Professional Documents

Culture Documents

Mibw'-$6Lla ?Fil-14Wi - : ND Aakcted

Uploaded by

TAHIR MAHMOODOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mibw'-$6Lla ?Fil-14Wi - : ND Aakcted

Uploaded by

TAHIR MAHMOODCopyright:

Available Formats

●

MIbW’-$6llA

-

?fIL-14wi — inspection; Radio- welding machines, torches, regulators, and

graphic filler metal feed mechanisms shall be capable (

of making satisfactory welds, when operated

MIL14366 — Inspection; Penetrnnt,

by a certified @der or weiding operator

Method of

using satisfactory filler rod or electrode

MIL-I-6B& — lnapection Process, where applicable.

Magnetic Partick

3.21.1 If the Covemmeti representitivt

MIlzl-6%’tO —lnsptction Require-

has reason to doubt the capability of any

ments, Non-Jkstruc-

welding apparatus to function satisfactorily

tive; for Aircraft Ma-

he shalI require welder’s eertifkation tests as

terials and Parts

deacribsd in Specifiution MILT-5021 ap-

Ml Lt14?75 — H e a t Treatment of plicable to the type of work for which the

Steels (Aircraft) : quipment is intended. The tests are to be

Process for made by a welder certified for the materinl

and type of welding, ●nd aakcted by the au- .

M! I~k’-751(i - Flux, Welding, Corr&

thorised Government representative. Mttlti-

sion and Heat Resist-

ple operator sets shall tM tested while the

ing Alloys

maximum number of operators am welding.

M1LA?AY)7 -- Electrodes, W e 1d - If under these conditions the applicable re- 1

i n g, Ferrous, Cov- Quirementi cannot be met, the equipment

ered, Heat ‘IYeatable shall not be used until the necessary repairs,

adjustments, or replacements have been

STANDARDS

made.

FEOmAL

4

3Z2 Heating apptirmees. Furnaors used

Test Method Std. 151

for preheating parts prior to welding or for {

Metals: Test Method

postheathtg parb after welding shall have

suitable pyrometric controls such ‘fiatthe

PUBLICATIONS

temperature varies not more thnn = 25°F.

A?4G!5 Strength of Metal Aircraft Ek Torches or induction heating coils may be

ments used for preheating provided the specified

(Copies O! spteifkmtions, standsrds, snd drswin~ temperature range is maintained by usimc n

quid by contmctom in cenntction with specifl, suitable contact pyrometer. acceptable tem-

pracumunt functionr should be obtained from tlw peratum-indicating sticks, or mceptib}e twn-

procuring scttntv nr u dtwetxl by thr contrmtin~ ptrstu-indicating liquids.

Omcer).

3.3 Materiah

3. RWUIREMENTS

xl. 1 hre MetCd. stAs with a Cat+oll

3.1 Welder or Welding opemtor. We)ding equivalent greater than 0.44 % and harden-

shall be performed only by welder or welding ability gveater than that of MILS-501M

operators who have met the requirements of shall not be welded without approval of the

Specification MTLT-5021 for the particular procuring agency. For such approval the

noup of materials and types of welding in- proposed welding procedure details and test

volved . reaulta of repreaentativt specimens, exam-

ined in ●zordanee with methods specified in

X2 Equipment. =]on 4, shall be submitted. Carbon Equiv-

aknts may be determined by using the fol-

1~1 (%nrd. Welding equipment, such as lowing fonrmls:

You might also like

- MIl W 8611.PDF Rev ADocument10 pagesMIl W 8611.PDF Rev ABryan MartinezNo ratings yet

- Mlw4611A : 4.4.1 %nplinfl Vepair Suaids. Aii Repairs IcDocument1 pageMlw4611A : 4.4.1 %nplinfl Vepair Suaids. Aii Repairs IcTAHIR MAHMOODNo ratings yet

- TechnicalspecificationDocument15 pagesTechnicalspecificationorbits1s3No ratings yet

- Weld Quality and Inspection Requirbments For Ip Cylinder Fabrications For 236 MW TurbineDocument4 pagesWeld Quality and Inspection Requirbments For Ip Cylinder Fabrications For 236 MW TurbineveeramalaiNo ratings yet

- Commissioning High Voltage EquipmentDocument13 pagesCommissioning High Voltage EquipmentJesus RodriguezNo ratings yet

- TP-GT01 GeneratorDocument10 pagesTP-GT01 Generatorوليد موسىNo ratings yet

- SIRE 2.0 Technical Article - Highres FINALDocument4 pagesSIRE 2.0 Technical Article - Highres FINALChris Teoh100% (1)

- Electrical CommissioningDocument19 pagesElectrical CommissioningLuis EnriqueNo ratings yet

- Api 510 NotesDocument26 pagesApi 510 NotesAhmed ShakirNo ratings yet

- Steam Turbine RegulationsDocument41 pagesSteam Turbine RegulationsAlvin PanjaitanNo ratings yet

- Work Scope - Pelotn Runner Refurbishment !Document3 pagesWork Scope - Pelotn Runner Refurbishment !manikanthNo ratings yet

- STANDART PROCEDURE Welding Dan TestingDocument6 pagesSTANDART PROCEDURE Welding Dan TestingvayakunNo ratings yet

- Substation Pre Commissioning TestsDocument13 pagesSubstation Pre Commissioning Testsrasheed313100% (2)

- MIL-A-22771D - Aluminum Forgings, Heat TreatedDocument24 pagesMIL-A-22771D - Aluminum Forgings, Heat TreatedklinedavidklineNo ratings yet

- 1) Technical Specification - 63MVA, 132kVDocument98 pages1) Technical Specification - 63MVA, 132kVGuru Mishra100% (1)

- Equipment Wise Recommendation SummaryDocument4 pagesEquipment Wise Recommendation SummaryBasharat AliNo ratings yet

- Dilw-Sma: That Atmngth Ievel. (Document1 pageDilw-Sma: That Atmngth Ievel. (TAHIR MAHMOODNo ratings yet

- D-Approved Instaliiation ProcedureDocument8 pagesD-Approved Instaliiation Procedurevin ssNo ratings yet

- Commissioning: Commissioning High Voltage EquipmentDocument14 pagesCommissioning: Commissioning High Voltage Equipment2091979No ratings yet

- Specific Requirements Regarding Welding: CPTP-Volume I - Chapter VDocument10 pagesSpecific Requirements Regarding Welding: CPTP-Volume I - Chapter VHaythem Ben ZidNo ratings yet

- Saudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202Document7 pagesSaudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202nadeem shaikhNo ratings yet

- SOW For BF5 Annual Maintenace JobsDocument26 pagesSOW For BF5 Annual Maintenace JobsShafiulla BaigNo ratings yet

- tEsT Performance Boiler PDFDocument136 pagestEsT Performance Boiler PDFPower PlantNo ratings yet

- Saudi Aramco Test Report: External Tank Bottom Testing 3-Jul-18 CP-SATR-X-3204Document7 pagesSaudi Aramco Test Report: External Tank Bottom Testing 3-Jul-18 CP-SATR-X-3204karthi51289No ratings yet

- A. General 1. B. Documents For Approval 1Document11 pagesA. General 1. B. Documents For Approval 1yayanNo ratings yet

- MCC and Panels Maintenance ProcedureDocument15 pagesMCC and Panels Maintenance ProcedureÁlvaro Manterola Lazcano100% (19)

- Testing of Control PanelDocument7 pagesTesting of Control PanelsasikumarNo ratings yet

- Eep-Field Inspection and Testing of MediumVoltage Motor Control Centres MCCsDocument4 pagesEep-Field Inspection and Testing of MediumVoltage Motor Control Centres MCCsabdulyunus_amirNo ratings yet

- 6umdent: Insofsraa FMN Each WeldingDocument1 page6umdent: Insofsraa FMN Each WeldingTAHIR MAHMOODNo ratings yet

- Section - Iv: Erection, Testing and Commissioning 4.1Document14 pagesSection - Iv: Erection, Testing and Commissioning 4.1Vinod ViparNo ratings yet

- HooksDocument4 pagesHooksomar sadiqNo ratings yet

- MCC and Panels Maintenance ProcedureDocument15 pagesMCC and Panels Maintenance ProcedureEldhose PaulNo ratings yet

- Saudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Document7 pagesSaudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Sreni Excel MacrosNo ratings yet

- Saudi Aramco Test Report: Plant Potential Survey Testing 24-Jul-18 CP-SATR-X-3203Document10 pagesSaudi Aramco Test Report: Plant Potential Survey Testing 24-Jul-18 CP-SATR-X-3203nadeem shaikhNo ratings yet

- POWER TRANSFORMER - Rev 6Document44 pagesPOWER TRANSFORMER - Rev 6Samuel DelgadoNo ratings yet

- Voltage Transformer TestingDocument19 pagesVoltage Transformer TestingAfrin HossainNo ratings yet

- Specifications For MV Panels Upto 415VDocument8 pagesSpecifications For MV Panels Upto 415VNATHANNo ratings yet

- Saudi Aramco Test Report: External Tank Bottom Testing 24-Jul-18 CP-SATR-X-3204Document7 pagesSaudi Aramco Test Report: External Tank Bottom Testing 24-Jul-18 CP-SATR-X-3204nadeem shaikhNo ratings yet

- Technical Explanations 2Document16 pagesTechnical Explanations 2jordi galiNo ratings yet

- PSP1Document171 pagesPSP1Klich77No ratings yet

- 63MVA 220KV-66KV Power Transformer - Syd Specific 1 - TenderDocument103 pages63MVA 220KV-66KV Power Transformer - Syd Specific 1 - TendermidhunvarNo ratings yet

- Asme Sec Ix - Short NotesDocument29 pagesAsme Sec Ix - Short NotesRavindra S. Jivani100% (2)

- 2 Welding Procedure 2 PDFDocument6 pages2 Welding Procedure 2 PDFMustafa MubderNo ratings yet

- SWYD - Commissioning ProcedureDocument9 pagesSWYD - Commissioning Procedurekrishna100% (2)

- QYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementDocument6 pagesQYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementAbdul Khaleem KhanNo ratings yet

- Indian Standard 3637Document10 pagesIndian Standard 3637Aman DeepNo ratings yet

- Section: Data OoDocument46 pagesSection: Data OoScaricatore92No ratings yet

- Enbridge Pipeline Repair Workplan Welding PDFDocument23 pagesEnbridge Pipeline Repair Workplan Welding PDFquiron2014No ratings yet

- WI-NG-6460-002-103 Work Instruction For - Ammeter Rev00Document7 pagesWI-NG-6460-002-103 Work Instruction For - Ammeter Rev00Mohamed NasrNo ratings yet

- Power TransformerDocument19 pagesPower TransformerMakesh IndhuNo ratings yet

- 1851Document11 pages1851Md Tajijul IslamNo ratings yet

- Operation and Maintenance of 220KV Receiving SubstationDocument5 pagesOperation and Maintenance of 220KV Receiving SubstationPrakash Chavan100% (1)

- T. in The Case of Current-Limiting Fuses, The Maximum Arc Energy May Occur at Current LevelsDocument20 pagesT. in The Case of Current-Limiting Fuses, The Maximum Arc Energy May Occur at Current Levelsnandana_849065438No ratings yet

- Astm F2249 PDFDocument7 pagesAstm F2249 PDFAngel Navarro100% (1)

- Anybus Modbus To Bacnet Gateway DatasheetDocument5 pagesAnybus Modbus To Bacnet Gateway DatasheetmohannadNo ratings yet

- API 577 QuestionsDocument14 pagesAPI 577 QuestionsabdoNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- 4Document1 page4TAHIR MAHMOODNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesTAHIR MAHMOODNo ratings yet

- Foreword: EN ISO 15611:2003 (E)Document1 pageForeword: EN ISO 15611:2003 (E)TAHIR MAHMOODNo ratings yet

- 1 Scope: EN ISO 15611:2003 (E)Document1 page1 Scope: EN ISO 15611:2003 (E)TAHIR MAHMOODNo ratings yet

- GPSA - Engineering Data Book, 12ed 1Document1 pageGPSA - Engineering Data Book, 12ed 1TAHIR MAHMOODNo ratings yet

- Hydrate Prediction Based On Composition For Sweet Gases: Fig. 20-19 Through 20-21Document1 pageHydrate Prediction Based On Composition For Sweet Gases: Fig. 20-19 Through 20-21TAHIR MAHMOODNo ratings yet

- En Iso 15611:2003 (E)Document1 pageEn Iso 15611:2003 (E)TAHIR MAHMOODNo ratings yet

- En Iso 15611:2003 (E)Document1 pageEn Iso 15611:2003 (E)TAHIR MAHMOODNo ratings yet

- Charge LimitsDocument1 pageCharge LimitsTAHIR MAHMOODNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesTAHIR MAHMOODNo ratings yet

- EN ISO 15611: European Standard Norme Européenne Europäische NormDocument1 pageEN ISO 15611: European Standard Norme Européenne Europäische NormTAHIR MAHMOODNo ratings yet

- Charge LimitsDocument1 pageCharge LimitsTAHIR MAHMOODNo ratings yet

- 3Document1 page3TAHIR MAHMOODNo ratings yet

- Refrigerant Classification: 16 Pages 66 Refrigerants Classified 109 Refrigerants Classified 71 PagesDocument1 pageRefrigerant Classification: 16 Pages 66 Refrigerants Classified 109 Refrigerants Classified 71 PagesTAHIR MAHMOODNo ratings yet

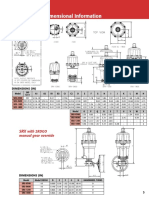

- Electric Spring Return Actuators: SeriesDocument1 pageElectric Spring Return Actuators: SeriesTAHIR MAHMOODNo ratings yet

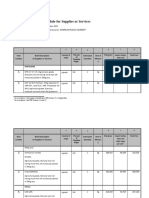

- Cap FactorsDocument1 pageCap FactorsTAHIR MAHMOODNo ratings yet

- Refrigerant ClassificationDocument1 pageRefrigerant ClassificationTAHIR MAHMOODNo ratings yet

- AS/NZS/ISO 817 and AS/NZS5149.1-4 Refrigeration ImpactsDocument1 pageAS/NZS/ISO 817 and AS/NZS5149.1-4 Refrigeration ImpactsTAHIR MAHMOODNo ratings yet

- Dragon Standard Production Equipment CatalogDocument1 pageDragon Standard Production Equipment CatalogTAHIR MAHMOODNo ratings yet

- Refrigeration Standards Update: Safety and Environmental RequirementsDocument1 pageRefrigeration Standards Update: Safety and Environmental RequirementsTAHIR MAHMOODNo ratings yet

- Flammability Class 2LDocument1 pageFlammability Class 2LTAHIR MAHMOODNo ratings yet

- Dragon Standard Products Catalog by Size and Pressure 7 11 18Document28 pagesDragon Standard Products Catalog by Size and Pressure 7 11 18SSNo ratings yet

- Technical and Dimensional Information: SRX ModelsDocument1 pageTechnical and Dimensional Information: SRX ModelsTAHIR MAHMOODNo ratings yet

- About: Dragon Products Pes, IncDocument1 pageAbout: Dragon Products Pes, IncTAHIR MAHMOODNo ratings yet

- MUPW+611.4: Material .4) 83 Itwh or Ksa Be The Flange, LapDocument1 pageMUPW+611.4: Material .4) 83 Itwh or Ksa Be The Flange, LapTAHIR MAHMOODNo ratings yet

- Milw'-W 1A: DeaimDocument1 pageMilw'-W 1A: DeaimTAHIR MAHMOODNo ratings yet

- Horizontal 2-Phase: Contents - Page 2Document1 pageHorizontal 2-Phase: Contents - Page 2TAHIR MAHMOODNo ratings yet

- 6umdent: Insofsraa FMN Each WeldingDocument1 page6umdent: Insofsraa FMN Each WeldingTAHIR MAHMOODNo ratings yet

- JOC PeptidesDocument14 pagesJOC PeptidesludoNo ratings yet

- Muhammad Athar Mahmood 2018 (S) - MS-AME-17 Research Supervisor: Dr. Ghulam Moeen Uddin 2022Document79 pagesMuhammad Athar Mahmood 2018 (S) - MS-AME-17 Research Supervisor: Dr. Ghulam Moeen Uddin 2022Ghanva KhanNo ratings yet

- Application of Ftir For The Characterisation of Sustainable Cosmetics and Ingredients With Antioxidant PotentialDocument9 pagesApplication of Ftir For The Characterisation of Sustainable Cosmetics and Ingredients With Antioxidant PotentialChiper Zaharia DanielaNo ratings yet

- PolymersDocument16 pagesPolymersantonija.trontel4152No ratings yet

- E-Catalog enDocument35 pagesE-Catalog enrajesh kothariNo ratings yet

- Final Project Report On and EraDocument51 pagesFinal Project Report On and EraDera kharia100% (1)

- Characterization of Three Different Potato Starches and Kinetics of Their Enzymatic Hydrolysis by An A-AmylascDocument9 pagesCharacterization of Three Different Potato Starches and Kinetics of Their Enzymatic Hydrolysis by An A-Amylascgerpo123No ratings yet

- Bismuth Crackle W-Notes by Ned G - 2 PDFDocument6 pagesBismuth Crackle W-Notes by Ned G - 2 PDFPijush SarkarNo ratings yet

- JBL Brochure Biotope Aquarium Water en PDFDocument21 pagesJBL Brochure Biotope Aquarium Water en PDFGeorge PotoleaNo ratings yet

- Yeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Document8 pagesYeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Mohammed AsherNo ratings yet

- Effect of Trace Impurities On Hot Ductility of As-Cast Cupronickel AlloysDocument6 pagesEffect of Trace Impurities On Hot Ductility of As-Cast Cupronickel AlloysKay WhiteNo ratings yet

- 00 B 7 D 518 B 57865 e 961000000Document20 pages00 B 7 D 518 B 57865 e 961000000aminNo ratings yet

- Geo Material For Self Healing Agents of MortarsDocument12 pagesGeo Material For Self Healing Agents of MortarsWan T TriantoNo ratings yet

- 47 01 000 - CenDocument54 pages47 01 000 - CenRicardo Vitoriano100% (2)

- Minerals PPT 2023-2024Document46 pagesMinerals PPT 2023-2024nicoleclarostudentNo ratings yet

- Chapter 1 - Thermochemistry PDFDocument87 pagesChapter 1 - Thermochemistry PDFannaNo ratings yet

- The Gravimetric Determination of Sulfate in A Soluble SampleDocument6 pagesThe Gravimetric Determination of Sulfate in A Soluble SampleUgur ASİT87% (15)

- Table UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CDocument3 pagesTable UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CMechanicalNo ratings yet

- Stress Cracking Corrosion of Duplex Stainless SteelDocument288 pagesStress Cracking Corrosion of Duplex Stainless Steelboypai100% (1)

- Zinnabu TassewDocument105 pagesZinnabu TassewTeklit GebrerufaelNo ratings yet

- 620oswaal CBSE Class-10, Term-1 Science - Revision NotesDocument22 pages620oswaal CBSE Class-10, Term-1 Science - Revision NotesDivyam RohillaNo ratings yet

- Price Schedule Pest LantexDocument11 pagesPrice Schedule Pest LantexMwesigwa DaniNo ratings yet

- Flexi Band: Universal Single-Sided High-Adhesive TapeDocument2 pagesFlexi Band: Universal Single-Sided High-Adhesive TapeMarina MelentiNo ratings yet

- Desmodur N 75 BADocument4 pagesDesmodur N 75 BASergiu Tarala100% (1)

- Chevron Base Oils Feb 2013 General SlidesDocument28 pagesChevron Base Oils Feb 2013 General SlidesTudor Ratiu0% (1)

- Carriage of Fertilizers: February 2019Document4 pagesCarriage of Fertilizers: February 2019Олег Шашкин100% (1)

- Lesson Plan 1 Activty SeriesDocument7 pagesLesson Plan 1 Activty SeriesMarky CieloNo ratings yet

- Mix Design FormatDocument3 pagesMix Design FormatAkshay MitraNo ratings yet

- Herbal ShampooDocument8 pagesHerbal ShampooSatpal kumarNo ratings yet

- Composites IntroductionDocument112 pagesComposites Introductionsanthosh smartNo ratings yet