 - 13 PDFsat palNo ratings yet

- Low Temperature Large-Area Brazing of Damage Tolerant Titanium StructuresDocument9 pagesLow Temperature Large-Area Brazing of Damage Tolerant Titanium StructuresMan MNo ratings yet

- Nd-Yag Laser Beam and Gta Welding of Ti-6Al-4V Alloy: Abdel-Monem El-Batahgy, Tarasankar DebroyDocument8 pagesNd-Yag Laser Beam and Gta Welding of Ti-6Al-4V Alloy: Abdel-Monem El-Batahgy, Tarasankar DebroyerpublicationNo ratings yet

- MIL T 81955 Immersion TinDocument9 pagesMIL T 81955 Immersion TinGerardo RiveraNo ratings yet

- Abstract of ASTM F835M 1992Document7 pagesAbstract of ASTM F835M 1992Jesse ChenNo ratings yet

- Rulefinder Version 9.21 (January 2014) - Lloyd's Register Rules and Regulations - Section 2Document9 pagesRulefinder Version 9.21 (January 2014) - Lloyd's Register Rules and Regulations - Section 2Walter TrajadaNo ratings yet

- Nippon Steal Guidelines G2593R8Document20 pagesNippon Steal Guidelines G2593R8Grady HopkinsNo ratings yet

- Creep Behavior of 2.25Cr-1Mo Steel Shield Metal Arc WeldmentDocument10 pagesCreep Behavior of 2.25Cr-1Mo Steel Shield Metal Arc WeldmentTrushar ParmarNo ratings yet

- Technical Specification For PCC PolesDocument8 pagesTechnical Specification For PCC Polesexecutive engineer1No ratings yet

- AISE No. 7 Specifications For Ladle HooksDocument7 pagesAISE No. 7 Specifications For Ladle HookscadyfemNo ratings yet

- WELDING CONSUMABLES STORAGE AND CAREDocument1 pageWELDING CONSUMABLES STORAGE AND CAREanouar82No ratings yet

- MIL-S-38249 Superseded by AMS 3374Document13 pagesMIL-S-38249 Superseded by AMS 3374HenryNo ratings yet

- Abstract of ASTM F835 2000Document7 pagesAbstract of ASTM F835 2000Jesse ChenNo ratings yet

- Mil-S-10736H Stove, Gasoline Burner, M1950, and CaseDocument26 pagesMil-S-10736H Stove, Gasoline Burner, M1950, and Casecjnjr1No ratings yet

- Sae Ams 5796D 2000 (En) PDFDocument6 pagesSae Ams 5796D 2000 (En) PDFWilliam LooNo ratings yet

- TSCDocument17 pagesTSCmailbkraoNo ratings yet

- Reihani 2015Document12 pagesReihani 2015CHONKARN CHIABLAMNo ratings yet

- Standard Specification for Zinc (Hot-Dip Galvanized) CoatingsDocument4 pagesStandard Specification for Zinc (Hot-Dip Galvanized) CoatingsPisut LeelalumlertNo ratings yet

- 10 2118@178431-PaDocument6 pages10 2118@178431-Pathlim19078656No ratings yet

- 11CrMo9-10 Evolution of MicrostructureDocument15 pages11CrMo9-10 Evolution of MicrostructureDaniele CastellaniNo ratings yet

- The Foseco Foundryman's Handbook: Facts, Figures and FormulaeFrom EverandThe Foseco Foundryman's Handbook: Facts, Figures and FormulaeT.A. BurnsRating: 3 out of 5 stars3/5 (2)

- Composite MaterialsFrom EverandComposite MaterialsA.T. Di BenedettoRating: 1 out of 5 stars1/5 (1)

- 4Document1 page4TAHIR MAHMOODNo ratings yet

- 1 Scope: EN ISO 15611:2003 (E)Document1 page1 Scope: EN ISO 15611:2003 (E)TAHIR MAHMOODNo ratings yet

- En Iso 15611:2003 (E)Document1 pageEn Iso 15611:2003 (E)TAHIR MAHMOODNo ratings yet

- En Iso 15611:2003 (E)Document1 pageEn Iso 15611:2003 (E)TAHIR MAHMOODNo ratings yet

- Foreword: EN ISO 15611:2003 (E)Document1 pageForeword: EN ISO 15611:2003 (E)TAHIR MAHMOODNo ratings yet

- GPSA - Engineering Data Book, 12ed 1Document1 pageGPSA - Engineering Data Book, 12ed 1TAHIR MAHMOODNo ratings yet

- Hydrate Prediction Based On Composition For Sweet Gases: Fig. 20-19 Through 20-21Document1 pageHydrate Prediction Based On Composition For Sweet Gases: Fig. 20-19 Through 20-21TAHIR MAHMOODNo ratings yet

- ISO Welding Procedure StandardsDocument1 pageISO Welding Procedure StandardsTAHIR MAHMOODNo ratings yet

- 3Document1 page3TAHIR MAHMOODNo ratings yet

- Charge LimitsDocument1 pageCharge LimitsTAHIR MAHMOODNo ratings yet

- EN ISO 15611: European Standard Norme Européenne Europäische NormDocument1 pageEN ISO 15611: European Standard Norme Européenne Europäische NormTAHIR MAHMOODNo ratings yet

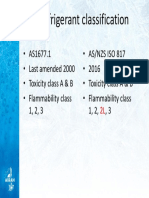

- Refrigerant ClassificationDocument1 pageRefrigerant ClassificationTAHIR MAHMOODNo ratings yet

- Charge LimitsDocument1 pageCharge LimitsTAHIR MAHMOODNo ratings yet

- Cap FactorsDocument1 pageCap FactorsTAHIR MAHMOODNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesTAHIR MAHMOODNo ratings yet

- Refrigerant Classification: 16 Pages 66 Refrigerants Classified 109 Refrigerants Classified 71 PagesDocument1 pageRefrigerant Classification: 16 Pages 66 Refrigerants Classified 109 Refrigerants Classified 71 PagesTAHIR MAHMOODNo ratings yet

- Technical and Dimensional Information: SRX ModelsDocument1 pageTechnical and Dimensional Information: SRX ModelsTAHIR MAHMOODNo ratings yet

- Electric Spring Return Actuators: SeriesDocument1 pageElectric Spring Return Actuators: SeriesTAHIR MAHMOODNo ratings yet

- Horizontal 2-Phase: Contents - Page 2Document1 pageHorizontal 2-Phase: Contents - Page 2TAHIR MAHMOODNo ratings yet

- AS/NZS/ISO 817 and AS/NZS5149.1-4 REFRIGERATION IMPACTSDocument1 pageAS/NZS/ISO 817 and AS/NZS5149.1-4 REFRIGERATION IMPACTSTAHIR MAHMOODNo ratings yet

- Refrigeration Standards Update: Safety and Environmental RequirementsDocument1 pageRefrigeration Standards Update: Safety and Environmental RequirementsTAHIR MAHMOODNo ratings yet

- Flammability Class 2LDocument1 pageFlammability Class 2LTAHIR MAHMOODNo ratings yet

- Dragon Standard Products Catalog by Size and Pressure 7 11 18Document28 pagesDragon Standard Products Catalog by Size and Pressure 7 11 18SSNo ratings yet

- Milw'-W 1A: DeaimDocument1 pageMilw'-W 1A: DeaimTAHIR MAHMOODNo ratings yet

- 6umdent: Insofsraa FMN Each WeldingDocument1 page6umdent: Insofsraa FMN Each WeldingTAHIR MAHMOODNo ratings yet

- Mibw'-$6Lla ?Fil-14Wi - : ND AakctedDocument1 pageMibw'-$6Lla ?Fil-14Wi - : ND AakctedTAHIR MAHMOODNo ratings yet

- Dragon Standard Production Equipment CatalogDocument1 pageDragon Standard Production Equipment CatalogTAHIR MAHMOODNo ratings yet

- About: Dragon Products Pes, IncDocument1 pageAbout: Dragon Products Pes, IncTAHIR MAHMOODNo ratings yet

- Mlw4611A : 4.4.1 %nplinfl Vepair Suaids. Aii Repairs IcDocument1 pageMlw4611A : 4.4.1 %nplinfl Vepair Suaids. Aii Repairs IcTAHIR MAHMOODNo ratings yet

- Sample - Solution Manual Diffusion, Mass Transfer in Fluid Systems 3rd Edition E. L. CusslerDocument10 pagesSample - Solution Manual Diffusion, Mass Transfer in Fluid Systems 3rd Edition E. L. CusslerGlasst Innovacion 2019No ratings yet

- E839 ThermocoupleDocument17 pagesE839 ThermocouplefarhanNo ratings yet

- Combined Stresses and Mohr'S Circle: James Doane, PHD, PeDocument41 pagesCombined Stresses and Mohr'S Circle: James Doane, PHD, Pesalem gergiNo ratings yet

- Ultracool Flow Diagram and Component IdentificationDocument1 pageUltracool Flow Diagram and Component IdentificationAjayNo ratings yet

- Thermal Design of Shell & Tube Type Heat Exchangers (HTFS)Document57 pagesThermal Design of Shell & Tube Type Heat Exchangers (HTFS)Muhammad NaeemNo ratings yet

- Phys Sciences p1 QP Gr11 Nov2019 - EnglishDocument18 pagesPhys Sciences p1 QP Gr11 Nov2019 - EnglishLihle SetiNo ratings yet

- Engineering Structures: Trusses and Analysis MethodsDocument18 pagesEngineering Structures: Trusses and Analysis MethodsNishant mishraNo ratings yet

- F1249 - Transmisión de VaporDocument5 pagesF1249 - Transmisión de VaporNelson VivancoNo ratings yet

- Exam Style Answers 18 Asal Physics CBDocument2 pagesExam Style Answers 18 Asal Physics CBAnshul ShahNo ratings yet

- Flopam™ An 913 Sep: Technical Data SheetDocument1 pageFlopam™ An 913 Sep: Technical Data SheetMohsin ModiNo ratings yet

- Thermography Report 125Document3 pagesThermography Report 125madhavanNo ratings yet

- Part-C Defects - Nptel PDFDocument5 pagesPart-C Defects - Nptel PDFLakhwant Singh KhalsaNo ratings yet

- Mechanics of Materials Chap 05-04 PDFDocument12 pagesMechanics of Materials Chap 05-04 PDFFelipe PinzonNo ratings yet

- Test Plan Delphi TechnologiesDocument2 pagesTest Plan Delphi TechnologiesFRANCISCONo ratings yet

- Wind LoadDocument13 pagesWind LoadHimani NagarNo ratings yet

- Hvac R Service Tools 8 27Document28 pagesHvac R Service Tools 8 27Iskandar FirdausNo ratings yet

- Effective Viscosity Prediction of Crude Oil-Water Mixtures With High Water FractionDocument11 pagesEffective Viscosity Prediction of Crude Oil-Water Mixtures With High Water FractionVanessa RiosNo ratings yet

- Hydrostatic PressureDocument6 pagesHydrostatic Pressurebkewill6No ratings yet

- Acids and Bases: William L Masterton Cecile N. Hurley Edward J. NethDocument91 pagesAcids and Bases: William L Masterton Cecile N. Hurley Edward J. NethRezel C. PerezNo ratings yet

- Soil Mechanics LabDocument4 pagesSoil Mechanics LabMewnEProwtNo ratings yet

- Metallography Is Defined As The Study of Metal and Its AlloysDocument6 pagesMetallography Is Defined As The Study of Metal and Its AlloysbazilNo ratings yet

- EE 105: Microelectronic Devices and Circuits: University of California at BerkeleyDocument12 pagesEE 105: Microelectronic Devices and Circuits: University of California at BerkeleynandhakumarmeNo ratings yet

- INSTRUMENTAL METHODS OF ANALYSIS QUESTION BANK FOR B Tech BIOTECH PDFDocument3 pagesINSTRUMENTAL METHODS OF ANALYSIS QUESTION BANK FOR B Tech BIOTECH PDFFabian MataloNo ratings yet

- Motion in Two Dimensions: Constant Velocity Constant AccelerationDocument53 pagesMotion in Two Dimensions: Constant Velocity Constant Accelerationabdullah naseerNo ratings yet

- A Real-Time Mathematical Model For The Two-DimensionalDocument11 pagesA Real-Time Mathematical Model For The Two-DimensionalMatheus Brandão TheodoroNo ratings yet

- Ec6 Eurocode-6 - Lateral-Resistance - 19 - 01 - 091 PDFDocument8 pagesEc6 Eurocode-6 - Lateral-Resistance - 19 - 01 - 091 PDFHeris DoggaNo ratings yet

- Ground Improvementtechniquein HSRDocument15 pagesGround Improvementtechniquein HSRZanele MbathaNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- Enhance Mixing & Reduce Smoke from Flare StacksDocument20 pagesEnhance Mixing & Reduce Smoke from Flare Stacks12mchc07No ratings yet

- Shark Screw Air Compressor: Installation, Maintenance and User ManualDocument43 pagesShark Screw Air Compressor: Installation, Maintenance and User ManualSatria Baru Perkasa RetesterNo ratings yet