Professional Documents

Culture Documents

Asnt Radiography Level I Amp II

Asnt Radiography Level I Amp II

Uploaded by

Mauricio ceballos0 ratings0% found this document useful (0 votes)

10 views138 pagesOriginal Title

Asnt Radiography Level i Amp II

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views138 pagesAsnt Radiography Level I Amp II

Asnt Radiography Level I Amp II

Uploaded by

Mauricio ceballosCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 138

The ASNT

PERSONNEL TRAINING|

RADIOGRAPHIC TESTING

STUDENT GUIDE

Compiled for ASNT by

Bahman Zoofan

The Ohio State University

‘The American Society for Nondestructive ‘Testing, Inc.

Published by The American Society for Nondestructive Testing, Inc.

1711 Arlingate Lane

Columbus, OH 43228-0518

Copyright © 2007 by The American Society for Nondestructive Testing, Inc: All rights

reserved. ASNT is not responsible for the authenticity or accuracy of information herein, and

published opinions or statements do not necessarily teflect the opinion of ASNT. Products or

services that are advertised or mentioned do not carry the endorsement or recommendation of

ASNT.

IRRSP, Materials Bvaluation®, NDT Handbook, Nondestructive Testing Handbook,

The NDT Technician and are trademarks of The American Society for

Nondestructive Testing, Inc. ACCP, ASNT, Level IIT Study Guide, Research in Nondestructive

Evaluation and RNDE ate registered trademarks of The American Society for Nondestructive

Testing, Inc.

ASNT oxists to create a safer world by promoting the profession and technologies of

nondestructive testing

Edited by Ann Spence

ISBN-13: 978-1-57117-160-3

Printed in the United States of America

Second printing with revisions 11/09

Third printing 5/11

Nondestructive Testing Training Program

Student Guide

L, Introduction to the Radiographic Testing Student Guide

‘The materials in this training package are designed to provide basic knowledge of the

fundamentals of radiographic testing. The taining program that you are participating in will

contain the following classroom hours of instruction to present the information suggested in

the ASNT publication Recommended Practice No. SNT:

A.

Level I training will include lectures on chapters 1 through 5, with an average of

approximately oie hour per lesson, Level Il training will include lectures on all eight

chapters with an average of approximately one hour per lesson, with emphasis on chapters 6

through 8.

‘The student shall assume the responsibility for reading all assignments, including the

Radiographic Testing Classroom Training Book, additional reference materials associated

with the Student Guide, attend all lectures, atid participate in classroom discussions. Short

exams will be adm

istered after cach lesson to provide the student with an indicator of their

progress and to stimulate study.

I. Contents of Training Package

Your training package contains the following materials, with specific instructions and

assignments to be given by the course instructor.

1. Student Guide

A. Student Guide Introduction that outlines the purpose, content, and use of

the training material

B. Radiographic Testing Classroom Training Book that serves as the major text

for the training course.

C. Printed copy of the electronic lecture Radiographic Testing consisting of eight

individual lessons on the fanéamentais of radiographic testing. The copy of

the electronic lecture is identical to the presentation used by the instructor

uring the lectures on each chapter. During the lecture the stuclent should use

the Student Guide to make additional notes, and it will also be valuable to

study at a later date,

D. Quizzes. The instructor may elect to remove the quizzes from your packet

prior to starting the course and administer them as cach lesson is completed. A

quiz, will be furnished for each of the lessons in the training course. ¢

2, Outline of Lessons and Related Reading Ass

‘ignments

‘The reading assignments will be made by the instructor and will correlate with the lectures

‘The Radiographic Testing Classroom Training Book published by ASNT follows the

lessons/lectures in the training course in the following order.

Lesson I ~ Introduction to Radiographic ‘Testing

‘Lesson 2 ~ Radiographic Testing Principles

Lesson 3 — Equipment.

Lesson 4~ Radiographic Film.

Lesson 5 ~ Safety.

Lesson 6 ~ Specialized Radiographic Applications

Lesson 7 — Digital Radiographic Imaging.

Lesson 8 ~ Special Radiographic Techniques. ~

Personnel Training Publications

IIL. Optional Reference Material

‘The followi

imaterials are available from ASNT and are suggested for students looking for

additional information on radiographic testing.

7,

Nondestructive Testing Handbook, third edition: Volume 4. Radiographic Testing.

ASNT Level I Study Guide: Radiographic Testing Method.

ASNT Level Ilf Study Guide: Radiographic Testing Method, second edition.

Supplement to Recommended Practice No. SNE-TC-1A (Q & A Book):

Radiographic Testing Method.

Supplement to Recommended Practice No. SNT-TC-1A (Q & A Book): Neutron

Radiographic Testing Method.

Radiographic Interpretation, Revised.

Gamma Radiation Safety Study Guide, second edition.

Working Safely in Radiography, second edition.

‘Siudlent Guide: Radiographic Testing

it

Table of Contents

Nondestructive Testing Training Program: Student Guide

Introduction to the Radiographic Testing Student Guide .

Contents of Training Package

Student Guide . i

Outline of Lessons and Related Reading. Assignment Ss

Optional Reference Material .

Table of Contents ....

Lesson 1 - Introduction to Radiographic Testing -

Radiography ......

‘Advantages of Radiograph :

Linatations of Radiographic Testing

‘Test Objective .

Safety Considerations .

Qualification

Certification.

Lesson 1 ~ Qui

Lesson 2 ~ Radiographic Testing Principles . .

Penetration and Differential Absorption .....

Geometric Exposure Principles .

Film/Detector Image Shar} Mess «

Image Distortion ..... mt

X-radiation and Gamma Radiation

X-rays... é

Electron Source |

Blectron Target :

Electron Acceleration .

Radiation Intensity .

Inverse Square Law ... .

X-ray Quality Characteristics .

Interaction With Matter -

Photoelectric Absorption...

Compton Bffect ...

Pair Production

Scatter Radiation .

Internal Scatter .

Sidescatter ....-

Backscatter .......45

Gamma Rays... 200s 0. e0 2

Natural Isotope Sources

Artificial Sources.

Gamma Ray Intensity .

Specific Activity

Half Life ....

Gamma Ray Quality Charactetistics “|

Lesson 2~ Quiz .... eee

Lesson 3 - Equipment

X-ray Equipment. .....

Portable X-ray Units -

Xaay Tube.......

Tube Envelope «

Cathode

Filament Heating :

Anode ;

Focal Spot’. .

near Accelerators

X-Ray Beam Configuration «

Accelerating Potential , :

Iron Core Transformers <.......

Heat Dissipation ..... :

Equipment Shielding :

Control Panel... eee sees

Gamma Ray Equipment

Gamma Ray Sources...

Rodham oc ueceecee aes iiet

Artificial Radioisotopes -

Isotope Cameras 0.2.5.

Lesson 3 ~ Quiz . :

Lesson 4 - Radiographic Film ............5 5

Introduction ... : fe

Usefulness of Radiographs |;

Radiographic Contrast .

Subject Contrast .

Film Contrast . :

Film Characteristic Curves ||:

Film Speed . :

Graininess ....

Film Selection Factors . . :

Bilm Processing ......2 20000022. ceceecec

Tank Processing ........

‘Tank Processing Procedures

Developing :

Stop Bath

Fixing.

Washing

Drying

Automatic Film Processing

Darkroom Facilities and Equipment

Lesson 4- QUIZ 2... eevee eee

Lesson 5 ~ Safety ........ceeseeeeeeeteees

Introduction... ci as

Units of Radiation Dose Measurement

Roentgen (R).....ceeeee scree

Radiation Absorbed Dose (rad)...

Quality Factor ...s...-e. ses

Roentgen Equivalent Mammal (rem) f

International System of Units (SI) Measurements... -

Becquerel Replaces Curie ....... A

Coulomb per Kilogram Replaces Roentgen

Gray (Gy) Replaces Rad... .....-

w Personnel Training Publications

aa

Sievert (Sv) Replaces Rem

Maximum Permissible Dose .

Protection Against Radiation

Allowable Working Time .

Working Distance

Shielding .......

Exposure Area

Radiation Protective Construction .

Gamma Ray Requirements .....

United States Nuclear Regulatory Commission «

Occupational Radiation Exposure Limits .

Levels of Radiation in Unrestricted Areas

Personnel Monitoring... cee

Cauition Signs, Labels and Signals

Exposure Devices and Storage Containers .

Radiation Survey Instrumentation Requirements

Radiation Surveys .......+ 4+ cae

Detection and Measurement Instruments -......0005

Pocket Dosimeters ... : petieseeed

Personal Electronic Dosimeters. .. oy

Film Badges and Thermoluminescent Dosimeters . .

Optically Stimulated Luminescence (OSL) Badges -

Ionization Chambers ......

Geiger-Mueller Counters.

Area Alarm Systems

Blectrical Safety... 2022220045

Lesson §~ Quit to. e eee ence tee

Lesson 6 - Specialized Radiographic Applications -

Introduction a

Selection of Equipment ....-

‘Accessory Equipment .

Diaphragms, Collimators and Cones

Filters...

Screens

Fluorescent Screens

Lead Screens . .

Masking Materials... . 0...

Image Quality Indicators (Ql) -

Shim Stock ...

Film Holders and Cassettes 0.1...

Identification and Location Markers

Area Shielding Equipment .

Densitometer.. .

X-Ray Exposure Charts 0...

Preparation of an Exposure Chart

Film Latitude . :

Gamma Ray Exposure Chart * |:

Dated Decay Curves... ....505

Film Characteristic Curves .

Radiographic Equivalent Factors’.

Exposure Variables

Movement .

Source Size...

Source-to-Film Distance (SFD) «

Radiographic Applications .

Radiography of Welds ........ Erie 90

Tube Angulation .... 90 (

Incident Beam Alignment 290

Discontinuity Location . ...- 291

Gritical and Noncritical Criteria 91

Improper Interpretation of Discontinuities a1

Elimination of Distortion ....... 92

Proper Identification and Image Quality Indicator Piacement | 11111! 92

Radiography of Welded Flat Plates . : pode

Radiography of Welded Comer Joints

Single-Wall Radiography of Tubing

Double-Wall Radiography of Tubing

Tubing up to 3.5 in. (9 cm) Outside Diameter # (OD)

Radiography of Closed Spheres

Radiography of Closed Tanks...

Radiographic Multiple Combination Application

Radiographic of Hemispherical Sections :

Panoramic Radiography . . :

Radiography of Large Pipe Welds

Radiographic Techniques of Discontinuity Location”

Alignment . :

Discontinuity Depth Location Techniques

Radiography of Brazed Honeycomb .

Radiography of Semiconductors...

Techniques of Semiconductor Radiography :

Alignment of Semiconductors

Lesson 6 Quiz . .

Lesson 7 — Digital Radiographic Imaging .......- euce 105

Introduction ...... 5

Development.

Detectors for Digital Imaging

Principles of Digital X-ray Detectors -

Charge Coupled Devices.

Thin Film Transistor ........

Light Collection Technology

Radiation Conversion Material <<...

Storage Phosphors .......-60.005

Linear Arrays . a

Scanning Beam, Reversed Geometry pete

Detection Efficiency . a 110

Spatial Resolution . . SeeeeaTAD

Modulation ‘Transfer Function (Mf Heat ate)

Gain and Offset Correction. . Lilo

Radiation Damage «2,-0.4. tees HD

Selection of Systems to Match, Application Seeing:

X-ray Detector Technology .. seed

Amorphous Silicon Detectors - aera ery

Amorphous Selenium Detectors . c12,

Chasge Coupled Device Radiographic Systems | fe eeuiaa|

Linear Detector Arrays ae be ee ee LD3

Lesson 7 ~ Quiz ....... ce LDS :

t

vii ‘Parsonnel Training Publications

Lesson 8 = Special Radiographic Techniques .

“ Introduction

( Fluoroscopy...

Image Amplifier...

Television Radiography

Xeroradiography......

Stereoradiography and Double Exposure

Steteoradiography

Double Exposure (Parallax Radiographic Teclnigue) «

Flash Radiography... . os...

In-M« mm Radiography . .

Conclusion . f

Lesson 8 ~ Quiz

Siudent Guide; Radiographic Testing

Chapter 1: Radiographic Testing Principles

In this lesson you will learn about:

* Concepts of radiography.

* Advantages and limitations of radiographic testing.

© Test objectives.

* Personnel qualifications and certifications.

Lesson 1

Introduction to Radiographic Testing

RADIOGRAPHY

1. In radiography, test objects are exposed to X-rays, gamma rays or neutrons, and an

image is produced.

2. — Radiography is used to test a variety of products, such as castings, forgings and

weldments, It is also used heavily in the aerospace industry for the detection of

cracks in airframe structures, detection of water in honeycomb structures and

detection of foreign objects.

~( Advantages of Radiographic Testing

1. Radiography can be used on most materials,

2. Radiography provides a permanent record of the test object.

3. Radiography reveals discontinuities within a material.

4, — Radiography discloses fabrication errors and often indicates the need for corrective

action.

Limitations of Radiographic Testing

yey

‘The radiographer must have access to both sides of the test object.

Planar discontinuities that are not parallel to the radiation beam ate difficult to defect.

Radiography is an expensive testing method.

Film radiography is time consuming.

Some surface discontinuities or shallow discontinuities may be difficult, if not

impossible, to detect.

‘The objective of radiographic testing is to ensure product reliability. Performing the actual

radiographic test is only part of the procedure. The test results must then be interpreted to

acceptance standards by qualified personnel, and an evaluation of the results must be made,

Safety Considerations

Radiation can cause damage to the cells of living tissue, so it is essential that personnel be

aware and protected. Compliance with state and federal safety regulations is mandatory.

QUALIFICATION

1. It is important that personnel responsible for radiographic testing have adequate

training, education and experience.

2. Guidelines are for the qualification and certification of nondestructive testing

personnel.

3. ASNT has published guidelines for training and qualifying nondestructive testing

(NDT) personnel since 1966. These are known as: Recommended Practice No.

SNT-TC-IA: Personnel Qualification and Certification in Nondestructive Testing.

4. Recommended Practice No. SNT-TC-1A describes the knowledge and capabilities

of nondestructive testing personnel in terms of certification levels,

5. Per SNF-TC-1A, there are three basic Jevels of qualification applied to NDT

personnel:

a. Lovel

b. Level Il

c. Level Ill.

Personnel Training Publications

C

CERTIFICATION

‘The formal certification of a person in NDT to a Level I, Level IT and Level ITT is a

‘written festimony that the individual has been properly qualified.

Certification is meant to document the actual qualification of the individual in a

specific NDT method.

Propet qualification and certification are extremely important in mod

n

manufacturing, fabrication and inservice inspection due to the impact on the health

and safety of the public,

“Snident Guide: Radiograph Testing

Notes

Lesson 1

Quiz

Please answer true or false to the following

statements,

1, Radiography can reveal all types of

discontinuities within a material,

2. Radiography cannot be used in

aerospace due to radiation safety

constraints.

3. In zadiography, access to both sides of

the test object is not necessary

Radiography provides a permanent

visual record of internal discontinuities.

5. Every radiographer can decide

acceptance or rejection of a test object.

Chapter 2: Radiographic Testing Principles

In this lesson you will learn about:

* Penetration and differential absorption.

* Geometric exposure principles,

+ Film/detector image sharpness.

+ Characteristics of X-radiation and gamma radiation.

a * X-ray tubes.

* Inverse square law.

* X-ray quality characteristics.

« Interaction of radiation with matter.

* Gamma rays (natural isotope sources, artificial sources

and gamma ray intensity).

Lesson 2

Radiographic Testing Principles

PENETRATION AND DIFFERENTIAL ABSORPTION

‘X-rays and gamma rays have the ability to penetrate materials, including materials

that do not transmit light.

Depending on the thickness and density of the material, and the intensity of the

source being used, the amount of radiation that is transmitted through the test

object will vary.

‘The rac

jon transmitted through the test object produces the radiographic image.

Figure 2.1 in the Radiographic Testing Classroom Training Book illustrates the partial

absorption characteristies of radiation. Thicker portions of the test object or dense inclusions

will appear lighter because of more absorption of the radiation.

2.

G

OMETRIC EXPOSURE PRINCIPLES

A radiograph is a shadow picture of a test object placed between the film/detector

and the X-ray or gamma radiation source.

If the film/detector is placed too far from the test object, the image will be

enlarged.

If the test object is too close to the source, the image will be greatly enlarged,

resulting in the loss of resolution.

‘The degree of enlargement will vary according to the relative distances of the test

object from the film/detector.

‘As shown in Figure 2.2 in the Radiographic Testing Classroom Training Book, the

: i Dees

image enlargement: 5" is equal to the ratio: 7

i D, sea ra

i

Film/Detector Image Sharpness

i

The sharpness of a radiographic image is determined by:

a, The size of the radiation source.

b, The ratio of the object-to-film/detector distance,

c. The source-to-object distance.

The unsharpness or fuzziness around an image is called geometric unsharpnes

(penumbra), as shown in Figure 2.3 in the Radiographic Testing Classroom Training

Book.

To minimize the geometric unsharpness (U/,) in the image, the test object should be

placed as close to the film/detector as possible.

‘Most radiographic codes recommend the maximum acceptable values for

‘geometric unsharpness

Geometric unsharpness can be calculated by using the following formula:

Fa Co

D

u,

a, Uy is the geometric unsharpness (in millimeters or inches).

b. Fis the source size (the maximum projected dimension of the radiation

soutce, of effective focal spot size).

©. Dis the distance from the source of the radiation to the object being

radiographed.

4. dis the distance from the source side of the test object to the film/detector.

Optimum geometric unsharpness of the image is obtained when:

a. The radiation source is small.

b. The distance from the source to the test object is relatively large.

c. The distance from the test object to the film/detector plane is small,

B

Persone] Training Publications

Image Distortion

‘Two possible causes of radiographic image distortion ate:

1, The test object and the film/detector plane are not parallel.

2. ‘The radiation beam is not directed perpendicular to the film/detector plane.

X-RADIATION AND_ GAMMA RADIATION

1. X-rays and gamma rays are part of the electromagnetic spectrum.

2. These rays have high energy and short wavelengths.

X-rays

‘The conditions required to generate X-rays ate

1. Assource of electrons.

2, — Asuitable target for electrons to strike.

3. A means of speeding the electrons in the desired direction.

Characteristic X-rays: When an electron from a higher energy level interacts with an

electron in a lower orbit of an atom, characteristic X-rays may be generated.

Continuous radiation: The generated X-rays have a continuous energy spectrum and are

not entirely dependent on the disturbed atom’s characteristics,

Bremsstrahlung radiation: This is a German name for braking or continuous radiation,

Ke¥ (Kilo-electron volts): This unit corresponds to the amount of kinetic energy that an

clectron would gain when moving between two points that differ in voltage by T kV.

MeV (1 000 000 electron volts): This unit corresponds to the amount of Kinetic energy an

electrons gains when moving between two points that differ in voltage by 1 MV.

‘Snulent Guides Radiographic Testing

|

|

|

|

|

|

Electron Source

1. When a suitable material is heated, some of its charged negative particles .

(€lectrons) become agitated and escape the material as free electrons

Cathode: In an X-ray tube, 2 coil of wire or filament (known as the cathode)

serves as the electron source.

Electron Target

For industrial radiography applications, a solid material of high atomic number, usually

tungsten, is used as the target in the tube anode.

Electron Acceleration

1, By placing a positive charge on the anode of an X-ray tube and a negative charge

on the cathode, free electrons are accelerated from the cathode to the anode.

{

2. The electron path should occur in a vacuum a

Radiation Intensity

1. The number of X-rays created by electrons striking the target is one measure of the

intensity of the X-ray beam.

2. Intensity depends on the number of electrons available at the X-ray tube cathode.

3. Keeping the other factors constant, an increase in the current through the tube

filament will increase the cathode temperature, causing emission of more electrons

and consequently increasing the intensity of the X-ray beam.

4, Similarly, though to a lesser degree, an inctease in the applied tube voltage will

increase the beam intensity.

5. The output rating of an X-ray tube is expressed in volts (KV or MeV).

¢

is

Personnel Training Publications

Inverse Square Law

‘The intensity of an X-ray beam varies inversely with the squate of the distance

from the radiation source.

‘The relationship is known as the inverse square law:

ADE

ate

where 1) and Jy are the received radiation intensities at distances D, and Dy.

X-Ray Quality Characteristics

‘The spectrum of continuous X-rays covers a wide band of wavelengths, as shown,

in Figure 2.9 in the Radiographic Testing Classroom Training Book.

‘An increase in applied voltage in an X-ray tube increases the intensity (quality) of

‘X-rays. This produces higher energy rays with greater penetrating power.

X-rays with higher energy (shorier wavelengths) are called hard X-rays.

X-rays with lower energy (longer wavelengths) are called soft X-rays.

‘Variation in wibe current changes the intensity of the beam, but the spectrum of

wavelengths produced remains unchanged. (See Figure 2.11 in the Radiographic

Testing Classroom Training Book.)

Effects of changes in kilovoltage and (ube current on the produced X-rays are

summatized in Table 2.1 in the Radiographic Testing Classroom Training Book.

‘Sudent Guide: Radiographic Testing i

INTERACTION Wir MATTER iC

1. Any action that disrupts the electrical balance of an atom and produces ions is,

called ionization

2, X-rays passing through matter cause ionization in their path

3. X-rays are photons (bundles of energy) traveling at the speed of light.

4. In passing through matter, X-rays lose energy to atoms by ionization processes

known as:

8. Photoelectric absorption.

b. Compton effect.

©. Pair production.

Photoelectric Absorption

L. In photooleetric absorption, when X-rays (photons) with relatively low energy pass (

through matter, the photon etergy may be transferred to an orbital electron (see ~

Figure 2.12 in the Radiographic Testing Classroom Training Book).

2. Part of the energy is expended in ejecting the electron from its orbit, and the

remainder gives velocity to the electron,

3. This phenomenon usually takes place with low energy photons of 0.5 MeV or less.

4, This absorption effect is what makes radiography possible.

Compton Effect

1, When higher energy photons (0.1 to 3 MeV) pass through matter, part of the

photon energy is expended in ejecting an electron. The remaining slower energy

photons travel at different angles compared to the original photon path (see

Figure 2.13 in the Radiographic Testing Classroom Training Book).

2, This process is repeated, progressively weakening the photon, until the (

photoelectric effect completely absorbs the last photon,

Personnel Training Publications

Pair Production

Pair production occurs only with higher energy photons of 1.02 MeV or mote (see

Figure 2.14 in the Radiographic Testing Classroom Training Book).

Scatter Radiation

1, The major components of scatter radiation are the low energy rays represented by

photons weakened in the Compton process.

2. Scatter radiation is low-level energy content of random direction

Internal Scatter

1, Internal seater is the scattering that occurs in the object being radiographed (see

Figure 2.15 in the Radiographic Testing Classroom Training Book).

2. — It affects image definition by blurring the image outline.

3, ‘The increase in radiation passing through matter caused by scatter in the forward

direction is known as buildup.

Sidescatter

1, Sidescatter is the scattering from walls and the surrounding of the object in the

vicinity of the test object that cause rays to enter the sides of the test object.

2, — Sidescatter obscures the image outline just as internal scatter does.

Backscatter

1. Backscatter is the scattering of rays from the surface or from objects beneath or

behind the test object (see Figure 2.17 in the Radiographic Testing Classroom

Training Book).

2. — Backscatter also obscures the test object.

‘Snident Guides Radiographic Testing a

GAMMA Rays.

1. Gamma rays are produced by the disintegration of the nuclei of a radioactive

isotope.

2. Isotopes are vatieties of the same chemical clement having different atomic

weights.

‘The wavelength and intensity of gamma waves are determined by the source

isotope characteristics and cannot be controlled or changed,

Natural Isotope Sources

1, Some heavy natural elements

integrate because of their inherent instability.

2. Radium is the best known and most used natural radioactive source.

3. Natural radioactive sources release energy in the form of:

a. Gamma rays.

b. Alpha particles: Positively charged particles having mass and charge equal in

magnitude of @ helium nuclei.

Beta part

Jes: Negatively charged particles having charge and mass equal in

magnitude to those of the electron.

‘The penetrating power of alpha and beta particles is relatively negligible.

Artificial Sources

1, There are two ways of manufacturing radioactive isotopes, or so-called radioisotopes:

‘By using the by-product of nuclear fission in atomic reactors, such as

cesium-137 (Cs-137)

b. By bombarding certain elements with neutrons to make them unstable,

Examples include cobalt-60 (Co-60), thulium-170 (Tm-170), selenium-75

(Se-75) and itidium-192 (11-192)

2, These artificial isotopes emit gamma rays, alpha particles and beta particles.

® Personnel Training Publications

Gamma Ray Intensity

1. The activity of a gamma ray source determines the intensity of its radiation

2. The measure of activity is the curie, which is 3.7 x 10! becquerel (Bq) or

disintegrations per second.

Specific Activity

1, Specific activity is defined as the degree of concentration of radioactive material

within a gamma ray source

2. Specific activity is expressed in terms of curies per gram or curies per cubic

centimeter.

3. Specific activity is an important measure of radioisotopes because the smaller the

source, the sharper the radiographic image that can be produced (as shown in

Figure 2.4 in the Radiographic Testing Classroom Training Book).

Half Life

1. The length of time required for the activity of a radioisotope to decay to one half

of its initial intensity is called its half life

2, The half life of a radioisotope is a basic characteristic and depends on the

particular isotope of a given element,

Dated decay curves (similat (o the one shown in Figure 2.18 in the Radiographic

Testing Classroom Training Book) are supplied by source suppliers for each

particular radioisotope and should be used by radiographers to determine the exact

source intensity

Gamma Ray Quality Characteristics

1, Radiation from a gamma ray source consists of rays whose wavelengths and

{ energy are determined by the nature of the source,

‘Student Guide: Radiographic Testing w

Each of the commonly used radioisotopes has a specific application because of

the fixed gamma energy characteristics.

‘Table 2.3 in the Radiographic Testing Classroom Training Book lists the most

common radioisotopes for radiography and their equivalent energy.

Gamma rays and X-rays have identical propagation characteristics, and both

conform to the inverse square Jaw.

‘The mechanism of interaction of gamma rays with matter is identical to those

discussed for X-rays.

Personnel Tralning Publications

Notes

Notes

Lesson 2

Quiz

Please answer true or false to the following 5.

statements,

1. Geometric unsharpness can be seen on

‘an image, and it is not an important

issue in industrial radiography. 6

X-rays and gamma rays are both

clectromagnetic radiation. The only

difference is their source of generation.

X-rays and gamma rays are detectable

‘by human senses.

2. Small radioactive sources produce less

geometric unsharpness. 1.

3. Most radiographic codes recommend

minimum acceptable geometric

unsharpness.

= 8

To minimize the geometric unsharpness,

the distance between test object and

film/detector should be as large as 9.

possible.

If the source-to-film/detector distance

increases 4x, the intensity that is

received by the detector is also

increased 4x.

‘The spectrum of X-rays generated in an

Xray tube is very wide.

Increasing the applied voltage in an

X-ray unit produces X-rays with larger

wavelengths,

3

10. By changing the tbe current, the

X-ray wavelength spectrum remains

unchanged.

Personnel Training Publications

i

Chapter 3: Equipment

In this lesson you will learn about:

* X-ray equipment.

* Gamma ray equipment.

+ Equipment protection devices.

* Radioisotopes.

Lesson 3

Equipment

X-RAY EQUIPMENT

There are three basic requirements for the generation of X-rays:

A source of free electrons.

2. A means of rapidly accelerating the beam of electrons.

3. Assuitable target material to stop the electrons.

Portable X-ray Units

In field radiography, such as inspection of pipelines, bridges, vessels, and ships, portable

X-ray units are very important. The characteristics of these tubes are:

1. Lightweight.

2. Compact.

3. Usually air-cooled.

X-ray Tube

1, The main components of X-ray equipment include:

a, Tube: Enclosed in a high-vacuum envelope of heat-resistant glass or ceramic.

b. Cathode: To produce five eleotrons

c. Anode: Target which the electrons strike.

2. Associated with the tube are the following parts:

a, Equipment that heats the filament, accelerates, and controls the resultant free

electrons.

b, Equipment to remove the heat generated by the X-rays.

Shielding of the equipment.

3, There are many varieties in the size and shape of X-ray tubes.

‘Tube Envelope

1. The tube envelope is constructed of glass or ceramic that has:

a, Ahigh melting point

b. Sufficient strength.

2. For the following reasons, a high-vacuum environment for the tube element is

necessary.

a, Prevents oxidation of the electrode material

b. Permits ready passage of the clectron beam without ionization of gas within

the tube,

cc, Provides electrical insulation between the electrodes.

Cathode

‘The cathode of an K-ray tube consists of:

1, Focusing eup: Functions as an electrostatic lens.

2, Filament: A coil of tungsten wire that produces a cloud of electrons by flowing an

electrical current through it.

28 Personnel Trainhig Publications

2.

3

4

Filament Heating

‘Acsinall flow of current through the filament is enough to heat it to a temperature

‘that causes electron emission.

‘A change in the number of emitted electrons varies with the current flow through

the filament.

‘The tube current is measured in milliamperes (mA), and it controls the intensity of

X-rays.

Anode

“The anode of an X-ray tube is usually made of copper.

Copper and tungsten are the most common anode material

‘A dense target material is required to ensure & maximum number of collisions.

Material with a high melting point is necessary for a target to withstand the

excessive heat.

Focal Spot

‘The image sharpness is partly determined by the size of the focal spot.

‘The electron beam is focused so that it bombards a rectangular arca of the target.

‘The projected area of the electron beam is the effective focal spot (see Figure 3.2

in the Radiographic Testing Classroom Training Book).

‘The size to which the focal spot can be reduced is limited by the heat generated by

target bombardment.

Saudent Guide: Radiographic Testing 2B

Linear Accelerators

‘There are two types of linear accelerators:

1. Standing wave linear accelerator for energy up to 200 MeV,

2. ‘Traveling wave linear accelerator for energy up to 30 GeV (giga-clectron volts or

billion electron yolts).

X-ray Beam Configuration

1, Once the X-rays are created, they cannot be focused or otherwise directed.

2. The direction of useful X-radiation is determined by the positioning of the target

and the lead shielding.

Accelerating Potential

1. The applied potential between the cathode and anode determines the penetrating.

effect of the produced X-ray,

‘The higher the voltage, the greater the electron velocity along with shorter

wavelengths and more penetrating power for the generated X-rays.

Tron Core Transformers

1, ‘The majority of X-ray equipment for industrial radiography (up to 400 KV) use

iron core transformers.

2. Their basic limitations are their size and weight,

Heat Dissipation

1, X-ray generation is a very inefficient process as most of the electron energy is

expended in producing heat.

2, Heat dissipation in the X-ray tube is achieved by & flow of oil, gas of water,

3. _Bifficieney of an X-ray tube cooling system is the main factor in determining the

duty cycle of the tube.

%

Personnel Training Publications

QUIPMENT SHIELDING

‘To prevent unwanted radiation, lead is used to shield the X-ray tube,

‘The shielding design varies with different X-ray tubes, but in all cases, it serves

to absotb that portion of the radiation that is not traveling in the desired direction,

CONTROL PANEL

‘The control panel of an X-tay system is designed to permit a.radiographer to set

the desired exposure parameters,

‘The control panel also provides critical indications for tube performance, such as

the flow of oil or water in the cooling system,

GAMMA Ray EQUIPMEN'

Handling and storage of gamma ray sources are extremely important since they

cannot be shut off.

The United States Nuclear Regulatory Commission (NRC) and various state

agencies recommend safety standards for propes transportation, storage and

handling of radioisotopes.

Every inspection firm should propare a comprehensive safety procedure for the

storage and handling of all their radioisotopes. More infoimation on this ean be

found in Lesson 5.

Gamma Ray Sources

‘There are two types of gamma ray sources:

a. Natural isotopes.

b. Artificial isotopes.

‘Most isotopes used in industrial radiography are round wafers encapsulated in a

stainless steel cylinder.

‘Student Guide: Radiographic Testing ETS

Radium

Radium is a natural radioactive substance having a half life of about 1600 years.

Most radium sources consist of radium sulfate packaged in either spherical or

cylindrical capsules

Because of its low specific activity and its long half life, radium is rarely used in

industrial radiography.

Artificial Radioisotopes

‘The artificial radioisotopes used in industrial radiography for gaging purposes are:

a, Cobalt-60 (Co-60).

b. _Iridium-192 (fr-192).

c. Selenium-75 (Se-75).

4, Thulium-170 (Tm-170).

fe, Cesium-137 (Cs-137)

‘Table 3.2 in the Radiographic Testing Classroom Training Book gives a summary

of the main characteristics of the most used isotopes.

Isotope Cameras

‘The equipment to accomplish safe handling and storage of radioisotope sources is

called a camera or exposure device.

‘These cameras are self-contained units, meaning no external power supply is

required.

‘The exposure devices contain self-locking mechanisms ensuring safety in

accordance with ANSI and ISO requirements, in addition to NRC and JAA

requirements

%

Personnel Training Publications

Notes

Notes.

= Lesson 3

Quiz

Please answer true or false to the following 6, Typical isotope equipment is often

statements, referred (o as a camera or projector.

1. Ahigh vacuum environment for an

X-ray tube is to make it lighter for easy Compared to cobalt-60, iridium-192

transportation. has a shorter half life,

‘The function of a focusing cup in the

cathode of an X-ray tube is to focus the

tion.

produced X-radi

3. The isotopes used in industrial

radiography are usually natural

isotopes,

4. A major disadvantage of isotope

radiography is the high cost of isotope

equipment and sources

5. Afler-a radioactive material is stored, its

~ ‘gamma radiation shuts off.

35

Chapter 4: Radiographic Film

In this lesson you will learn about:

+ Radiographic contrast.

+ Film density.

+ Film characteristic curves.

* Film graininess.

« Film selection factors.

* Film processing (manual and automatic).

+ Darkroom facilities.

7

Lesson 4

Radiographic Film

aH

INTRODUCTION

Radiographic film consists of:

a. Base: A thin, transparent plastic sheet.

b, Emulsion coat: A coat of an emulsion of gelatin about 0.001 in, (0,003 cm)

thick on one or both sides. The emulsion coat containis very fine grains of

silver bromide (AgB:).

Latent (hidden) image: Exposure of radiation on the film that cannot be detected

until chemical processing occurs.

Visible image: Image on the film after developed by chemical processing.

Usefulness of Radiographs

Film density: Degree of darkening on the developed film,

Radiographic contrast; Difference between bwo film areas. The darker area,

(higher density) has received more radiation compared to the area of light density,

Definition: Sharpness of any change in film density.

Contrast and definition are important for a successful interprétation of radiographs.

RADIOGRAPHIC CONTRAST

‘The film density D is a logarithmic value defined as:

D= log, 4

where (Ig ) is the intensity of the incident light and / is the intensity of the

transmitted light through the film. The higher the number, the darker the film,

eH If the intensity of light is 1000 units and the film allows only one unit of that

intensity to pass through, the film density based on the previous equation will be:

D= logy A 3

3. Radiographic contrast (as shown in Figure 4.2 in the Radiographic Testing

Class

10m Training Book) is defined as the difference in the film density between

two selected areas of the exposed and developed film.

4. Higher contrast is better for film interpretation.

5. Radiographic contrast is a combination of:

a, Subject contrast

b. Film contrast.

6. Radiographic contrast depends on:

a, Applied radiation energy (penetrating quality)

b. Contrast characteristics of the film:

¢. Amount of exposure (tie product of radiation intensity and exposure time),

d, Film screen,

e, Film processing.

f. Scattered radiation,

Subject Contrast

Subject contrast is the relative radiation intensities passing through any two

selected portions of material. Subject contrast depends on the following factors:

a. Type and shape of the test object.

b. Bnetgy of the applied energy radiation (wavelength, type of source).

c. Scattered radiation

2. Subject contrast decreases as the wavelength of the incident radiation decreases.

@

Personnel Training Publications

3. Higher subject contrast cait be- achieved by:

( a, Larger thickness variation,

b. Use of different X-ray or gamma ray energies.

©. Masks.

4. Diaphragms

e. Filters or screens,

Film Contrast

1. The ability of film to detect and record different radiation exposures as differences

in film density is called film contrast.

2. — The relationship between the amount of exposure and the resulting film density is

expressed in the form of film characteristic curves and is determined by the

following factors:

a. Film grain size,

¢ b. Chemistry of the film processing chemicals.

©. Concentration of the processing chemicals.

d. Development time,

e. Development temperature.

f, Agitation in the developer solution

Film Characteristic Curves

1, Figure 4.3 in the Radiographic Testing Classroom Training Book shows a film

characteristic curve.

a. ‘The vertical axis is the resulting film density.

b. The horizontal axis is expressed in a logarithm of relative exposure.

¢. The minimum point of the curve on the vertical axis is called fog density.

4d. Based on this curve, as the exposure increases, film conttast increases,

tadiographio Testing a

2. A film characteristic curve has two different sections:

a, A tail of lower densi

b. A straighter portion (with a higher slope on the curve).

3. High radiographic contrast is achieved with densities along the straight portion of a

characteristic curve, This is the reason that films should always be exposed for a

density of at least 1.5.

4. Most radiographic codes, standards and specifications usually give upper and lower

density limits within a range of 1.8 to 4.0.

Film Speed

1, Film speed is an important consideration in determi

1g the proper exposure time

to obtain the desired film density.

2, Figure 4.4 in the Radiographic Testing Classroom Training Book illustrates films

with high, medium and tow speeds.

3. Knowing film speed is important when selecting film for each particular

radiographic testing task,

Graininess

1. Graininess is the visible evidence of the grouping into clumps of the silver

particles that form the imago on the radiographic film.

2. — Figure 4.5 in the Radiographic Testing Classroom Training Book shows the effect

of grain variation on the image definition

3. The degree of graininess of an exposed film depends on the following factors:

a. Grain size.

b. The quality of the radiation

c. Film processing conditions.

4d, Type of film screens.

Parsoniiel Training Publications

FILM SELECTION FAcrors

When not otherwise specified by the customer or governing standards, the

selection of film is made by the radiographer, Most of the time, the selection of

film is based on the following factors:

a. Need for certain contrast and definition quality.

b, ‘Thickness and density of the test object.

¢. The type of indication or discontinuity normally associated with the object.

4. Size of an acceptable indication.

e. Accessibility, location and configuration of the test object,

£. Customer requirements,

In film selection, remember that:

a. Film contrast, film speed and graininess are interrelated.

b. Faster films need shorter exposure time but usually have larger grains and

poor resolution/sensitivity.

©. Slower films need longer exposure time but have finer grain and good

resolution/sensitivity.

d. Film manufacturers’ recommendations for film sclection are a useful tool in

sclecting the proper film for a given application.

FILM PROCE:

iG

Film processing makes the latent image visible.

‘The following general precautions must be observed during film processing:

a. Follow manufacturer recommendations for chemical concentrations,

temperature and processing time

b. Use equipment, tanks, trays and holders thet can withstand the chemical

action,

c. Ensure tanks are clean,

‘Suudent Guide: Radiographic Testing

d. Use recommended safelights and checked them regularly.

¢. Maintain cleanliness in the darkroom to avoid any artifacts on developed

radiographs.

f. Avoid any contamination of different solutions.

TANK PROCESSING

‘The arrangement of a tank processing (manual processing) unit is shown in Figure 4.6 in the

Radiographic Testing Classroom Training Book.

1

‘The tanks for processing solutions and wash water should be deep enough for the

film to be submerged.

‘The chemicals in the tanks must be

.d and the temperature must be checked

with a calibrated thermometer before tuming off the ambient light,

All requited equipment should be arranged before turning off the ambient light.

All unnecessary materials should be kept away from the processing area.

‘Test the safelights and arcange them for easy viewing. Follow the standard

recommendations for regular checking.

Lock the darkroom door to prevent accidental exposure to ambient light.

‘To load the film inside the hangers, grasp it by its edges ot corner to avoid

fingerprints, bending, wrinkling or crimping during handling.

Keep the loading area completely dry,

Follow the tank processing procedures.

Tank Processing Procedures

‘There are five separate steps in tank processing:

1

2

3

Developing.

Stop bath

Fixing

or

Personnel Training Publications

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Trump Sena MaliatDocument1 pageTrump Sena MaliatPeterNo ratings yet

- 75th Golden GlobeDocument3 pages75th Golden GlobePeterNo ratings yet

- Lady GaGa Gharn 19Document3 pagesLady GaGa Gharn 19PeterNo ratings yet

- Gorooh Bandi Jam JahaniDocument3 pagesGorooh Bandi Jam JahaniPeterNo ratings yet

- Emperatour JapanDocument1 pageEmperatour JapanPeterNo ratings yet

- Nawaz Sharif MontaghedDocument3 pagesNawaz Sharif MontaghedPeterNo ratings yet

- America HaririDocument1 pageAmerica HaririPeterNo ratings yet

- Khodahafezi BaShokoohDocument4 pagesKhodahafezi BaShokoohPeterNo ratings yet

- Final Tour TennisDocument2 pagesFinal Tour TennisPeterNo ratings yet

- Boriz Johnson To IranDocument2 pagesBoriz Johnson To IranPeterNo ratings yet

- Trump Putin TohinDocument2 pagesTrump Putin TohinPeterNo ratings yet

- Czech MilliardDocument1 pageCzech MilliardPeterNo ratings yet

- Hem 1217-2 192302Document72 pagesHem 1217-2 192302Ale OjedaNo ratings yet

- Thema v1.5Document423 pagesThema v1.5AndreaRamos1No ratings yet

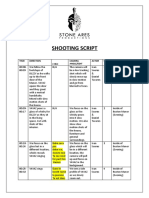

- Unit 8 - Shooting ScriptDocument5 pagesUnit 8 - Shooting Scriptapi-660822705No ratings yet

- Composición Fotográfica en CineDocument50 pagesComposición Fotográfica en CineEsteban Cuello50% (2)

- Audio Pre & Post Production in FilmsDocument45 pagesAudio Pre & Post Production in FilmssuriyaprakashNo ratings yet

- Fotografia Odontológica - Ebook-CompactadoDocument50 pagesFotografia Odontológica - Ebook-CompactadomarceloNo ratings yet

- Resumo Das Aulas Fotografia PDFDocument21 pagesResumo Das Aulas Fotografia PDFJMS Fotografia StudioNo ratings yet

- Trabajo Práctico #1 - INGRESO 2021Document23 pagesTrabajo Práctico #1 - INGRESO 2021Nicolas VallejoNo ratings yet

- Photoshop User Magazine May-June 2013Document120 pagesPhotoshop User Magazine May-June 2013benzzenhdNo ratings yet

- Aerial Cameras, Aerial Films, and Film ProcessingDocument14 pagesAerial Cameras, Aerial Films, and Film ProcessingPedro MendoncaNo ratings yet

- Digital PhotographerDocument116 pagesDigital PhotographerQuynh Anh100% (2)

- Forensic 1 ReviewerDocument5 pagesForensic 1 ReviewerMaria Rafaella P. DadoNo ratings yet

- Bases Xxii Zocan 2021Document8 pagesBases Xxii Zocan 2021ErnestoNo ratings yet

- Surrealism Notes and Assignment SheetDocument3 pagesSurrealism Notes and Assignment Sheetapi-253337869No ratings yet

- A Fotografia É A Sua Linguagem-Ivan LimaDocument57 pagesA Fotografia É A Sua Linguagem-Ivan LimaMisac AbdenagoNo ratings yet

- DJI Mini 2 - Specifications - DJIDocument12 pagesDJI Mini 2 - Specifications - DJIf.veneri92No ratings yet

- Tiny Epic Kingdoms Meeples de Papel para Tek 109140Document3 pagesTiny Epic Kingdoms Meeples de Papel para Tek 109140Andrew SnakeNo ratings yet

- Peter Galassi Two Stories American PhotographyDocument51 pagesPeter Galassi Two Stories American PhotographyivanespauloNo ratings yet

- Jairo Adrian Marmolejo Urquiza Mapa Conceptual Elementos Del Contabilidad GeneralDocument5 pagesJairo Adrian Marmolejo Urquiza Mapa Conceptual Elementos Del Contabilidad GeneralREINO RANA GNo ratings yet

- DJI GO 4 Manual PORTUGUES OK CAPA VIDEOS DRONE PDFDocument43 pagesDJI GO 4 Manual PORTUGUES OK CAPA VIDEOS DRONE PDFGlauber CostaNo ratings yet

- Del Ojo A La Mano-Nilda Fernanda Román BustosDocument42 pagesDel Ojo A La Mano-Nilda Fernanda Román BustosNilda RomanNo ratings yet

- Colorize A Black and White PhotoDocument3 pagesColorize A Black and White Photonesimtzitzii78No ratings yet

- Personal PhotoStickers HowTo PhotoshopDocument3 pagesPersonal PhotoStickers HowTo PhotoshopSuzanaNo ratings yet

- Sertões, Luz e TrevasDocument3 pagesSertões, Luz e TrevasBruno Yutaka SaitoNo ratings yet

- Jueves 23 ArteDocument4 pagesJueves 23 Artejuan miguel levano urbinaNo ratings yet

- Materiais e Metodos TCCDocument2 pagesMateriais e Metodos TCCFelipe GomesNo ratings yet

- Plantilla Presentaciones Uan 202iDocument8 pagesPlantilla Presentaciones Uan 202iANGELLY PATRICIA VELANDIA FONSECANo ratings yet

- Manual de Servicio PDFDocument153 pagesManual de Servicio PDFjazztecnoNo ratings yet

- Travelogue - Sir JeromeDocument67 pagesTravelogue - Sir JeromeJohn Paul M. NatividadNo ratings yet

- Colour and Form-I: Design Course The Fundamentals of Colour by Ms. Nijoo Dubey NID Campus, BengaluruDocument40 pagesColour and Form-I: Design Course The Fundamentals of Colour by Ms. Nijoo Dubey NID Campus, BengaluruKalpa RNo ratings yet