Professional Documents

Culture Documents

Sanayi Ve Ticaret Ltd. Şti.: Inspection Certificate

Sanayi Ve Ticaret Ltd. Şti.: Inspection Certificate

Uploaded by

Ali KayaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sanayi Ve Ticaret Ltd. Şti.: Inspection Certificate

Sanayi Ve Ticaret Ltd. Şti.: Inspection Certificate

Uploaded by

Ali KayaCopyright:

Available Formats

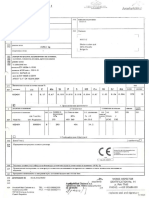

BOZTAŞ CİVATA INSPECTION CERTIFICATE EN 10204 - 3.

CUSTOMER

Cert. No

SANAYİ VE TİCARET LTD. ŞTİ.

K.SN.014

Page No 1/2

Kayabaşı Mah.Fabrikalar Mevkii 1729. Sk. No : 9/A 34494 Başakşehir / ISTANBUL / TURKEY Cert. Date 14.10.2021

Phone : +90 (212) 691 18 48 / 256 99 60 Obx Fax: +90 (0212) 691 18 49 Order No PR-1

Web : www.boztascivata.com.tr / E-mail : boztascivata@boztascivata.com.tr Purchase Order No : Rev. No -

DESCRIPTION

Heat No Notes

İtem No Quantity Size (mm) Standart Quality Coating Marking Heat Treatment Mill Cert. No

D2114790 1 796 M30X L=120 EN 14399-4 10.9 H.D.GLV.(TZn) BOZTAŞ HV 10.9 Quenched & Tempered 2110254 -

D2114790 2 260 M30X L=100 EN 14399-4 10.9 H.D.GLV.(TZn) BOZTAŞ HV 10.9 Quenched & Tempered 2110254 -

D2114790 3 256 M30X L=90 EN 14399-4 10.9 H.D.GLV.(TZn) BOZTAŞ HV 10.9 Quenched & Tempered 2110254 -

2104213006 4 896 M27X L=120 EN 14399-4 10.9 H.D.GLV.(TZn) BOZTAŞ HV 10.9 Quenched & Tempered 611 -

2104213006 5 64 M27X L=110 EN 14399-4 10.9 H.D.GLV.(TZn) BOZTAŞ HV 10.9 Quenched & Tempered 611 -

2104213006 6 1296 M27X L=100 EN 14399-4 10.9 H.D.GLV.(TZn) BOZTAŞ HV 10.9 Quenched & Tempered 611 -

2104213006 7 24 M27X L=90 EN 14399-4 10.9 H.D.GLV.(TZn) BOZTAŞ HV 10.9 Quenched & Tempered 611 -

2104213006 8 24 M27X L=85 EN 14399-4 10.9 H.D.GLV.(TZn) BOZTAŞ HV 10.9 Quenched & Tempered 611 -

2104213006 9 40 M27X L=80 EN 14399-4 10.9 H.D.GLV.(TZn) BOZTAŞ HV 10.9 Quenched & Tempered 611 -

91183 10 640 M24X L=90 EN 14399-4 10.9 H.D.GLV.(TZn) BOZTAŞ HV 10.9 Quenched & Tempered 730 -

CHEMICAL ANALYSIS ( % ) PHYSICAL PROPERTIES

Heat No C Si Mn P S Cr Mo Cu Sn V Al Ti Ni B CONTROLLED PROPERTIES Acc. Rj. Notes

D2114790 0,430 0,250 0,720 0,015 0,025 1,08 0,09 0,16 0,015 - - - 0,14 -

VISUAL CONTROL

2104213006 0,400 0,070 0,710 0,004 0,013 0,980 - 0,090 - - - - - -

91183 0,410 0,240 0,650 0,014 0,014 0,940 - 0,250 - - - - - -

DIMENSIONAL CONTROL

COATING CONTROL TZn

MARKING CONTROL

CHECKED BY HAKAN YÖRÜK

MECHANICAL PROPERTIES

Yield Strength Tensile Strength Proof Load Impact Test - Charpy HARDNESS

Elongation Red.Of Area

Heat No Rockwell Brinell Vickers Notes

( N/mm2 ) ( N/mm2 ) (%) (%) Test ( N ) KV (J) ( ….°C) HRC (Min.) HRC (Max.) HB (Min.) HB (Max.) HV (Min.) HV (Max.)

D2114790 1012 1165 11 56 - - - - 37 38 - - - - M30X120

D2114790 1001 1159 12 55 - - - - 37 38 - - - - M30X100

D2114790 1023 1174 11 56 - - - - 37 38 - - - - M30X90

2104213006 1009 1155 12 55 - - - - 36 38 - - - - M27X120

2104213006 999 1149 13 57 - - - - 36 38 - - - - M27X110

2104213006 1014 1163 11 56 - - - - 37 38 - - - - M27X100

2104213006 1008 1168 11 56 - - - - 37 38 - - - - M27X90

2104213006 1011 1158 12 55 - - - - 37 38 - - - - M27X85

2104213006 1003 1167 11 55 - - - - 37 38 - - - - M27X80

91183 998 1147 13 56 - - - - 36 38 - - - - M27X90

APPROVAL

2138

NOTES : " We certify that the materials were manufactured, sampled, tested and inspected in accordance with the above specification and other requirements designated in the purchase order and was found to meet those requiremets. © "

Documment No : FR.08.07 / Rev./Rev.Date : 04/04.01.2016

You might also like

- Concrete Method Statement PDF FreeDocument14 pagesConcrete Method Statement PDF FreeAli Kaya100% (2)

- Flexible Hose DatasheetDocument7 pagesFlexible Hose DatasheetchintanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- MTC Forged Fitting ElbowDocument1 pageMTC Forged Fitting Elbowfreeman11072000100% (1)

- Pttep Arthit Field Development Central Facilities: Piping Material Class Specification A-1-PP-PI-SP-0011Document45 pagesPttep Arthit Field Development Central Facilities: Piping Material Class Specification A-1-PP-PI-SP-0011api-19762124100% (1)

- Jolly Phonics Picture Flashcards in Print Letters by Sue Lloyd Sara WernhamDocument6 pagesJolly Phonics Picture Flashcards in Print Letters by Sue Lloyd Sara Wernhamalagshilpi17% (6)

- 740 Hydraulic PDFDocument2 pages740 Hydraulic PDFJacques Van Niekerk100% (1)

- BS-HWC4 - Butterfly ValveDocument10 pagesBS-HWC4 - Butterfly Valvesidparikh254No ratings yet

- Data Sheet 1.60 Issue C: OS&Y Flanged Gate Valve F4 Series Fig. 116FFDocument2 pagesData Sheet 1.60 Issue C: OS&Y Flanged Gate Valve F4 Series Fig. 116FFMohammed sabatinNo ratings yet

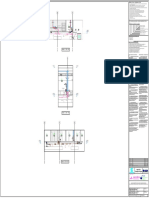

- MSCL-SEC-ME-ISO-002 Rev.BDocument2 pagesMSCL-SEC-ME-ISO-002 Rev.BMohd Sami UddinNo ratings yet

- Comment EHK-PRWG-IS-DTS-015 Datasheet For Pressure Safety Valve Rev 1 - CEK 2Document9 pagesComment EHK-PRWG-IS-DTS-015 Datasheet For Pressure Safety Valve Rev 1 - CEK 2nathaNo ratings yet

- 07.TRITURADORA CH550 - CM - Tank - 01 - SPC - R223.1438.en-01Document38 pages07.TRITURADORA CH550 - CM - Tank - 01 - SPC - R223.1438.en-01AndersonNo ratings yet

- A 2 FMDocument4 pagesA 2 FMMadhu RajagopalanNo ratings yet

- Fig 1432-1432L-1432C-1432LC Hatt DS 0922Document1 pageFig 1432-1432L-1432C-1432LC Hatt DS 0922Dan HawthorneNo ratings yet

- L100 X 100 X 6Document2 pagesL100 X 100 X 6eliaNo ratings yet

- Ins PT005Document1 pageIns PT005faisal hajjNo ratings yet

- Bill No-144Document1 pageBill No-144Mahmud AlamNo ratings yet

- Cooling Gas Compressor: Cable CalculationsDocument4 pagesCooling Gas Compressor: Cable CalculationsHaitham AbdEl-TawabNo ratings yet

- Scope of Supply - 2023 03 10 15 55 04Document31 pagesScope of Supply - 2023 03 10 15 55 04sachin pukaleNo ratings yet

- Material Test ReportDocument5 pagesMaterial Test ReportJuan Carlos Sua SuaNo ratings yet

- CRCI-M98-34-M204-DA: Dresser Al-Rushaid Valve & Instrument Co. LTDDocument6 pagesCRCI-M98-34-M204-DA: Dresser Al-Rushaid Valve & Instrument Co. LTDrajindo1No ratings yet

- MTC Elbow 6inDocument1 pageMTC Elbow 6inhenryNo ratings yet

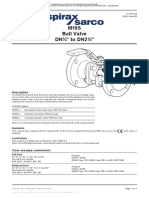

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- MR E4802 Stucture RepairDocument2 pagesMR E4802 Stucture RepairKaneashavarmah ThambirajaNo ratings yet

- MFF Spect. Blind 6 CL 150Document1 pageMFF Spect. Blind 6 CL 150Mohamed RaafatNo ratings yet

- 2012 Versys Parts Diagram: Air CleanerDocument2 pages2012 Versys Parts Diagram: Air CleanerMohamad Sapree SobangNo ratings yet

- FR21 083 2 1Document1 pageFR21 083 2 1Huber Pucuhuayla RojasNo ratings yet

- Mill Test Certificate-En10204/3.1-2004Document2 pagesMill Test Certificate-En10204/3.1-2004Rescos KasarachiNo ratings yet

- Certificati LSE03-61172 P. 10-11-17-18Document6 pagesCertificati LSE03-61172 P. 10-11-17-18pippoNo ratings yet

- 1995 KX™80 RadiatorDocument2 pages1995 KX™80 RadiatorkrzysiolejszynNo ratings yet

- Classe de Matériel Tuyauterie 100CP11: 6117-XH-SL-STC-2/3Document17 pagesClasse de Matériel Tuyauterie 100CP11: 6117-XH-SL-STC-2/3Guillaume de PluviéNo ratings yet

- Hav HKN 219001 Gas Me DS 0017Document5 pagesHav HKN 219001 Gas Me DS 0017bkm dizaynNo ratings yet

- KD6114 KD6114Z: Wuxi Kipor Power Co., LTDDocument2 pagesKD6114 KD6114Z: Wuxi Kipor Power Co., LTDConstantinBogdanNo ratings yet

- Fcaw Bohler Ti60k2 - Lot 613912Document1 pageFcaw Bohler Ti60k2 - Lot 613912Ahmad KamilNo ratings yet

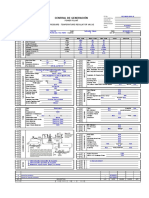

- Central de Generación: Power Plant Pressure - Temperature Regulator ValveDocument1 pageCentral de Generación: Power Plant Pressure - Temperature Regulator Valvejuan carlos suaNo ratings yet

- Karcher HD 923 DE Parts ListDocument2 pagesKarcher HD 923 DE Parts ListBharat SinghNo ratings yet

- 1 1 Name Plate Plate 1, 160 X 100 A240 TP316 (L) Qty Description Dimensions Material CommentsDocument1 page1 1 Name Plate Plate 1, 160 X 100 A240 TP316 (L) Qty Description Dimensions Material CommentsHiệp Phạm VănNo ratings yet

- BRD - klee-NSK Datasheet BQH72Document1 pageBRD - klee-NSK Datasheet BQH72Yayan RnsNo ratings yet

- Vessel Backup Condenser CDocument4 pagesVessel Backup Condenser CAzhar BudimanNo ratings yet

- A11627SE-04 - CVDS Rev C Technical Specification 840GDocument2 pagesA11627SE-04 - CVDS Rev C Technical Specification 840GMichael Adu-boahenNo ratings yet

- Main-BFP-10071-9-V9B-MPGB-00019-Instrument List & Excel Spreadsheet (Main BFP)Document4 pagesMain-BFP-10071-9-V9B-MPGB-00019-Instrument List & Excel Spreadsheet (Main BFP)mohamed abouraya100% (1)

- Mill Test Certificate: 唐山中厚板材有限公司 Tangshan Heavy Plate Co.,Document1 pageMill Test Certificate: 唐山中厚板材有限公司 Tangshan Heavy Plate Co.,engbilal.qaqc786No ratings yet

- PCV-2013 DatasheetDocument1 pagePCV-2013 DatasheetraufyNo ratings yet

- Part Karcher k2 Full AssymblyDocument2 pagesPart Karcher k2 Full AssymblyAlosh AlnaimiNo ratings yet

- Piese Motor KD2V86Document2 pagesPiese Motor KD2V86Popescu RoxanaNo ratings yet

- 2008 - 2 - Tube & PipeDocument7 pages2008 - 2 - Tube & PipecanettijNo ratings yet

- Crci-M98-34-M204-Da: R47-FV - 0282BDocument5 pagesCrci-M98-34-M204-Da: R47-FV - 0282Brajindo1No ratings yet

- 25 - 99405-01-012-19221 (Item25)Document6 pages25 - 99405-01-012-19221 (Item25)shahar swissaNo ratings yet

- Sample Test Cert. 07.09.2011 - 02Document1 pageSample Test Cert. 07.09.2011 - 02Vipul PanchalNo ratings yet

- Contractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)Document4 pagesContractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)BABILIN VNo ratings yet

- 025a1s10dxxd52rx (Sa Actuator)Document1 page025a1s10dxxd52rx (Sa Actuator)sathish1801No ratings yet

- Sizing PSV-100 R0Document5 pagesSizing PSV-100 R0XxavierNo ratings yet

- 4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Document11 pages4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- DataSheet 105723Document2 pagesDataSheet 105723ThirukkumaranBalasubramanianNo ratings yet

- 315020-DOC-7015 - (Instrument Datasheet - Pressure Regulator Valve) - RevADocument3 pages315020-DOC-7015 - (Instrument Datasheet - Pressure Regulator Valve) - RevAanwar sadatNo ratings yet

- 26 Portable Dry Powder Fire Extinguisher MS1539Document1 page26 Portable Dry Powder Fire Extinguisher MS1539eafarmihar2554No ratings yet

- WHCP - Instrument Data Sheet: Mellitah Oil & Gas B.V. Libyan BranchDocument18 pagesWHCP - Instrument Data Sheet: Mellitah Oil & Gas B.V. Libyan BranchYasin ElaswadNo ratings yet

- Vedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKDocument23 pagesVedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKPRAKASH PANDEYNo ratings yet

- 2006 Ninja® Zx™-6R Parts Diagram: Air CleanerDocument2 pages2006 Ninja® Zx™-6R Parts Diagram: Air CleanerFer TotoNo ratings yet

- 210 Short Spare Parts List (1.602-600.3)Document2 pages210 Short Spare Parts List (1.602-600.3)Nele von ŠabovićNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Hydrometer Calculations 2021-08-31Document3 pagesHydrometer Calculations 2021-08-31Ali KayaNo ratings yet

- Concrete Coarse Aggregate ChartDocument12 pagesConcrete Coarse Aggregate ChartAli KayaNo ratings yet

- First Folder: Last Folder:: Select by BATCHNODocument11 pagesFirst Folder: Last Folder:: Select by BATCHNOAli KayaNo ratings yet

- Schuco Window AWS 65Document2 pagesSchuco Window AWS 65Ali KayaNo ratings yet

- Blank 0.45 Power ChartDocument27 pagesBlank 0.45 Power ChartAli KayaNo ratings yet

- Hilti HIT-RE 500 V4 Injection Mortar: English 2-53 French 54-123 124-177 PolishDocument177 pagesHilti HIT-RE 500 V4 Injection Mortar: English 2-53 French 54-123 124-177 PolishAli KayaNo ratings yet

- ENEC Serie 221 RichtigDocument45 pagesENEC Serie 221 RichtigAli KayaNo ratings yet

- Merten Aquadesign - MTN400114Document2 pagesMerten Aquadesign - MTN400114Ali KayaNo ratings yet

- 'Hydrostatic ProcedureDocument7 pages'Hydrostatic ProcedureYuwantoniAlNo ratings yet

- Sikafiber Ppm-12: Polypropylene Fibers For Mortar and ConcreteDocument3 pagesSikafiber Ppm-12: Polypropylene Fibers For Mortar and ConcreteAli KayaNo ratings yet

- Orion: New Pta Complex ProjectDocument1 pageOrion: New Pta Complex ProjectAli KayaNo ratings yet

- Hydrostatic Test Procedure PDF FreeDocument9 pagesHydrostatic Test Procedure PDF FreeAli KayaNo ratings yet

- 00 090 PD 0020Document112 pages00 090 PD 0020Ali KayaNo ratings yet

- Chemical Composition of Welding Wire % (Typical) StandardsDocument1 pageChemical Composition of Welding Wire % (Typical) StandardsAli KayaNo ratings yet

- Material Approval Request: See Attached ListDocument19 pagesMaterial Approval Request: See Attached ListAli KayaNo ratings yet

- Geka sg2 Tig 2021 BV - 61f8f1d9e8c83Document1 pageGeka sg2 Tig 2021 BV - 61f8f1d9e8c83Ali KayaNo ratings yet

- Type Approval Certificate: Kaynak Teknigi Sanayi Ve Ticaret A.SDocument1 pageType Approval Certificate: Kaynak Teknigi Sanayi Ve Ticaret A.SAli KayaNo ratings yet

- Masterseal P 770Document3 pagesMasterseal P 770Ali KayaNo ratings yet

- Material Handling Control Procedure PDF FreeDocument9 pagesMaterial Handling Control Procedure PDF FreeAli KayaNo ratings yet

- Thermo-Lag 3000-SP PDSDocument4 pagesThermo-Lag 3000-SP PDSAli KayaNo ratings yet

- Concrete Method Statement PDF FreeDocument14 pagesConcrete Method Statement PDF FreeAli KayaNo ratings yet

- Ceramic Submittal Opt.1 Vitra by AkDocument33 pagesCeramic Submittal Opt.1 Vitra by AkAli KayaNo ratings yet

- We Fight For The Hope of A Better Tomorrow: and A Social Activist From Gaya (Bihar)Document4 pagesWe Fight For The Hope of A Better Tomorrow: and A Social Activist From Gaya (Bihar)Saurabh SinhaNo ratings yet

- Brief History of The Relational ModelDocument5 pagesBrief History of The Relational ModelSaleem KhanNo ratings yet

- 207 Money Saving FixesDocument149 pages207 Money Saving FixesCarmen Elena Nastasă100% (3)

- NCAHFSDocument6 pagesNCAHFSJay Mark Marcial JosolNo ratings yet

- Gigabit Ethernet Micro Switch Twisted Pair Uplink PoEDocument7 pagesGigabit Ethernet Micro Switch Twisted Pair Uplink PoEFredNo ratings yet

- U.S. Vs Ruiz, GR L-35645Document2 pagesU.S. Vs Ruiz, GR L-35645Luke VerdaderoNo ratings yet

- Case 8 General Motors PDFDocument4 pagesCase 8 General Motors PDFDahniar AmalinaNo ratings yet

- TM-ZT1005H S G PDFDocument5 pagesTM-ZT1005H S G PDFEdwardhutaurukNo ratings yet

- Nokia N97 UG enDocument173 pagesNokia N97 UG enRubén MenaNo ratings yet

- Specifications: Cab and Controls Engine Travel SystemDocument2 pagesSpecifications: Cab and Controls Engine Travel SystemBart JohnNo ratings yet

- 1 IP AddressingDocument95 pages1 IP AddressingJeet KarmakarNo ratings yet

- Ansible Best Practices Roles & ModulesDocument36 pagesAnsible Best Practices Roles & ModulesINA INDNo ratings yet

- Lampiran Jurnal Process Simulation and Optimization of Crude Oil Stabilization Scheme Using Aspen Hysys SoftwareDocument11 pagesLampiran Jurnal Process Simulation and Optimization of Crude Oil Stabilization Scheme Using Aspen Hysys SoftwareKevinNo ratings yet

- Humanitarian Trip India 2016 Clarós FoundationDocument16 pagesHumanitarian Trip India 2016 Clarós FoundationclinicaclarosNo ratings yet

- Solution Manual For Paralegal Professional 5th Edition Goldman Cheeseman 0134130847 9780134130842Document36 pagesSolution Manual For Paralegal Professional 5th Edition Goldman Cheeseman 0134130847 9780134130842laurenburtonctnkbgqawx100% (29)

- The Role of Accreditation in Improving Education Quality: Arif Rahman Hakim, Nugraha SuhartoDocument4 pagesThe Role of Accreditation in Improving Education Quality: Arif Rahman Hakim, Nugraha SuhartoLmj75 ntNo ratings yet

- Product Recommendation New Holland TX TX 34 (1987-1994)Document3 pagesProduct Recommendation New Holland TX TX 34 (1987-1994)ANo ratings yet

- Back UpDocument9 pagesBack UpIssam SouissiNo ratings yet

- Connecticut Wing - Jul 2014Document26 pagesConnecticut Wing - Jul 2014CAP History LibraryNo ratings yet

- 4AA12 P4DatasheetsDocument47 pages4AA12 P4DatasheetsalejandroNo ratings yet

- Biometric AttendanceDocument1 pageBiometric AttendancePronoy SinhaNo ratings yet

- Payment Process Through Rocket For Jagannath UniversityDocument1 pagePayment Process Through Rocket For Jagannath UniversityMustafiz KhanNo ratings yet

- Template - List of Contextualized Learning Resource Per Learning AreaDocument4 pagesTemplate - List of Contextualized Learning Resource Per Learning AreaJase SunNo ratings yet

- Philacor Credit Corporation V. Commissioner of Internal RevenueDocument10 pagesPhilacor Credit Corporation V. Commissioner of Internal RevenueCharity Gene AbuganNo ratings yet

- b2 Teacher BookDocument1 pageb2 Teacher BookIgnasius ValenNo ratings yet

- MANISH SHAH - Downstream CatalogueDocument7 pagesMANISH SHAH - Downstream CatalogueMANISH SHAHNo ratings yet

- International TaxationDocument20 pagesInternational Taxationdhruvi.ksNo ratings yet