Professional Documents

Culture Documents

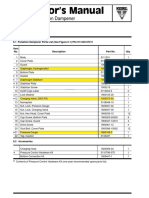

Product Dimensions - Ribt Series Material Specifications: Code D T Characteristic Value Test Method

Uploaded by

HKC EQUIPEMENTSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Dimensions - Ribt Series Material Specifications: Code D T Characteristic Value Test Method

Uploaded by

HKC EQUIPEMENTSCopyright:

Available Formats

Medium Wall Busbar Insulating

Tubes

RIBT

REPL Heat Shrinkable Busbar Medium Wall Insulating Tubes (RIBT)

are used to insulate copper and aluminium busbars, preventing

flashovers and accidentally induced discharge.

The tubes are made from thermally stabilized, cross linked, non-

tracking and weather resistant polymeric material and have a

nominal shrink ratio of 3:1 and an unlimited shelf life when stored

at normal warehouse temperatures.

T

- Halogen Free

- Tracking Resistant

- UV & Weather Resistant

E

- Shrink Ratio: 3:1

- Minimal Shrink Temperature: 1200c

E

Expanded As Supplied

Fully Recovered After

Heating

H

*Drawing depicts typical dimensions (Dimensions are all in mm)

S

MATERIAL SPECIFICATIONS PRODUCT DIMENSIONS – RIBT Series

CHARACTERISTIC VALUE TEST METHOD D (mm) T (mm)

Physical Properties CODE E S S

A

Specific Gravity 1.19 ± 0.2 ASTMD - 1505 Min Max ± 0.2

Water Absorption 1% (max) ASTM D – 570/ISO 62 RIBT 15/6 * 15 6 2.50

Tensile Strength ≥ 14 MPa ASTM D – 2671 RIBT 20/8 * 20 8 2.50

Ultimate Elongation ≥ 300% (min) ASTM D – 2671 RIBT 25/10 * 25 10 2.50

T

Hardness 45 ± 3 Shore D ASTM D - 2240 RIBT 30/12 * 30 12 2.50

Longitudinal Change ± 10 % ESI 09 - 13 RIBT 40/16 * 40 16 2.50

Shrink Temperature 120Oc (min) IEC - 216 RIBT 50/20 + 50 20 2.80

A

Thermal Ageing Tests (120Oc ± 3oc for 168 hours) RIBT 60/24 + 60 24 2.80

Ultimate Elongation ≥ 200% (min) ASTM D – 2671 RIBT 70/28 + 70 28 2.80

Tensile Strength >10 MPa ASTM D – 2671 RIBT 80/32 + 80 32 2.80

Thermal Tests RIBT 100/40 + 100 40 2.80

D

Heat Shock (30min, 200oc) No Cracking / No Flow ESI 09-13 RIBT 120/48 + 120 48 2.80

Low Temp. Flexibility (-40%) No Cracking ASTM D - 2671

Flammability Self-Extinguishing ASTM D – 2671 - B E – As Supplied | S – After Recovery

Electrical Properties * Available in 30 meter spools

Dielectric Strength ≥ 19 kV/mm (min) ASTM D – 149 /IEC 243

+ Available in 15 meter spools

Dielectric Constant ≤ 3.5 ASTM D – 150 / IEC 250

Volume Resistivity 1x1014 Ohm-cm (min) ASTM D – 257 / IEC 93 - Custom sizes are available on request with minimum volume

requirements

No Tracking, erosion or ASTM D - 2303

Resistant to Tracking & Erosion flame failure up to 3.25kV

for 20 mins

Chemical Properties

Fungus Resistance 1 (max) ASTM G - 21

Chemical resistance immersion See overleaf for recommendations on application range and

in following liquids NaOH (40%), Good clearance reduction …

ISO 175

H2So4 (3%), Toluene acetone for (no visual defects)

24 hrs at room temperature

RIBT 16/02

REPL International Ltd.

Email: info@repl.com

Web: www.repl.com

Medium Wall Busbar Insulating

Tubes

RIBT

APPLICATION RANGE

Rectangular Busbar

Section Round Busbar Section

CODE L+T d = Diameter

Min Max Min Max

RIBT 15/6 12 18 6.5 12

T

RIBT 20/8 15 24 9 16

RIBT 25/10 19 31 11 20

RIBT 30/12 22 38 13.5 25

RIBT 40/16 29 50 18 34

E

RIBT 50/20 36 63 22 42

RIBT 60/24 43 76 26 51

RIBT 70/28 50 89 31 60

E

RIBT 80/32 57 102 35 69

RIBT 100/40 70 130 44 86

RIBT 120/48 70 156 44 100

H

S

A

T

CLEARANCE REDUCTION GUIDANCE

A

Round Busbars Rectangular Busbars

With RIBT Without With RIBT Without

Voltage Level

D

(kV) Phase- Phase- IEC 71-2 Air Phase- Phase- IEC 71-2 Air

Phase Earth Clearance Phase Earth Clearance

mm mm mm mm mm mm

12kV 55 65 120 65 75 120

17.5kV 70 85 160 85 105 160

24kV 95 125 220 115 150 220

36kV 150 205 320 200 285 320

The table above is for guidance only on the potential clearances when using RIBT busbar tubing based on typical

applications. Any unusual geometries will affect dimensions possible.

The user should test on actual applications to ensure adequate performance level

RIBT 16/02

REPL International Ltd.

Email: info@repl.com

Web: www.repl.com

You might also like

- Creepage Extension Sheds: Product Dimensions - Ces SeriesDocument1 pageCreepage Extension Sheds: Product Dimensions - Ces SeriesHKC EQUIPEMENTSNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- Sabic Chile Ptfe Hoja TecnicaDocument1 pageSabic Chile Ptfe Hoja Tecnicae.vicente.caballeroNo ratings yet

- RHRB & RHSB: Material SpecificationsDocument1 pageRHRB & RHSB: Material SpecificationsHKC EQUIPEMENTSNo ratings yet

- Styrolux 684D SBC Ineos TDS enDocument3 pagesStyrolux 684D SBC Ineos TDS enfabianmendez2875No ratings yet

- Styroflex 2G66: Styrene Butadiene Copolymer (SBC)Document3 pagesStyroflex 2G66: Styrene Butadiene Copolymer (SBC)Ronaldo CamargoNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Heat Shrink Bus Bar Tube: GMB / GHB Series Tubes GSC Series TubesDocument2 pagesHeat Shrink Bus Bar Tube: GMB / GHB Series Tubes GSC Series TubesCarlos Berrospi ChacaNo ratings yet

- PC-ABS Cycoloy™ C6600Document2 pagesPC-ABS Cycoloy™ C6600countzeroaslNo ratings yet

- Aludecor Al 45 Firewall En13501-1 Class A2 Technical SpecificationDocument2 pagesAludecor Al 45 Firewall En13501-1 Class A2 Technical Specificationsoham senNo ratings yet

- 1 TDS - KIMMCO-ISOVER Glass Mineral Wool Batt-Blanket - KBR - 24kg - 25mm - FSK - Formal-1Document3 pages1 TDS - KIMMCO-ISOVER Glass Mineral Wool Batt-Blanket - KBR - 24kg - 25mm - FSK - Formal-1Kareem HelalNo ratings yet

- Technical Brief Galal Make SleevesDocument1 pageTechnical Brief Galal Make SleevesSELVAGANAPATHINo ratings yet

- Virgin Ptfe DatasheetDocument1 pageVirgin Ptfe DatasheetFelipe Zúñiga ParedesNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- ABS Cycolac X37Document3 pagesABS Cycolac X37countzeroaslNo ratings yet

- PK605DMDocument2 pagesPK605DMKan Sang MokNo ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- 3M Heavy Wall Heat Shrink Tubing ITCSNDocument4 pages3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- PA6EDocument1 pagePA6EDiego ReggianiniNo ratings yet

- ABS Cycolac MG47Document3 pagesABS Cycolac MG47countzeroaslNo ratings yet

- LEXAN™ Resin - 141R - Asia - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141R - Asia - Technical - Data - SheetTruc Thao NguyenNo ratings yet

- Electroarc Wraparound SleeveDocument1 pageElectroarc Wraparound SleeveVenkata Reddy100% (1)

- LNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetDocument2 pagesLNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetYJ WangNo ratings yet

- Scotch 130c TdsDocument3 pagesScotch 130c TdsKishan MohtaNo ratings yet

- T-Top800 T-Top800 Top81Document1 pageT-Top800 T-Top800 Top81CADTDDNo ratings yet

- PolycarbonateDocument1 pagePolycarbonatezainudinNo ratings yet

- Sabic 1004RDocument3 pagesSabic 1004Rlcesaksham23No ratings yet

- Able UCT S: Wiring ChannelsDocument8 pagesAble UCT S: Wiring ChannelsberdinsonNo ratings yet

- LEXAN™ Resin - 123R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 123R - Americas - Technical - Data - SheetRodrigoMachadoNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Document2 pagesMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealNo ratings yet

- Sika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - SgmyDocument3 pagesSika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - Sgmymultifocus sb100% (1)

- SABIC® PC Resin - PC1803R - Global - Technical - Data - SheetDocument3 pagesSABIC® PC Resin - PC1803R - Global - Technical - Data - SheetLeandro SalvadorNo ratings yet

- PC-ABS Cycoloy C2950HFDocument3 pagesPC-ABS Cycoloy C2950HFcountzeroaslNo ratings yet

- T Work9000Document2 pagesT Work9000Maike SongNo ratings yet

- General PropertiesDocument2 pagesGeneral PropertiesIsrael ExporterNo ratings yet

- Test Report FBE 2Document1 pageTest Report FBE 2Anderson VelandiaNo ratings yet

- Cycoloy®: C2950 Americas:COMMERCIAL ABS+PC Thermoplastic AlloyDocument3 pagesCycoloy®: C2950 Americas:COMMERCIAL ABS+PC Thermoplastic AlloymikeybhabaNo ratings yet

- Rain Sheds Rightangle Boots Straight BootsDocument2 pagesRain Sheds Rightangle Boots Straight BootsEhab Abd-allaNo ratings yet

- Ptfe - G400Document1 pagePtfe - G400Alessio Di BellaNo ratings yet

- Especificación Membrana GeotextilDocument1 pageEspecificación Membrana GeotextilMiguel RamírezNo ratings yet

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Document2 pagesScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaNo ratings yet

- TDS Pe 202 SP4808Document2 pagesTDS Pe 202 SP4808Desri AkbarNo ratings yet

- Proton PF-15Document1 pageProton PF-15HirenNo ratings yet

- PC Lexan 500 10%GLDocument3 pagesPC Lexan 500 10%GLcountzeroaslNo ratings yet

- Pa 6 GF 30 (En)Document1 pagePa 6 GF 30 (En)Alessandro WeissNo ratings yet

- LEXAN™ Resin - 241R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 241R - Americas - Technical - Data - Sheetr92g5478cxNo ratings yet

- JUNE2020 Transparent Noise Barrier Technical Datasheet Final ReducedDocument2 pagesJUNE2020 Transparent Noise Barrier Technical Datasheet Final Reducedionut cerneaNo ratings yet

- Spur Gear Spec Some Manufactures Dimension PDFDocument52 pagesSpur Gear Spec Some Manufactures Dimension PDFagus wahyudiNo ratings yet

- Rockinsul RB Slabs - 48 KG Per m3 75 MM - Technical Data SheetDocument1 pageRockinsul RB Slabs - 48 KG Per m3 75 MM - Technical Data SheetDushyant SharmaNo ratings yet

- Lumiplas Ld7890: Description ApplicationDocument2 pagesLumiplas Ld7890: Description ApplicationLong HomaNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- Datasheet LTM-2125 PDFDocument1 pageDatasheet LTM-2125 PDFjavadmohammadiNo ratings yet

- KXNEDocument2 pagesKXNEJan GawełNo ratings yet

- PBT Valox 420SEO 30%GLDocument3 pagesPBT Valox 420SEO 30%GLcountzeroaslNo ratings yet

- Microstructure Evolution in Metal Forming Processes (2012)Document2 pagesMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNo ratings yet

- GP100ORXP enUS ASTMDocument1 pageGP100ORXP enUS ASTMRaul ArmendarizNo ratings yet

- 1.8 Thong So Ky Thuat Bao On AeroflexDocument1 page1.8 Thong So Ky Thuat Bao On AeroflexDatNo ratings yet

- Pe1000 PDFDocument2 pagesPe1000 PDFrohitdakngNo ratings yet

- Hydril K20 SPDocument2 pagesHydril K20 SPHKC EQUIPEMENTSNo ratings yet

- Oil&Gas Drilling Hose Catalog 2011Document24 pagesOil&Gas Drilling Hose Catalog 2011HKC EQUIPEMENTS100% (1)

- MWH Full Product CatalogDocument100 pagesMWH Full Product CatalogHKC EQUIPEMENTSNo ratings yet

- Bop Control Unit SpecificationsDocument5 pagesBop Control Unit SpecificationsHKC EQUIPEMENTSNo ratings yet

- LEADER BOP Stack InformationDocument1 pageLEADER BOP Stack InformationHKC EQUIPEMENTSNo ratings yet

- PONS EN - Catalogue 2013 - Page 179Document1 pagePONS EN - Catalogue 2013 - Page 179HKC EQUIPEMENTSNo ratings yet

- RICPI21ATP550-Atlas Fire Hydrant Non Traffic Symetric OutletsDocument7 pagesRICPI21ATP550-Atlas Fire Hydrant Non Traffic Symetric OutletsHKC EQUIPEMENTSNo ratings yet

- Brochure IRwin Methane Leak Detector ENG 202003Document6 pagesBrochure IRwin Methane Leak Detector ENG 202003Sheikh Umer AftabNo ratings yet

- Hidrantes-Ficha IngDocument1 pageHidrantes-Ficha IngHKC EQUIPEMENTSNo ratings yet

- Marland ClutchDocument2 pagesMarland ClutchHKC EQUIPEMENTSNo ratings yet

- Pro hs680 enDocument4 pagesPro hs680 enHKC EQUIPEMENTSNo ratings yet

- GD 5000 Technical Data Sheet Rev2 (Jan 22)Document1 pageGD 5000 Technical Data Sheet Rev2 (Jan 22)HKC EQUIPEMENTSNo ratings yet

- P 7426 SC A4 - CeusDocument2 pagesP 7426 SC A4 - CeusHKC EQUIPEMENTSNo ratings yet

- Manuli Hydraulics Uk Ltd. Unit 8 Block 5, Shenstone Trading Estate Bromsgrove Road Halesowen, ENG United KingdomDocument1 pageManuli Hydraulics Uk Ltd. Unit 8 Block 5, Shenstone Trading Estate Bromsgrove Road Halesowen, ENG United KingdomHKC EQUIPEMENTSNo ratings yet

- Manuli Hydraulics Uk Ltd. Unit 8 Block 5, Shenstone Trading Estate Bromsgrove Road Halesowen, ENG United KingdomDocument1 pageManuli Hydraulics Uk Ltd. Unit 8 Block 5, Shenstone Trading Estate Bromsgrove Road Halesowen, ENG United KingdomHKC EQUIPEMENTSNo ratings yet

- Plastic Two Bolt Cleat: 374 SeriesDocument2 pagesPlastic Two Bolt Cleat: 374 SeriesHKC EQUIPEMENTSNo ratings yet

- Certificate of Distributorship: Emdad LLCDocument1 pageCertificate of Distributorship: Emdad LLCHKC EQUIPEMENTSNo ratings yet

- Liftstar & Pullstar Air Series: World's 1st "Lube Free" Air Winch RangeDocument8 pagesLiftstar & Pullstar Air Series: World's 1st "Lube Free" Air Winch RangeHKC EQUIPEMENTSNo ratings yet

- Manuli Hydraulics Uk Ltd. Unit 8 Block 5, Shenstone Trading Estate Bromsgrove Road Halesowen, ENG United KingdomDocument1 pageManuli Hydraulics Uk Ltd. Unit 8 Block 5, Shenstone Trading Estate Bromsgrove Road Halesowen, ENG United KingdomHKC EQUIPEMENTSNo ratings yet

- Liftstar® & Pullstar® Series Air Winches: 0.3 - 10 T Load CapacityDocument9 pagesLiftstar® & Pullstar® Series Air Winches: 0.3 - 10 T Load CapacityHKC EQUIPEMENTSNo ratings yet

- RAM R 2.5P Air Winch: 5,000 Lbs. Capacity On Top LayerDocument1 pageRAM R 2.5P Air Winch: 5,000 Lbs. Capacity On Top LayerHKC EQUIPEMENTSNo ratings yet

- Installation Documentation PE Typ 47 - enDocument3 pagesInstallation Documentation PE Typ 47 - enHKC EQUIPEMENTSNo ratings yet

- Product Dimensions - Rsek Series: Kit Number Cable Type Diameter Range MM Cable Size Range - MM 12kV 24kV 36kVDocument1 pageProduct Dimensions - Rsek Series: Kit Number Cable Type Diameter Range MM Cable Size Range - MM 12kV 24kV 36kVHKC EQUIPEMENTSNo ratings yet

- RBG Series: Bolted Cable Glands For MV CablesDocument1 pageRBG Series: Bolted Cable Glands For MV CablesHKC EQUIPEMENTSNo ratings yet

- RHT (X) - V - YY - NNN - NN N - N/C: - Cable Termination D Esigner For Cables 7kV - 42kVDocument6 pagesRHT (X) - V - YY - NNN - NN N - N/C: - Cable Termination D Esigner For Cables 7kV - 42kVHKC EQUIPEMENTSNo ratings yet

- Rins / Risb: MV Termination Accessories: Stand-Off Insulators & Support BracketsDocument1 pageRins / Risb: MV Termination Accessories: Stand-Off Insulators & Support BracketsHKC EQUIPEMENTSNo ratings yet

- Abb MCCDocument76 pagesAbb MCCfridjatNo ratings yet

- FS 4004-Lighting & Power Distribution PanelsDocument8 pagesFS 4004-Lighting & Power Distribution PanelsDinesh RajNo ratings yet

- Copper Busbar Jointing Methods - EEPDocument5 pagesCopper Busbar Jointing Methods - EEPMahmoud FawzyNo ratings yet

- PM FormatDocument51 pagesPM FormatKevin LexterNo ratings yet

- Summer Training at UpppclDocument35 pagesSummer Training at UpppclAayush guptaNo ratings yet

- Heater Calaculation For 33kV VCBDocument3 pagesHeater Calaculation For 33kV VCBMuthu Kumaran100% (1)

- P1300C Usen PDFDocument56 pagesP1300C Usen PDFJUANNo ratings yet

- Abstract of CPWD-Part 1 - Electrical Notes & ArticlesDocument18 pagesAbstract of CPWD-Part 1 - Electrical Notes & Articleshemant kumarNo ratings yet

- Commented - GS Control Offer of LT PANELSDocument16 pagesCommented - GS Control Offer of LT PANELSGautam MishraNo ratings yet

- Bus Bar Size CalculatorDocument6 pagesBus Bar Size CalculatorPrashanth RajuNo ratings yet

- Design Criteria ElectricalDocument38 pagesDesign Criteria ElectricalPramod B.Wankhade100% (4)

- Panel Design and Calculate Bus Bar SizeDocument14 pagesPanel Design and Calculate Bus Bar SizeThirumal100% (1)

- Busbar Sizing CalculationDocument4 pagesBusbar Sizing CalculationRahul Bhattacharyya100% (1)

- NEX17 Brochure PDFDocument26 pagesNEX17 Brochure PDFDaniela Jimenez VallejoNo ratings yet

- Catalogo RCP - Resin - Busbar - 2021Document24 pagesCatalogo RCP - Resin - Busbar - 2021carlos william zapata sernaNo ratings yet

- ABB UNISWITCH 36kV CA ENDocument20 pagesABB UNISWITCH 36kV CA ENVictor GuzmanNo ratings yet

- Cast Resin Betobar CSDocument20 pagesCast Resin Betobar CSWei Jiang NgNo ratings yet

- NEDALDocument1 pageNEDALkhan4luvNo ratings yet

- UniGear ZS1Document8 pagesUniGear ZS1SOUMENNo ratings yet

- ELinsMegaduct Brochure 2020Document36 pagesELinsMegaduct Brochure 2020surendar lakshmananNo ratings yet

- As 2067Document8 pagesAs 2067Muhammad MohsinNo ratings yet

- SwitchboardDocument6 pagesSwitchboardsopan sa100% (1)

- Q400 Technical Manual V8.4 Oct 14Document262 pagesQ400 Technical Manual V8.4 Oct 14Rufat Ilyasov100% (6)

- Low Voltage Distribution and Control Systems Eaton Cap 40Document20 pagesLow Voltage Distribution and Control Systems Eaton Cap 40Hugo Dennis Mattos EspinozaNo ratings yet

- Simoprime SwithgearDocument16 pagesSimoprime Swithgearmohamed IbrahNo ratings yet

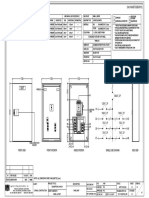

- 01 - Panel Mdp-Panel LayoutDocument1 page01 - Panel Mdp-Panel LayoutEdison EstrellaNo ratings yet

- Transmission Procedure TP109: The National Grid Company PLCDocument42 pagesTransmission Procedure TP109: The National Grid Company PLCPaul JonesNo ratings yet

- Solution 2000 MCC - E - 1904Document16 pagesSolution 2000 MCC - E - 1904anwar anwNo ratings yet

- ABB MNS System GuideDocument34 pagesABB MNS System GuideLeslie HallNo ratings yet

- List of Test Equipments: S.No. Equipment Name Quantity Make Model PurposeDocument3 pagesList of Test Equipments: S.No. Equipment Name Quantity Make Model PurposehaafilismailNo ratings yet