Professional Documents

Culture Documents

Air Release Valve Amstrong Class 600 Psi

Air Release Valve Amstrong Class 600 Psi

Uploaded by

moh. rusli bahtiar0 ratings0% found this document useful (0 votes)

7 views2 pagesOriginal Title

Air Release Valve Amstrong class 600 psi

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesAir Release Valve Amstrong Class 600 Psi

Air Release Valve Amstrong Class 600 Psi

Uploaded by

moh. rusli bahtiarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

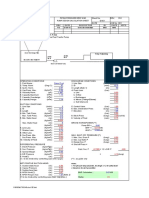

Free Floating Lever Air/Gas Vents - Forged Steel

Tee

‘Maximum Operating Pressures of fee floating lever vents with weighted floats for

diferent orifice sizes, andthe specific graviies on which they can be used

PEE ic ee

‘Spec. Grav_]1.00] 0.95] 0.90] 0.85 0.80) 0.75 0.70] 0.65] 0.60] 0.55

Float wt, oz. |11.8|112|108| 100/84] 89 [e3|77| 71 [65

High Temperature Service

Maximum allowable working pressures of

floats decrease at temperatures above 100

Seaaked iereparoti sia Orifice Size (in) Maximum Operating Pressure, psi

+ 10% decrease at 200 °F ane ai [39 [37 [ 35 | 33 | 31 | 29 | 27 | 25 | 28

+ 15% deorease at 300 °F 8 8 | 64 | 61] 58 | 54 | 81 | 47 | a4 | at | a7

+ 20% decrease at 400 °F 36 149] 142] 134] 127 | 120] 172 | 105] 97 | 20 | 8s

“The oat is not always the limiting factor,

waz] 257] 244 [231219 | 205] 109 | 180) 168] 165] 142

however. Consult with Armstrong

Aptieson Coenen keauiot "e__[ 439] 417] 305] 376 [352 [330 | 209] 207] 205 [249

high-temperature application that also Tis [582 [594 [508 [478 [450] «23 [05/367] 330 311

requires maximum operating pressures. #38 [600] 600] 600] ses | 561 626 | 407] 457| 422 [207

wise [00/600 [600 [600 [600/600 [00] 600] 600 [571

Sour Gas Service EREVAN Ce Mace

Spec. Grav? | 1.00] 098 | 020 | 8s [Oa [OTe |O7a] Des] O80

Forged steel and stainless steel traps can Float wt,oz_[ 149 | 742] 134 [127 [120 [12] tos [ 97 [90

be modified to resist hydrogen sulfide Orifice Size (in) ‘Maximum Operating Pressure, psi

stress corrosion. These modifications T ayTaTseTelv[elsluys

involve annealing the float, which will ED 45 [43 [41 [38 [36 [34 [32 [30 | 27

reduce the maximum working pressure of S16 vz | eo | 65 [61 [58 [se | st | a7 [ ae

the float to about half of its normal value. S132 se_| oi | a7 | 62 | 77 | 72 | 66 | 63 | 58

Consult Armstrong Application 14, jaa | 137 [130 [123 | 116 | 109 | toa | a4 | 37

Engineering for allowable working 188 208 | 198 | tee | ire | tee | ise | 148 | 18 | 128

aaa ai6 | s08 [aoe [are | ase [ one [ood [ve [203 [108

er Sa 404 | 460 | 437 [413 | 309 | 365 | 342 | 318 | 294

“ie [woo] oa [ane [ 205 | rar [ran [oar | oa | 5

Tee {900 [200 [200 | 200 | 00 [ 200 [aes [022 | 760

36-AV Maximum Operating Pressures

‘Spee. Grav. | 1.00] 095 [090] 085 [0.80 [075] 0.70] 065 | 0.60 [055 | 050 | 045 | 040

Float wt, oz. | 735] 698 [652] 625/555 [ 551] 515 [475] 441] 404 |o5s] 331 [p00

[Orfce Size (in) Maximum Operating Pressure, psi

ie [2 [ala[ele[v[elu[ ol elu] we

78 sfa>a[o|=[=lelala|s@|e| «|

3 50 [a | a5 | 3 | 0 | se] 05 | 33 | so | 28 | 25 | a | 20

3 7] 73 | 68 | 66 | e2 | so | 54 | 00 | 4] 3 | o8| 6 | ot

ae [wafer |ale|[el7[wl|a7|ely|a|o|a

2 rae [ 140 | 199 | x28 [ai [ava] soe | o7 | 0 |e | 75 | ar | 00

Tie | 2x0 | 200] 180 | 179 | vee | 158 | cae | tar | war | rte | 108 | 98 | es)

3] 531] 315 | 290 | 262 | 266 | 249 [ 253 | 216 | 200 | 12a | 167 | 151 | 198

Fase 421 | at0 | 396 [ are | 956 [332 | 10 | 200 | 208 | 24s [229 | 20; [79

wie | sar | 630 | sti | 488 | 455 | 427 | a00 | ari | 942 | 250 | 250 | 250 | 200

ana | ra | 706 | 69 | 620 | 506 | ssa | 622 | a5 | aaa | 250 | 250 | 250 | 250

‘ua [1000] 1000] o79 [ sas [ars [arr | 7a | 710 | «58 | 250 | 250 | 20 | 250

7132 | 1000 r000| 1000] 1000] 7000] 1000] 1000] 7000| @26 | 250 | 250 | 250 | 250

3116 | 1000] 1000] 7000] 1000] r000] 1000] 1000] 1000 | 000) 250 | 250 | 250 [250

“Trapectie gravy fas beween fase shown, use ren Towest-eg Wf achal gravy 6 O73, use O70

specie gravity data

6

Free Floating Lever Air/Gas Vents - Forged Steel

32AV, 33AV and 36AV - Forged steel vents For apy ns where high air/gas ver

using the same proven free floating lever capacity is required up to 1000 psi.

mechanisms used in Armstrong steam traps.

List of Materials

vane

weet | | wee Tne | | cn cnt

sin :

7 Stainless Stainless. ‘Stainless ASTM A-105 ASTM A193 Gr. B7

Bary] Soc | Sane | Seae | Atay | Nonsbosos i

asi Ai cea

Gener

Forged Steal

Mode! No.

SZAT 3-AVT 3eAVT

Pipe Connection Size in (rm) Ta 15,20 Aad 20, 25 TA2 40, 50

At in (ram) % a7 8 203 Wh 301

Bin (mm) 10% 258 1% 294 11 435

‘Dein (mm) Me 141 oa 154 8 228

Kn (ramp 1 32 The 37 a 4

"Lin (mm) Be 86 ve 98 oie 154

‘Approx. Web (ka) 3 14 48 2 163 7

600 psig at bar 1000 psig 69 bar 1000 psig 69 bar

Max. Allow. Pressure @iwor | @3s-c | @toor | @sec | @t0r | @asc

(Vessel Design) 500 psi 34 bar 600 psig 41 bar 600 psig 41 bar

@7so'e | @s9'c | @7s0'r | @ssac | @7s0% | @as9'c

‘Available in Type 316 SS. Consult Factory. Pipe size of side connections Wf provided are samme as that of inlet and oulle connections. Some

floats are ol filed - Consult factory for deta

* | Rt

Models 32-AV, 33-AV and 36-AV

All dimensions and weights are approximate. Use certtied print for exact dimensions

7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Floating Water IntakeDocument2 pagesFloating Water Intakemoh. rusli bahtiarNo ratings yet

- Intake Screen For River Pump Size 24in-X-24inDocument1 pageIntake Screen For River Pump Size 24in-X-24inmoh. rusli bahtiarNo ratings yet

- Ball Valve Class 600# Size 3/4 in (DN20)Document1 pageBall Valve Class 600# Size 3/4 in (DN20)moh. rusli bahtiarNo ratings yet

- Water Heater Calculation - PW (XZSGTCTWVFTQWJT)Document3 pagesWater Heater Calculation - PW (XZSGTCTWVFTQWJT)moh. rusli bahtiarNo ratings yet

- Butterfly Valve Class 150 & 600Document1 pageButterfly Valve Class 150 & 600moh. rusli bahtiarNo ratings yet

- Weight of Water-Filled Steel Pipe Based On FM Global Property Loss Prevention Data Sheet & Pipedata Pro72Document11 pagesWeight of Water-Filled Steel Pipe Based On FM Global Property Loss Prevention Data Sheet & Pipedata Pro72moh. rusli bahtiarNo ratings yet

- Flammable Combustible Worksheet May2018 0Document1 pageFlammable Combustible Worksheet May2018 0moh. rusli bahtiarNo ratings yet

- Piping Pressure Drop and Pump Design Calculation Sheet: R-0 07-06-18 Issued For Information MRB MRBDocument2 pagesPiping Pressure Drop and Pump Design Calculation Sheet: R-0 07-06-18 Issued For Information MRB MRBmoh. rusli bahtiarNo ratings yet

- PRV e 50b 4kg1kolDocument2 pagesPRV e 50b 4kg1kolmoh. rusli bahtiarNo ratings yet

- Screw Pump - X - GearDocument1 pageScrew Pump - X - Gearmoh. rusli bahtiarNo ratings yet

- Solid Cast: Process Pigs & Utility PigsDocument3 pagesSolid Cast: Process Pigs & Utility Pigsmoh. rusli bahtiarNo ratings yet

- Cooling & Heating LoadDocument32 pagesCooling & Heating Loadmoh. rusli bahtiarNo ratings yet

- Foam Pig Selection GuideDocument8 pagesFoam Pig Selection Guidemoh. rusli bahtiarNo ratings yet

- Pig Launching ProceduresDocument1 pagePig Launching Proceduresmoh. rusli bahtiarNo ratings yet

- Comparison-Chart-Foam PigDocument1 pageComparison-Chart-Foam Pigmoh. rusli bahtiarNo ratings yet

- Maximum Distance Hanger or Support FFDocument1 pageMaximum Distance Hanger or Support FFmoh. rusli bahtiarNo ratings yet