Professional Documents

Culture Documents

2017 - Formulation & Adjuvant Technology 25

Uploaded by

Catherine Tang0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

2017_formulation & adjuvant technology 25

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 page2017 - Formulation & Adjuvant Technology 25

Uploaded by

Catherine TangCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

VIEWPOINT

Thin-shell quick-release microcapsule Seed-coating technology

suspension technology

GoodAgro has a 15-year history of industrialized FS production,

GoodAgro is the world’s third ranking manufacturer, next to specializing in FS processing for export on an OEM basis,

BASF and Syngenta, and has successfully developed the second- having produced accumulated quantities of 5,000 tons. Since

generation microcapsule suspension (quick release), being China’s 2012, GoodAgro has become China’s pesticide formulation

sole company offering such technology. The 450g/l pendimethalin industry leader, having utilized its technical superiority to register

CS, developed by GoodAgro, has less than 1% capsule wall 7 FS products, which are of the same, or near, the FS quality

material, with a micro-capsule size being 5 - 8 μm in average, of multinationals. There is, indeed, a gap between Chinese FS

providing a low-melting point for technical material. No organic products and those of multinationals, in terms of quality and

solvent is used, and this kind of formulation is environment- varieties, particularly a large gap between Chinese enterprises and

friendly, and the suspension system can endure dozens of freeze Syngenta or Bayer CropScience. GoodAgro is determined to move

thawing tests (-18-20). The product is not only released quickly, into this sector, this being a strategic goal for the transformation of

its field efficacy is comparable to EC product but, with the slow the company.

release effect of a microcapsule, offers a long-lasting function for Over the last 3 years, GoodAgro has made efforts in quality

45-60 days. This feature enables capsule suspension to be widely improvement in 4 areas, according to international standards:

applied in crop fields. 1) Granule size is controlled to high standards. GoodAgro uses

In 2016, GoodAgro built two 2,000-ton microcapsule suspension imported advanced third-generation grinding and full cold chain

production lines, while meeting internationally advanced levels. processing techniques, which could control FS size at D90

Following its 450g/l pendimethalin CS, GoodAgro targeted the < 2μm, D50 < 1μm, having reached the quality standards of

more difficult 480g/l trifluralin CS. multinationals; 2) Imported high molecular auxiliary agents and

Trifluralin is a broadly applied soil surface sealing herbicide film-forming agents are used to enhance the rheological property

used across the world. Due to the restraint of its physical property of FS grinding, storage and coating. Good rheological property

of high vapor pressure and ultra-low melting point, there has been facilitates lower viscosity, even if for high demand products,

so far not a single commercialized product in the world. such as imidacloprid 600g/LFS and thiamethoxam 48% FS. The

Trifluralin technical has a melting point of 43℃ to 47.5℃ and appearance looks thin, with easy dumping, better levelling and

high vapor pressure of 6.1mPa (25℃ ), which is presently the lower film fall off; 3) Color paste of international standard is used to

case for all emulsifiable concentrates, being prone to volatility and achieve a finished look of a seed coating agent; 4 ) Biostimulants

photolysis. Therefore, it is required to be covered with soil timely are selected worldwide, which not only enhances the rooting and

and its lasting effect is not long enough, which causes restrictions growth of coating agents, but also helps to resist damage from the

in applications. Goodagro has managed to make a high-content cold.

microcapsule without an organic solvent, where proportion of

the capsule wall material is ≤0.8%, which achieves both the slow Future: entry to international markets

release of microcapsules and the quick efficacy of emulsifiable with innovative formulations and high-

concentrates. The product has undergone -18℃ to 20℃ freeze- end products

thaw test 30 times, where the microcapsule remained intact. This

solves the crystal separation problem of trifluralin EC under low- Based on successful practices in the Chinese paddy rice

temperature condition. market, GoodAgro is planning a promotion of its Gengshangpao

The innovative achievement indicates that GoodAgro’s macrogranule and the 450g/l pendimethalin CS to rice growing

environment-friendly, thin-shell + quick release microcapsule countries in Southeast Asia.

EC has reached an internationally advanced level. The 480g/L Furthermore, GoodAgro is currently locating excellent

microcapsule EC will no doubt become a shining pearl standing biostimulants from throughout the world to expand the product mix

on the top of microcapsule EC, which fills up the gap of the global of GoodAgro. Based on the biostimulant, GoodAgro is prepared to

pesticide formulation. develop seed coasting agents using biostimulants as additives to

The product has been so far put under field trial for application facilitate the growth and development of crops, including heading

to soy and wheat in Australia, with an outstanding field effect and fruit bearing.

having been achieved. The product is expected to become a GoodAgro is looking forward to exchanges and cooperation

unique product of GoodAgro, with which GoodAgro will step into with global stimulant manufacturers to jointly create superior

the global market. product to benefit growers throughout the world.

www.agropages.com 2017 Formulation & Adjuvant Technology 23

You might also like

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlFrom EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNo ratings yet

- 2017 - Formulation & Adjuvant Technology 24Document1 page2017 - Formulation & Adjuvant Technology 24Catherine TangNo ratings yet

- Roquette Industry Paper Board Brochure CorrugatingDocument36 pagesRoquette Industry Paper Board Brochure Corrugatingzaryab khanNo ratings yet

- Roquette Industry Paper Board Brochure Corrugating PDFDocument36 pagesRoquette Industry Paper Board Brochure Corrugating PDFsyifa latifa zahidaNo ratings yet

- Fluid Bed Systems: P Ro / P Lu SDocument20 pagesFluid Bed Systems: P Ro / P Lu SmarciojunkNo ratings yet

- Presented By: M. Pharm Dr. B.C.Roy College of Pharmacy & AhsDocument49 pagesPresented By: M. Pharm Dr. B.C.Roy College of Pharmacy & AhsHafizur RahmanNo ratings yet

- COCO PEAT MARKETING ReferenceDocument41 pagesCOCO PEAT MARKETING ReferenceSanskruti lifespaces100% (1)

- Pseudomona PHADocument1 pagePseudomona PHACtme PolimerosNo ratings yet

- Industrial Training ReportDocument43 pagesIndustrial Training ReportApurba Sarker Apu80% (10)

- GEA Technology: Sugar & Sweetener IndustryDocument26 pagesGEA Technology: Sugar & Sweetener IndustryNora Carcamo100% (2)

- Pharmaceutical Production Area & Production Processes by KhalidDocument59 pagesPharmaceutical Production Area & Production Processes by Khalidkhalidfaani100% (23)

- Mycoharvester For Imprving CFU - Home - Forestgrowers - Public - HTML - Wp-Content - Uploads - 2017 - 04 - BIO-T010Document9 pagesMycoharvester For Imprving CFU - Home - Forestgrowers - Public - HTML - Wp-Content - Uploads - 2017 - 04 - BIO-T010Reza RanjbarNo ratings yet

- A Review of The Innovative Drying Technologies For BiopharmaceuticalsDocument12 pagesA Review of The Innovative Drying Technologies For BiopharmaceuticalsIJAR JOURNALNo ratings yet

- Ingeo 2003DDocument3 pagesIngeo 2003Djsk789No ratings yet

- Letter of TransmittalDocument18 pagesLetter of TransmittalSifat KhondokerNo ratings yet

- Single Pot Processing-ColletteDocument16 pagesSingle Pot Processing-ColletterandatagNo ratings yet

- Company Profile UflexDocument14 pagesCompany Profile UflexsherrysherryNo ratings yet

- Uflex Investor Presentation FY17Document55 pagesUflex Investor Presentation FY17Chirag GothiNo ratings yet

- Berghof Filtration ConceptDocument3 pagesBerghof Filtration Conceptskthen72No ratings yet

- 2021 - Seedtreatment Agropages 11Document1 page2021 - Seedtreatment Agropages 11Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 11Document1 page2021 - Seedtreatment Agropages 11Catherine TangNo ratings yet

- Uratex FinalDocument7 pagesUratex FinalJoy MorilesNo ratings yet

- FBG Fluid Bed GranulatorDocument1 pageFBG Fluid Bed GranulatorJUANNo ratings yet

- FBG Fluid Bed GranulatorDocument1 pageFBG Fluid Bed GranulatorJUANNo ratings yet

- Troy Corp Polyphase 663-TDSDocument6 pagesTroy Corp Polyphase 663-TDSib22No ratings yet

- APOTEKDocument50 pagesAPOTEKDinie NoviantyNo ratings yet

- Grain INC: SolutionsDocument17 pagesGrain INC: SolutionsAvinash WaghNo ratings yet

- A Project Report On Labor Absenteeism at Riddhi Siddhi Gluco Biols LTDDocument75 pagesA Project Report On Labor Absenteeism at Riddhi Siddhi Gluco Biols LTDBabasab Patil (Karrisatte)No ratings yet

- What Is BioisopreneDocument3 pagesWhat Is BioisoprenemanojiocindiatimesNo ratings yet

- Biodegradble Plastic BagDocument29 pagesBiodegradble Plastic BagRajesh KumarNo ratings yet

- Vikas WSP Annual Report 2011 12Document43 pagesVikas WSP Annual Report 2011 12didwaniasNo ratings yet

- Ud He TechnologyDocument16 pagesUd He TechnologyBejavada Suresh100% (1)

- CBG Project - Goal Bio Oil - 6 TPD - 13 PagesDocument13 pagesCBG Project - Goal Bio Oil - 6 TPD - 13 PagesAWANEENDRA DUBEY100% (1)

- Makrolon 2458Document6 pagesMakrolon 2458markcoates100% (1)

- CAM - Project ReportDocument17 pagesCAM - Project ReportSHAHNAWAZ QAMARNo ratings yet

- Polymers Technical Booklet: MelamineDocument20 pagesPolymers Technical Booklet: MelaminelyesNo ratings yet

- C B HealthcareDocument18 pagesC B HealthcareBenika RajputNo ratings yet

- 6 Vol. 4, Issue 1, January 2013, IJPSR, RE 806, Paper 6Document13 pages6 Vol. 4, Issue 1, January 2013, IJPSR, RE 806, Paper 6Isma Yanti100% (1)

- Tapasya Product CatalogueDocument104 pagesTapasya Product Cataloguethaonguyendc100% (1)

- Uflex Limited: India's Largest Multinational Flexible Packaging Materials and Solution CompanyDocument53 pagesUflex Limited: India's Largest Multinational Flexible Packaging Materials and Solution CompanyAbha SinghNo ratings yet

- Hydrogarden Promotes Urban Growing System: 18 March 2016Document3 pagesHydrogarden Promotes Urban Growing System: 18 March 2016inter buddyNo ratings yet

- Ingeo Resin Grades Brochure - PDF PDFDocument2 pagesIngeo Resin Grades Brochure - PDF PDFPilar UscateguiNo ratings yet

- Tds DR Bio 7212 Pla FillerDocument3 pagesTds DR Bio 7212 Pla FillerMukul SareenNo ratings yet

- Profile of The Company: Coco Peat"Document23 pagesProfile of The Company: Coco Peat"nikithaNo ratings yet

- 20-140 - Nadhila S.tanjung - Tugas 3 Pemeriksaan Similarity Menggunakan SoftwareDocument7 pages20-140 - Nadhila S.tanjung - Tugas 3 Pemeriksaan Similarity Menggunakan SoftwareNadhila TanjungNo ratings yet

- In Plant Training Report at Rangs Pharmaceuticals LTDDocument29 pagesIn Plant Training Report at Rangs Pharmaceuticals LTDboornoNo ratings yet

- Bi 5 55 PDFDocument9 pagesBi 5 55 PDFKarine Jéssica SantanaNo ratings yet

- Draft 1Document47 pagesDraft 1Viral BhogaitaNo ratings yet

- Pharmaceutical Spray DryingDocument16 pagesPharmaceutical Spray DryingLBNo ratings yet

- Easychair Preprint: Kholoud Al-Ajlouni, Paul D. Fleming and Alexandra PekarovicovaDocument17 pagesEasychair Preprint: Kholoud Al-Ajlouni, Paul D. Fleming and Alexandra PekarovicovaKholoud Al-AjlouniNo ratings yet

- Jatropha Bio Fuel Investment ReportDocument44 pagesJatropha Bio Fuel Investment ReportphatrsamonNo ratings yet

- Itaconic Acid SimulationDocument8 pagesItaconic Acid SimulationMARIEN TERESA BLANCO DURANNo ratings yet

- TB and HeteroDocument20 pagesTB and Heterokatta venkata vynateyaNo ratings yet

- Ghani Glass Containers Catalog 2017Document44 pagesGhani Glass Containers Catalog 2017karachi85No ratings yet

- PLANT COMPILATION FINAL FROM CHAPTER 1 To REFERENCES C MARCH 7 2020Document111 pagesPLANT COMPILATION FINAL FROM CHAPTER 1 To REFERENCES C MARCH 7 2020Joshua ClimacoNo ratings yet

- Management Discussion and Analysis 1. Macroeconomic OverviewDocument4 pagesManagement Discussion and Analysis 1. Macroeconomic OverviewChandra SekaranNo ratings yet

- A Guide to Good Agricultural Practices for Commercial Production of Ginger under Field Conditions in JamaicaFrom EverandA Guide to Good Agricultural Practices for Commercial Production of Ginger under Field Conditions in JamaicaRating: 5 out of 5 stars5/5 (1)

- Bottles, Preforms and Closures: A Design Guide for PET PackagingFrom EverandBottles, Preforms and Closures: A Design Guide for PET PackagingRating: 4.5 out of 5 stars4.5/5 (3)

- Agropage - 2019 Review 75Document1 pageAgropage - 2019 Review 75Catherine TangNo ratings yet

- Agropage - 2019 Review 72Document1 pageAgropage - 2019 Review 72Catherine TangNo ratings yet

- Agropage - 2019 Review 69Document1 pageAgropage - 2019 Review 69Catherine TangNo ratings yet

- Agropage - 2019 Review 67Document1 pageAgropage - 2019 Review 67Catherine TangNo ratings yet

- Agropage - 2019 Review 68Document1 pageAgropage - 2019 Review 68Catherine TangNo ratings yet

- Agropage - 2019 Review 76Document1 pageAgropage - 2019 Review 76Catherine TangNo ratings yet

- Agropage - 2019 Review 73Document1 pageAgropage - 2019 Review 73Catherine TangNo ratings yet

- Agropage - 2019 Review 71Document1 pageAgropage - 2019 Review 71Catherine TangNo ratings yet

- Agropage - 2019 Review 70Document1 pageAgropage - 2019 Review 70Catherine TangNo ratings yet

- Agrochemical Industry in China: From Self-Reliance To Export To Discovery & DevelopmentDocument1 pageAgrochemical Industry in China: From Self-Reliance To Export To Discovery & DevelopmentCatherine TangNo ratings yet

- Agropage - 2019 Review 78Document1 pageAgropage - 2019 Review 78Catherine TangNo ratings yet

- Agropage - 2019 Review 1Document1 pageAgropage - 2019 Review 1Catherine TangNo ratings yet

- Agropage - 2019 Review 77Document1 pageAgropage - 2019 Review 77Catherine TangNo ratings yet

- Agropage - 2019 Review 83Document1 pageAgropage - 2019 Review 83Catherine TangNo ratings yet

- Agropage - 2019 Review 85Document1 pageAgropage - 2019 Review 85Catherine TangNo ratings yet

- Agropage - 2019 Review 79Document1 pageAgropage - 2019 Review 79Catherine TangNo ratings yet

- Agropage - 2019 Review 81Document1 pageAgropage - 2019 Review 81Catherine TangNo ratings yet

- Agropage - 2019 Review 86Document1 pageAgropage - 2019 Review 86Catherine TangNo ratings yet

- Agropage - 2019 Review 84Document1 pageAgropage - 2019 Review 84Catherine TangNo ratings yet

- Oils, Surfactants and Other Additives For Farm Chemicals: Revised 2014 EditionDocument1 pageOils, Surfactants and Other Additives For Farm Chemicals: Revised 2014 EditionCatherine TangNo ratings yet

- Chemicals - Revised 2014 Edition: (Photo: Bill Gordon, Bill Gordon Consulting)Document1 pageChemicals - Revised 2014 Edition: (Photo: Bill Gordon, Bill Gordon Consulting)Catherine TangNo ratings yet

- Agropage - 2019 Review 87Document1 pageAgropage - 2019 Review 87Catherine TangNo ratings yet

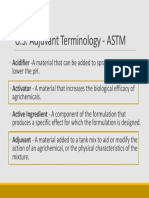

- U.S. Adjuvant Terminology - ASTMDocument1 pageU.S. Adjuvant Terminology - ASTMCatherine TangNo ratings yet

- Questions? Contact The NAPPC PesticideDocument1 pageQuestions? Contact The NAPPC PesticideCatherine TangNo ratings yet

- 2017 Crop Protection Adjuvants in The US and Canada 4Document1 page2017 Crop Protection Adjuvants in The US and Canada 4Catherine TangNo ratings yet

- 2017 Crop Protection Adjuvants in The US and Canada 5Document1 page2017 Crop Protection Adjuvants in The US and Canada 5Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 45Document1 page2021 - Seedtreatment Agropages 45Catherine TangNo ratings yet

- 2017 Crop Protection Adjuvants in The US and Canada 1Document1 page2017 Crop Protection Adjuvants in The US and Canada 1Catherine TangNo ratings yet

- A Full Palette of Vibrant, Customizable, 40 CFR Part 180 Compliant Color SolutionsDocument1 pageA Full Palette of Vibrant, Customizable, 40 CFR Part 180 Compliant Color SolutionsCatherine TangNo ratings yet

- 2017 Crop Protection Adjuvants in The US and Canada 3Document1 page2017 Crop Protection Adjuvants in The US and Canada 3Catherine TangNo ratings yet

- Food Processin UpscDocument208 pagesFood Processin Upscpradeep kumarNo ratings yet

- Title of Activity Date Venue Participants Proponents Persons Involved Prof. Carlo M. Cornejo Ma. Karen B. FajardoDocument4 pagesTitle of Activity Date Venue Participants Proponents Persons Involved Prof. Carlo M. Cornejo Ma. Karen B. FajardoAira Mae BotorNo ratings yet

- GOWE UgandaDocument137 pagesGOWE Ugandaybbvvprasada raoNo ratings yet

- Growing Catfish in The PhilippinesDocument5 pagesGrowing Catfish in The PhilippinesNorman Rodriguez LlorandoNo ratings yet

- Submitted Towards The Partial Fulfillment of Master of Business Administration Awarded by Rajasthan Technical University, KotaDocument61 pagesSubmitted Towards The Partial Fulfillment of Master of Business Administration Awarded by Rajasthan Technical University, KotaHarsh PahariyaNo ratings yet

- Cotton Varieties of PakistanDocument175 pagesCotton Varieties of PakistanMuhammad Boota Sarwar100% (6)

- Xpress Dditions: Able OF Ontents NtroductionDocument14 pagesXpress Dditions: Able OF Ontents NtroductionRevista Devir FilosofiaNo ratings yet

- LO1. Harvest Horticultural/ Crop Produce: The Learner Independently Harvest Matured Crops and Markets Them ProperlyDocument6 pagesLO1. Harvest Horticultural/ Crop Produce: The Learner Independently Harvest Matured Crops and Markets Them ProperlyJaideHizoleSapul100% (1)

- Biology ProjectDocument15 pagesBiology ProjectPriyabrata PattanaikNo ratings yet

- Resistance and Revolt NotesDocument8 pagesResistance and Revolt NotesKNo ratings yet

- Glosario JardineríaDocument0 pagesGlosario JardineríaOlympia GarcíaNo ratings yet

- Land Tenure Systems and Agricultural Development in Sub Saharan AfricaDocument23 pagesLand Tenure Systems and Agricultural Development in Sub Saharan AfricaSandra DziwaniNo ratings yet

- ICAR Telephone Directory 2023Document196 pagesICAR Telephone Directory 2023Harshit AgarwalNo ratings yet

- Little MilletDocument2 pagesLittle MilletRandolf DaitNo ratings yet

- Feb 10th Pages - GowrieDocument12 pagesFeb 10th Pages - GowrieTonya HarrisonNo ratings yet

- Climate Change and Resilient Food Systems: Vinaya Kumar Hebsale Mallappa Mahantesh Shirur EditorsDocument423 pagesClimate Change and Resilient Food Systems: Vinaya Kumar Hebsale Mallappa Mahantesh Shirur EditorsDHANARAJA D FOOD TECH (RESEARCH SCHOLAR)No ratings yet

- Organic Food ChinaDocument36 pagesOrganic Food ChinaSoumyabuddha DebnathNo ratings yet

- Mango MoodsDocument5 pagesMango MoodsRia AthirahNo ratings yet

- Nebbia v. New York, 291 U.S. 502 (1934)Document36 pagesNebbia v. New York, 291 U.S. 502 (1934)Scribd Government DocsNo ratings yet

- Principles Practices BeeDocument2 pagesPrinciples Practices BeeMc 'RageNo ratings yet

- Nature Conservation ActDocument31 pagesNature Conservation ActDaphne AgosinNo ratings yet

- Social Impact of Green RevolutionDocument2 pagesSocial Impact of Green RevolutionRehaanBisht100% (1)

- Social Science IX Chapter Wise Question BankDocument34 pagesSocial Science IX Chapter Wise Question Bankhoney1002100% (4)

- Methods For The Assessment of Productivity of Small Hold FarmsDocument49 pagesMethods For The Assessment of Productivity of Small Hold FarmsMonaliz NagrampaNo ratings yet

- PDF Revised Agricultural CREDIT PDFDocument23 pagesPDF Revised Agricultural CREDIT PDFanand sahuNo ratings yet

- As 5013.15-2006 Food Microbiology Microbiology of Food and Animal Feeding Stuffs - Horizontal Method For TheDocument8 pagesAs 5013.15-2006 Food Microbiology Microbiology of Food and Animal Feeding Stuffs - Horizontal Method For TheSAI Global - APACNo ratings yet

- Compare and Contrast Animal Farm/Anthem EssayDocument7 pagesCompare and Contrast Animal Farm/Anthem EssayErika0% (1)

- Morkans Company ProfileDocument20 pagesMorkans Company ProfileFxgNo ratings yet

- Amul InformationDocument20 pagesAmul Informationprernasoni_791571517No ratings yet

- FruitsDocument11 pagesFruitsKanagavarshini NarayananNo ratings yet